【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

一、题目及专题:

1、题目 机械设备模具的计算机设计与加工

2、专题 吹风机外壳的模具设计与加工

二、课题来源及选题依据

本课题题目自拟;21世纪将成为塑料制品工业迅猛发展的时代,而大多数塑料制品的制造是靠塑料成型的,用模具生产的塑料制品具有高精度、高复杂程度、高一致性、高生产率和低消耗、低成本等特点。

三、本设计(论文或其他)应达到的要求:

1.要了解整个模具行业近十年来设计的发展概况以及应用水平,特别是注塑模具设计的先进技术和方法。

2.熟练掌握UG应用软件,了解目前应用较为广泛的其他应用软件,如Pro/E、Mastercam、AutoCAD软件等。

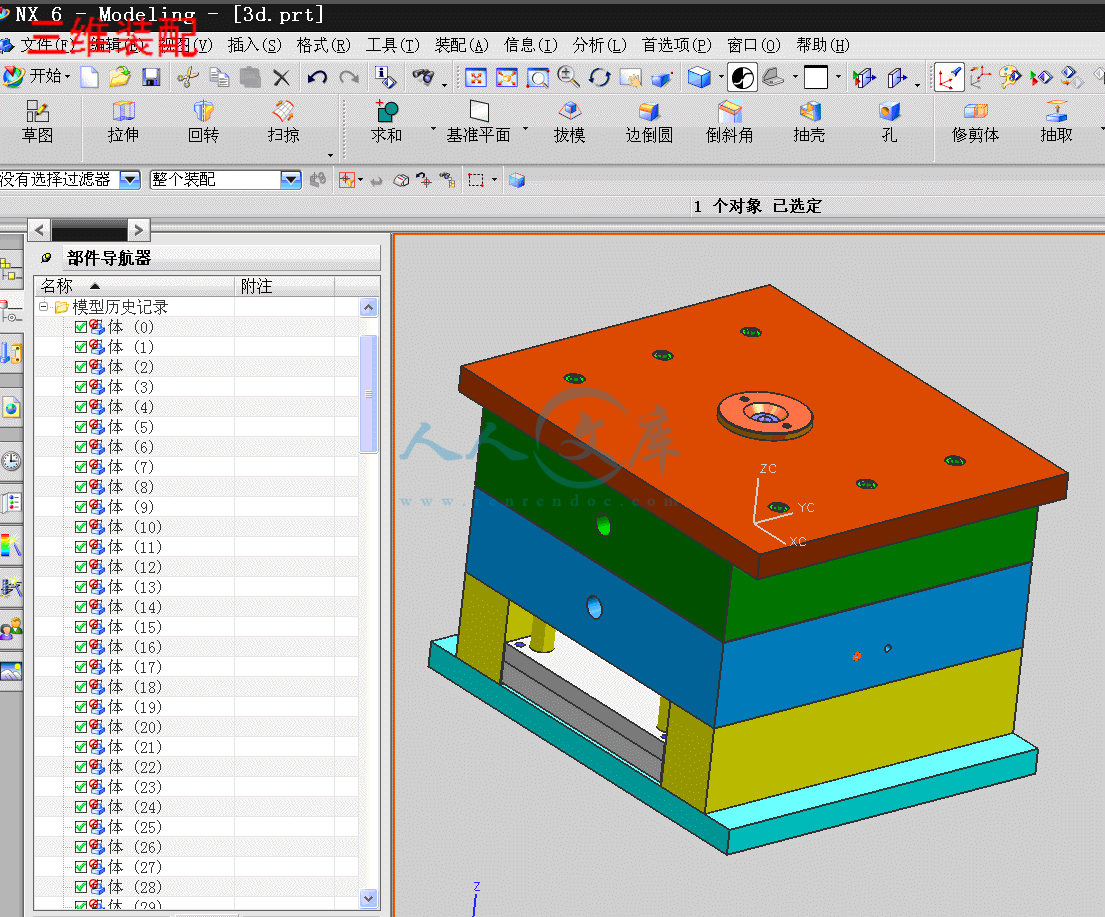

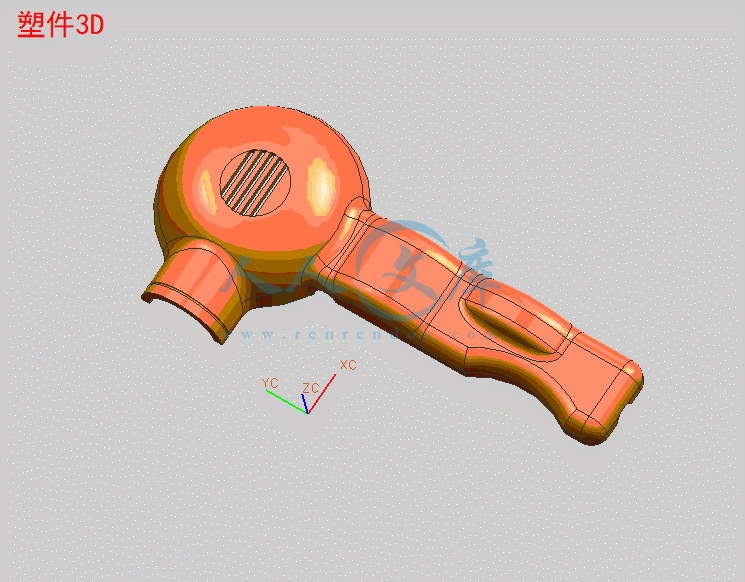

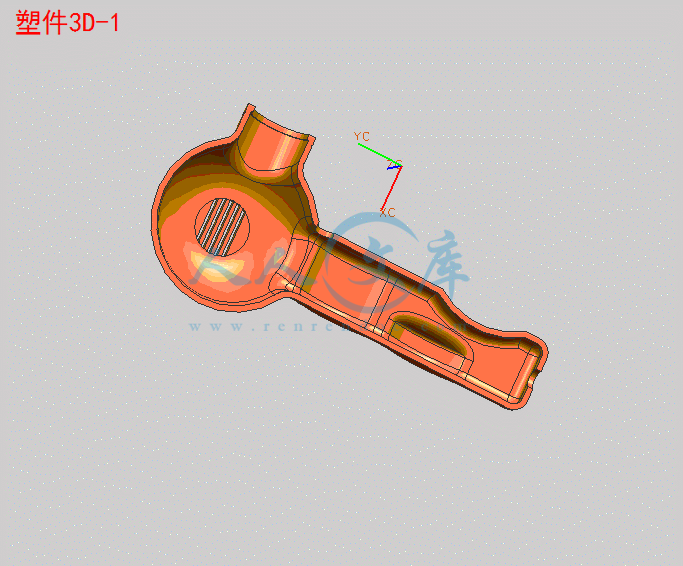

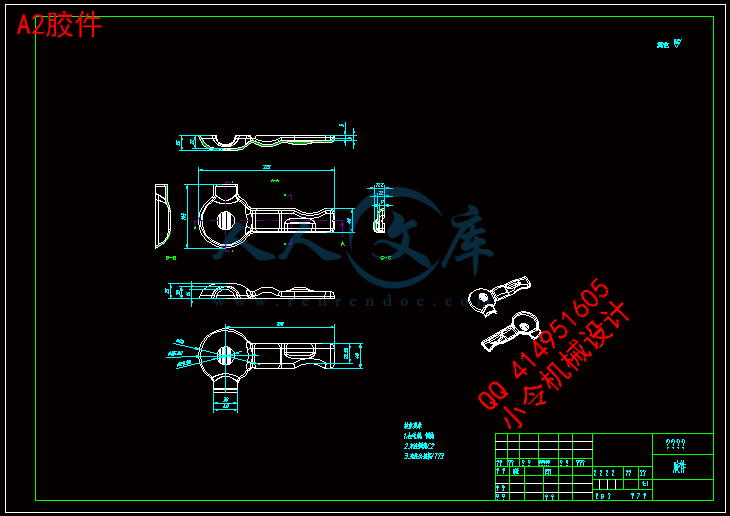

3.对成型材料的成型特性有足够的了解,最重要的是掌握注塑模具的设计特点和结构特点。 4.我要解决的主要问题是设计吹风机外壳的注塑模具(特别是结构设计),最后需要利用UG软件绘出该零件注塑模具的三维图,然后利用UG出工程图,在用AutoCAD修改完善工程图,以及利用UG对凸、凹模进行加工仿真。 所有这些资料必须通过图书馆查找期刊文献、会议文献以及专业书籍得到,所以还要熟练资料的检索。观标准和主观标准综合评价重建图像的质量;

摘 要

近几年好多国家都在发展机械行业,与机械相关的各个行业都越来越重视CAD/CAM技术,如今CAD/CAM技术已发展成为一项比较成熟的共性技术,我国家电工业的高速发展对模具工业,尤其是塑料模具提出了越来越高的要求,2004年,塑料模具在整个模具行业中所占比例已上升到30%左右,据有关专家预测,在未来几年中,中国塑料模具工业还将持续保持年均增长速度达到10%以上的较高速度的发展。国内塑料模具市场以注塑模具需求量最大,其中发展重点为工程塑料模具。同时还因为塑料制品及模具的3D设计与成型过程中3D分析正在塑料模具工业中发挥越来越重要的作用。在本次毕业设计中,通过运用三维实体造型高端软件UG对“吹风机外壳”外形进行3D造型,同时也设计了其塑料外壳注塑模的3D模型;还根据所设计的模具尺寸选择安装了相应的模架,最终生成了直观的结构设计图;此外还利用CAD绘制了模具装配图以及各种成型零件图。这是本人第一次利用UG软件对一整套模具进行设计,使大学四年所学的知识得到运用,并加以指导老师的指导,受益匪浅!

关键词:CAD/CAM;塑料;模具;UG

Abstract

Years, a lot of countries in the development of the machinery industry, mechanical industry more and more attention to the CAD / CAM technology, today's CAD / CAM technology has developed into a more mature common technology, the rapid development of China's household electrical appliance industry moldindustry, especially the plastic mold ever-increasing demands, 2004, plastic mold in the mold industry proportion has risen to about 30% in the coming years, experts predict China plastic mold industrywill continue to maintain an average annual growth rate of more than 10% higher speed. Domestic plastic mold market to the demand for plastic injection mold, the focus of development for engineering plastics mold. Also because the plastic products and mold 3D design and molding process 3D analysis play an increasingly important role in the plastic mold industry. In this graduation project, through the use of dimensional solid modeling high-end software UG "hair dryer shell" shape 3D modeling, at the same time also designed the its plastic shell injection mold 3D model; also based on the design of the mold size choose to install the corresponding mold, the resulting intuitive structure design; addition, the use of CAD drawing mold assembly drawing and a variety of molded parts diagram. This is the first time I use the the UG software on a set of mold design, four years in college to learn to use the knowledge and to the guidance of the instructor and benefit!

Key words:CAD/CAM;plastics;mold;UG

目 录

摘 要 III

ABSTRACT IV

目 录 V

1 绪论 1

1.1 本课题的研究内容和意义 1

1.2 国内外的发展概况 2

2 产品材料 5

2.1 成型产品材料 5

2.2 注塑模具材料 6

3 成型工艺分析 8

3.1 吹风机外壳零件图 8

3.2 塑件的工艺性分析..............................................................................................................8

3.2.1 功能分析 8

3.2.2 塑件的原材料分析 8

3.2.3 ABS的主要性能指标 9

3.3 ABS塑料的注射过程及工艺 10

3.3.1 注射成型过程 10

3.3.2 ABS的注射工艺参数 10

3.3.3 ABS的主要缺陷及消除措施 11

3.3.4 尺寸精度分析 12

3.3.5 表面质量分析 12

3.4 模塑设备的选择 12

3.5 塑件注射工艺参数的确定 12

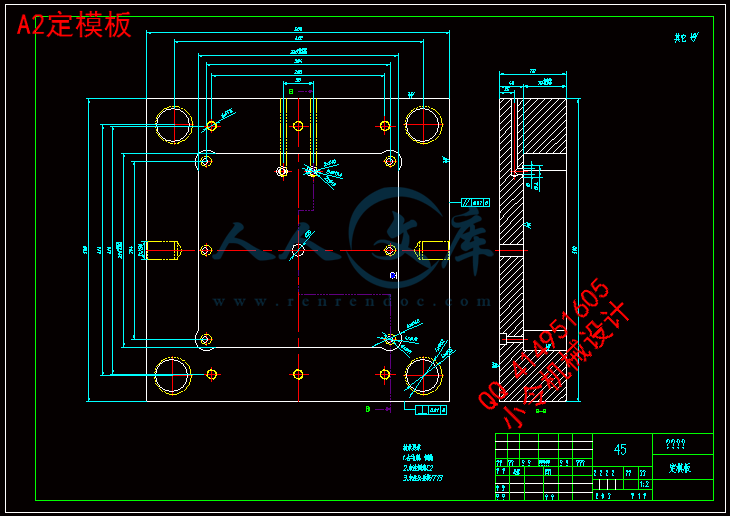

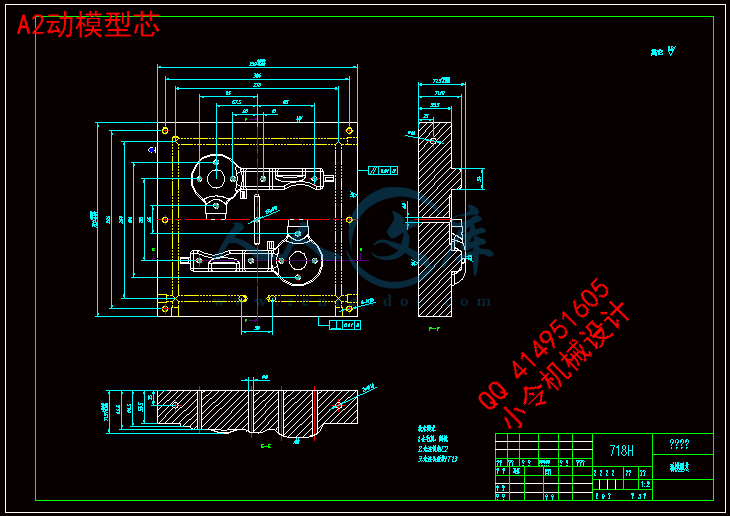

3.6 注射模的结构设计 13

3.6.1 分型面的选择 13

3.6.2 确定型腔的排列方式 13

3.6.3 浇注系统的设计 14

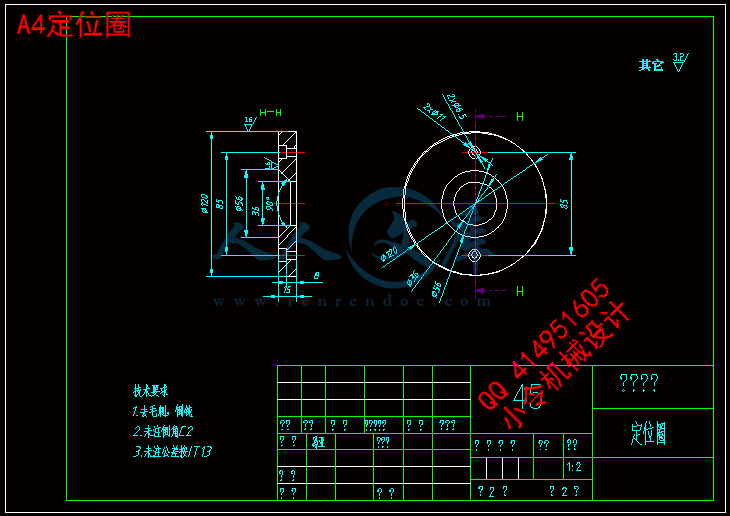

3.6.4 主流道设计 15

3.6.5 浇注系统的平衡 16

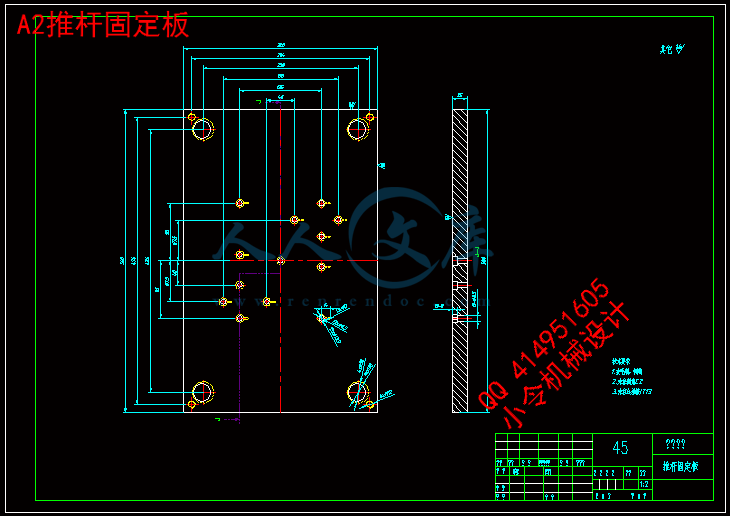

3.6.6 推件机构的设计 16

4 模具的有关计算 19

4.1 型腔和型芯工作尺寸计算 19

4.2 型腔侧壁厚度和底版厚度计算 21

5 模架的选择 22

6 注射机的校核 24

6.1 最大注射量的校核 24

6.2 注射压力的校核 24

6.3 锁模力的校核 24

6.4 模具外形尺寸校核 24

6.5 开模行程的校核 25

7 模具的加工 26

8 结论与展望 28

8.1 结论 28

8.2 不足之处与未来展望 28

致 谢 29

参考文献 30

1 绪论

1.1 本课题的研究内容和意义

模具是基础工业的生产技术和设备,发展和振兴我国的模具行业,日益受到人们的关注和重视。模具工业的一个组成部分是属于高新技术产业,重要组成部分是装备工业。在每一个国家的模具被称为“工业(百业)之母”,“重点行业”,“不可估量的电力行业”,“产业发展”的全部秘密,“效益放大器”和一系列的声誉。模具行业的现状是很重要的,而且在国民经济工业机械,石化,汽车,电子,建筑的五大支柱,需要相应的模具行业。在资源节约的当今时代,塑料工业的强大也要求注塑模具的发展紧随其后,所以相关研究也逐步深入并实现实践。注塑模具的研究包含着产品材料、模具设计、模具制造,国内外研究学者投入的心血都转化成海量的文献,对注塑模具的发展有着承前启后的作用。

模具是用来成型物品的工具,这种工具有各种零件构成。不同的模具是通过所成型材料物理状态的改变来实现,模具是由不同的零件所构成的。它主要是通过所成型材料的物理状态改变来实现物品外形的加工。在挤压、模锻、成形冲压、冷镦、冲裁、压力铸造、粉末冶金件压制,以及工程陶瓷、橡胶、塑料等制品的注塑或压塑的成型加工中,用以在外力作用下使坯料成为有特定形状和尺寸的制件的工具。

而注塑模具工业发展始于历史1943年,位于葡萄牙马立尼亚.格兰特市(Marinha Grande)一家小型玻璃模具厂股东阿尼巴尔(AníbalH.Abrantes)萌发了生产注塑模具的构想。由于未能获得其他股东的支持,阿尼巴尔不得不出售自己拥有的公司股份以筹集资金,并开始专注于注塑模具的研发和制造。2年后,他成功地制造了第一只注塑模具。发展至今,注塑模具是生产各种工业或其他产品的重要工艺装备,随着塑胶模具设计工业的迅猛发展以及塑胶制品在汽车、船舶、机械、电子、航太和航空等工业部门的推广应用,所有产品对模具的要求越来越高,传统的塑胶模具设计方法从而已经无法适应产品的提高质量的要求和更新换代。因此快速发展的计算机提供的电脑辅助工程技术已成为产品加工、模具设计及塑胶产品开发中这些明显薄弱环节的最有效的途经。

注射模具,全称为注射成型模具,也就是塑料注射成型所用的模具,它是实现注射成型工艺的重要工艺装备。所谓注塑成型(Injection Molding)是指,受热融化的材料由高压射入模腔,经冷却固化后,得到成形品的方法。该方法适用于形状复杂部件的批量生产,是重要的加工方法之一。注射成型过程大致可分为以下6个阶段“合模-注射-保压-冷却-开模-制品取出”,上述工艺反复进行,就可连续生产出制品。

注射模具的设计,其成型原理是将塑料从注塑机的料斗送进加热的料筒中,经过加热熔化呈流动状态后,在柱塞和螺杆的推动下,熔融塑料被压缩并向前流动,再通过装在料筒前的那个喷嘴以相当快的速度注到温度比较低的闭合模腔里面,熔料充满在型腔在受压的条件下,经过冷却和固化后即可保持模具腔所给予的形状,接着开模后分型获得成型塑件。因此,完成一个循环的生产过程的操作。正常情况,一个模制周期的时间长度范围从几秒钟到几分钟,取决于塑件的形状,大小和厚度、模具的结构、注射机的类型及塑料的品种和成型工艺条件等因素。

注塑模的分类方法很多,按其所用注塑机的类型可分为卧式注塑机用注塑模、立式注塑机用注塑模、角式注塑机用注塑模及双色注塑机用注塑模等;按模具的型腔数目可分为单型腔和多型腔注塑模;按分型面的数量可分为单分型面和双分型面或多分型面注塑模;按浇注系统的形式可分为普通浇注系统和热流道浇注系统注塑模;另外还有气辅注塑模具、蒸汽模具、重叠式模具(叠模)。一般大体分为普通注射模具和特种注射模具,特种注射模具又可分为:滑动型芯式注射模、瓣合式注射模具、螺纹注射模具、滑动型芯与瓣

川公网安备: 51019002004831号

川公网安备: 51019002004831号