螺纹轴车削加工及数控车削机床仿真的研究

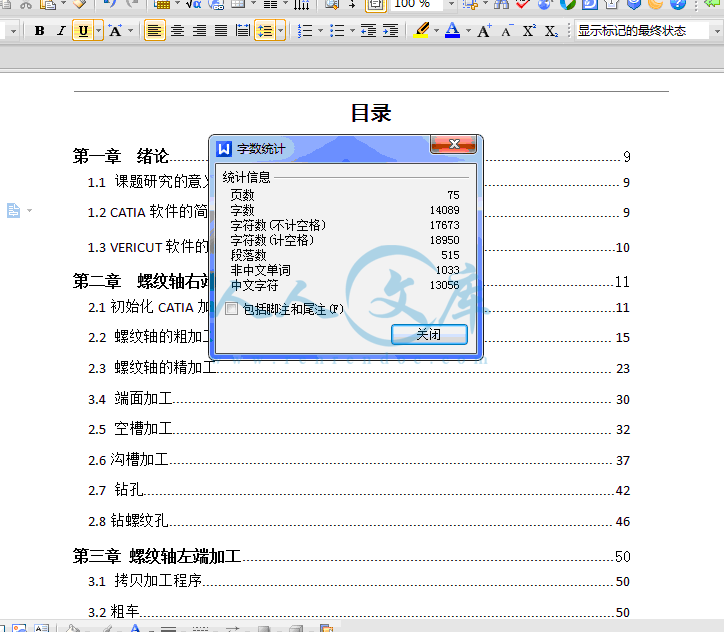

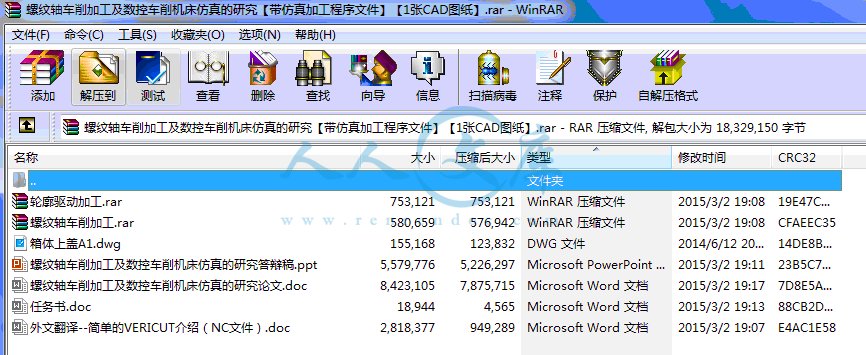

75页 14000字数+说明书+任务书+外文翻译+答辩稿+1张CAD图纸【详情如下】

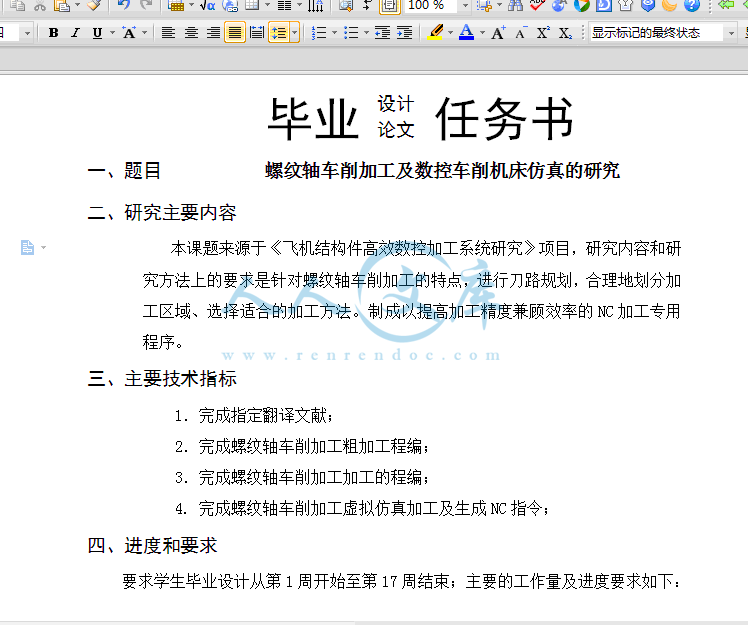

任务书.doc

外文翻译--简单的VERICUT介绍(NC文件).doc

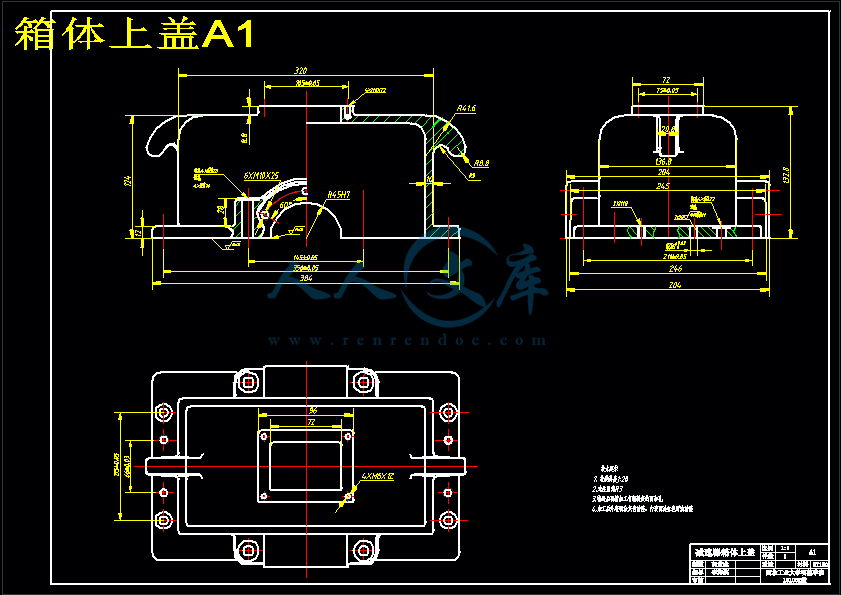

箱体上盖A1.dwg

螺纹轴车削加工.rar

螺纹轴车削加工及数控车削机床仿真的研究答辩稿.ppt

螺纹轴车削加工及数控车削机床仿真的研究论文.doc

轮廓驱动加工.rar

摘 要

随着全球制造业竞争的日益激烈,先进制造技术的不断出现,现代数控加工技术的普遍应用,使得产品的加工周期大幅度缩短,产品的加工质量不断改善,加速了产品的更新换代,增强了产品的竞争力。因此数控加工技术的研究已成为研究重点。

在这个计算机技术发展迅速,新科技日新月异的信息社会中,制造业也发生着革命性的变化。计算机模拟、仿真技术省去了大量的工作量,大大节约了原材料成本,提高了生产效率。工厂里现在大部分机床使用的都是数控机床,数控加工出来的零件既符合外观及精度有要求,又方便操作者进行操作。掌握计算机制造技术已经是新时代我们势在必行的必须课。

作者在查阅和搜索大量与本毕业设计相关资料的基础上,对数控加工进行研究,并在老师的耐心指导下,首先分析零件模型,根据零件的外形特点,确定加工方法。利用CATIA P3 V5R20进行数控加工程序的编制,设计出该零件的NC加工方法,并且尝试找出最合理的加工方法。从而进行零件的动态模拟数控加工。此次设计中以螺纹轴为加工对象,利用粗车,精车,切空槽,切沟槽,钻孔,钻螺纹孔等进行加工。最后,结合CATIA中设计好了的模型实例展现了VERICUT环境下数控加工仿真的全过程。

关键词:粗车,精车,CATIA,仿真,VERICUT

ABSTRACT

Since the competition of global manufacturing industry is increasingly intense, advanced manufacturing technologies appeared continuously. The general application of the modern Numerical Control Manufacturing technology, has made the processing cycle of the products shorten by a large margin, has improved the processing quality of the products, has accelerated the update of the products, and has strengthened the competitive power of the products. So the research of the process technology of numerical control has become the focal point of studying.

The manufacturing method changes a lot with the development of the computer technology in the modern society. Computer simulation saves a lot of time for the workers and greatly saves the cost of raw materials. Also computer simulation increases production efficiency. At present, most of the factory machines are used in CNC machine tools. CNC machining parts achieved the requirement both in the appearance and in the accuracy. To master the computer manufacturing technology for the engineering working in the field of aviation is imperative.

After looking up plenty of relevant articles, author researched the process technology of Numerical Control. Under the guidance of the teacher's patience,author analysis the mold of the part at first and according to the shape characteristics of parts , assure the method of processing. Finally utilized CATIA P3 V5R20 carrying on characteristic modeling and carry on Numerical Control establishment to process procedure and designed NC processing method of the part and try to find out the most reasonable method of processing .Thus the dynamic simulation Numerical Control of carrying on the part is processed. Regarding thread spindle as the target of processing in this design . author has used Rough Turning operation, Profile Finish Turning operation, Recess Turning operation, Groove Turning operation, Drilling, Reverse Threading. Further,the whole process of NC simulation under VERICUT is shown combining with designed model instance in CATIA.

KEYWORDS: rough turning operation,profile finish turning operation,CATIA,simulation,VERICUT

目录

第一章 绪论9

1.1 课题研究的意义9

1.2 CATIA软件的简单介绍9

1.3 VERICUT软件的简单介绍10

第二章 螺纹轴右端加工11

2.1初始化CATIA加工环境11

2.2 螺纹轴的粗加工15

2.3 螺纹轴的精加工23

3.4 端面加工30

2.5 空槽加工32

2.6沟槽加工37

2.7 钻孔42

2.8钻螺纹孔46

第三章 螺纹轴左端加工50

3.1 拷贝加工程序50

3.2粗车50

3.3精车52

3.4切沟槽53

3.5 加工螺纹55

第四章 VERICUT数控仿真加工58

4.1数控加工仿真技术概述58

4.2 数控加工仿真技术的操作步骤61

4.3 数控加工的发展趋势62

4.4 VERCUT仿真加工步骤63

第五章 总结与展望74

参考文献77

致谢78

毕业设计小结79

第一章 绪论

1.1 课题研究的意义

随着科学技术的飞速发展和经济竞争的日趋激烈,产品更新的速度越来越快,多品种、中小批量生产的比重明显增加。同时,随着航空工业、汽车工业和轻工业消费品生产的高速增长,复杂形状的零件越来越多,精度要求也越来越高。此外,激烈的市场竞争要求产品研制、生产周期越来越短,传统的加工设备和制造方法已难以适应这种多样化、柔性化与复杂形状零件的高效、高质量加工要求。因此,近几十年来,世界各国十分重视发展能有效解决复杂、精密、小批量、多变零件加工的数控加工技术。在机械制造业中,大量采用以微电子技术和计算机技术为基础的数控技术,并将机械技术与现代控制技术、传感检测技、信息处理技术、网络通信技术有机地结合在一起,使其生产方式发生了革命性变化。因此研究该课题意义在于使数控技术和数控机床不断更新换代,向高速度、多功能、智能化、开放型以及高可靠性等方面迅速发发展。毕业设计小结

在这近三个月的时间里,我在导师的认真,细心的指导下,以紧张而有序的节奏顺利完成了论文工作。作者在搜索,查阅,分析有关资料的基础上,对计算机辅助制造技术有了深刻的了解,并能运用CATIA软件进行了数控加工仿真。本章下文将对作者的毕业设计做一简要小结,并讲述这个毕业设计的几点心得和体会。

1.通过作者的辛勤努力,完成了下列工作:

1).在查阅和搜索大量与本毕业设计相关的资料的基础上,在导师的耐心指导下,完成了本次毕设的螺纹轴车削加工及数控机床的仿真,也更进一步的了解了加工工艺的流程。

2).在完成加工仿真的过程中,对各种加工参数也有了进一步的认识。

2.三个月的论文工作即将结束,至此,作者谈一下在毕业设计中的几点体会:

1).为一个即将走工作岗位的大学生,在掌握本学科,本专业的知识的基础上,要了解它们最新发展趋势。只有这样,才能跟踪国内外先进的技术知识,才能在一个高起点上进行自己的研究工作。

2).保持虚心求教的精神。现代科技的飞速发展,使一个人的能力和知识面显得极为有限,特别是目前学科内容的不断拓宽,多研究领域的交叉发展,所以,只有不断向相关领域的同仁们学习,请教,才能弥补个人知识面的不足。

3).要大胆创新,勇于开拓。传统的知识方法固然成熟,可靠,但针对集体的问题它必然有其不可弥补的缺陷,此时,我们要在仔细分析其产生缺陷原因的基础上,从中大胆提出自己富有特色的办法,这往往是解决问题的关键。

3.以后的的打算

通过这次毕业设计的锻炼,对CATIA软件和数控加工技术有了新的认识,并且初步掌握了一些CATIA加工的方法,以后会在此基础上,进一步的深化学习,以达到全面掌握。有时间的话会了解一下CATIA其他的模块,为更好地工作和幸福的生活奠定基石。

参考文献

[1] 谢龙汉等. CATIAV5数控加工[M].北京:清华大学出版社,2005年4月.

[2] 谢龙汉等.CATIAV5机械设计[M].北京:清华大学出版社,2005年4月.

[3] 谢龙汉等.CATIAV5机械设计应用实例[M].北京:清华大学出版社,

2005年4月.

[4] 谢龙汉等.CATIAV5逆向造型设计[M].北京:清华大学出版社,

2005年4月.

[5] 谢龙汉等.CATIAV5自由曲面造型[M].北京:清华大学出版社,

2005年4月.

[6]谢龙汉等.CATIAV5数控加工实例[M].北京:清华大学出版社,2005年4 月.

[7]卜昆等.计算机辅助制造[M].北京:机械工业出版社,2006.

[8] 计算机辅助制造.编著:王先逵.清华大学出版社.1999年1月第一版.

[9] 计算机辅助制造.编著:罗学科.化学工业出版社.2002年11月第一版.

川公网安备: 51019002004831号

川公网安备: 51019002004831号