基于有限元分析的汽车车架优化设计

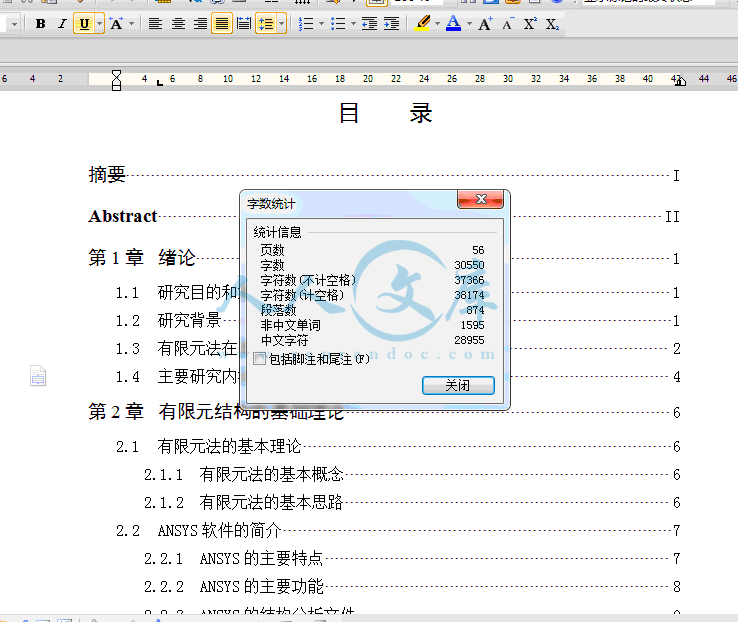

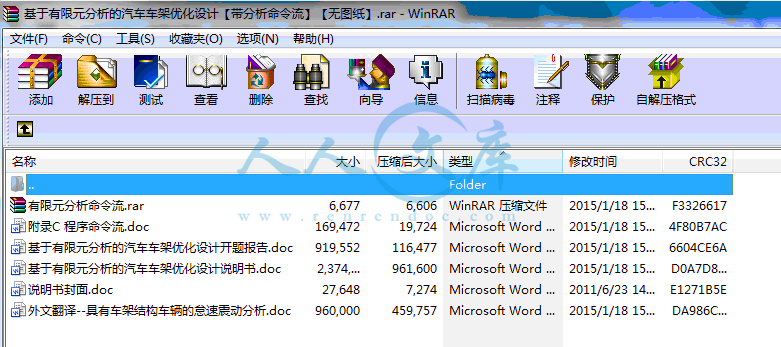

56页 30000字数+说明书+外文翻译+开题报告+有限元分析命令流【详情如下】

基于有限元分析的汽车车架优化设计开题报告.doc

基于有限元分析的汽车车架优化设计说明书.doc

外文翻译--具有车架结构车辆的怠速震动分析.doc

有限元分析命令流.rar

说明书封面.doc

附录C 程序命令流.doc

摘要

车架是汽车上重要的承载部件,车辆所受到的各种载荷最终都传递给车架,因此,车架结构性能的好坏直接关系到整车设计的成败。通过有限元法对车架结构进行性能分析,在设计时考虑车架结构的优化,对提高整车的各种性能,降低设计与制造成本,增强市场竞争力等都具有十分重要的意义。大型通用有限元软件ANSYS凭借其强大的分析功能和高度可靠性,在结构静力分析和动力分析以及优化设计等方面具有无可比拟的优越性。

本文以CA1040货车车架结构为研究对象,通过对Pro/E和ANSYS软件的消化与吸收,采用实体单元,对车架结构的有限元建模、车架结构的静、动态特性分析问题进行了研究。以实体单元为基础创建了车架结构的简单的尺寸优化模型,以车架的纵梁截面尺寸为设计变量,以车架结构的总体积最小为优化目标,对车架纵梁的截面尺寸进行优化并分析了优化结果。阐述了应用ANSYS进行结构优化设计的基本指导思想及方法,推广到解决以板壳单元为基础的车架优化问题,根据实际需要调整优化的设计变量、状态变量以及目标函数。通过对CA1040型货车车架结构的有限元仿真及优化,得到了一些有益的结论,为车架的设计提供了指导作用。

关键词:车架;载荷;轻量化;有限元分析;三维建模;ANSYS

ABSTRACT

Frame is as an important assembly bearing loads of an automobile,which all kinds of 10ads will pass to,and as a result the performance of frame structure affects whether the automobile design is successful or not.Using finite element method to analyze automobile frame structure and to take frame structure optimization into account makes sense in improving automobile performance,reducing the cost of design and automotive manufacture and increasing capability of market competition.ANSYS software takes on unexampled advantages in static analysis,dynamic analysis and optimization design etc by right of its powerful analysis function and high reliability.

Through studying Pro/E and ANSYS software the FEA model of a CA1040 truck with solid elements Was built.Based on the model the static and dynamic performance of the truck’S frame structure was studied.A topological optimization model and a simple optimization model was built based on solid elements.With the objection that the volume of the frame is minimal,the carling section dimensions was optimized and the results of optimization Was analyzed.This paper analyzes the principles and methods of optimization design,which Can be generalized to shell element model.The design variables,state Vadables and objective functions can be adjusted to meet the actual needs.

Through the finite element simulation and optimization of a CA1040 truck frame structure some useful conclusions has been got for the design of the frame.

Key words:Frame; loads; Lightweight; Finite element analysis; Three-dimensional modeling; ANSYS

目 录

摘要I

AbstractII

第1章绪论1

1.1研究目的和意义1

1.2研究背景1

1.3有限元法在国内外车架结构设计中的研究现状2

1.4主要研究内容及技术路线4

第2章有限元结构的基础理论6

2.1有限元法的基本理论6

2.1.1有限元法的基本概念6

2.1.2有限元法的基本思路6

2.2ANSYS软件的简介7

2.2.1ANSYS的主要特点7

2.2.2ANSYS的主要功能8

2.2.3ANSYS的结构分析文件9

2.2.4ANSYS提供的分析类型9

2.3本章小结10

第3章车架有限元模型的建立12

3.1模型的建立原则12

3.1.1几何建模的注意事项12

3.1.2几何建模的简化13

3.2建立车架模型14

3.2.1建模时的简化处理14

3.2.2车架模型的建立14

3.2.3应用ANSYS对车架模型进行网格划分14

3.2.4对实体单元Sold 92的简要介绍15

3.3本章小结16

第4章车架结构的有限元静态分析17

4.1车辆载荷分析17

4.1.1行驶载荷17

4.1.2操作载荷17

4.1.3特殊载荷18

4.2车架受力情况18

4.2.1静载荷18

4.2.2动载荷19

4.3车架结构的静力性能分析19

4.3.1静力分析的基本概念及流程19

4.3.2车架结构静力分析工况及约束处理20

4.3.3车架结构静力分析规范21

4.4车架结构的静力性能分析结果22

4.4.1弯曲工况静力分析结果22

4.4.2扭转工况静力分析结果24

4.5本章小结26

第5章车架结构的动力性能分析27

5.1车架结构的动力性能分析27

5.1.1车架的模态分析27

5.1.2结构动力性能分析方程28

5.1.3刚度矩阵和质量矩阵形成29

5.1.4车架结构模态分析规范30

5.1.5车架结构模态分析结果31

5.2本章小结33

第6章车架结构参数的优化设计34

6.1优化设计的理论基础34

6.1.1优化设计的步骤34

6.1.2优化设计的数学描述38

6.1.3ANSYS的基本优化方法38

6.2优化设计数学模型的建立40

6.2.1优化设计数学模型建立的原则40

6.2.2简单的车架纵梁优化设计模型的建立40

6.3定义优化变量及运行优化43

6.3.1定义优化变量43

6.3.2设置并运行优化43

6.4优化结果分析44

6.5本章小结47

结论48

参考文献49

致谢51

附录52

附录C 程序命令流59

附录C1弯曲分析命令流59

附录C2扭转分析命令流63

附录C3模态分析命令流70

附录C4优化设计命令流76

绪 论

研究目的和意义

随着现代汽车设计要求的日益提高,将有限元法运用于车架设计已经成为必然的趋势,主要体现在:

①运用有限元法对初步设计的车架进行辅助分析将大大提高车架丌发、设计、分析和制造的效能和车架的性能。

②车架在各种载荷作用下,将发生弯曲、偏心扭转和整体扭转等变形。传统的车架设计方法很难综合考虑汽车的复杂受力变形情况,有限元法正好能够解决这一问题。

③利用有限元法进行结构模态分析,可以得到车架结构的动态特性。从设计上避免车架出现共振的现象。

④通过对车架结构的优化设计,可以进一步降低车架的重量,在保证车架性能的前提下充分的节省材料,对降低车架的成本具有重要的意义。综上所述,有限元法已经成为现代汽车设计的重要工具之一,在汽车产品更新速度快,设计成本低、轻量化和舒适性要求越来越高的今天,对于提高汽车产品的质量、降低产品开发与生产制造成本,提高汽车产品在市场上的竞争能力具有重要意义。

通过本文的研究,预计达到以下目的:

①建立车架结构有限元分析的规范化步骤,为将有限元技术应用于车架设计做好基础性工作。

②通过运用有限元软件对车架结构进行分析,可供车架设计有关人员提供参考。

③对所研究的车架进行结构的静、动态特性分析,为车架的设计提供理论支持。

④对车架结构的优化进行初步探讨,为优化设计运用于车架设计进行初步的尝试,以便于以后更好地为车架设计服务。

研究背景

在汽车行业中,有限元法广泛应用于各大汽车总成,包括车架、车身、车桥、离合器、轮胎、壳体等零部件以及驾驶室噪声的分析,大大提高了汽车的设计水平,正在成为设计计算的强有力工具之一。

目前,在进行汽车车架设计时,设计人员主要采用的还是传统的办法对车架进行简化的计算,或者由其它部门进行有限元分析计算。车架的这种设计模式导致的问题

包括两个方面:一是车架简化计算精度不够,为保证强度及刚度要求而使车架的设计过于安全,造成设计出的车架结构过重,增加了设计成本;二是造成车架的设计与计算分离,不利于提高车架设计人员的设计水平。为了促进车架设计水平的提高,保证整车在市场上的竞争能力,必须将车架有限元分析技术提高到战略的高度上来。因此,本文以3.2t轻型货车车架为研究对象,主要对车架结构有限元模型的建立,静、动态特性分析以及设计参数的优化等内容进行研究与探讨,最终掌握车架结构的特性,对车架结构进行评价,得出车架结构纵梁优化模型,为车架结构的强度及动力特性的仿真以及优化提供基础。有限元结构的基础理论

有限元法的基本理论

有限元法的基本概念

有限单元法是随着电子计算机的发展而迅速发展起来的一种现代数值计算方法。它以弹性力学为理论基础,又与经典的弹性力学解析法不同。有限单元法将连续体理想化为有限个单元集合而成,这些单元仅在有限个节点上相连接,亦即用有限个单元的集合来代替原来具有无限个自由度的自由体。有限元单元的分割和节点的配置非常灵活,它可适应于任意复杂的几何形状,处理不同的边界条件。单元有各种类型,包括线、面和实体或称为一维、二维和三维等类型单元。节点一般都在单元边界上,单元之间通过节点连接,并承受一定载荷,这样就组成了有限单元集合体。

在此基础上,对每一单元假设一个简单的位移函数来近似模拟其位移分布规律,通过虚位移原理求得每个单元的平衡方程,即是建立单元节点力和节点位移之间的关系。最后把所有单元的这种特性关系集合起来,就可建立整个物体的平衡方程组。考虑边界条件后利用计算机解此方程组求得节点位移,并计算各单元应力。而且,单元细化程度越高,所得的解越接近精确值。

有限元法的基本思路

(1)物体离散法

将某个工程结构离散为有各种连结单元组成的计算模型,这一步称作单元剖分。离散后单元与单元之间利用单元的节点相互连接起来。单元节点的设置、数目等问题的性质,由计算精度而定(一般情况,单元划分越细则描述变形情况越精确,即越接近实际变形,但计算量越大)。所以有限元法中分析的结构已不是原有的物体或结构物,而是同样的材料由众多单元以一定方式连接成的离散物体。这样,用有限单元分析计算所获得的结果只是近似的。如果划分单元数目非常多而又合理,则所获得的结果就与实际情况相符合。

(2)单元特性分析

选择未知量模式

在有限单元法中,选择节点位移作为基本未知量时称为位移法;选择节点力作为基本未知量时称为力法;取一部分节点力和一部分节点位移作为基本未知量时称为混合法。位移法易于实现计算机自动化,所以在有限单元法中位移法应用范围最广。

在车架的结构分析中,有限元法由于其能够解决结构形状和边界条件都非常任意的力学问题的优点而被广泛使用,各种汽车结构件都可以用有限元法进行静态分析、固有特性分析和动态分析。在进行静力学分析时,通过有限元分析,可看到构件在各个载荷状况下的变形情况,可以得到刚度、强度等各种力学性能。之后可将这些结果返回到设计过程中,修改其中不合理的参数,经过反复的优化,使得产品在设计阶段就可保证满足使用要求从而缩短设计试验周期,节省大量的试验和生产费用,它是提高汽车设计的可靠性、经济性、适用性的方法之一。因此,为了保证其设计的精确性和缩短设计周期,基于有限元分析,研究它的静、动态力学特性,对其结构进行优化设计,是非常重要和必须的。

①运用ANSYS对车架结构的静态进行了分析研究,并对分析过程步骤进行了规范化。通过分析,掌握了车架结构的特性,对车架结构进行了评价。车架有限元分析结果表明车架在满载弯曲工况和满载扭转工况下,最大应力发生在发动机后悬架与第四纵梁附近。并且在给定动载系数情况下,最大应力值未超过许用应力值。根据强度评价参数,车架的结构强度符合要求。同时对分析过程的规范化缩短了车架结构有限元分析的时间,提高了工作效率。

②运用ANSYS对车架的模态进行了分析研究,并对这一分析过程步骤进行了规范化,得出了车架前十阶模态频率,并且与汽车发动机CA488和汽车行驶路面的频率进行了比较,得出结论,车架的前低阶频率小于发动机怠速运转时的频率,并且小于汽车正常行驶时的频率,因此,不会产生共振,车架符合设计要求。

③对车架结构纵梁进行了优化,探讨并建立了基于实体单元的车架结构纵梁优化模型,对设计参数的优化问题进行了初步的探讨,并对以后ANSYS的运用进行了铺垫。通过优化,使得车架右纵梁的体积从0.42560E+07下降到0.29438E+07,减少30%左右,优化效果显著。

参考文献

[1]宝生,李杰,林明芳.汽车优化设计理论与方法[D].北京:机械工业出版社,2000.

[2]王海霞,汤文成等.客车车骨架有限元建模技术及结果分析[D].机械强度,2002.24(1):77~80.

[3]靳福来.汽车轻量化技术现状[J].汽车技术,1995,7:56~58.

[4]华润兰.论汽车轻量化[J].汽车工程,1994,209(6):375~383.

[5]李波.某载货车车架结构分析与优化设计[D].合肥工业大学硕士学位论文,2005.10.

[6]杨中明.EQ1040型汽车架结构性能研究[D].华中科技大学硕士学位论文,2005.10.

[7]叶勤.轻型载货汽车车架有限元分析与优化[D].武汉理工大学硕士学位论文,2007.11.

[8]刘惟信.汽车设计[M].北京.清华大学出版社,2001.

[9]王望予.汽车设计[M].北京.机械工业出版社,2004.

[10]宋允祁,王中亭.解放CA1040系列轻型货车构造与维修[M].吉林科学技术出版社,1995.

[11]宋允祁.中国第一汽车集团公司汽车产品构造图册[M].人民交通出版社,2000.

[12]唐金松.简明机械设计手册[M].上海科学技术出版社,2000.

[13]成大先.机械设计手册[M].化工工业出版社,2001.1.

[14]西南交通大学应用力学与工程系.工程力学教程[M].高等教育出版社,2004.7

[15]于志伟,李明.Pro/ENGINEER完全手册[M].人民邮电出版社,2007.

[16]龚曙光.ANSYS基础应用及范例解析[M].机械工业出版社,2002.

[17]黄贵东,沈光烈.汽车车架有限元分析模型的改进与应用[J].装备制造技术,2007.2.

[18]曲昌荣,郝玉莲,戚洪涛.汽车车架的有限元分析[J].轻型汽车技术,2008.9.

[19]刘新田,黄虎,刘长虹,郭辉,范平清.基于有限元的汽车车架静态分析[J].上海工程技术大学学报,2007.6.

[20]冯宝林,赵韩,董晓慧.基于参数化有限元分析的某客货两用汽车车架的改型研究[J].农业工程学报,2008.1.

[21]李黎明.有限元分析实用教程[M].清华大学出版社,2005.

[22]董振国,刘大维,严天一,陈秉聪.半挂牵引车车架强度的有限元分析[J].拖拉机与农用运输车,2005.8.

[23]钟佩思,孙雪颜,赵丹,魏群,苏超.基于ANSYS的货车车架的有限元静态分析[J].拖拉机与农用运输车,2008.4.

[24]Burnett,David S.Finite element analysis.Addison-Wesley Pub.1987.

[25]Eilabu,Zahavi.The Finite Element Method in machine design.Newjersey Prentice—Hall,1992.

[26]Cheng z Q et a1.Experience in Reverse-engineering of a Finite Element Automobile Crash Model.FiniteElements inAnalysis and Design,2001(37).

[27]沈萌红,关金生.基于Pro/E的三维参数化零件库的建立[J].现代设计与制造.2003(7):115~118

[28]冯国胜,杨绍普.车辆现代设计方法[M].北京:科学出版社.2005.

[29]小飒工作室.最新经典ANSYS及Workbench教程[M].北京:电子工业出版社.2004.

[30]商跃进.有限元原理与ANSYS应用指南[M].北京:清华人学出版社.2005.

川公网安备: 51019002004831号

川公网安备: 51019002004831号