【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

目录

1绪论 1

2设计任务书 2

3设计计算说明书 3

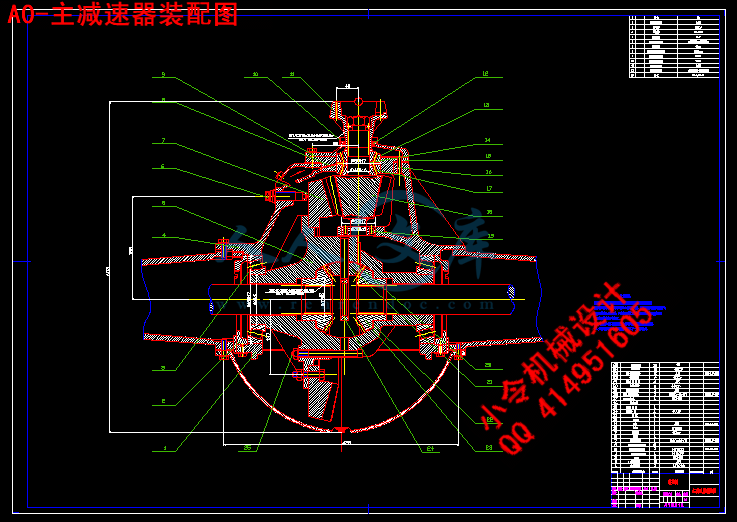

3.1 主减速器的结构形式的选择 3

3.1.1 主减速器的齿轮类型选择 3

3.1.2 主减速器的减速形式选择 5

3.1.3 主减速器主、从动双曲面齿轮的支承型式 7

3.2 主减速器基本参数的选择与计算载荷的确定 9

3.2.1车轮滚动半径和主减速比的确定: 9

3.2.2主减速器齿轮计算载荷的确定 10

3.2.3主减速器齿轮基本参数的确定 12

3.3主要计算 17

3.3.1 单位齿长上的圆周力 17

3.3.2轮齿的弯曲强度计算 18

3.3.3 轮齿的接触强度计算 20

3.4 主减速器轴承的计算 21

3.4.1 双曲面齿轮的轴向力和径向力计算 21

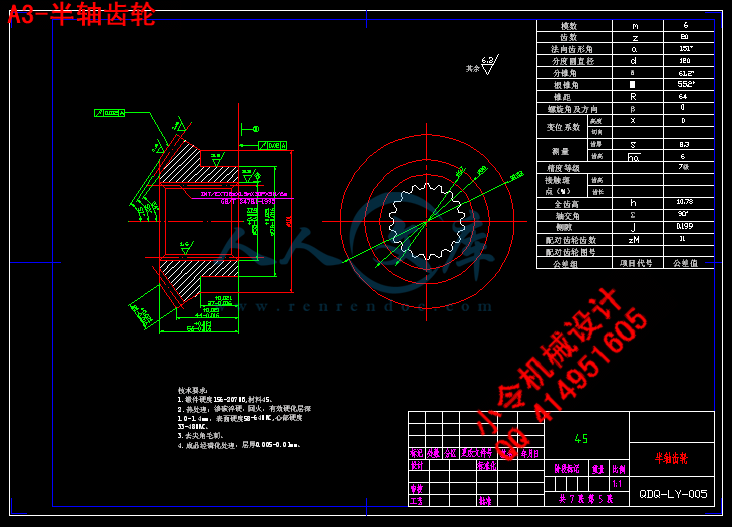

3.5 主减速器齿轮的材料及热处理 22

3.6 差速器总成的设计 23

3.6.1 差速器结构形式选择 24

3.6.2 差速器齿轮主要参数选择 25

3.6.3 差速器齿轮强度计算 28

4使用说明书 29

4.1主要参数 29

4.2主减速器及差速器工作原理 29

4.3润滑使用及维修 30

5标准审查报告 30

5.1 产品图样的审查 30

5.2 产品技术文件的审查 31

5.3 标注件的使用情况 31

5.4 审查结论 31

结 论 32

参考文献 33

致谢 34

载重汽车主减速器及差速器设计

摘 要:汽车主减速器及差速器是汽车后桥的主要部件之一,其基本的功用是增大由传动轴或直接由变速器传来的转矩,再将转矩分配给左右驱动车轮,并使左右驱动车轮具有汽车行驶运动所要求的差速功能。同时,驱动桥还要承受作用于路面和车架或承载车身之间的铅垂力、纵向力、横向力及其力矩。其质量、性能的好坏直接影响整车的安全性、经济性、舒适性、可靠性。

本文参考了东风EQ1090E载重汽车驱动桥,在论述载重汽车汽车驱动桥运行机理的基础上,提练出了在驱动桥设计中应掌握的满足汽车行驶的平顺性和通过性、降噪技术的应用及零件的标准化、部件的通用化、产品的系列化等三大关键技术;阐述了汽车驱动桥的基本原理并进行了系统分析;根据经济、适用、舒适、安全可靠的设计原则和分析比较,确定了载重汽车驱动桥结构形式、布置方法、主减速器总成、差速器总成的结构型式;并对主要零部件进行了强度校核,完善了主减速器及差速器的整体设计。

通过本课题的研究,开发设计出适用于装置大功率发动机载重汽车的单级驱动桥产品,确保设计的载重汽车驱动桥经济、实用、安全、可靠。

关键词:载重汽车; 主减速器; 差速器; 设计

毕业设计说明书中文摘要

毕业设计说明书外文摘要

Differential design of the main gear and truck

Abstract

Automotive final drive and rear axle differential is one of the main components, its basic function is to increase the drive shaft or transmission came directly from the torque, then torque distribution to the left and right drive wheels, and to drive the wheels with the car driving around the required differential movement capabilities. Meanwhile, the drive axle must bear the effect on the body surface and the frame or between the vertical load force, longitudinal force, lateral force and torque. Its quality, performance, a direct impact on vehicle safety, economy, comfort and reliability.

This reference to the east EQ1090E truck drive axle, in his discussion of automotive drive axle truck running mechanism, based on the extraction of a bridge design in the driver should have to meet the comfort and vehicle driving through sex, noise reduction technology and standardization of parts, components of the universal, the product series such as the three key technologies; describes the basic principles of automotive drive axle and a systematic analysis; based on economic, suitable, comfortable, safe and reliable design principles and analysis and comparison identified the truck driver bridge structure, layout methods, the main gear assembly, the

differential assembly structure; and strength check of major components were to improve the final drive and the overall design of differential .

Through this research project, designed to develop high-power engine on the device for single-stage drive axle truck products, ensure that the design of the truck drive axle economic, practical, safe and reliable.

Keywords : heavy truck; Final drive; Differential; Design.

川公网安备: 51019002004831号

川公网安备: 51019002004831号