【温馨提示】 购买原稿文件请充值后自助下载。

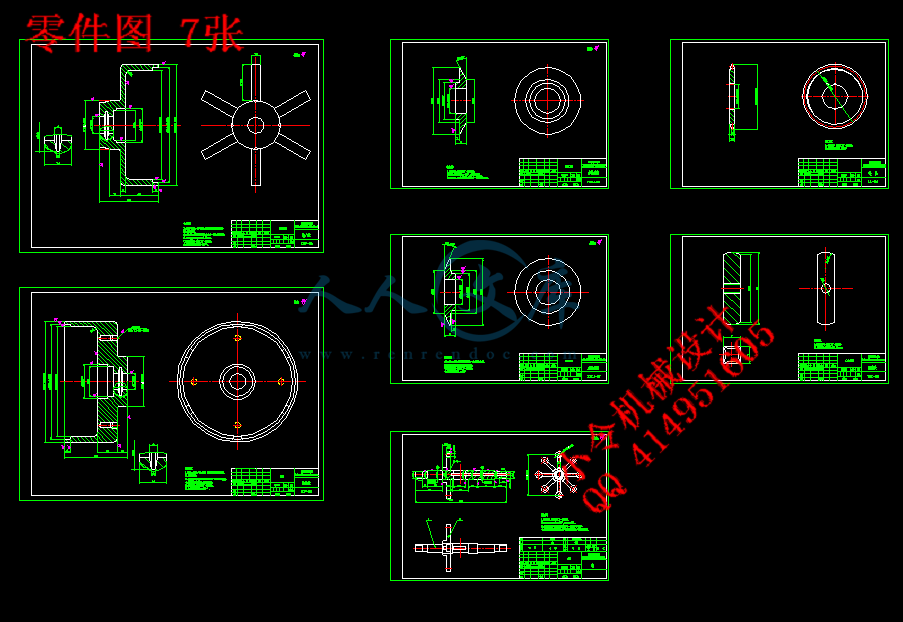

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

目录

1 绪 论 3

1.1 机械无级变速器的概述及应用 3

1.2 无级变速器的分类 3

1.3 机械无级变速器的发展 4

1.4 无级变速自行车研究现状 6

1.5 毕业论文设计内容和要求 7

2 钢球行星式无级变速器的总体方案选择 9

2.1 采用螺旋传动实现球架的左右移动 9

2.2 依靠左右推动实现球架的移动 10

2.3 两方案的选择与比较 10

3 钢球行星式无级变速器部分零件的设计计算 11

3.1 钢球的设计计算 11

3.2 钢球支轴转角的设计计算 12

3.3 轴槽的长度及卡盘的倾斜角的设计计算 13

3.4 轴的设计计算 14

3.4.1 轴的选材及最小直径的计算 14

3.4.2 轴的结构设计 15

3.4.3 轴的校核 16

3.5 滚动轴承的选择 18

3.6 自行车无级变速器的安装 19

4 钢球行星式无级变速器的变速原理论证 20

4.1 关于本文的无级变速器 20

4.2 无级变速的运动结构分析 20

4.2.1无级变速的运动 20

4.2.2 变速原理分析 22

5 结论 23

参考文献 24

致谢 25

外文翻译 26

自行车用无级变速器结构设计

专业:机械设计制造及其自动化

学生:朱杨华 指导老师:聂松辉

摘 要

无级变速器传动是指在某种控制的作用下,使机器的输出轴转速可在两个极值范围内连续变化的传动方式。而无级变速器是这样的一种装置,它具有主动和从动两根轴,并能通过传递转矩的中间介质(固体、流体、电磁流)把两根轴直接或间接地联系起来,以传递动力。当对主、从动轴的联系关系进行控制时,即可使两轴间的传动比发生变化(在两极值范围内连续而任意地变化)。本文在分析各种无级变速器和无级变速自行车的基础上,把钢球外锥式无级变速器进行部分改装,从而形成了自行车的无级变速装置。该装置通过八个钢球利用摩擦力将动力进行输入输出,用一对斜齿轮进行分度调速,从而使自行车在0.75~1.22之间进行无级调速。研究表明:无级变速器被用于自行车方面可以大大改善自行车的使用性能,方便广大消费者使用。

关键字: 无级变速自行车 无级变速器 调速

The design of the CVT on bicycle

Major:Mechanical design manufacturing and automation

Student: Zhu Yang Hua Supervisor:Nei Song Hui

Abstract

Have no the class gearbox spread to mean under the function that is a certain to control, make the exportation stalk of machine turn soon can at two pole is worth the continuous variety in the scope of spread a way.But have no class gearbox is such a kind of device, it has active with from move two stalks, and can pass to deliver the middle of turning the Ju to lie quality(the solid, fluid and electromagnetism flows) to contact two stalks directly or indirectly to deliver power.When to lord, from move an axial contact relation to carry on a control, can immediately make spreading of 2 compare occurrence variety.(be worth to change in a row but at will inside the scope in two poles).Based on the analysis of various CVT and CVT bikes,in this dissertation ,we change some parts of the Kopp-B CVT forming a new kind of CVT used to the bicycle .They are used to input or output the power through the friction and a pair of helical gears is also used to adjust the speed, so the speed can change between 0.75 and 1.22.This research shows that when the CVT are used in the bicycle ,they can significant improve the performance of bike so that all customers can use it convenient.

Keyword: CVT bike CVT Speed control.

1 绪 论

1.1 机械无级变速器的概述及应用

机械无级变速器是一种传动装置,是在输入转速一定的情况下实现输出转速在一定范围内连续变化的一种运动和动力传递装置,由变速传动机构、调速机构及加压装置或输出机构组成。

机械无级变速器转速稳定、滑动率小、具有恒功率机械特性、传动效率较高,能更好地适应各种机械的工况要求及产品需要,易于实现整个系统的机械化、自动化,且结构简单,维修方便、价格相对便宜。机械无级变速器的适用范围广,有在驱动功率不变的情况下,因工作阻力变化而需要调节转速以产生相应的驱动力矩者(如化工行业中的搅拌机械,即需要随着搅拌物料的粘度、阻力增大而能相应减慢搅拌速度);有根据工况要求需要调节速度者(如起重运输机械要求随物料及运行区段的变化而能相应改变提升或运行速度,食品机械中的烤干机或制药机械要求随着温度变化而调节转移速度);有为获得恒定的工作速度或张力而需要调节速度者(如断面切削机床加工时需保持恒定的切削线速度,电工机械中的绕线机需保持恒定的卷绕速度,纺织机械中的浆纱机及轻工机械中的薄膜机皆需调节转速以保证恒定的张力等);有为适应整个系统中各种工况、工位、工序或单元的不同要求而需协调运转速度以及需要配合自动控制者(如各种各样半自动或自动的生产、操作或装配流水线);有为探求最佳效果而需变换速度者(如试验机械或离心机需调速以获得最佳分离效果);有为节约能源而需进行调速者(如风机、水泵等);此外,还有按各种规律的或不规律的变化而进行速度调节以及实现自动或程序控制等。

综上所述。可以看出采用无级变速器,尤其是配合减速传动时进一步扩大其变速范围与输出转矩,能更好的适应各种工况要求,使之效能最佳,在提高产品的产量和质量,适应产品变换需要,节约能源,实现整个系统的机械化、自动化等各方面皆具有显著的效果。故无级变速器目前已成为一种基本的通用传动形式,应用于纺织、轻工、食品、包装、化工、机床、电工、起重运输矿山冶金、工程、农业、国防及试验等各类机械。

1.2无级变速器的分类

机械无级变速器分为刚性式、行星式、链式、带式和脉动式四大类。

(1)摩擦式无级变速器 由刚性传动元件组成,不调速时各传动件的回转轴线位置固定不变。它具有结构简单、形式多样的特点。它分为有中间滚轮与无中间滚轮两大类,前者有较大的调速比(Rb≤16~20),后者的Rb<6。为提高功率体积比常采用多中间体的分汇流传传动方式。对于既升速又降速的变速装置一般需用两套加压装置。传动件接触区可设计成初始点或线接触的结构,前者承载能力稍差,但相对滑动较小,并能补偿受力变形及加工装配等误差;后者承载能力较高,但对制造和装配要求较高。

(2)行星式无级变速器 具有作行星运动的中间滚动体,依靠滚动副间的牵引(摩擦)力,通过改变太阳轮或行星轮的工作半径来实现变速的无级变速器。其传动原理与一般锥齿轮行星轮系很相似,但没有轮齿因而工作半径在运动过程中可以调整。

由于上述传动原理 的特点,使行星无级变速器的结构、性能与刚性式无级变速器不同。行星无级变速器的共同特点:1、变速范围较宽广;2、输出转速恒低于输入转速;3、输出特性好;4、采用多行星轮分汇流传动;5、结构紧凑,加压和调速操纵机构比较简单。

链式无级变速器 通过两相对锥轮之间形成楔形夹槽,夹持着特殊结构的变速传动链,依靠压紧力使链和链轮形成力(或准形)封闭运动副,依靠摩擦力来传递动力,它属于钢质挠性变

川公网安备: 51019002004831号

川公网安备: 51019002004831号