陈四楼矿240万吨新井设计

陈四楼矿240万吨新井通风安全设计【优秀开采矿区矿井新井设计+7张CAD图纸】

【带外文翻译+69页@正文35000字】【详情如下】【需要咨询购买全套设计请加QQ1459919609 】.bat

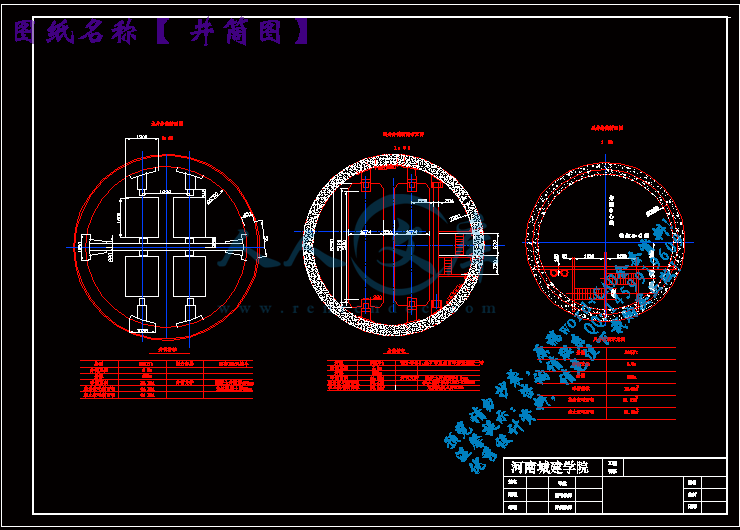

井筒图.dwg

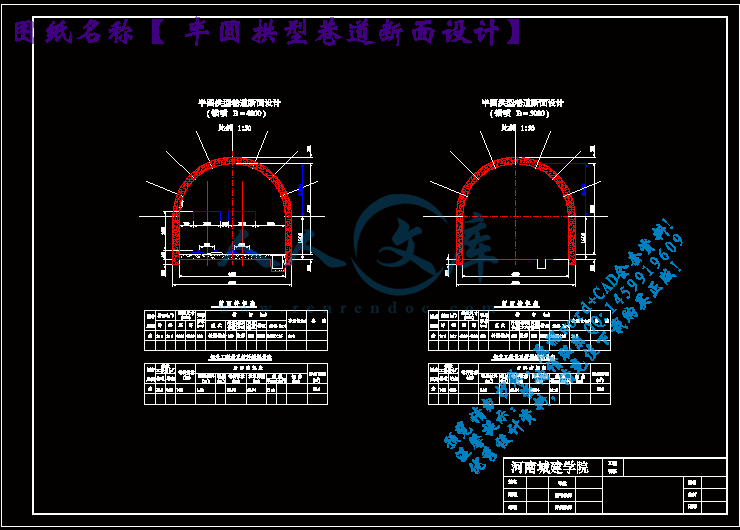

半圆拱型巷道断面设计.dwg

外文翻译.doc

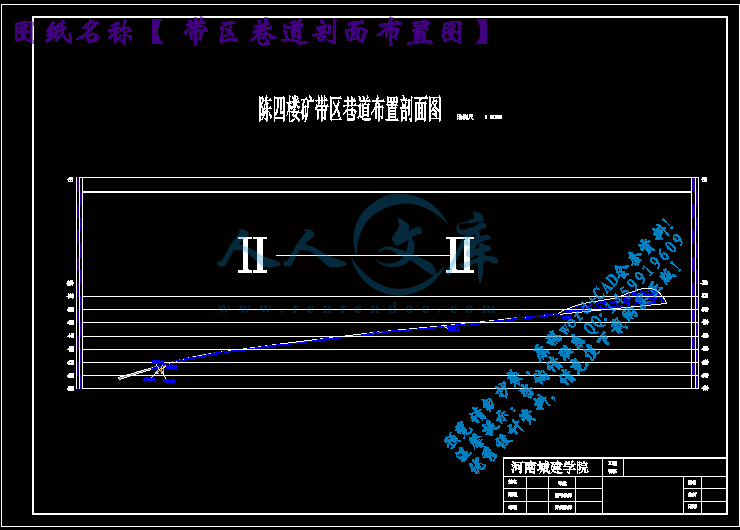

带区巷道剖面布置图.dwg

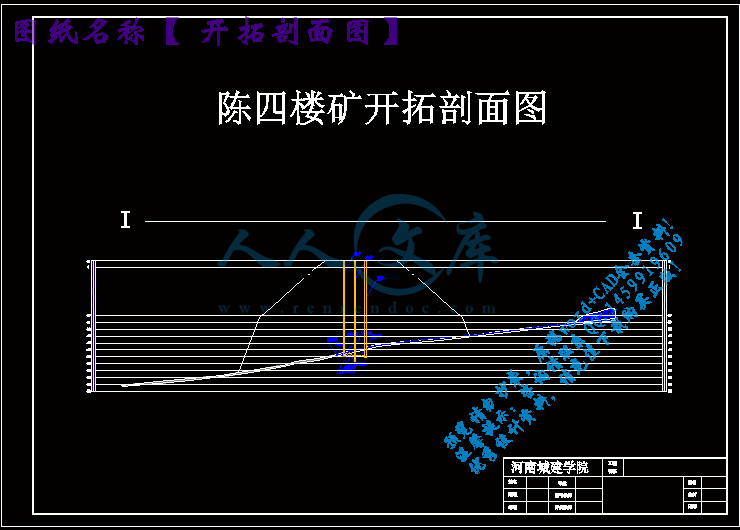

开拓剖面图.dwg

陈四楼煤矿带区巷道布置图.dwg

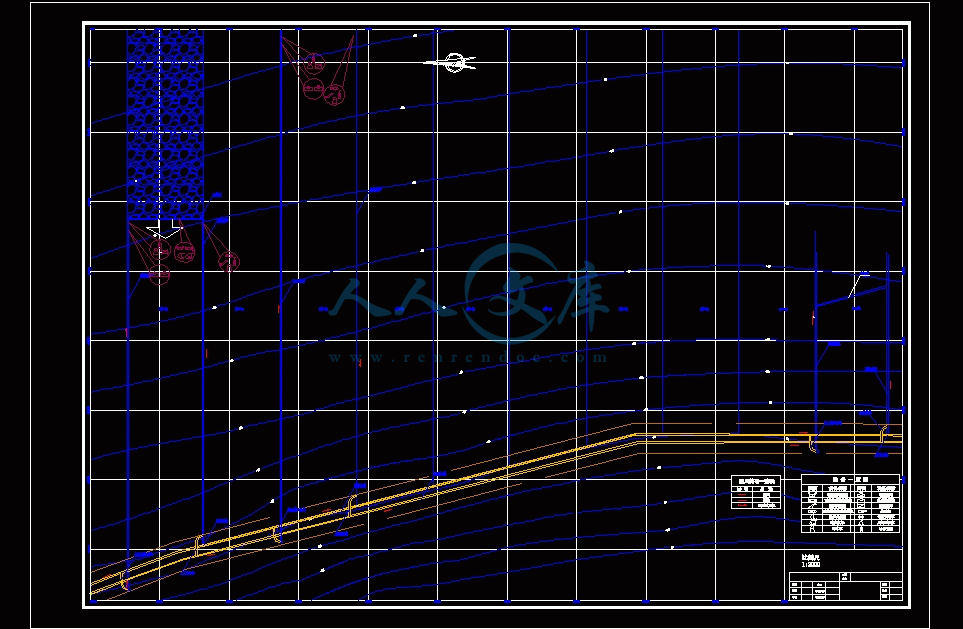

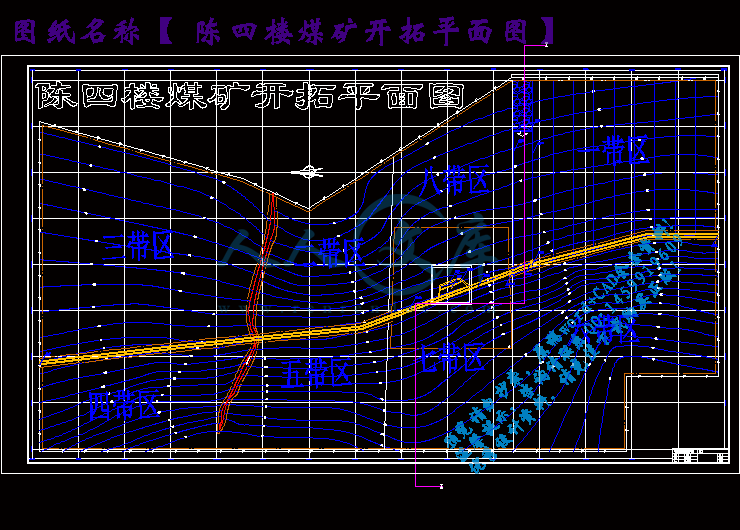

陈四楼煤矿开拓平面图.dwg

陈四楼矿240万吨新井设计正文.doc

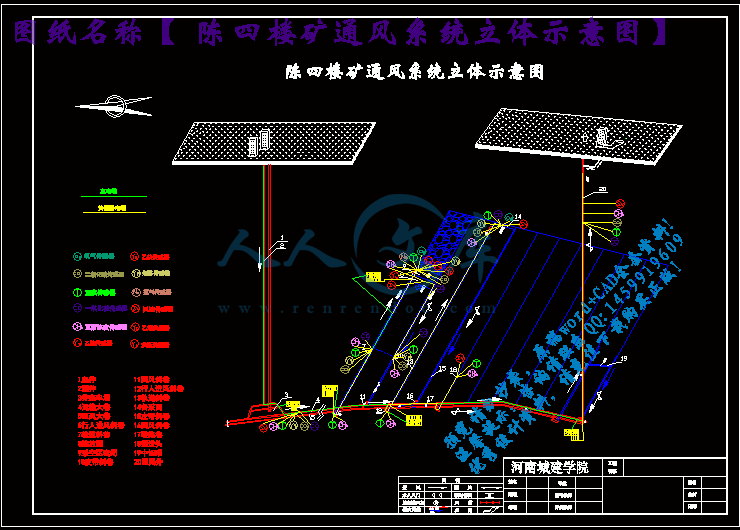

陈四楼矿通风系统立体示意图.dwg

陈四楼矿240万吨新井通风安全设计

摘 要

本设计分为一般部分和科技英语翻译部分。一般部分为永城矿区陈四楼煤矿240万吨/年新井通风安全设计;科技英语翻译部分为计算机映射采矿中的断层。

陈四楼煤矿设计生产能力为240万吨/年,矿井服务年限为55年,采用立井单水平,回风大巷布置在岩层中作为本矿井的开拓方案。水平设在-520米。带区布置采用带区单一煤层分带巷道布置,初期在一带区布置一个综合机械化放顶煤工作面,采用倾斜长壁一次开采。矿井采用抽出式通风方式,轨道斜巷进风,皮带斜巷回风。根据通风容易和困难时期的风量和通风阻力计算选择主要通风机,并对通风系统进行了评价。

设计对矿井的瓦斯、自然发火等自然灾害提出了有效的防治措施,特别对自然发火的防治进行了详细的叙述和黄泥灌浆设计,可有效防治自然发火。

科技英语翻译部分探讨了计算机映射采矿中的断层,并举例说明!

关键词:立井; 长壁; 抽出;突水;断层

ABSTRACT

This design is made up of the ordinary part and the scientific English translation part. The ordinary part is the ventilation safety design of 2.4 Mt/a. The scientific English translate part is about the mining’s chasm in the post of the computer.

Chensi colliery designing production capability is 2.4Mt/a, and the service time limit is 55 years. Its mining method is of the vertical shaft with single levels up and down hill. The level is on -520m. The set-up of the belt area applies single seam zone roadway layout. In the early period, we set up an integrated mechanized caving face with a tilt-wall mining. The mining applies Out of a ventilation shaft, the track Inclined Drift into the wind, Inclined Drift back to the wind belt. The mine’s ventilation machine is chosen according to the mine’s air quantity in easy and difficulty ventilation periods and the calculation of the mine’s ventilation resistance, and the mine’s ventilation system is evaluated.

We put forward some effective measures to prevent the disasters of methane, natural fire and so on, and we especially dwell on the prevention of natural fire and the design of yellow mud grouting, and it has a good result.

The scientific English translate part proclaims that the mining’s chasm in the post of the computer and gives some examples.

Key words: vertical mining; longwall; draw out; sudden inflow of water; chasm

目 录

1 矿区概述及井田地质特征1

1.1 矿区概述1

1.2井田地质特征1

1.2.1 勘探程度2

1.2.2 地层2

1.2.3 地质构造3

1.2.4 水文地质3

1.3 煤层特征4

1.3.1 煤层4

1.3.2 煤的特征5

1.3.3 开采技术条件5

2 井田开拓6

2.1井田开拓的基本问题6

2.2井筒形式确定7

2.3工业广场及井筒位置7

2.4开采水平的确定8

2.5 大巷和井底车场的布置8

2.6 矿井开拓方案8

2.7 矿井的基本巷道8

3 采煤方法与采区巷道布置9

3.1带区巷道布置及生产系统9

3.1.1带区准备方式的确定9

3.1.2生产系统11

3.1.3带区内巷道掘进11

3.2带区主要硐室12

3.3采煤方法12

3.1采煤工艺方式12

4 矿井通风13

4.1 矿井通风系统选择13

4.1.1矿井地质概况13

4.1.2开拓方式14

4.1.3开采方法14

4.1.4变电所、充电硐室、火药库14

4.1.5工作制、人数14

4.2矿井通风系统的确定14

4.2.1矿井通风系统的基本要求14

4.2.2、矿井通风方式的选择15

4.2.3.确定矿井通风方法17

4.2.4带区通风系统的要求17

4.2.5、工作面通风方式的选择18

4.3矿井风量计算20

4.3.1矿井风量的计算原则20

4.3.2 总风量的计算20

4.3.3 矿井风量分配23

4.4 掘进通风24

4.4.1 掘进通风方法的选择24

4.4.2 掘进通风量25

4.4.3 掘进工作面设备选择25

4.5全矿通风阻力的计算27

4.5.1矿井最大阻力路线27

4.5.2矿井通风阻力计算32

4.5.3 矿井通风总风阻37

4.5.4 矿井通风等积孔38

4.5.5 矿井通风系统的分析与评价38

4.6 矿井主要通风机选型39

4.6.1 矿井自然风压的计算39

4.6.2 通风机的选择40

4.6.3 电动机的选择42

4.6.4对矿井主要通风设备的要求44

4.6.5对反风、风峒的要求44

4.7 矿井反风措施及装置44

4.7.1矿井反风的目的和意义45

4.7.2 矿井反风设施的布置45

4.7.3 对矿井通风设备的要求46

4.8概算矿井通风费用46

5 矿井安全技术措施47

5.1 矿井火灾47

5.1.1 矿井自然发火概况48

5.1.2 矿井自然发火分析48

5.1.3 防止煤层自燃发火的预报及监测措施50

5.1.4 防灭火措施51

5.2 矿井瓦斯55

5.2.1 矿井瓦斯地质条件57

5.2.2 矿井及采区瓦斯涌出概况57

5.2.3 矿井瓦斯防治措施58

5.3井下防治水措施61

5.4 避灾路线61

参考文献:62

致 谢65

参考文献:

[1].煤炭部.煤炭工业设计规范,煤炭工业出版社,1979

[2].徐永祈.采矿学,中国矿业大学出版社,2003

[3].林在康.井筒断面图册,中国矿业大学出版社,2003

[4].林在康.巷道断面图册,中国矿业大学出版社,2003

[5].林在康.井底车场图册,中国矿业大学出版社,2003

[6].林在康.风机装置性能图册,中国矿业大学出版社,2003

[7].陈昌荣.地质学基础,中国矿业大学出版社,1994

[8].吴则智.兖州矿区综合机械化放顶煤开采的实践与认识,煤炭工业出版社,1997

[9].戴绍城.高产高效综合机械化采煤技术与装备,煤炭工业出版社,1997

[10].陈炎光、徐永祈.中国采煤方法,中国矿业大学出版社,1991

[11].钱鸣高、刘庭成.矿山压力及控制,煤炭工业出版社,1991

[12].王省身.矿井灾害防治理论与技术,中国矿业大学出版社,1989

[13].岑传鸿.采场顶板控制与检测技术,中国矿业大学出版社,1998

[14].林在康、左秀峰.矿业信息及计算机应用,2000

[15].蒋国安、吕家立.采矿工程英语,1998

[16].全国自然科学名词审定委员会.煤炭科技名词,1996

[17].兖矿集团东滩煤矿.东滩煤矿矿山压力控制实践与研究,1999

[18].《综采设备管理手册》编委会.《综采设备管理手册》,煤炭工业出版社,1994

[19].中国煤矿专用设备成套服务公司.《采煤机械化成套设备参考手册》,煤炭工业部,1984

[20].中国统配煤矿总公司物资供应局.《煤炭工业设备手册》,中国矿业大学出版社,1992

[21].洪晓华.矿井运输提升,中国矿业大学出版社,2000

[22].东兆星、吴士良.井巷工程,中国矿业大学出版社,2004

[23].王德明.矿井通风与安全, 中国矿业大学出版社,2005

[24]. 洪晓华.矿井运输提升, 中国矿业大学出版社,2005

[25].钱鸣高、石平五.矿山压力与岩层控制,中国矿业大学出版社,2003

[26] 孟宪锐、李建民.现代放顶煤开采理论与实用技术;江苏徐州:中国矿业大学出版社,2001。

[27] 徐兴子.厚煤层分层综采技术;北京:煤炭工业出版社,2002。

[28] 周冠军.矿图;北京:煤炭工业出版社,1993。

[29] 煤炭工业部安全监察局.国内外煤矿粉尘防治技术资料选编;2002。

[30] 史富 等.矿井综合防尘技术与管理;北京:煤炭工业出版社,1994。

[31] 汪理全、梁雪勤.采矿概论;北京:煤炭工业出版社,2002。

[32] 赵益芳.矿井防尘理论及技术;北京:煤炭工业出版社,1995。

[33] 徐兴子.安全规程;北京:煤炭工业部出版社,2002。

[34] 《煤矿矿井采矿设计手册》编写组.煤矿矿井采矿设计手册(上、下册);北京:煤炭工业出版社,1984。

[35] 徐永圻.中国采煤方法图集;徐州:煤炭工业出版社,1990。

[36] 中华人民共和国煤炭工业部制定.煤炭工业设计规范;北京:煤炭工业出版社,2000。

[37] 国家煤矿安全监察局制定.煤矿安全规程;北京:煤炭工业出版社,2001。

[38] 王省身.矿井灾害防治理论与技术;徐州:中国矿业大学出版社,1986。

[39] 任洞天.矿井通风与安全;北京:煤炭工业出版社,2002。

[40] 周逎荣,严万生.矿山固定机械手册;北京:煤炭工业出版社,1986。

[41] 亓延宝.厚煤层分层综采技术;北京:煤炭工业出版社,2002。

[42] 续魁昌.风机手册;北京:机械工业出版社,1999。

[43] 萧景瑞.矿井通风;徐州:中国矿业大学出版社,1984。

[44] 纪登平.建井通风与安全;北京:煤炭工业出版社,1994。

[45] 徐兴子.厚煤层分层综采技术;北京:煤炭工业出版社,2002。

[46] 郑西贵.采矿AutuCAD2006入门与提高;徐州:中国矿业大学出版社,2005。

[47] 万博.Photoshop 6.0中文版实战入门新概念;北京:中国水利水电出版社,2001.10。

[48] 丁颖.计算机应用基础;徐州:中国矿业大学出版社,2001。

[49] 曹虎斌.综采工作面通风防尘的实践与探讨;煤;2005年4月,56-60。

[50] 马志宏.综放工作面防尘技术实践;煤;1999年3月,25-29。

川公网安备: 51019002004831号

川公网安备: 51019002004831号