【温馨提示】 购买原稿文件请充值后自助下载。

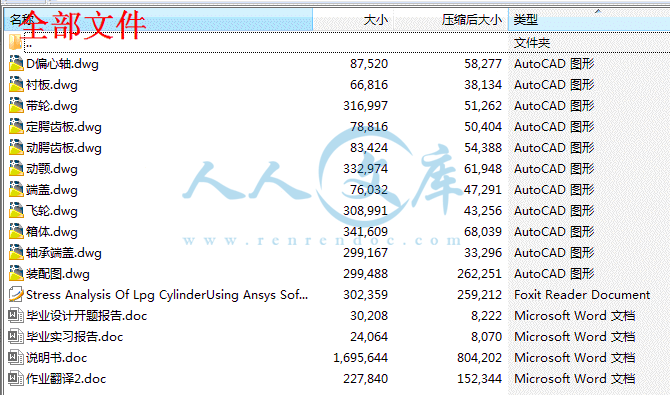

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘要

目前国内使用的破碎机类型很多,主要有鄂式破碎机、锤式破碎机、圆锥破碎机、反击式破碎机和辊式破碎机。复摆式颚式破碎机与简摆式相比较,其优点是:质量较轻,构件较少,结构更紧凑,破碎腔内充满程度较好,所装物料块受到均匀破碎,加以动颚下端强制性推出成品卸料,故生产率较高,比同规格的简摆颚式破碎机的生产率高出20-30%;物料块在动颚下部有较大的上下翻滚运动,容易呈立方体的形状卸出,减少了像简摆式产品中那样的片状成分,产品质量较好。

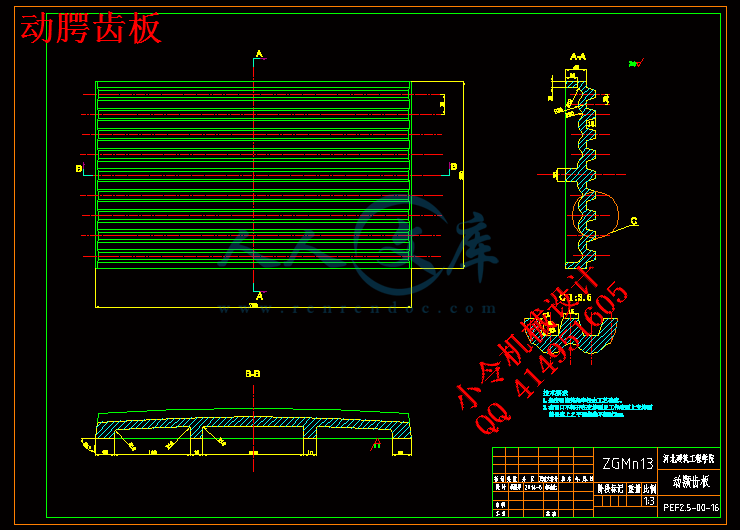

本设计需求参数为进料口尺寸:250×400mm;最大进料粒度:210mm;处理能力:3-13m3/h;偏心轴转速:300r/min;排料口调整范围:20-60mm;电动机功率:11-15KW。设计分析了破碎机的发展现状和研究颚式破碎机的意义及复摆颚式破碎机机构尺寸对破碎性能的影响,计算确定了PE250×400的机构参数,设计内容主要包括复摆颚式破碎机的动颚、偏心轴、皮带轮、动颚齿板、定颚齿板、机架等一些重要部件;另外,对颚式破碎机的工作原理及特点和主要部件的作用作了介绍,包括保险装置、调整装置、机架结构、润滑装置等;同时对机器的参数(主轴转速、生产能力、破碎力、功率等)作了计算。此外,对破碎的意义、破碎工艺和破碎比的计算,颚式破碎机的主要部件的安装、操作及维修作了简单介绍。

关键词:复摆颚式破碎机 带传动 飞轮 磨损

ABSTRACT

Currently ,the type of the crusher is multitudinous in domestic, mainly including jaw crusher, hammer crusher, cone crusher, impact breaker and roll crusher. Compared with fine impact crusher ,SBM(swinging jaw break machine)´s advantage is: quality is lighter, less compact structure component, broken lumen filled with degree is good, with materials by uniform broken, to block bottom mandatory move jaw is unloading, launch finished higher, than with specifications productivity of fine impact crusher 20-30% higher than the productivity; Material blocks in the lower have bigger jaws move up and down movement, a cube tumbling to the shape of, reducing the discharged as Jane tilting products that flake composition, product quality is better.

This design is done for:the feeding port size is 250×400mm; Maximum feeding granularity is 210mm; Production efficiency is 3-13m3/h; Eccentric shaft speed is 300r/min; Discharging mouth adjustment range 20mm to 60mm; Motor power is 11-15KW. This design analysis of the current development of the crushier,the meanings of researching the crusher,how the dimensions of jaw crusher effect on the performance of the broken, calculate and determine the PE250 x 400 structure parameters, the design content mainly includes swing jaw, eccentric shaft, pulley, seing jaw gear plate, and settled jaw gear plate and frame and some other important components; In addition, jaw crusher principle and characteristics and main component function is introduced, including insurance device, adjusting devices and frame structure, lubrication device, etc.; Also on the machine parameters (spindle speed, production capacity, crushing strength, power) calculate as well. In addition, the significance of broken, crushing process and calculation of crushing ratio, jaw crusher main component installation, operation and maintenance are introduced.

KEY WORDS:Jaw crusher Belt drive Flywheel Wear

目录

第1章 绪论··················································································1

1.1引言·························································································1

1.2复摆颚式破碎机的特点 ··································································3

1.3国内外颚式破碎机的发展及现状·························································5

第2章 总体设计············································································8

2.1复摆鄂式破碎机的基本结构····························································· 8

2.2复摆鄂式破碎机的工作原理·····························································10

第3章 主要参数的确定··································································12

3.1已知参数··················································································12

3.2部分结构参数的确定·····································································12

3.3动鄂的摆动次数···········································································14

3.4电动机的选择·············································································15

3.5四连杆机构各杆长度的确定·····························································16

3.6最大破碎力················································································17

3.7各部件受力分析···········································································17

第4章 传动装置的设计··································································20

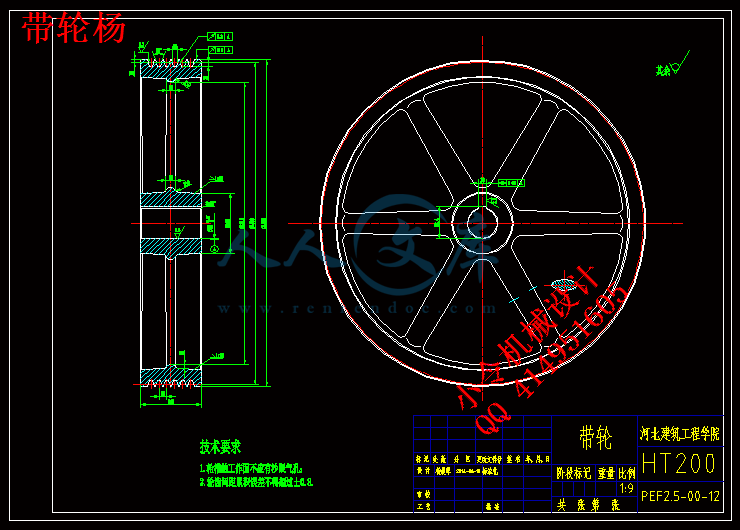

4.1带轮的设计················································································20

4.2偏心轴的设计·············································································25

4.3飞轮的设计················································································27

4.4轴承的选择与校核········································································29

4.5轴承座的设计·············································································31

4.6配重的选择················································································32

4.7外形尺寸的设计···········································································33

第5章 各基本构件的设计······························································35

5.1动鄂的设计···············································································35

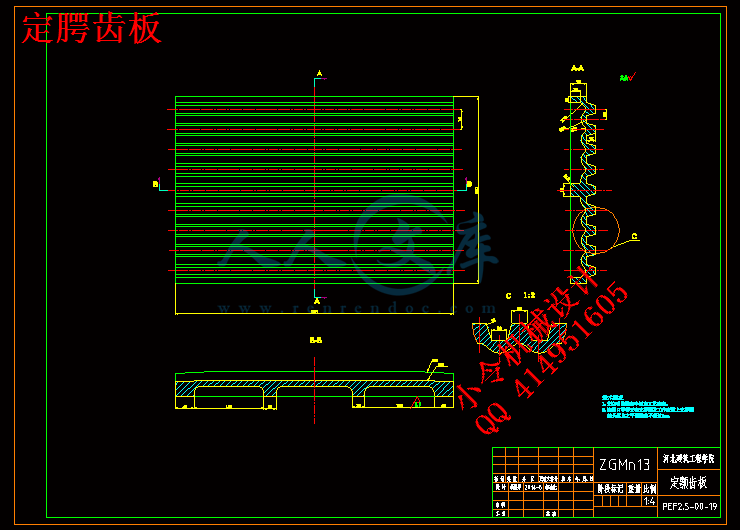

5.2齿板的设计················································································38

5.3推力板的设计·············································································40

5.4调整装置的设计···········································································41

5.5破碎腔型的形状···········································································43

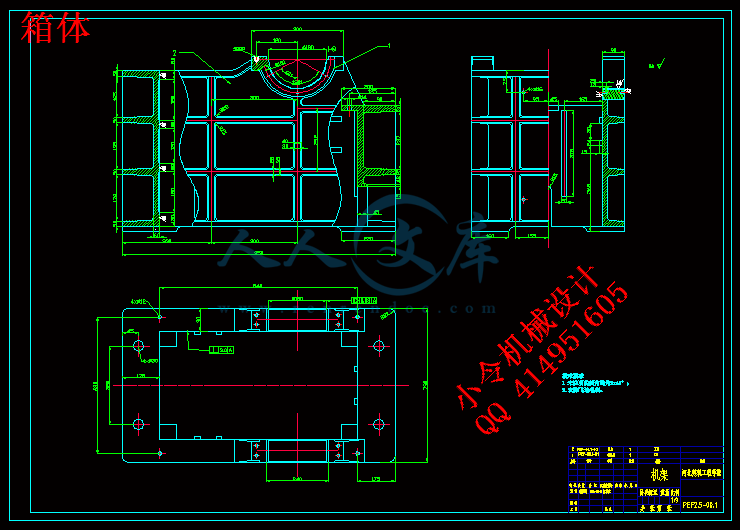

5.6机架的设计···············································································44

第6章 复摆鄂式破碎机的安装························································47

6.1破碎机的安装·············································································47

6.2机架的安装···············································································47

6.3偏心轴和机架的安装·····································································48

6.4肘板的安装···············································································48

6.5动鄂的安装···············································································49

6.6齿板的安装···············································································49

第7章 颚式破碎机的磨损······························································50

7.1齿板的磨损分析··········································································50

7.2颚板磨损机制·············································································51

7.3颚板材质的选择··········································································52

第8章 破碎机出口扬尘的解决和噪声防治·········································54

8.1破碎机出口扬尘的解决··································································54

8.2破碎机的噪声危害及防治途径···························································55

第9章 颚式破碎机的使用·····························································56

9.1颚式破碎机的操作········································································56

9.2颚式破碎机的维护与保养·······························································57

总结···························································································59

鸣谢···························································································60参考文献·····················································································61

川公网安备: 51019002004831号

川公网安备: 51019002004831号