秸秆纤维锤片粉碎机的设计【优秀农业用机械设计类+6张CAD图纸】

秸秆锤片粉碎机的设计

锤片粉碎机设计

秸秆粉碎机的设计

秸秆纤维锤片粉碎机的设计【优秀农业用机械设计类+6张CAD图纸】

【带外文翻译+37页@正文15300字】【详情如下】【需要咨询购买全套设计请加QQ1459919609 】.bat

上机壳.dwg

下机壳.dwg

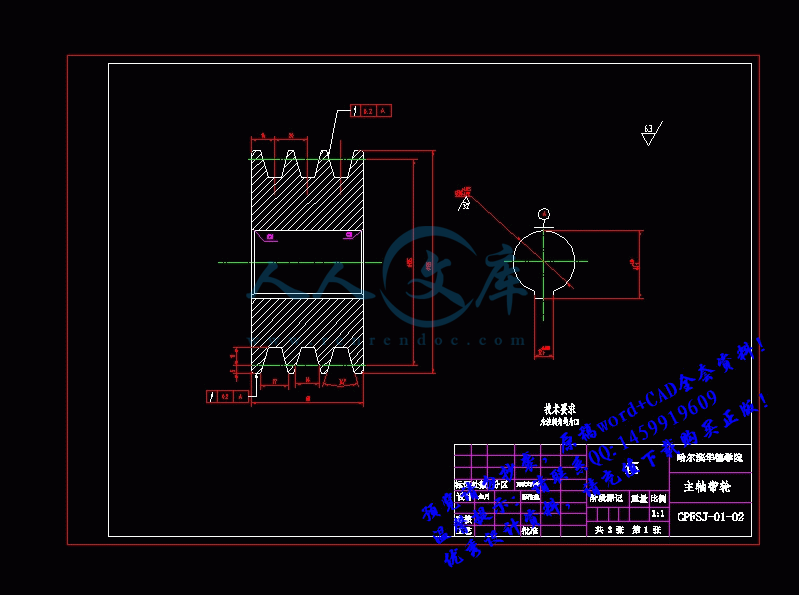

主轴带轮.dwg

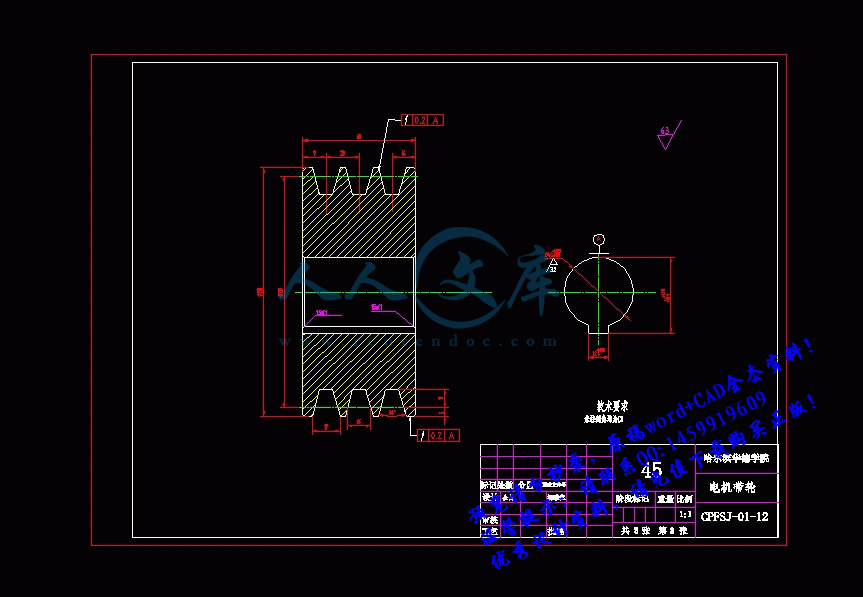

电机带轮.dwg

秸秆纤维锤片粉碎机的设计正文.doc

装配图.dwg

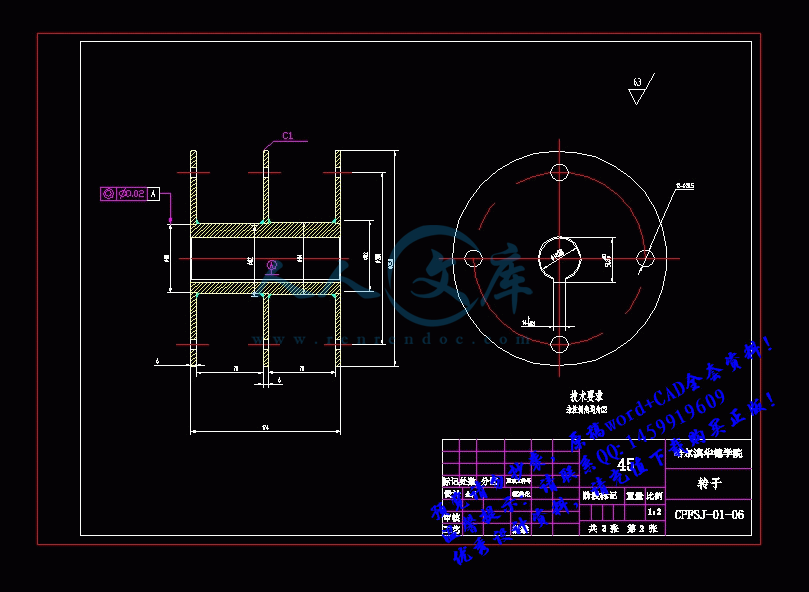

转子.dwg

锤片式粉碎机械设计外文文献翻译.doc

摘 要

秸秆纤维的制取一直是生物工程领域关注的问题,本文通过对传统秸秆制取方式和纤维粉碎的各种方法的对比分析,采用机械原理制取微小秸秆纤维,并保证其生产率和纤维质量。

首先通过讨论传统的秸秆纤维粉碎制取的方法,分析各种方法的优点与缺点。综合各种粉碎方法,决定采用两次粉碎的方法制取秸秆纤维,即先用连续冲压模具锤击初步粉碎,再利用锤片式粉碎机二次粉碎。冲压模具的选取上,决定采取牙型模具配合传统空气锤。在众多种类的粉碎机中,通过比较,决定采取锤片式带筛粉碎机,并配合风选系统,提高效率,本文主要进行粉碎机的设计,首先进行结构设计,包括两部分,一个是粉碎部分的结构与功率的设计;二是风选部分的结构与功率的设计。粉碎部分包括锤片的选择,筛网的选择等等,其次进行主轴的校核与轴承的校核。

关键词:起重机;桥式;起升机构;小车;卷筒组

Abstract

Manufacture of the straw’s fiber is always the focus which the field of Biological Engineering concern about. The article through contrasting and analyzing the traditional manufacture ways the straw’s fiber and crushing ways of fiber ,it introduces manufacturing of ways the straw’s fiber machinery and ensures its productivity and fibrous quality.

The article discuss the advantage and disadvantage of tradition method which manufacturing fiber of the straw and ways of machinery crush. Comprehensive various method I decide to choice firstly continuous Stamping die to first Smash, and use Hammer mill for again smashing. In the many types of pulverizers, I decided to take hammer-mill with screening by comparison, With the wind-election system?for improving efficiency?.The article mainly carried out the design of Hammer Mill. First, I must choose design structure?.It consists of two parts, One is design of structure and power?which smash part; Another is design of structure and power which wind-election system . Smash part include choose hammer, Screen, and so on. Next?checking the spindle and bearing.

Key words Fiber of the straw manufactured;Teeth-shape die;Hammer mill

目 录

第1章 绪 论1

1.1 秸秆纤维的制取方法1

1.2 粉碎技术2

1.2.1 粉碎的方法种类2

1.2.2 破碎机构的种类3

1.2.3 粉碎机的分类5

1.2.4 粉碎机技术发展现状6

1.3 主要内容7

第2章 确定总方案8

2.1 方案的确定8

2.2 本章小结9

第3章 压力机与模具的选取10

3.1 模具的设计10

3.2 压力机的选择10

3.3 本章小结11

第4章 锤片粉碎机的原理及设计12

4.1 锤片粉碎机的基本原理12

4.1.1 原理及类工作型12

4.1.2 锤式破碎机的结构12

4.2主要部件零件的设计说明14

4.2.1 已知条件14

4.2.2 锤击转子的锤片个数计算15

4.2.3 离心风机的叶轮直径的计算16

4.2.4 功率的相关计算16

4.2.5 带传动的设计17

4.2.6 主轴设计及校核20

4.2.7 轴承选取与校核23

4.3 本章小结23

第5章 机器的使用和维护24

5.1 粉碎机的正确使用24

5.2 粉碎机的维护与保养24

5.3 本章小结25

总 结26

参考文献27

致 谢28

附录1 译 文29

附录3 中华人民共和国法定计量单位42

附录4 数字用法示例45

附录5 插表示例46

附录6 有关的技术制图国家标准46

附录7 有关电气图形符号、文字符号的国家标准46

第1章 绪 论

1.1秸秆纤维的制取方法

秸秆是纤维组分含量很高的农作物残留物,秸秆纤维是天然纤维素纤维,有着广泛的应用前景,原材料丰富,价格低廉并可以降解。能够适应符合环境要求的产品的开发。秸秆是成熟农作物茎叶(穗)部分的总称。通常指小麦、水稻、玉米、薯类、油料、棉花、甘蔗和其它农作物在收获籽实后的剩余部分。农作物光合作用的产物有一半以上存在于秸秆中,秸秆富含氮、磷、钾、钙、镁和有机质等,是一种具有多用途的可再生的生物资源,秸秆也是一种粗饲料。特点是粗纤维含量高(30%-40%),并含有木质素等。木质素虽不能为猪、鸡所利用,但却能被反刍动物牛、羊等牲畜吸收和利用。我国农民对作物秸秆的利用有优久的历史,只是由于从前农业生产水平低、产量低,秸秆数量少,秸秆除少量用于垫圈、喂养牲畜,部分用于堆沤肥外,大部分都作燃料烧掉了。随着农业生产的发展,我国自20世纪80年代以来,粮食产量大幅提高,秸秆数量也多,加之省柴节煤技术的推广,烧煤和使用液化气的普及,使农村中有大量富余秸秆。秸秆纤维的制取是一种比较有效处理秸秆,避免浪费资源,污染环境的方法。

秸秆的化学成分含纤维素、半纤维素和木质素。纤维素大分子链有规则的排列而聚合成微细纤维,若干微细纤维组成的细纤维,再组成纤维。半纤维素和木质素在植物细胞中起着“粘合剂”和“填充剂”的作用,分布在细纤维之间的间隙里。纤维素是有结晶区和无定型区交错联接而成。在结晶区内纤维素链分子的排列具有完全的规则性;在无定型区,纤维素链分子排列规则性较差,排列较不规则,结合得较松弛。秸秆的抵抗拉伸变形的能力很强。

秸秆纤维的制取一直是生物工程领域关注的问题。传统制取秸秆纤维可以采用多种方法,如:汽爆法、研磨法和锤击法等。

汽爆法所用的设备就是汽爆机,例如正道重机集团有限公司的QB200汽爆机是由汽爆腔、物料收集腔、2台高压蒸汽发生器、启爆执行系统及电气自动化等部分组成,汽爆时伴随有急促爆炸响声,区别于无爆炸声的热喷放。

目前粉碎秸秆最常用的设备是粉碎机,具体设备将在后面介绍。

参考文献

1 李学志,吴志军,张春风. 机械设计手册[M].北京: 清华大学出版社,2005.

2 刘品,李哲.机械精度设计与检测基础[M].哈尔滨:哈尔滨工业大学出版社,2004.1.??????????????? ???

3 李华. 机械制造技术[M]北京:高等教育出版社2004.

4 朱辉 唐保宁 陈大复 等。工程制图[M]上海:上海科学技术出版社 2004.8

5 宁宇. 影响锤片式粉碎机锤片使用寿命的因素[J]. 《柳州科技》2000年3期:9-10.

6 宗力,徐红梅,彭小飞. 锤片式粉碎机锤片磨损机理初探[J].《饲料工业》2004年25卷9期 :5-7

7 王德福 马力. 通风量对锤片粉碎机工作性能的影响[J]. 《农机化研究》2004年2期 :108-109.

8 孙德平. 锤式粉碎机的研讨与应用[J].《机电信息》2003年6期:20-22.

9 杨世良 曹秀媛. 环锤式粉碎机主要构件的设计与受力计算[J].《吉林农业 大学学报》1992年14卷2期:63-68.

10 李桂华. 锤式粉碎机的改造[J].《燃料与化工》:1993年24卷3期:131-132.

11 温汝增.空气锤打击能量计算问题的探讨[J].机械制造师,2003 .

12 王德拥.空气锤能量计算新理论及其应用[J].压力加工,1998,7(7):14-15.

13 杜小强. 锤片式粉碎机转子动力学特性研究[D].武汉:华中农业大学,2004.

14 吉颖风. 新型锤片式粉碎机筛分效率的研究[J]. 北京:中国农业大学,2000.

15 阳向军. 浅析影响锤片式粉碎机工作性能的主要因素[J]. 中国饲料2003年第9期26.

16 陈昌伟. 粉碎机锤头排列的优化[J]. 燃料与化工,mar.2003 vol.34 no.2 :80.

川公网安备: 51019002004831号

川公网安备: 51019002004831号