旋盖机理盖系统设计

自动旋盖机理盖器的设计【优秀机械设计+10张CAD图纸】

【带任务书+开题报告+外文翻译+文献综述+33页@正文13800字】【详情如下】【需要咨询购买全套设计请加QQ1459919609 】.bat

03-00出盖口.dwg

03-上盖.dwg

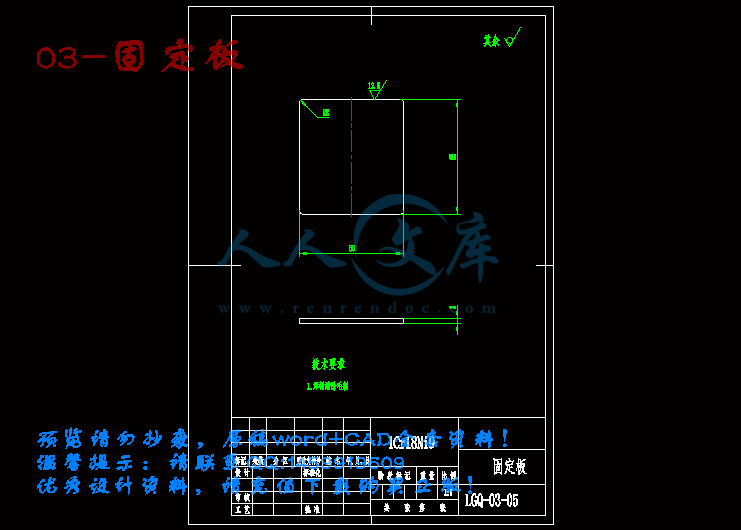

03-固定板.dwg

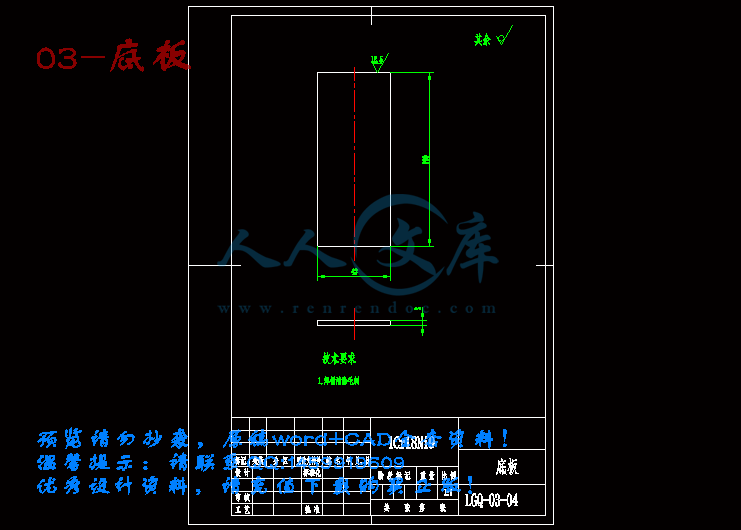

03-底板.dwg

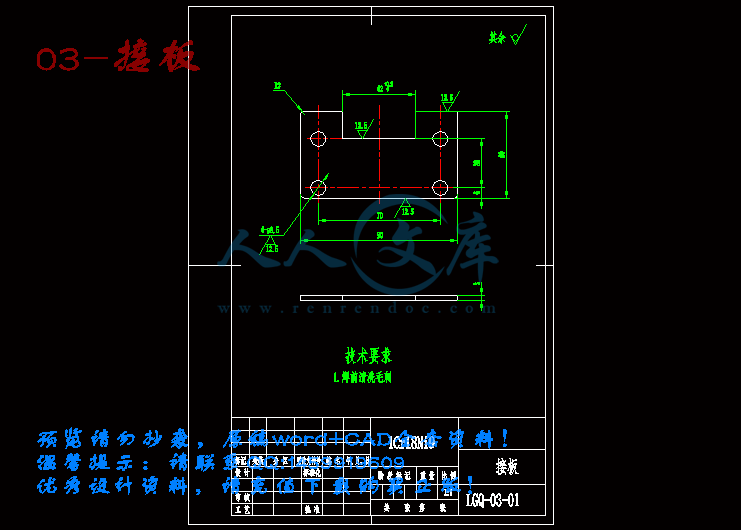

03-接板.dwg

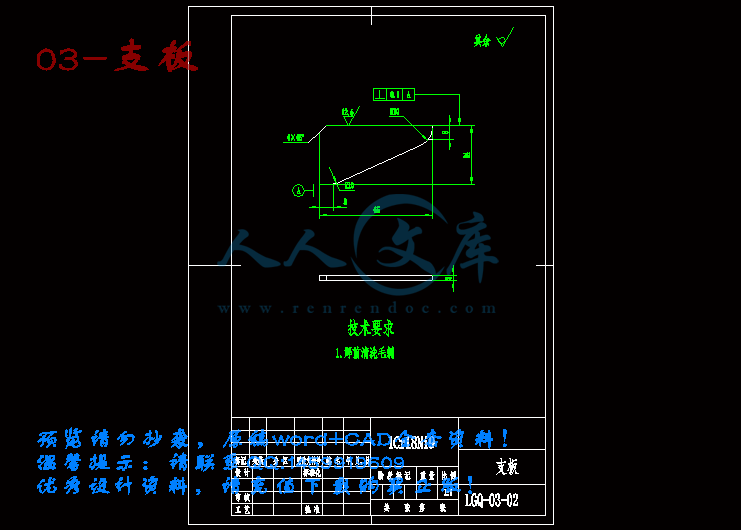

03-支板.dwg

caxa工程图.zip

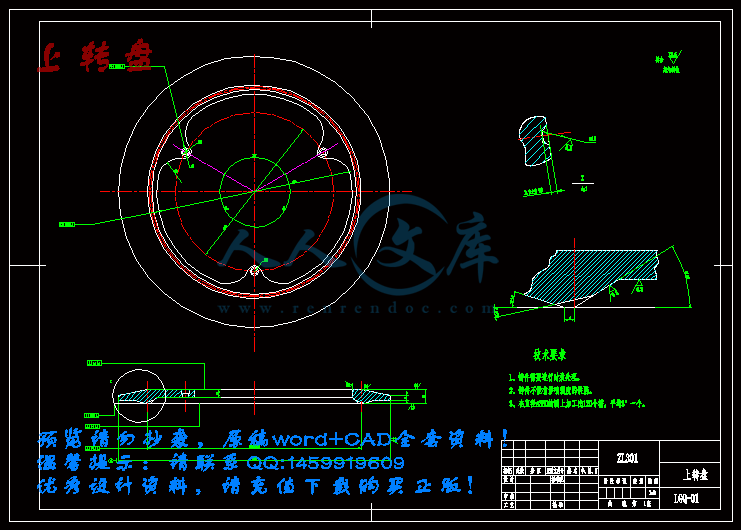

上转盘.dwg

下转盘.dwg

任务书.doc

取盖器.dwg

外文翻译.doc

开题报告.doc

文献综述.doc

自动旋盖机理盖器的设计正文.doc

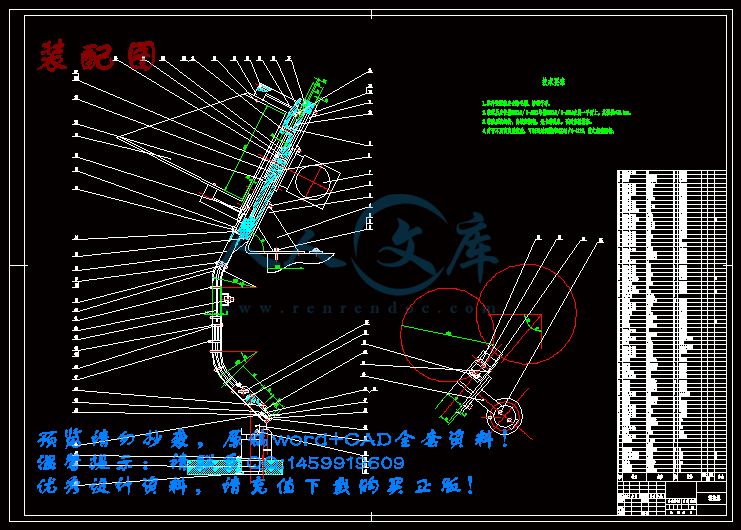

装配图.dwg

任务书

毕业设计(论文)题目:自动旋盖机理盖器的设计

总体设计要求及技术要点:

1980年以后, 电动阀投入使用, 随着酒阀的自动化程度的提高, 整机的传动系统、液、气控制系统、送盖系统都做了改进。目前, 世界含气饮料灌装压盖设备朝“高速度、高精度, 自动化灌装” 、“由繁到简”、“高质量、保鲜灌装” 、“低噪音” 、“兼用化” 五个方面发展。

旋盖机的主要功能是将塑料旋盖,端正牢固地密封在塑料瓶口上。主要结构有传动、理盖、送盖滑道、旋盖头等几个部分。

封盖传动 由主驱动涡轮减速箱输出轴上的齿轮来驱动封盖机工作。

旋盖头 封盖机每旋转一周,各冲头在凸轮的控制下升降一个行程,由旋盖头自身的旋转将瓶盖旋紧在瓶口上使胶垫变形而达到密封。

理盖器 瓶盖料斗底部有一理盖搅拌器,传动靠一部0.25KW的电动机带动涡轮减速器实现理盖。理盖器的送盖速度应大于150个/分。

瓶盖滑道 经过理盖起的处理瓶盖通过滑道送往压盖冲头的下端,而且经过一个翻盖自动剔除装置,确保正盖连续送给。在滑道最下端有一个空气喷嘴,能够将瓶盖顺利吹入抓盖头内。

工作环境及技术条件:

在环境温度在20度的情况下,能一次将配料成分纯净水和CO2气体混合成符合人们口感要求的液体饮料,灌装于饮料瓶中并封盖.在此过程中,减少了成品被污染的机会,使产品质量大大提高.减轻工人劳动强度.

1.理盖器设计。

根据要求,确定上转盘、下转盘、出盖口的结构。重点解决正盖输出反盖挡回的问题。提供形式为图纸。

2.上、下滑道设计。

设计上、下滑道板,支板,出盖口等部件,重点解决瓶盖连续送给问题,反盖自动剔除问题,提供形式为图纸。

3.理盖器的调整。

重点解决不同高度的防盗盖自动问题,提供形式为图纸。

时间进度安排:

第一阶段:搜集资料,学习一些相关知识。写出开题报告,文献综述,英文翻译。

(第5-第7周)。

第二阶段:旋盖理盖部分设计(第8-第12周)

第三阶段:检验,修正(第13-第14周)

第四阶段:总结,论文编写。(第15-第17周)

第五阶段:准备答辩。

摘 要

旋盖机理盖系统作为旋盖机的重要组成部分,其作用是将杂乱堆积的皇冠瓶盖进行快速整理和排序并准确地输送到旋盖位置,其理盖的准确性和速度直接影响到灌装生产线的产量。本文首先介绍了理盖器设计,接着介绍了上、下滑道设计,随后针对正盖输出反盖挡回的问题,瓶盖连续送给问题以及反盖自动剔除问题进行改进完善,最后对文章进行总结。

关键词 自动旋盖机 理盖系统 理盖器

Abstract

Capping mechanism cover system as an important part of the capping machine, its role is to be disorderly deposits crown cap for rapid collation and sort and accurate transmission to the capping position, its cover sorting accuracy and speed affects directly the filling production line output. This paper introduces the design of the cover, and then describes the design, the glide path,after the positive cover output reverse cover retaining back problems, and the cover cap continuous to automatic elimination problems is improved. Finally, the summary of the article. Capping mechanism cover system as an important part of the capping machine, its role is to be disorderly deposits crown cap for rapid collation and sort and accurate transmission to the capping position, its cover sorting accuracy and speed affects directly the filling production line output. This paper introduces the design of the cover, and then describes the design, the glide path,after the positive cover output reverse cover retaining back problems, and the cover cap continuous to automatic elimination problems is improved. Finally, the summary of the article.

Key Words automatic capping machine cover arranging system cap sorter

目 录

摘 要

Abstract

第1章 绪论1

1.1 课题背景1

1.2 主要研究内容2

1.3 设计方案与技术要求2

第2章 自动旋盖机的发展3

2.1 自动旋盖机的发展背景3

2.2 我国的发展现状4

第3章 理盖器的发展6

3.1 理盖器的用途6

3.2 我国的发展现状6

3.3 国外发展现状6

3.4 瓶盖的种类7

3.5 理盖器的种类8

第4章 理盖器的设计10

4.1 理盖器的结构和工作过程10

4.2 瓶盖定向原理14

第5章 上、下滑道的设计18

5.1 反盖自动剔除原理18

5.2 保证盖子的正确性18

第6章 主要参数的计算20

6.1 生产能力20

6.2 底盘转速20

6.3 上转盘与下转盘之间的间距21

6.4 储盖筒倾角22

第7章 结论23

致 谢24

参考文献25

第1章 绪论

1.1 课题背景

自动旋盖机理盖器是一种应用在饮料包装生产工厂的设备机器。它的作用是通过一系列的整理,传送,实现饮料瓶盖的自动化供料,其中瓶盖的状态是统一朝上或朝下的,然后通过输出滑道供料给其他装置。在液体饮料自动灌装生产线上,需要采用理盖器和供送机构将料斗中杂乱堆置的酒瓶盖整理成定向正确的瓶盖流,供送到封口机的机头处;因此,理盖器和供送机构就成为整条灌装生产线的“咽喉”,其理盖的准确性和供送速度直接影响到灌装生产线的产量。理盖系统由于处于饮料生产的一环,缺它不可:使用它,可以提高工厂的作业效率,减少人力成本,实现无人化,自动化操作,同时也提高安全性,所以它的重要性与日俱增,研究它的重要性也迫在眉睫。目前很多企业都缺少相应的理盖器产品,市场前景很大,相对于国外的理盖器技术,目前发展具有自主产权的理盖器技术意义重大。

参考文献

[1] 杨东拜.机械CAD制图与标准应用.中国标准出版社.1999.

[2] 马兰.机械制图.机械工业出版社. 2006.

[3] 张力强.灌装设备的维护.机械工业出版社.1999.

[4] 张聪.自动化食品包装机.广东科技出版社 2003 :50-55.

[5] 孙兰凤.工程制图.高等教育出版社.2004.

[6] 张聪.自动化食品包装机.广东科技出版社.2003:35-55.

[7] 焦昊昊,朱文坚.瓶盖同向排列设备的创新设计.华南理工大学机械工程学院.2005.

[8] 严书华.一种通用瓶盖理盖器与旋盖机构的设计.福建省建筑轻纺设计院 2006.

[9] 戚长正.自动化与生产线.科学出版社.2004 32-33.

[10] 邱服美.运动嘴盖理盖机[p].中国专利.CN97241234.4.2006.

[11] 厉善红,厉善君.普通理盖器[p].中国专利.CN200620122725.9? 2005.

[12] 史正,吉永林,刘守谦,侯高强.斜盘理盖器[p]?.中国专利.CN200720112181.2. 2007.

[13] Ayman Cheta.Counterfeit and Rogue Industrial Parts and Materials, and Their Impact on Safety and Reliability.ASME 2008 Pressure Vessels and Piping Conference.2008.

[14] Koetsu Yamazaki.Evaluation Method of Drinking Ease for Aluminum Beverage Bottles.ASME 2007 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference.2007.

川公网安备: 51019002004831号

川公网安备: 51019002004831号