汽车卧铺盖板拉延模设计

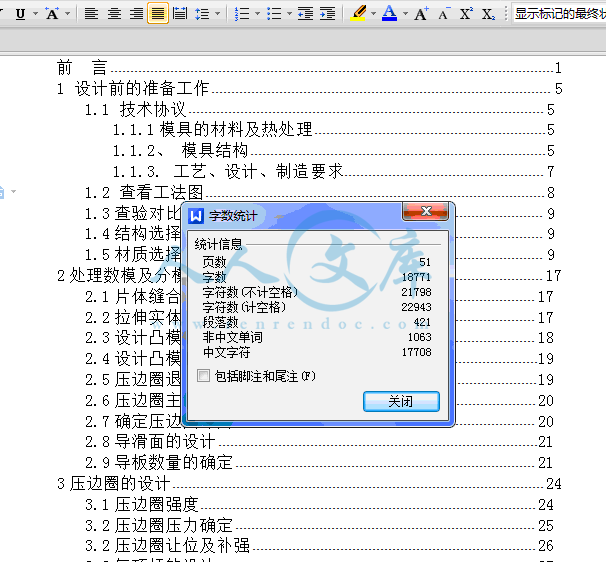

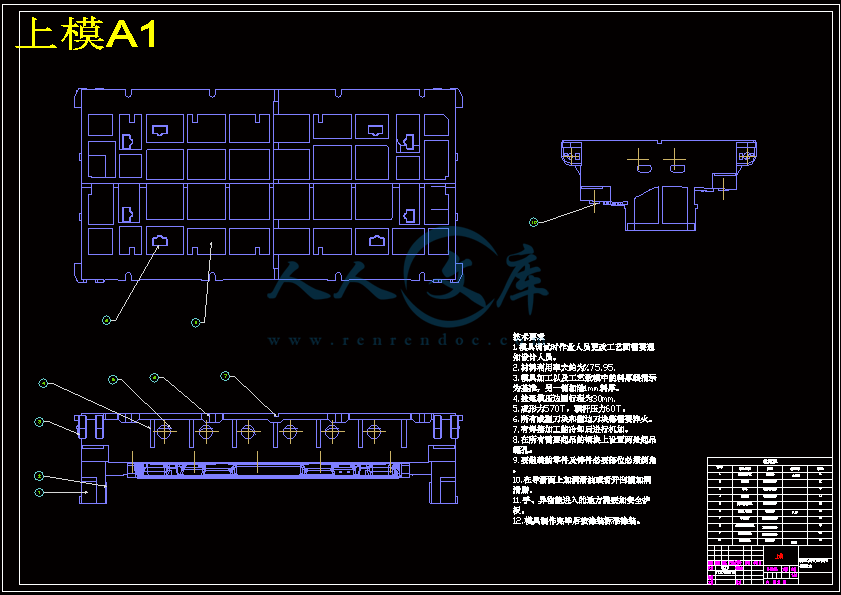

51页 18000字数+说明书+中英文翻译+开题报告+6张CAD图纸【详情如下】

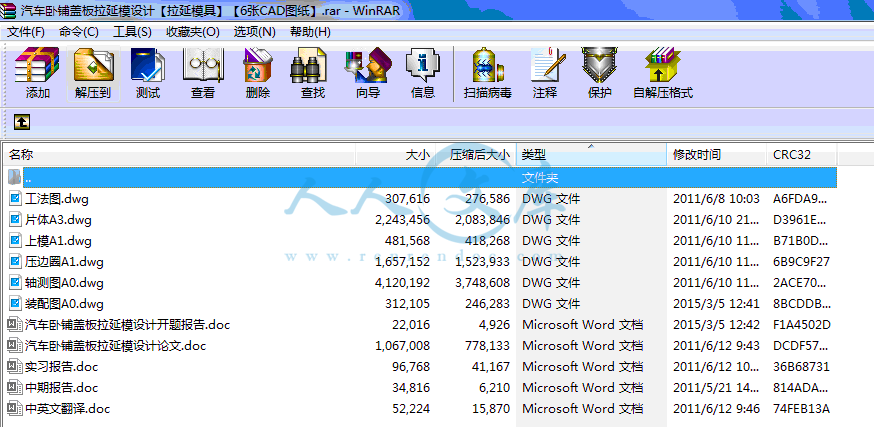

上模A1.dwg

中期报告.doc

中英文翻译.doc

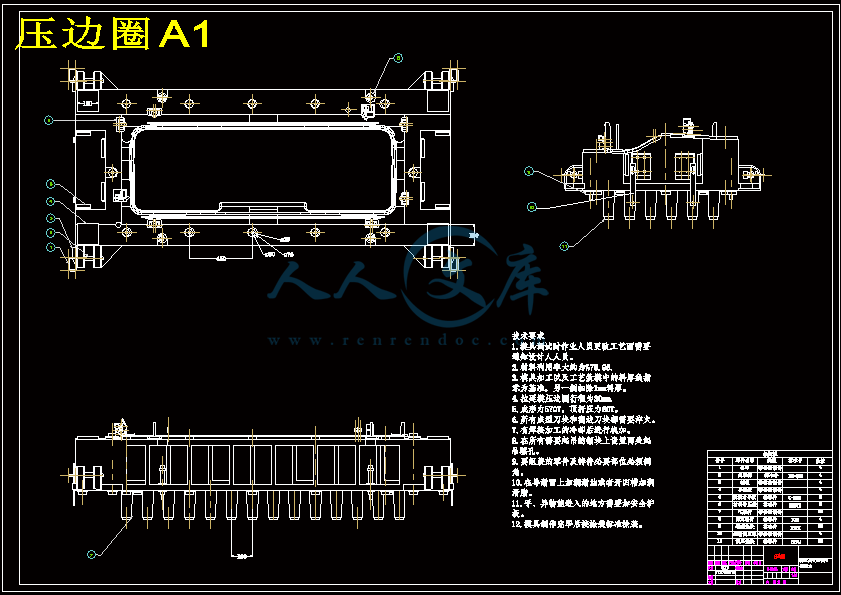

压边圈A1.dwg

实习报告.doc

工法图.dwg

汽车卧铺盖板拉延模设计开题报告.doc

汽车卧铺盖板拉延模设计论文.doc

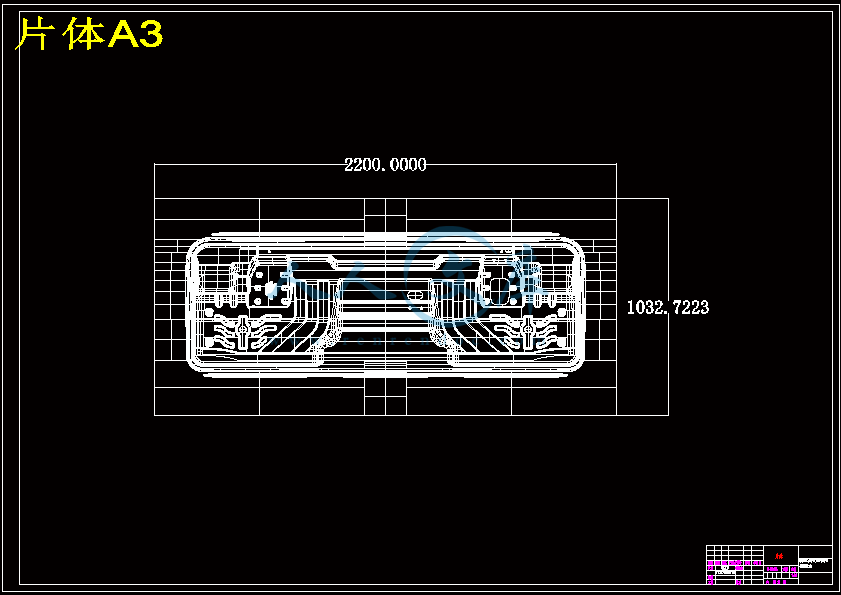

片体A3.dwg

装配图A0.dwg

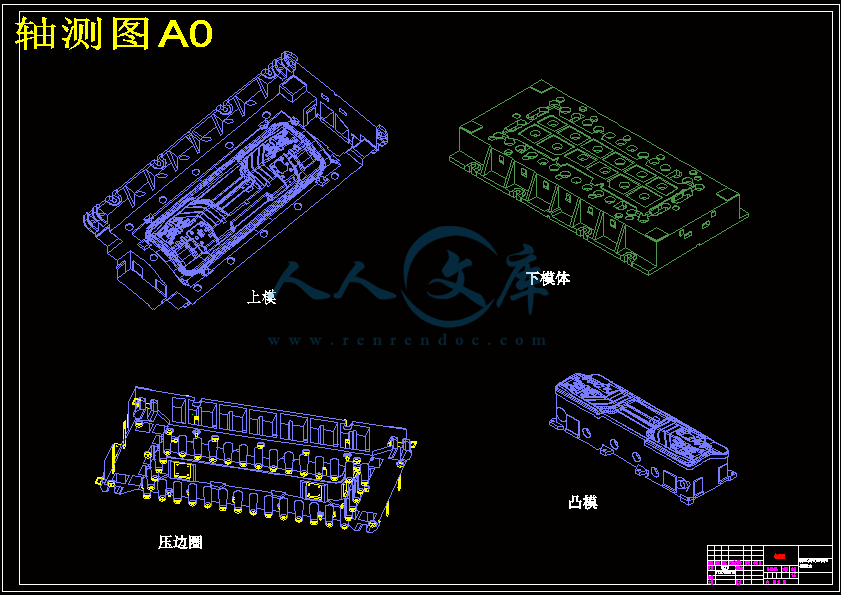

轴测图A0.dwg

摘 要

本次设计做的是汽车车身覆盖件冲压模设计中的第一序拉延模的设计。汽车模具在中国因为发展的时间比较短所以在很多方面现在比起一些机械工业发达的国家还有很大的差距。但我国近年来在汽车模具方面也取得不少的发展与进步。本次设计我做的是汽车盖板的拉延模设计。在模具设计中主要是根据设计好的板件来用UG软件进行三维造型设计来完成模具的结构设计然后进行模具加工调试来最终生产出合格的模具。在三维造型方面主要可以分为压边圈设计、上模设计、凸模设计和下模本体设计。在进行各部分设计时要严格按照模具结构设计规范来进行设计。

在本次设计中我严格按照冲压模设计标准来进行模具设计,其中有一部分技术规范属于企业内部规范。本设计经过反复检查没有发现大的纰漏,完全符合模具设计的要求。

关键词:汽车模具 UG 拉延模 设计标准

Abstract

The design do is auto body panel stamping die design sequence in the first drawing die design. Automotive die in China due to the development of a comparatively short time it is in many ways than some mechanical industrial developed countries there is a great gap. However, in recent years, China has also made the car a lot of mold development and progress. The design of the car I did the cover drawing die design. In the die design are mainly based on panels designed to use the UG software design to complete the three-dimensional structure of the mold and then mold design to final production of qualified commissioning of the mold. Main aspects of three-dimensional modeling can be divided into the blank holder design, the mold design, design and lower die punch body design. During the design of various parts of the structure to be in strict accordance with design specifications to the mold design.

In this design I strictly in accordance with design standards for stamping die mold design, including technical specifications are part of the internal specification. After repeated checking of the design found no major flaws, in full compliance with the mold design.

Keywords: car mold drawing die design standards UG

目录

前 言1

1 设计前的准备工作5

1.1 技术协议5

1.1.1模具的材料及热处理5

1.1.2、 模具结构5

1.1.3. 工艺、设计、制造要求7

1.2 查看工法图8

1.3查验对比9

1.4结构选择9

1.5材质选择9

2处理数模及分模线17

2.1片体缝合17

2.2拉伸实体17

2.3设计凸模退刀面18

2.4设计凸模主筋19

2.5压边圈退刀面的设计19

2.6压边圈主筋的设计20

2.7确定压边圈导向20

2.8导滑面的设计21

2.9导板数量的确定21

3压边圈的设计24

3.1压边圈强度24

3.2压边圈压力确定25

3.2压边圈让位及补强26

3.3气顶杆的设计27

3.4压边圈镶块设计28

3.5调压垫块与墩死垫块的设计28

3.6弹顶销的设计30

4上模的设计31

4.1上模型面及主筋31

4.2上模法兰面和辅筋31

4.3上模调压凸台的设计31

4.4上模起吊和反转结构的设计32

4.5压板槽的设计32

4.6导腿的设计32

4.7安全平台的设计32

4.8设计中心键槽及压板槽加强筋33

4.9上模弹顶销的设计33

4.10设计减轻空、流水孔及排气孔33

4.11定位板地设计34

5下模的设计41

5.1下模座的设计42

5.2设计墩死垫块42

5.3设计凸模安装固定法兰43

5.4设计安全螺钉43

5.5设计安全护板44

5.6运输连接的设计44

5.7导柱导向设计44

5.8下模导板窥视孔的设计44

5.9设计完成45

致 谢46

参考文献47

1 设计前的准备工作

1.1 技术协议

每一个项目都会与客户签定技术协义(或其它类似的文件),技术协义中包涵了客户对模具要求的所有相关信息。在进行模具设计之前必须仔细阅读技术协议严格按照里面的要求来进行设计。

1.1.1模具的材料及热处理

当冲压件的材料为高强度板(抗拉强度大于等于340MPa)或板厚>1.2mm时。压边圈采用HT300+Cr12MoV镶件结构;凹模采用基体部分HT300+压料面及模口部分Cr12MoV+内型面部分MoCr镶件结构;凹模也可采用基体部分MoCr+压料面及模口部分Cr12MoV镶件结构;凹模采用基体部分HT300+型面压料面Cr12MoV镶件结构;料厚小于等于1.2mm的凸模可采用(GGG70L),MoCr铸铁。表面淬火硬度不低于HRc50;凸模采用基体部分HT300+成型部分Cr12MoV结构;凸模采用基体MoCr+变形剧烈部分Cr12MoV结构(具体在图纸会签时确定)Cr12moV(SKD11韩国)。表面淬火硬度不低于HRc55~58。

1.1.2、 模具结构

模具结构形式,原则上按甲方提供的或甲方认定的乙方提供的结构设计。模具的闭合高度,根据模具的结构、操作要求、压机参数而定。一个零件系列模具的闭合高度应考虑一致性。中型模具 考虑联合安装式。(会签时根据具体情况商定)。上下模之间要设置四块等高的平衡垫块。模具的标准件及结构性外购件原则上选用三住、三协标准,超出范围的标准均需甲方的认可。(国内模具供应商标准件要选用上海三住、北京世贸、大连盘起的产品,氮气缸要求选用美国Hysow或瑞典Kaller或天津大石机械的产品或韩国TOSS的产品,顶料汽缸要求选用SMC的产品)。氮气缸选用原则为:氮气缸达到最大压缩量时应留有5mm余量,注入基准压力为12MPa。平衡用氮气缸的顶出力应在相应上模总重量的(1.5—2)倍以上。所有模具必须采用12.9级的螺钉(栓)。拉延模自动化生产线用模具压料圈采用内置式结构,上、下模互为导向体,压料圈与凸模互为导向体。模具尽可能考虑送料高度合理一致。自动化冲压生产线用模具应考虑机械人送料高度(参见模具设计标准-《一般设计》)。模具定位采用四点快速定位。 上下模四周铸出“V”型中心线槽。两侧铸出方向“→”箭头示前方。铸件加强筋间距≤300mm(封闭间距≤600mm),型面厚度≥50mm,筋厚按甲方标准。本体为实型铸铁, 应保证铸件的强度、刚度和外观质量。铸件的相关部位壁厚按甲方标准铸造.铸件本体带联体验棒(模具交付时至少保留两个验棒,验棒规格为¢30×200mm),联体位置适当,不能有干涉或隐含干涉。模具安装采用U型槽,数量为:模具长度L ≥ 1500mm时, 上下模6-8个U行槽; L<1500 mm时, 上下模各4—6个U行槽, U型槽厚度H=60mm(底板厚度H=50mm、压板台高度h=10mm).压板槽距模具端头小于500mm.模具要求定位准确,不易松动,操作方便、安全。拉伸件应考虑后续工位定位问题。拉延、成形类模具,要求有合模到底的压印标记,标记深度为0.3mm以内。

拉延模应在适当位置合理设置¢6的排气孔,并加防尘软管。

模具要设置安全平台。大型模具安全平台尺寸为200mm×200mm;中型模具安全平台尺寸不小于150mm×150mm;小型模具安全平台尺寸为100mm×100mm。上下模安全平台之间高度为120mm或170mm。(压机安全棒高度800mm)废料对角线长度不大于500mm,如超出范围须与甲方协商确定。小型模具修边废料,要能滑出模具外。中、大型模具要求滑出压机台外。采用折叠式废料滑板使废料排出压机台外。一级废料滑板的设置不得超出模具的外轮廓线。废料滑板的料厚t取2mm-2.5mm。(具体会签时确认)废料滑道的倾斜角度需大于等于25度,如果倾斜角度小于25度,废料滑板必须采用网纹板(滤油网板)。非自动化线冲孔类模具废料原则用废料盒接存,尽量集中接存,废料在模体内滑动要顺畅,不得泄露在压机工作台上。废料盒尽量少;废料盒抽出方向设置在模具前后向、方便取放倒废料,定位要可靠,且能够自锁。(具体会签时确认)模具采用铸入式或铸造式起重臂或插销式吊耳,插销式起重吊耳应配有自锁功能起重棒。对于重量大于5吨的模具必须采用插销式吊耳形式。铸入式起重棒设置在模具左右方向。退料(压料)板原则上采用导板或导柱导向、侧销限位结构,要求设有安全块或安全螺钉。板料厚度小于1.2mm的冲裁工序的压料器要在适当位置设置锥形限位块(四点)-(六点),且锥形限位块必须等高,板料厚度大于等于1.2mm的冲裁工序是否采用锥形限位块在模具图纸会签时确定。压料面在有效的范围以外全部空开深度H=1mm。压料、退料装置要设有缓冲装置。压料器溢出凹腔部位以下50mm需要布设斑马线标识,并在相应位置设置参照标记。

参考文献

[1] 李大鑫、张秀棉模具技术现状与发展趋势综述。 2005.02。

[2] 曹月君. 国内外汽车球墨铸铁件生产技术与发展趋势[J]汽车工艺与材料, 1994,02。

[3] 赵孟栋主编,冷冲模设计,北京:机械工业出版社,2007。

[4] 徐政坤主编,冲压模具及设备,北京:机械工业出版社,2007。

[5] 姜奎华主编,冲压工艺与模具设计,北京:机械工业出版社,2002。

[6] 李奇主编,模具设计与制造,北京:人民邮电出版社,2006。

[7] 拉延模结构设计标准,企业内部标准。

[8] 冲压模标准件设计标准,企业内部标准。

川公网安备: 51019002004831号

川公网安备: 51019002004831号