60吨冲床上料机械手的设计【优秀工业机械手设计+19张CAD图纸】

【带开题报告+外文翻译+中期报告+37页@正文18700字】【详情如下】【需要咨询购买全套设计请加QQ1459919609 】.bat

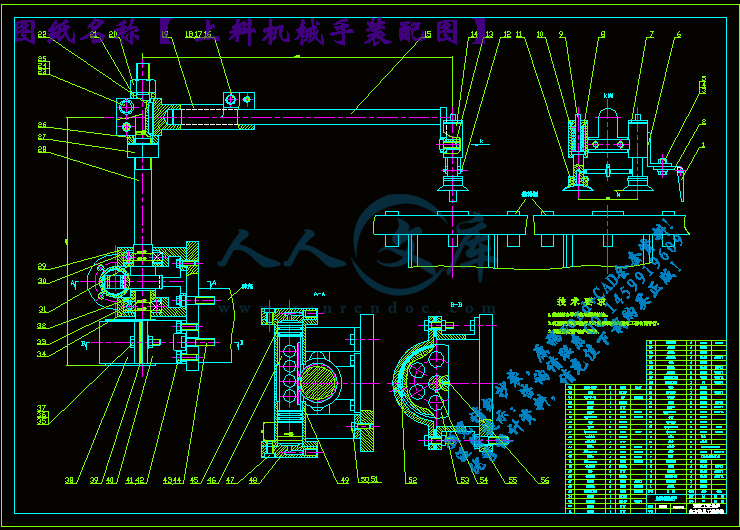

上料机械手装配图.dwg

两个轴气动人工肌肉机械手的一种新的相平面切换控制方法控制外文.pdf

中期报告.wps

储料支座.dwg

储料框底架.dwg

储料框座.dwg

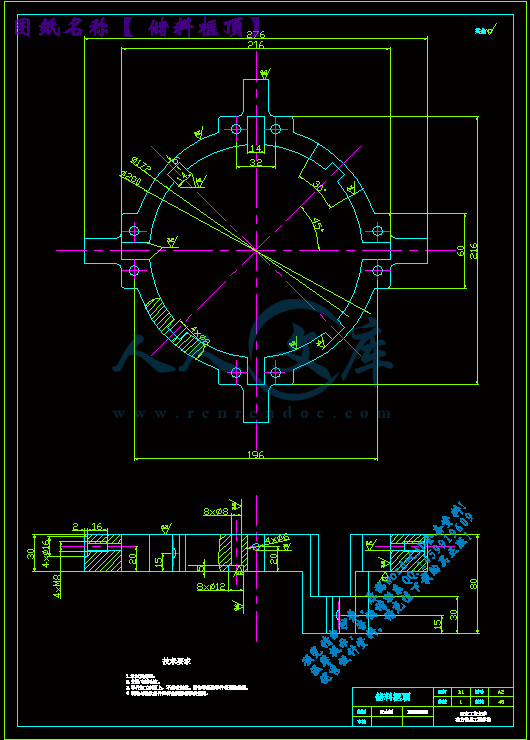

储料框顶.dwg

制 动 轮.dwg

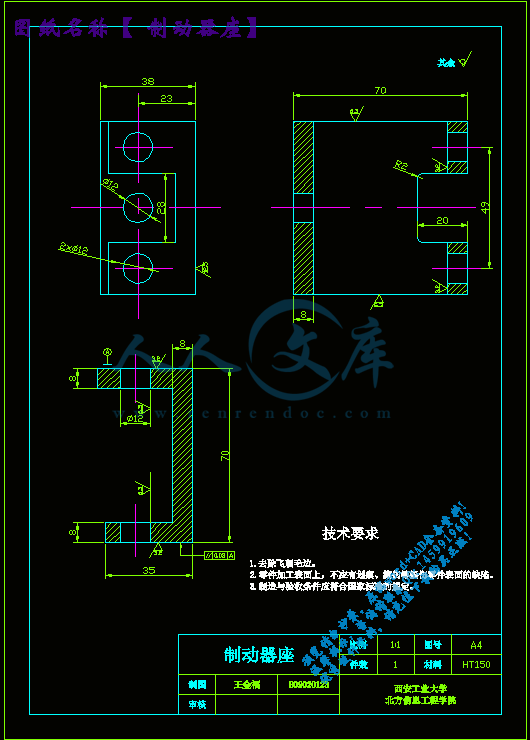

制动器座.dwg

制动器盖.dwg

压 盖.dwg

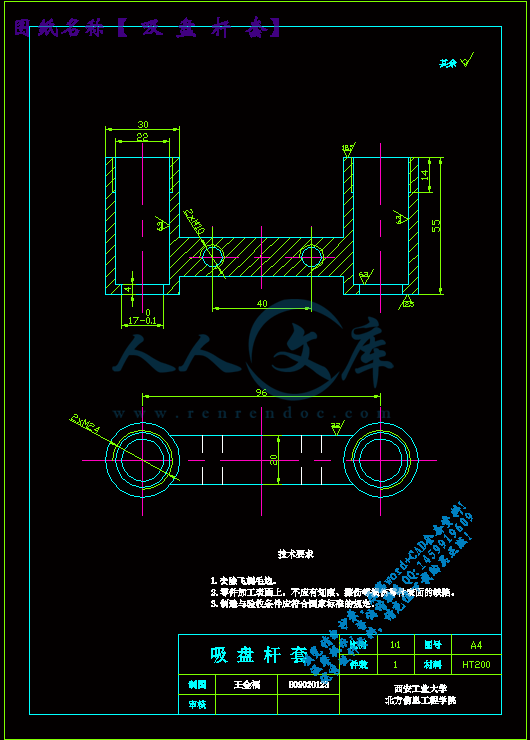

吸 盘 杆 套.dwg

吸 盘 杆.dwg

外文译文.wps

开题报告.doc

手 臂.dwg

手 臂 套.dwg

正文.doc

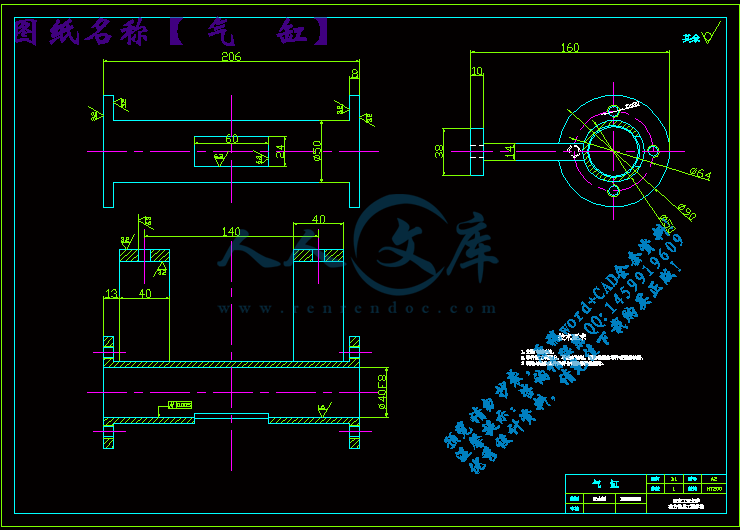

气 缸.dwg

气缸盖.dwg

活塞齿条.dwg

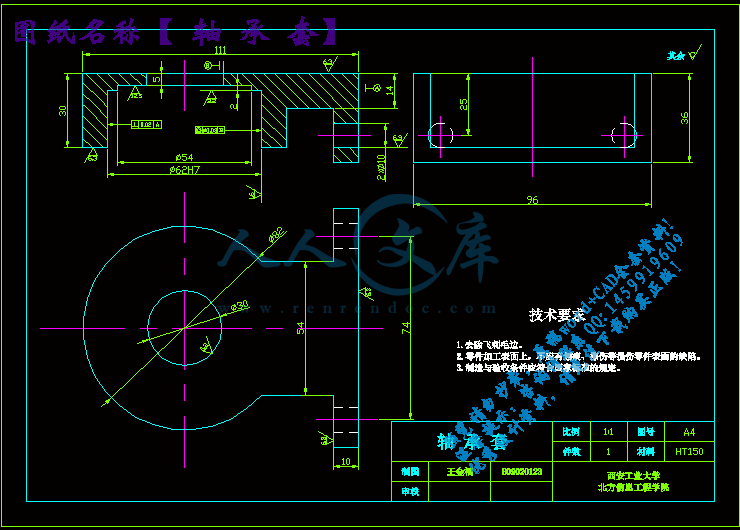

轴 承 套.dwg

轴 承 套2.dwg

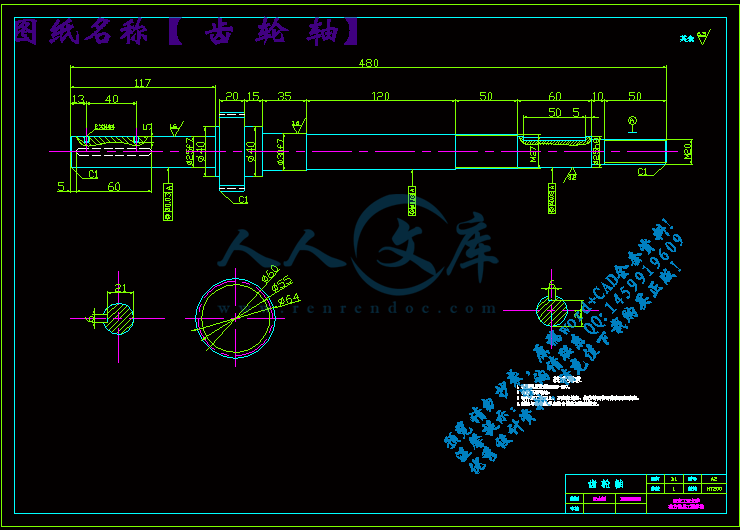

齿 轮 轴.dwg

摘 要

机械手是模仿着人手的部分动作,按给定程序、轨迹实现自动抓取、搬运和操作的自动机械装置。在工业生产中应用的机械手被称为“工业机械手”。本次设计的60吨冲床上料机械手根据规定的动作顺序,完成对机械手的设计,对机械手的工作原理,结构使用范围,特点参数选择等方面进行了阐述。此60吨冲床上料机械手主要是给冲床进行上料和从储料框中取料;机械手的抓重1Kg;1个自由度三个具体动作,自由度为腰座的转动,采用圆柱坐标;其余两个动作为机械手的升降和伸缩,采用螺母和螺栓调节,可根据生产的需要改变机械手手臂的高度和长度以及更换吸盘。回转角度:60度;送料频率:50-60次/分;驱动方式为气压传动;机械手的腰座回转采用气缸带动齿条齿轮驱动;本设计主要对手部进行了设计和计算,腰座回转采用回转气缸。

关键词:上料机械手;冲床上料;气压传动

Design for the punch manipulator

Abstract

Manipulator is imitate the part of the hand, according to the given program, track and for automatic mechanical device to realize the acquirement, handling and operation of the. The manipulator used in the industrial production is called "industrial manipulator". 60 tons punch the design of the manipulator according to the provisions of the action sequence, complete the design of manipulator, the working principle of the manipulator, the use range structure, gives the characteristic parameters. This 60 tons punch manipulator is mainly to press for feeding and from the material storage box material; mechanical hand catch weight 1Kg; 1 degrees of freedom three specific actions, degrees of freedom for rotation waist seat, using cylindrical coordinates; the remaining two of the mechanical hand movements and the expansion, the nut and bolt adjustment, according to production needs to change the mechanical arm height and length and replacing chuck. Because the rotary angle: 60 degrees; the feeding frequency: 50-60 times / points; drive mode for pneumatic drive; waist seat rotary manipulator cylinder is used to drive a rack gear drive; the design of the main part of the design and calculation, waist, rotating the rotary cylinder.

KeyWords:feeding manipulator;punch feeding;pneumatic transmission

目 录

1 绪论1

1.1 机械手简介1

1.2 机械手发展现状及应用1

1.2.1国内外发展现状1

1.2.2机械手的应用4

2 机械手的总体设计7

2.1 机械手的总体结构7

2.1.1 机械手组成7

2.1.2 机械手坐标形式的确定9

2.1.3上料机械手的组成及工作原理9

2.2 机械手腰座结构的设计11

2.1.1 机械手的驱动系统的确定12

2.1.2 机械手的机械传动机构的确定15

2.3 机械手手臂的结构设计18

2.4 机械手手部的结构设计19

3 机械手理论分析和设计计算21

3.1 系统设计计算21

3.1.1 确定气压系统基本方案21

3.1.2 气压缸的总机械载荷的计算22

3.1.3 气缸强度的计算及校核23

3.1.4 计算和选择气缸元件25

3.2 吸盘的选择和计算25

总 结29

参考文献30

致 谢31

毕业设计(论文)知识产权声明32

毕业设计(论文)独创性声明33

1 绪论

1.1 机械手简介

工机械手是模仿着人手的部分动作,按给定程序、轨迹和要求实现自动抓取、搬运或操作的自动机械装置。在工业生产中应用的机械手被称为“工业机械手”。生产中应用机械手可以提高生产的自动化水平和劳动生产率:可以减轻劳动强度、保证产品质量、实现安全生产;尤其在高温、高压、低温、低压、粉尘、易爆、有毒气体和放射性等恶劣的环境中,它代替人进行正常的工作,意义更为重大。因此,在机械加工、冲压、铸、锻、焊接、热处理、电镀、喷漆、装配以及轻工业、交通运输业等方面得到越来越广泛的引用。

机械手的结构形式开始比较简单,专用性较强,仅为某台机床的上下料装置,是附属于该机床的专用机械手。随着工业技术的发展,制成了能够独立的按程序控制实现重复操作,适用范围比较广的“程序控制通用机械手”,简称通用机械手。由于通用机械手能很快的改变工作程序,适应性较强,所以它在不断变换生产品种的中小批量生产中获得广泛的引用。

参考文献

[1] 李允文. 工业机械手设计[M]. 北京:机械工业出版社,1996.

[2] 蔡自兴.机械人学的发展趋势和发展战略[J].北京:机械人技术,2001,4.

[3] 王承义.机械手及其应用[M].北京:机械工业出版社, 1981.

[4] 金茂青.国外工业机械人发展的态势分析[J].北京:中国铁道出版社2001,2.

[5] 张建民.工业机器人[M].北京:北京工业大学出版社,1988.

[6] 唐保宁,高学满.机械设计与制造简明手册[M].上海:同济大学出版社,1993.

[7] 费仁元,张慧慧.机器人机械设计和分析[M].北京:北京工业出版社,1998.

[8] 周宏.气动工程手册[M].北京:国防工业出版社,1995.

[9] 周洪,陆鑫盛.自动化系统的优化设计[D].上海:上海科学技术文献出版社.

[10] 柳洪义,宋伟刚.机械人技术基础[M].北京:冶金工业出版社, 2002.

[11] 李允文. 工业机械手(上册)[M].上海:上海科学技术出版社 1978.

[12] 王承义.机械手及其应用[M].北京: 机械工业出版社, 1981.

[13] 万胜狄,王运赣等. 锻造机械化与自动化[M].北京:机械工业出版社,1983.

[14] 宋伟刚.机械零件设计手册(第三版)[M].北京:冶金工业出版社, 1994.

[15] (苏)别洛夫(А.П.Велов)著;闻清译.机械手.北京市:原子能出版社,1982.

[16] 沈阳市机床工业公司七、二一大学编著.工业机械手.沈阳市:辽宁人民出版社,1979.

[17] 天津大学《工业机械手设计基础》编写组编.工业机械手设计基础.天津市:天津科学技术出版社,1980.

[18] 陆祥生,杨秀莲编.机械手 理论及应用.北京市:中国铁道出版社.

[19] 加藤一郎编著;何学文译.图解机械手.正言出版社,1983.

[20] Kurt E Petersen.Silicon as a mechanical Material[C].Proc.IEEE,1982.

[21] ClavelR D.a fast robot with parallel geometry. Sydney: Symposium on in dustrial robots( ISIR),1988:91-100.

[22] John J.Craig,Introduction to Robotics Mechanics and Control.Second Edition.New York:Addison-Wesley Reading,1989.

川公网安备: 51019002004831号

川公网安备: 51019002004831号