【温馨提示】 购买原稿文件请充值后自助下载。

以下预览截图到的都有源文件,图纸是CAD,文档是WORD,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘 要

本次设计内容涉及了机械制造工艺及机床夹具设计、金属切削机床、公差配合与测量等多方面的知识。

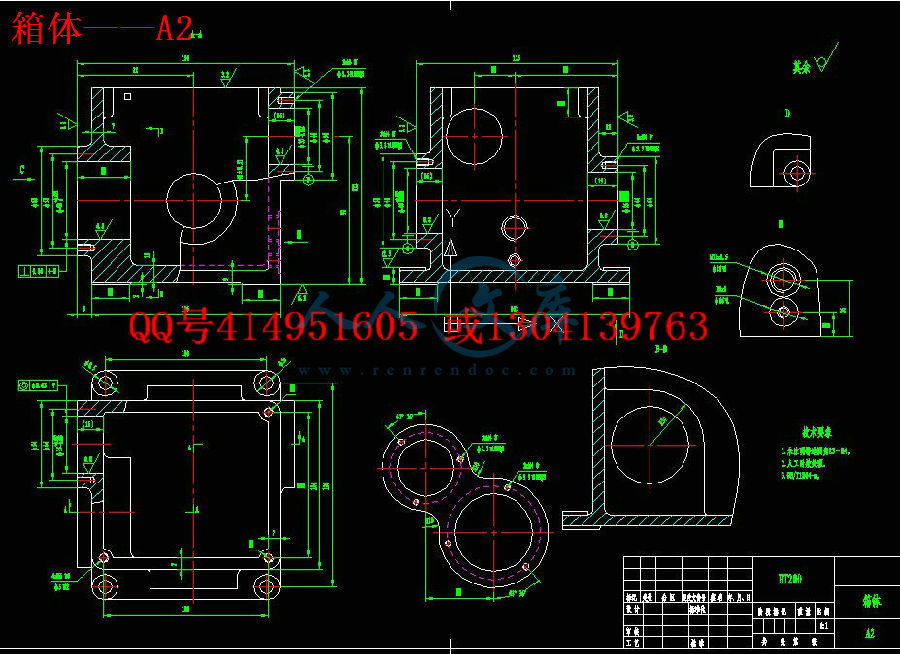

箱体零件的工艺规程及其钻、攻工件左端面6-M4深8孔深10螺纹的工装夹具设计是包括零件加工的工艺设计、工序设计以及专用夹具的设计三部分。在工艺设计中要首先对零件进行分析,了解零件的工艺再设计出毛坯的结构,并选择好零件的加工基准,设计出零件的工艺路线;接着对零件各个工步的工序进行尺寸计算,关键是决定出各个工序的工艺装备及切削用量;然后进行专用夹具的设计,选择设计出夹具的各个组成部件,如定位元件、夹紧元件、引导元件、夹具体与机床的连接部件以及其它部件;计算出夹具定位时产生的定位误差,分析夹具结构的合理性与不足之处,并在以后设计中注意改进。

关键词:工艺、工序、切削用量、夹紧、定位、误差。

Abstract

This design involves the machinery manufacturing process and fixture design, metal cutting machine tool, tolerance and measurement and other aspects of knowledge.

The part of the process and its drilling, tapping the left end surface of 6-M4 8 deep hole depth 10 threaded fixture design is including machining process design, process design and fixture design in three parts. In the process of design should first of all parts for analysis, to understand the parts of the process to design blank structure, and choose the good parts machining datum, design a part of the process route; then the parts of each step of the process dimension calculation, is the key to determine the process equipment and cutting the amount of each working procedure design; then the special fixture fixture design, selection of the various components, such as the connecting part positioning element, clamping elements, guiding elements, fixture and machine tools and other components; the positioning errors calculated fixture positioning, analysis the rationality and shortcoming of the fixture structure, pay attention to improve and design in later.

Keyword: Technology, process, cutting dosage, clamping, positioning, error.

目 录

摘要······················Ⅰ

Abstract···Ⅱ

绪论························1

1概述发展············2

1.1 机床夹具简介···································2

1.1.1 机床夹具的主要功能·····················2

1.1.2 机床夹具的组成·····························2

1.1.3 夹具设计的步骤和基本要求·········2

2箱体的机械加工工艺规程························9

2.1 毛坯的制造形式·····························9

2.2 零件的分析······································9

2.3 基面的选择····································11

2.3.1 粗基准的选择原则······················11

2.3.2 精基准的选择原则·······················12

2.4 制订工艺路线································12

2.5 确定切削用量及基本工时············13

3 箱体的夹具设计·····································47

3.1 问题的提出······································47

3.2 夹具的工作原理······························47

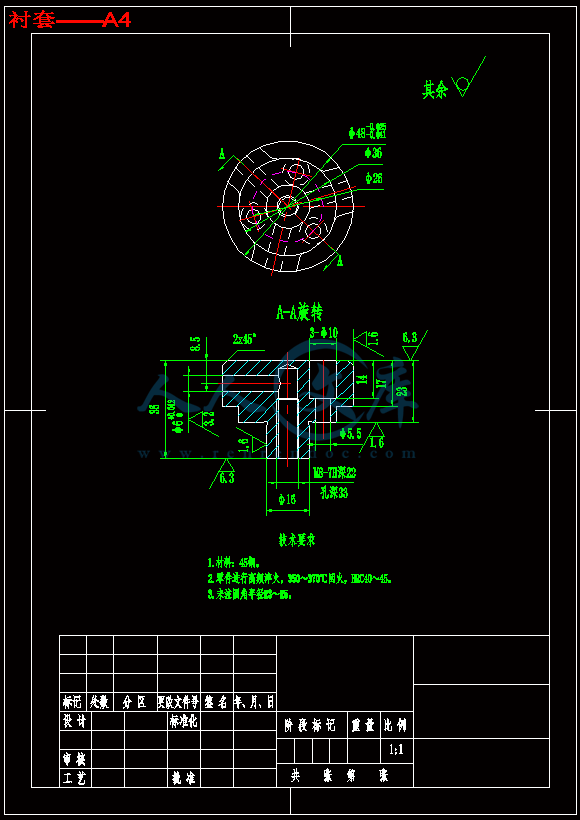

3.3 钻套的设计······································48

总结······················49

致谢······················50

参考文献··············51

川公网安备: 51019002004831号

川公网安备: 51019002004831号