PE400×600颚式破碎机的设计

颚式破碎机的设计

P破碎机的设计

PE400×600颚式破碎机的设计【优秀工程机械设备设计+5张CAD图纸】

【带文文翻译+46页@正文19000字】【详情如下】【需要咨询购买全套设计请加QQ1459919609 】.bat

PE400×600颚式破碎机的设计正文.doc

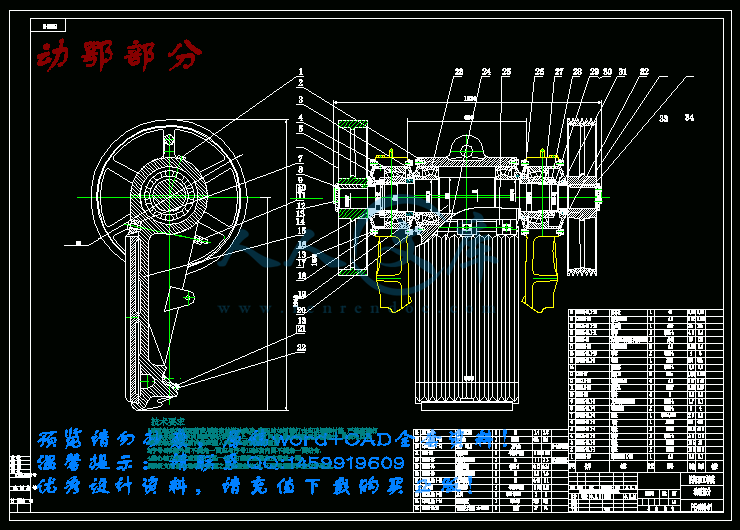

动鄂部分.dwg

大带轮A2.dwg

封面.doc

总装图.DWG

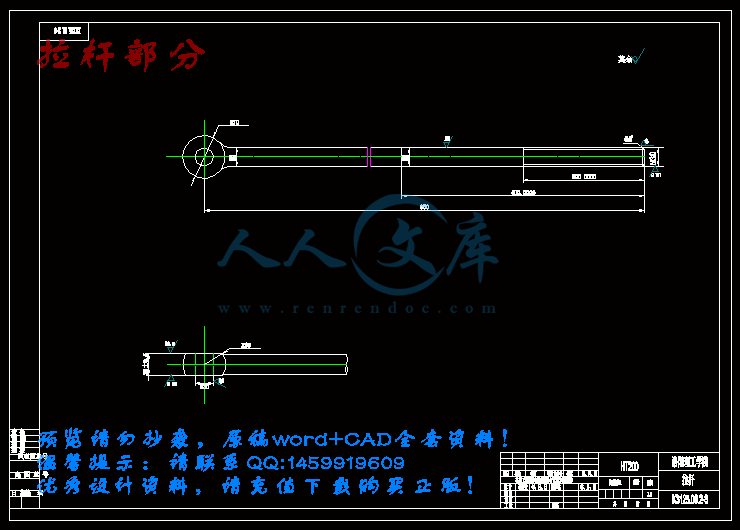

拉杆部分.DWG

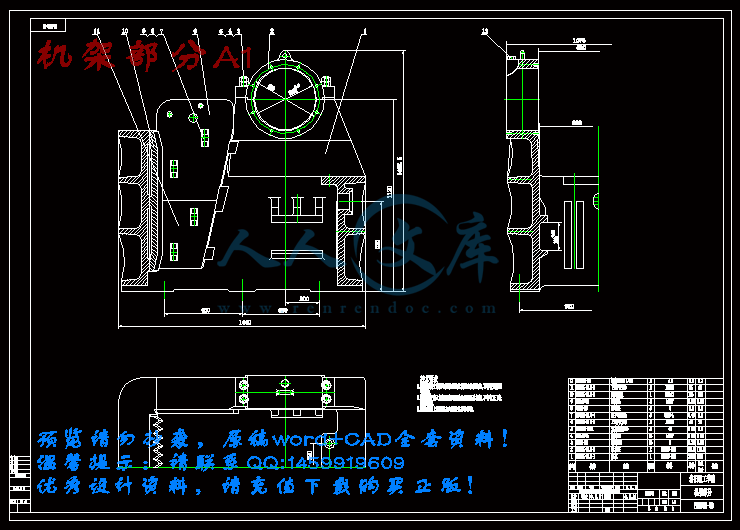

机架部分A1.DWG

PE400×600颚式破碎机的设计

摘 要

国内使用的颚式破碎机类型很多,但常见的还是传统的复摆颚式破碎机。复摆颚式破碎机的出现已有140多年的历史,经过人们长期的实践和不断完善与改进,其结构型式和机构参数日臻合理, 结构简单、制造容易、工作可靠、维修方便,故在冶金、矿山、建材、化工、煤炭等行业使用非常广泛。随着现代化的发展,各工业部门对破碎石的需求进一步增长,研究复摆颚式破碎机具有很重要的意义。本毕业设计主要是为满足生产需求:进料口尺寸:400×600 (mm);出料口尺寸:40~160 (mm);进料块最大尺寸:340(mm);产量:17~115吨/时而研究的。主要研究复摆颚式破碎机的运动分析、V带的选择,各种工作参数的选择,工作机构的优化。重点研究传动的设计和系统的优化。

关键词:复摆颚式破碎机,传动,运动分析

Design of PE400×600 Jaw-fashioned Crusher

ABSTRACT

The domestic use jaw type breaker type are very many, But common traditional duplicate pendulum Jaw-fashioned Crusher. The duplicate pendulum jaw type breaker appearance had more than 140 years history, And consummates and the improvement unceasingly after the people long-term practice, Its structure pattern and the organization parameter are day by day reasonable, The structure simple, the manufacture is easy, the work reliably, the service convenient, therefore in profession use and so on the metallurgy, mine, building materials, chemical industry, coal is extremely widespread. Along with the modernized development, various industry sector further grows to the broken crushed stone demand, studies the duplicate pendulum Jaw-fashioned Crusher to have the very vital significance. This graduation project mainly is for meets the production need: Feed head size: 400×600 (mm); Discharge hole size: 40~160 (mm); Feeding block greatest size: 340(mm); Output: 17~115 t/h. Mainly studies the duplicate pendulum Jaw-fashioned Crusher the movement analysis, V belt choice, the analysis which the Jaw-fashioned Crusher, the toothed rack wears, each kind of operational parameter choice, operating mechanism optimization. Detailed studies transmission design and system optimization.

KEY WORDS: Jaw-fashioned Crusher,Transmission, Kinematic Analysis

目 录

前 言1

第1章 选题背景3

1.1 研究的目的和意义3

1.2 特点和现状与发展4

1.2.1 复摆颚式破碎机的特点4

1.2.2 复摆颚式破碎机的现状与发展5

1.3 国内外复摆颚式破碎机的进展9

第2章 工作原理及构造11

2.1 工作原理11

2.2颚式破碎机的结构13

第3章 主要零部件的分析14

3.1 动颚14

3.1.1 动颚的结构14

3.1.2 动颚的工作过程14

3.2 齿板15

3.3肘板16

3.4调整装置17

3.5保险装置17

3.6机架结构18

3.7传动件19

3.8飞轮19

3.9润滑装置20

第4章 主要参数的设计计算21

4.1 颚式破碎机结构参数的计算21

4.1.1 钳角α21

4.1.2 动颚水平行程SY21

4.2 主要构件尺寸参数的设计计算21

4.2.1破碎腔高度H22

4.2.2偏心距e22

4.2.3动颚悬挂高度h22

4.2.4偏心距e对连杆长度l的比值λ22

4.2.5肘板长度K23

4.2.6传动角β23

4.2.7破碎腔形状的确定23

4.3 颚式破碎机工作参数的设计计算24

4.3.1 偏心轴转速n的设计计算24

4.3.2 生产率的计算24

4.3.3 破碎力的计算25

4.4 各个部件的受力分析26

第5章 重要零件的设计和校核28

5.1 电动机的选择28

5.2 V带传动的设计28

5.2.1 确定计算功率Pc28

5.2.2 确定V带的带型28

5.2.3确定带轮的基准直径,并验证带速28

5.2.4确定V带的中心距和基准长度29

5.2.5验算小带轮包角29

5.2.6确定V带根数z29

5.2.7计算单根V带的初拉力的最小值30

5.2.8计算压轴力30

5.3 飞轮的设计30

5.4 推力板的设计31

5.5 偏心轴的设计32

5.5.1 偏心轴的材料选择和最小直径估算32

5.5.2 偏心轴结构的设计33

5.5.3 偏心轴强度校核33

5.6 轴承的选择34

第6章 颚式破碎机的安装与运转35

6.1破碎机的安装35

6.2机架的安装35

6.3肘板的安装35

6.4动颚的安装36

6.5齿板的安装36

6.6破碎机的运转36

结 论37

谢 辞38

参考文献39

附 录41

外文资料翻译42

前 言

在基本建设工程中,需要大量的,各种不同粒径的砂、石作为生产之用。在没有合格的天然砂子和一台颚式破碎机问世以来,至今已有150余年的历史。在此过程中,其结构得到不断的完善,而颚式破碎机的结构简单,安全可靠,石料可供破碎机械来进行加工,来满足工程的需要。所以在生产中广泛的应用。而工程上应用最广泛的是复摆颚式破碎机,国产的颚式破碎机数量最多的也是复摆颚式破碎机。

破碎机是将开采所得的天然的石料按一定尺寸进行破碎加工的机械。颚式破碎机是有美国人E.W.Blake发明的。自第一台破碎机的出现,生产效率快,又满足安全条件,又能适应生产,大大加快了生产。

复摆颚式破碎机结构简单、制造容易、工作可靠、使用维修方便等优点,所有在冶金、矿山、建材、化工、煤炭等行业使用非常广泛。80年代以来,我国对复摆颚式的研究和产品开发取得了较大的发展。在充分吸收国外产品特点的基础上,结合国情研制开发了许多新型、高效的设备。上海建设。路桥机械设备有限公司率先对复摆颚式破碎机进行了重大的改进,即通过降低动颚的悬挂高度,改善动颚的运动轨迹,减小破碎腔的啮角,增大破碎比,增大了动颚的水平行程,提高生产能力等,大大改善了机器性能,完成了产品的更新换代。

复摆颚式破碎机主要是由两块颚板(活动颚板和固定颚板)组成。活动颚板对固定颚板周期性的往复运动,时而靠近,时而分开,由此使装在二颚板间的石块受到挤压、劈裂和弯曲作用而破碎。复摆颚式破碎机的机器重量较轻,结构简单(少了一件连杆、一块肘板、一根心轴和一对轴承),生产效率较高(比同规格的简摆颚式破碎机生产效率高20%-30%)。复摆颚式破碎机适合破碎中硬度石料。在工程中,多用他做中、细碎设备,起破碎比较大,可达江10。随着机械工业的进步,近年来,复摆颚式破碎机正朝着大型化发展。所以,一个合理的传动装置可以使复摆颚式破碎机运行的更加顺利,合理有效。动颚的优化可使磨损大大的降低,冲击、噪声、振动都相应的减少,也减少工作人员的劳动强度,提高生产的质量,降低制造成本和缩短生产周期。

但是,复摆颚式破碎机也有它的缺点,具体如下:

JB/z0 1032 - 87《颗板铸造技术条件》规定齿板寿命只有60h,按l0h工作制,每付齿板只能用6d,不到一星期就需更换一次齿板。不仅给维修带来很大的不便,而且增加了破碎物料的成本。

破碎机出口扬尘非常严重,从破碎机出来的块状和粉末状物料直冲矿石输送皮带,部分物料飞溅或滚淌到地面上,地面堆积厚厚一层物料,部分粉状物料飞扬在空中,给生产带来了很大的不便。较多的粉尘而直接影响安全生产和员工的健康,因此要采用相应的防尘设施是破碎机一个重大而不可忽略的问题。

参考文献

[1]水泥厂工艺设计手册编写组. 水泥厂工艺设计手册[M].北京: 中国建筑工业出版社, 1978.9.

[2]王三民. 机械设计计算手册[M].北京: 化学工业出版社, 2008.12.

[3]吴宗泽. 机械设计[M].北京: 中央广播电视大学出版社, 1998.6.

[4]刘建寿, 赵红霞. 水泥生产粉碎过程设备[M].武汉: 武汉理工大学出版社, 2010.6.

[5]任德斌. 材料力学[M].大连: 大连理工大学出版社, 2009.11.

[6]朱昆泉, 许林发. 建材机械工程手册[M].武汉: 武汉工业大学出版社, 2000.8.

[7]郎宝贤, 郎世平. 破碎机[M].北京: 冶金工业出版社, 2008.11.

[8]机械设计手册编委会. 机械设计手册[M].北京: 机械工业出版社, 2004.8.

[9]金波, 戴素江. PE750×1060复摆颚式破碎机的设计计算[J].矿山机械, 2007, 35(01): 45-48.

[10]章勇, 毛京伟, 冯宪冬. 颚式破碎机的挤压过程分析[J].机械管理开发, 2011(03): 73-75.

[11]罗红萍. 颚式破碎机曲柄摇杆机构的运动学分析[J].机械工程与自动化, 2007(05): 35-36.

[12]母福生. 双腔颚式破碎机的研究[J].矿冶工程, 1997(03): 24-26.

[13]傅祥志. 机械原理[M].武汉: 华中科技大学出版社, 2000.

[14]李燕. 基于MATLAB的机构运动分析系统开发[J].机电技术, 2005(02): 27-30.

[15]刘菊蓉. 偏置式曲柄滑块结构的优化设计及运动分析[J]. 机械研究与应用, 2005(15): 99-100.

[16]杨东亚. 应用MATLAB分析模块化机构运动[J]. 现代制造工程, 2006(02): 84-85.

[17]郎宝贤. 颚式破碎机现状与发展[J]. 矿山机械, 2004(01): 9-10.

[18]郎宝贤, 郎世平. 颚式破碎机设计与检修[M]. 北京: 机械工业出版社, 1990.

[19]郎宝贤等. 颚式破碎机动颚结构设计. 第二届全国选矿设备学术会议论文集. 北京: 冶金工业出版社, 1995.

[20]Kanda Y, Sano Y, Yashima Y. A consideration of grinding limit based on fracture mechanics. Power technology, 1986(3): 5-7.

[21]Sikong L, Hashimoto H, Ashima S, Breakage behavior of fine particles of brittle minerals and coal. Power technology, 1990(1): 11-15.

[22]王玉荣. 公差与技术测量[M]. 西安: 西北工业大学出版社, 1993: 3-6.

[23]朱宝库. 机械设计[M]. 哈尔滨: 哈尔滨工业大学出版社, 1989: 20-25.

川公网安备: 51019002004831号

川公网安备: 51019002004831号