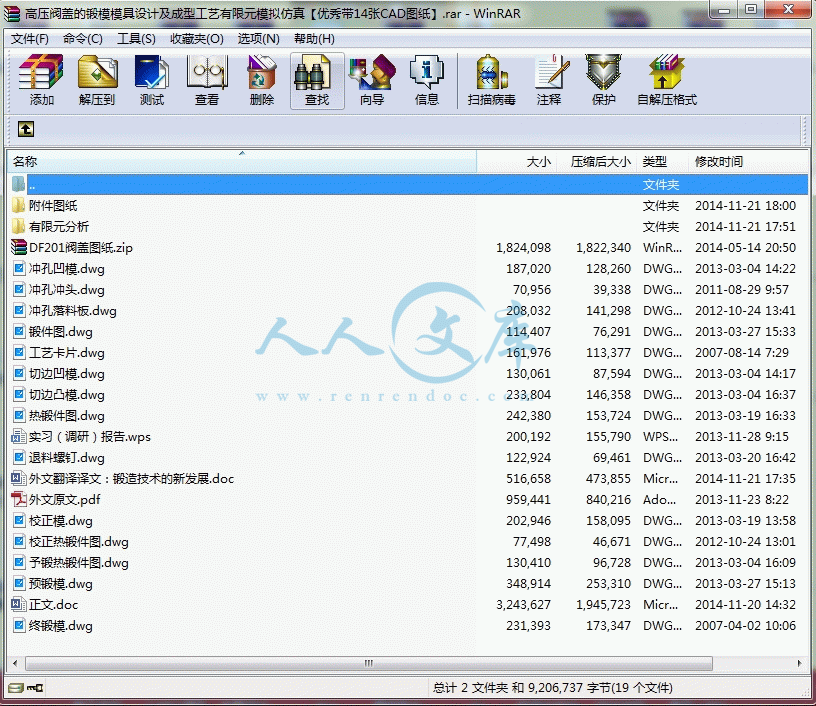

高压阀盖的锻模模具设计及成型工艺有限元模拟仿真【优秀带14张CAD图纸】

【带外文翻译+实习(调研)报告+36页@正文15700字】【详情如下】【需要咨询购买全套设计请加QQ1459919609 】.bat

DF201阀盖图纸.zip

予锻热锻件图.dwg

冲孔冲头.dwg

冲孔凹模.dwg

冲孔落料板.dwg

切边凸模.dwg

切边凹模.dwg

外文原文.pdf

外文翻译译文:锻造技术的新发展.doc

实习(调研)报告.wps

工艺卡片.dwg

有限元分析

校正模.dwg

校正热锻件图.dwg

正文.doc

热锻件图.dwg

终锻模.dwg

退料螺钉.dwg

锻件图.dwg

附件图纸

预锻模.dwg

摘 要

高压阀盖是一个中心对称的柄类与轴类锻件,调节阀门与气动调节阀的重要组成部分。它是一种难度系数介于常见盘类和轴类之间的锻件。普遍存在的质量缺陷如:折叠,充不满,密封不好,精度低等成为了制约我国精锻技术的发展和普及的主要因素。多数企业的技术人员仍是以一些成熟的经验作为设计准则,试模周期较长,成本较高,耗能较大,而且不能综合考虑成形缺陷形成的各个因素,造成设计结果与实际情况相差甚远,从而给企业带来了严重的经济损失。本文以大连大锻有限公司生产的某高压阀盖为研究对象,经过深入研究该锻件原始工艺方案的成形缺陷,利用分流原理提出了分流工艺方案,制定了预终锻锻件图,设计了模具结构,利用 DEFORM-3D 软件建立了有限元模型对原始对预锻和终锻方案过程进行数值模拟,分析了制坯,预锻,终锻的优缺点。对整个生产过程,做了一个比较系统的分析。通过与实际生产的对比,验证了工艺方案的可行性。通过本课题的研究,把高压阀盖制坯到预锻,终锻成形过程与塑性有限元技术、数值模拟仿真分析技术有效的结合,发现高压阀盖实际生产中的边角充不满,较大的飞边问题等缺陷,并提出解决方案。解决了实际生产问题。

关键词:高压阀盖 模锻 有限元数值模拟 仿真

ABSTRACT

High-pressure valve cover is a central symmetrical pattern classes and shaft forgings, an

important part of regulating valves and pneumatic control valve. It is a common difficulty

coefficient between the disc type and shaft forgings between. Common quality defects such as: folding, fully satisfied, sealing well, low accuracy has become a major factor restricting the development of technology and the popularity of forging. Most companies are still a number of technical personnel mature experience as a design criterion, tryout period is longer, higher costs, greater energy, and can not be taken into account various factors shaping defect formation, resulting in the design and actual results vary considerably far, giving enterprises a serious economic losses. Taking a high-pressure valve forging Co., Ltd. Dalian cover for the study, in-depth study of the forging forming defects original process plan, the use of the principle of triage triage process scheme is proposed to develop a pre-final forging forging figure, the mold structure design using DEFORM-3D software to build a finite element model of the original pre-forging and final forging process simulation program to analyze the blank, pre-forging, the final forging advantages and disadvantages. The entire production process, made a more systematic analysis. By comparison with the actual production process to verify the feasibility of the program. By studying this subject, the high-pressure valve cap system to pre-forging billet, forging process and the final plastic finite element techniques, effective analysis and numerical simulation techniques, found that the actual production of the high-pressure valve cover corners fully satisfied, the larger defects such as burr problem and propose solutions. Solve the problem of the actual production.

Key words:High-pressure valve cover forging finite element simulation

目 录

第一章 绪论1

1.1 锻造业的地位及其发展方向1

1.2 设计题目及其设计要求1

1.2.1设计题目1

1.3 设计任务及要求1

1.4 技术经济可行性分析2

1.5 小结3

第二章 锻件图的制定4

2.1 冷锻件图的制定4

2.1.1 分模面位置的选择4

2.1.2 锻件机械加工余量和公差4

2.1.3 模锻斜度5

2.1.4 圆角半径6

2.1.5 锻件的热处理和清理6

2.2小结6

第三章 成型工艺仿真8

3.1概述8

3.2 模拟技术在锻造工艺实践中的重要作用和地位8

3.3 UG平台下高压阀盖的特征造型及其模具造型9

3.4 DEFORM模拟仿真10

3.4.1 前处理器10

3.4.2 模拟处理器10

3.4.3 后处理器11

3.5 Deform软件操作流程概述11

3.6 小结16

第四章 模锻工步的选择17

4.1 计算毛坯17

4.1.1 飞边槽的设计17

4.1.2 绘制和计算毛坯的截面图和直径图18

4.2 确定锻造工步20

4.3 坯料截面计算20

4.4 坯料长度的计算20

4.5 确定设备吨位21

4.6 锻模结构设计21

4.6.1 模膛布置21

4.7锻模模具设计23

4.7.1确定热锻件23

4.8 模膛壁厚的确定24

4.8.1模块的确定25

4.9 小结25

第五章 切边模的设计26

5.1小结27

第六章 校正模的设计28

6.1 小结29

谢辞30

参考文献31

第一章 绪论

1.1 锻造业的地位及其发展方向

锻造是一种利用锻压机械对金属坯料施加压力,使其产生塑性变形以获得具有一定机械性能、一定形状和尺寸锻件的加工方法,锻压(锻造与冲压)的两大组成部分之一。通过锻造能消除金属在冶炼过程中产生的铸态疏松等缺陷,优化微观组织结构,同时由于保存了完整的金属流线,锻件的机械性能一般优于同样材料的铸件。相关机械中负载高、工作条件严峻的重要零件,除形状较简单的可用轧制的板材、型材或焊接件外,多采用锻件。该方法可追溯到公元前40 世纪自然金属如金、银的成形。在现代工业的今天, 展现在我们眼前的是全自动高速锻造生产线。最为典型的可举出曲轴、连杆热锻生产线, 齿轮、十字头的冷锻生产线以及以紧固件为代表的高速冷锻机成形。从“趁热打铁”可以自然的想到锻造是在高温下进行的。自1938 年德国发明了磷化皂化技术以来, 冷锻技术得到了广泛的应用。二战期间的德国, 为了以钢材代替铜来生产弹壳等军工产品, 发明了既具有附着性又兼备高延展性的磷化皂化皮膜。二战结束以后, 此技术先传到美国, 进而很快普及到全世界。60 年代以后, 汽车的大量生产又为冷锻技术的发展创造了广阔的天地[3]。

锻造可分为自由锻、镦粗、挤压、模锻、闭式模锻、闭式镦锻。自由锻。利用冲击力或压力使金属在上下两个抵铁(砧块)间产生变形以获得所需锻件,主要有手工锻造和机械锻造两种。模锻。模锻又分为开式模锻和闭式模锻.金属坯料在具有一定形状的锻模膛内受压变形而获得锻件,又可分为冷镦、辊锻、径向锻造和挤压等等。闭式模锻和闭式镦锻由于没有飞边,材料的利用率就高。用一道工序或几道工序就可能完成复杂锻件的精加工。由于没有飞边,锻件的受力面积就减少,所需要的荷载也减少。但是,应注意不能使坯料完全受到限制,为此要严格控制坯料的体积,控制锻模的相对位置和对锻件进行测量,努力减少锻模的磨损[2]。

1.2设计题目及其设计要求

1.2.1设计题目:

高压阀盖锻模设计及其成形数值模拟

1.3 设计任务及要求

1.设计(研究)内容和要求(包括设计或研究内容、主要指标与技术参数,并根据课题性质对学生提出具体要求)

(1)实习调研,翻译外文资料

1、实习调研,查阅文献15篇以上;

2、翻译不少于5000汉字的外文资料,要求外文文献与锻模设计相关;

3、查阅基于Deform的模拟锻造成形的相关论文;

4、查阅并整理锻模设计方面的文献。

(2)模具总体方案设计

1、根据任务书,结合实际,制定高压阀盖锻件生产工艺方案;2、设计锻模。

(3)模具设计

1、根据零件图制定锻件图,并计算毛坯,制定锻造工步,方案合理;

2、结合有限元模拟结果,应用CAD软件进行模具各零件和模具装配图的设计;

3、绘制模具总装配图及主要部件的零件图。要求设计并绘制完成2副模具的装配图、主要模具零件的零件图,图纸量2.5-3张A0,符合国标,模具要简单实用。

(4)设计说明书编写

参 考 文 献

[1] 李硕本,冲压工艺学,北京,机械工业出版社,1982.1;

[2] 李佑天,冲压工艺手册(修订本),长沙,湖南科学技术出版社,1984;

[3] 胡世光,板料冷压成形原理,北京,国防工业出版社,1990;

[4] 吴诗惇,冲压工艺学[M],西安,西北工业大学出版社,1987.6;

[5]史铁梁,模具设计指导[M],北京,机械工业出版社,2003.8;

[6]万战胜,冲压模具设计[M],北京,中国铁道出版社,1988;

[7] 李双义,冷冲模具设计[M],北京,清华大学出版社,2002.2;

[8] 湖南机械工程学会锻压分会,冲压工艺,长沙,湖南科学技术出版社,1984;

[9]梁炳文, 实用板金冲压工艺图(第一集)第1版,北京:机械工业出社,1991;

[10] 李志刚,模具CAD/CAM[M],北京,机械工业出版业,1995;

[11] 丁松聚,冷冲压设计,北京,机械工业出版社,1994.7;

[12] 王孝培,冲压手册[K],北京,机械工业出版社,1988.2;

[13] 王孝培,实用冲压技术手册[M],北京,机械工业出版社,2001;

[14] 《冲模设计手册》编写组,冲模设计手册[M],北京,机械工业出版社,1999;

[15] 肖景容,冲压工艺学[M],北京,机械工业出版社,2000.5;

[16] 李彦蓉、杜言利、肖作义,镶拼式冲模设计,模具技术[J],2000(3), 41-43;

[17] 第四机械工业部标准化研究所编,冷压冲模结构图册[M],北京,1981;

[18] 侯洪生,机械工程图学[M],北京,科学出版社,2005.1;

[19] 陈榕林,常用机械设计新旧标准对照手册[M],北京,中国建材工业出版社1992.11;

[21] 田嘉生,冲模设计基础[M],北京,航空工业出版社,1994.9;

[22] 模具制造编写组,模具制造手册[M],北京,机械工业出版社,1982;

[23] 冯炳尧等,模具设计与制造简明手册[M],上海,上海科学技术出版社,1983;

[24] 黄毅宏,模具制造工艺[M],北京,机械工业出版社,1988.6;

[25] 张春水,高效精密冲模设计与制造[M],西安,西安电子科技大学出版社,l990;

[26] 张钧,冷冲压模具设计与制造[M],西安,西北工业大学出版杜,1993;

[27] 肖景荣,模具计算机辅助设计与制造[M],北京,国防工业出版社,1990;

川公网安备: 51019002004831号

川公网安备: 51019002004831号