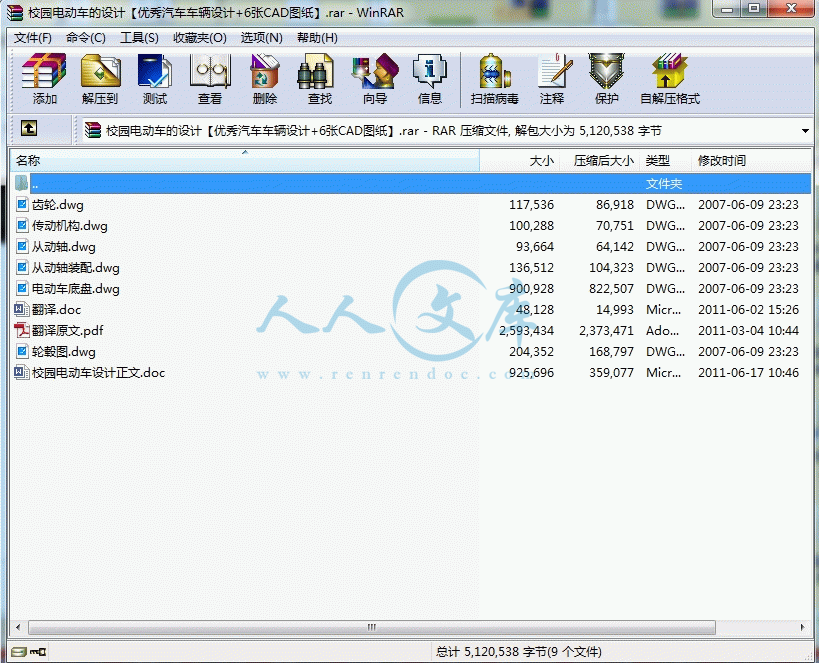

校园电动车的设计【优秀汽车车辆设计+6张CAD图纸】

【36页@正文14700字】【详情如下】【需要咨询购买全套设计请加QQ1459919609 】.bat从动轴.dwg

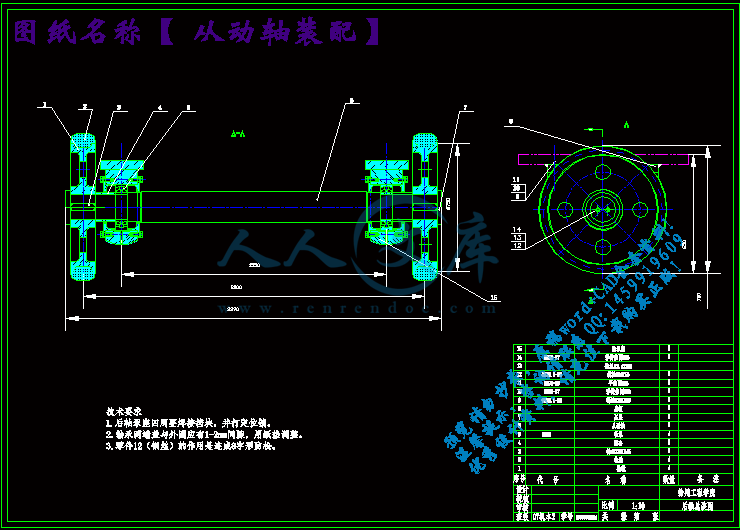

从动轴装配.dwg

传动机构.dwg

校园电动车设计正文.doc

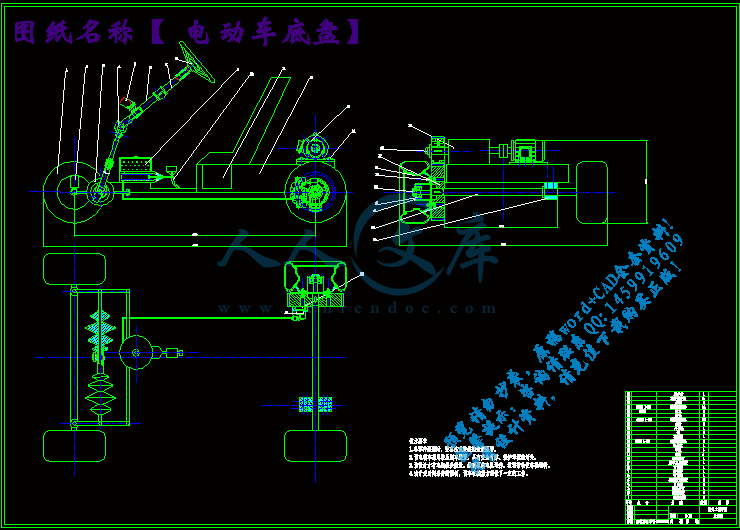

电动车底盘.dwg

翻译.doc

翻译原文.pdf

轮毂图.dwg

齿轮.dwg

摘要

校园电动车是近几年出现的一种新兴交通工具。校园电动车有着节能,环保,便捷等诸多的优点。因此本课题具有很强的现实意义和接近实际水平的设计要求,尤其是对机械设计部分和电气控制部分的设计。 本毕业设计主要进行了电动车的机械部分的分析和设计,包括电动车的减速器、差速器、轴承的选择设计、各主要零部件的强度校核与计算、以及基本的机械传动部分的实现等。通过所设计好机械各部分或者整体部分的结构以及相关尺寸,利用制图软件CAD进行相关的配图的绘制以及其他零件图的绘制。 根据电动车前进、后退、制动等基本控制要求,给出电动机的电气控制设计。

关键词: 校园电动车;交通工具;强度校核;机械传动

Abstract

Campus electric vehicle is the emergence of a new transport in recent years. Campus electric car has energy-saving, environmentally friendly, convenient, and many other advantages. Therefore, this issue has a strong practical and realistic level design requirement, especially the part of design for mechanical design and electrical control part.

The graduation project is mainly for the electric vehicle analysis and design of mechanical parts. Including electric reducer, differential, bearing choice design, the major components Strength check and calculation, and basic mechanical transmission part of the implementation and so on. Designed by a good mechanical parts or the whole part of the structure and related dimensions, Use graphics software related with CAD drawing and other component drawing.

According to electric cars forward, reverse, brake control and other basic requirements, electrical motor control design can be given.

Keywords: campus electric vehicles; transport; strength check; mechanical transmission

目 录

1绪论1

1.1概述1

1.2电动车的优势与发展2

1.3本设计的主要任务3

2 机械部分设计4

2.1概述4

2.1.1基本要求4

2.1.2 基本数据4

2.2 传动部分设计5

2.2.1减速器传动比计算5

2.2.2 齿型选择6

2.2.3 载荷计算6

2.2.4 齿轮材料选择7

2.2.5 齿轮强度计算8

2.3 差速器设计12

2.3.1 对称式圆锥行星齿轮差速器原理12

2.3.2 对称式圆锥行星齿轮差速器结构14

2.3.3 差速器齿轮基本参数选择14

2.3.4 差速器齿轮强度计算17

2.4 轴承选择与校核18

2.4.1 概述18

2.4.2 滚动轴承类型及代号19

2.4.3 滚动轴承选择21

2.4.4 滚动轴承约束设计22

3电动车电气控制设计24

3.1主电路24

3.1.1 H型双极模式PWM控制24

3.1.2控制电路25

3.1.3 SG3525的内部电路和参数26

3.2电动车电池设计方案27

3.2.1 电池槽27

结论28

致谢29

参考文献30

1绪论

1.1概述

校园电动车是近几年出现的并且不断发展日益增多的小范围内使用的交通工具,它的出现和广泛应用为校园内的师生提供了更为便利的交通,还可以作为校区的旅游和观光工具,目前在各大景区已经广泛使用。它有着诸多的优点,例如:首先,环保,电动车行驶零排放,不污染大气,是节能、环保的典范; 第二,需求量大,一辆电动自行车一次充电能行驶30-50公里,有较大的市场需求; 第三,操作简单,车速不高,每小时20公里左右,不会对其他人力自行车和行人构成威胁和安全问题; 第四,维修简单;第五,用户白天使用,夜晚充电,续航能力很强,也不影响日常的工作和生活。该设计集机械和电力电子技术于一体,充分体现了节能、环保和方便实用等特点。通过对其的设计,能够使自身综合能力与设计创新的思维得到很好的锻炼。

电池电动车的历史。世界上第一辆电动汽车于1881年诞生,发明人为法国工程师古斯塔夫·特鲁夫,这是一辆用铅酸电池为动力的三轮车,而在1873年,由英国人罗伯特·戴维森用一 次电池作动力发明的电动汽车,并没有列入国际的确认范围。后来就出现了铅酸、镍镉、镍氢电池,锂离子电池,燃料电池作为电力。电动车-行业前景 电动车行业在中国崛起仅仅几年时间,在这短短的几年内,电动车行业由无到有,由零星分布到大范围普及,取得了高速的发展和长足的进步。由于不需要核心技术,进入门槛低,赢利空间大,短时间内大量企业将目光锁住电动车这个新兴行业。电动车产业的发展具有较强的地域性,一方面表现在生产,一方面表现在消费领域,而且这也是一个渐进的过程。 经过十余年的发展,中国电动车行业从小到大,已经形成一个规模庞大的产业群,尤其是进入二十一世纪以后,整个产业呈现高速发展态势。2004年,中国电动车行业已有1000多家生产厂,年产量达675万辆。2005年,中国的电动车年产量达960万辆,市场保有量在1500万辆以上。2006年国内电动车产量达到近2000万辆,比上年增幅60%以上。2010年,中国轻型电动车的产销量将可能达到3000万辆,出口量将可能达500万-600万辆,实现工业产值700亿元,包括上下游带动产值的产业总体规模,将达1300亿元。 我们在为这个行业快速发展而欣喜的同时也应看到,目前电动车行业的整体发展质量并不高,主要表现在厂家虽多但质量不佳。具有自主研发能力、上规模的大品牌很少,而大多数是一些靠模仿拼装、以低价运作的厂家,有些小厂甚至几个人、几把螺丝刀就能组装销售。

参考文献

[1]赵明生.机械工程手册.专用机械[M].机械工业出版社.1995: 77-89

[2]刘永波主编.电力电子技术[M].北京:机械工业出版社.2005: 34-42

[3]郑堤、唐可洪主编.机电一体化设计基础[M]. 北京:机械工业出版社,2006: 109-116

[4]周开勤. 机械零件手册第五版[M]. 北京:高等教育出版社 .2001:50-63

[5]成大先.机械设计手册·机械传动[M].北京:化学工业出版社.2004:23-42

[6]成大先.机械设计手册·机械制图·极限与配合[M].北京:化学工业出版社.2004: 98-67

[7]席伟光、杨光、李波主编.机械设计课程设计[M].北京:高等教育出版社.2003:88-100

[8]章宏甲、黄谊主编.液压传动[M].机械工业出版社.2000.9:111 -132

[9]Jongsoo Lee. Passivity-based control of synchronous motors in mine hoist systems [J].Journal of Coal Science and Engineering.2001, 001(01):20-33

[10]ZHOU Xiuhua .Study in New Type Signaling Device for Mine Hoists [J].COAL MINE AUTOMATION, 2000,001(01):111-149

川公网安备: 51019002004831号

川公网安备: 51019002004831号