DX型钢丝绳芯带式输送机设计

54页 16000字数说明书+外文翻译+4张CAD图纸【详情如下】

DX型钢丝绳芯带式输送机设计说明书.doc

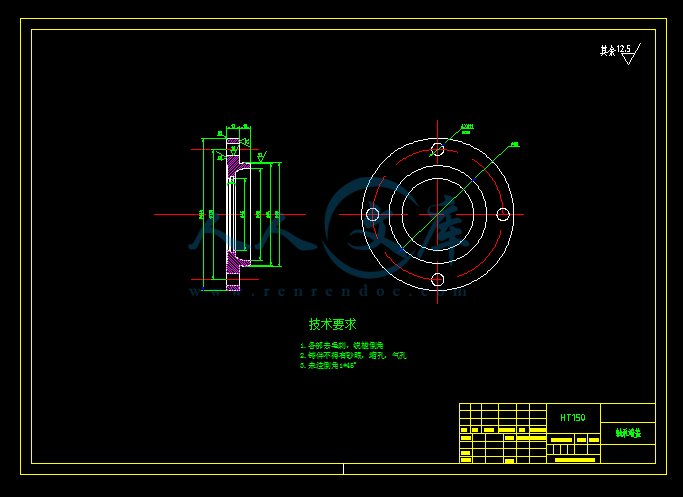

外文翻译--钢绞线带式输送机的发展.doc

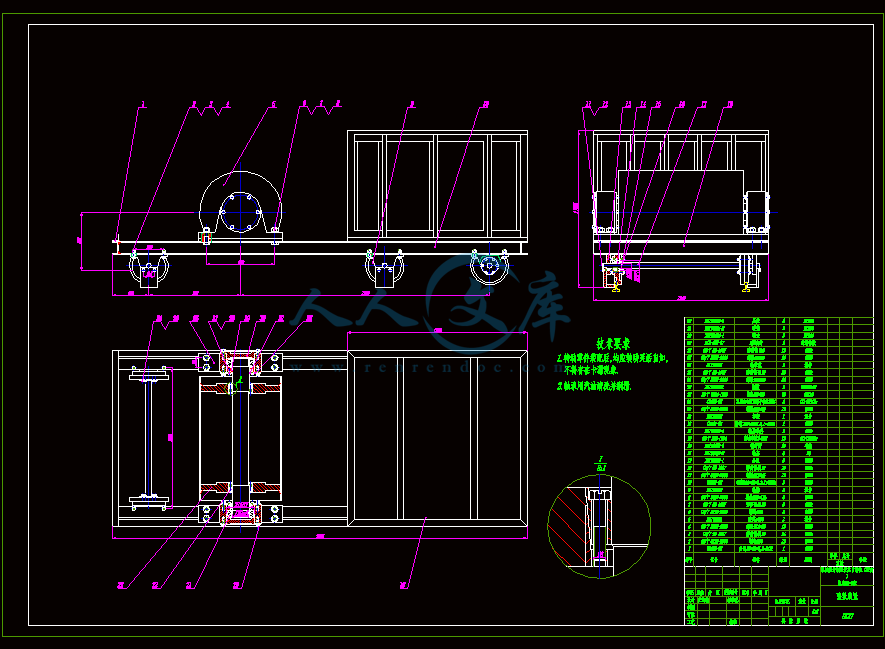

张紧装置.dwg

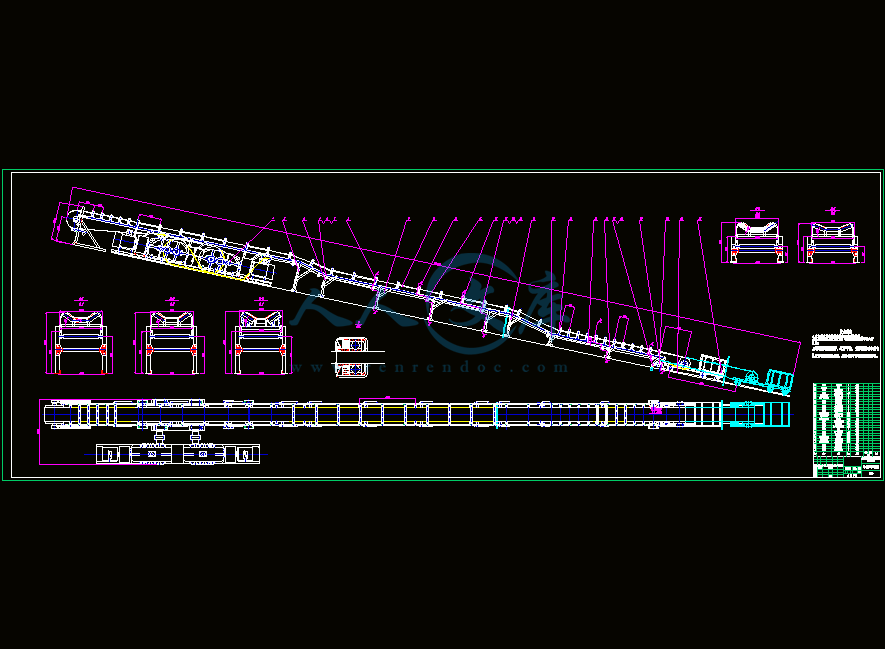

总装图.dwg

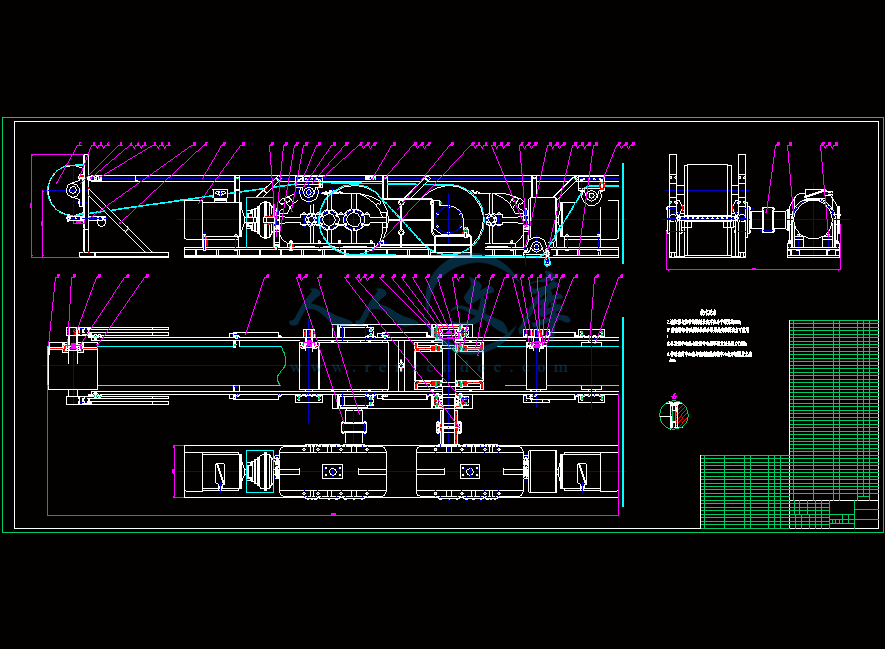

机头部.dwg

重锤清扫器.dwg

目 录

摘 要I

AbstractII

第1章 绪 论1

1.1 前言1

1.2 带式输送机的发展史1

1.2.1国外带式输送机的发展1

1.2.2国内带式输送机的发展2

1.2.3国内外带式输送机的差距2

1.2.4带式输送机的发展趋势3

1.3 带式输送机的分类3

1.4 带式输送机的特点及应用4

第2章 带式输送机的整体设计方案5

2.1 方案的确定5

2.2 工作原理7

第3章 带式输送机的主要部件与功能10

3.1 输送带10

3.1.1输送带的发展10

3.1.2输送带的种类及差异10

3.1.3输送带的要求11

3.1.4钢丝绳芯输送带11

3.2 拉紧装置12

3.2.1拉紧装置的作用12

3.2.2拉紧装置的分类及特点12

3.3 托辊14

3.3.1托辊的结构及作用14

3.3.2托辊的选择14

3.4清扫装置16

3.4.1清扫器的作用16

3.4.2清扫器的形式16

3.5 传动滚筒、改向滚筒17

3.5.1传动滚筒的分类17

3.5.2改向滚筒的选取18

3.5.3环形胀套19

3.6 机架的设计与选取20

3.6.1机头探架20

3.6.2中间支架20

第4章 带式输送机的设计计算21

4.1 设计参数21

4.2 根据实际输送量计算带宽21

4.3 运行阻力23

4.4 牵引力及运行功率28

4.5 输送带张力计算29

4.6 输送带强度验算31

4.7 滚筒直径的确定31

4.8驱动装置的选型及计算32

4.8.1电动机的选型32

4.8.2液力偶合器的选型32

4.8.3减速器的选型33

4.8.4联轴器的选型36

4.8.5制动器的选型及计算37

4.9 拉紧力计算40

4.10 托辊的选取41

4.10.1 静载荷计算41

4.10.2 动载荷计算43

结 论45

致 谢46

参考文献47

附录149

附录256

摘 要

带式输送机自它诞生以来,经过200多年不断完善和改进,已进入电力,冶金,煤炭,化工,矿山,港口等各行各业之中。其机构简单,输送物料范围广,输送量大,运距长,对线路适应性强,装卸料十分方便,可靠性高,营运费低廉,基建投资省,耗能低,效率高,维修费少。

本设计为DX型钢丝绳芯式带式输送机,采用机头双滚筒驱动,在保证滚筒不发生打滑的前提下来传递较大的功率,降低输送带的张力和提高使用寿命。文中根据第二滚筒围包角用足,依此算出输送机的各种参数,进行结构设计。由于倾角较大,按第二滚筒围包角用足进行等驱动功率单元法分配,本设计采用分配,得出尾部张力最小,根据布置原则,张紧装置一般布置在输送带张力最小处,所以本文采用重载车式张紧装置进行张紧。如今,带式输送机正向长距离、高带速、大功率、大运量的大型化方向发展,使其在煤炭行业得到广泛应用。

关键词 带式输送机 双滚筒驱动 张紧

Abstract

The belt conveyer with continue development and improvement has entered all trades and professions such as power, metallurgy, coal, chemical engineering, mine and port since being born for more than 200 years. Its construction is simple , it is broad to transport stock scope, it is big to transport quantity, the length of haul distance has strong adaptability for line, handling material is very convenient, reliability is high , it can reduce investment in basic construction, high efficiency, low maintenance cost.

The design is DX model core type belt conveyer of wire rope, the machine header adopts two cylinder drives ,in guarantee cylinder do not occur the prerequisite with slippery dozen transmit greater power, reduce raising the tension of belt conveyer and improve service life. In writing according to second cylinder surround bale angle use enough, according to this various parameters that make conveyer finally, carry out structural design. Since inclination is greater, according to second cylinder wait for drive with foot power unit law distribution, this design adopts 1: 1 is distributed , it is minimum to reach tail tension, basis arrange principle, tension station arranges normally, is in the tension minimum place of conveyer belt , so, this paper use the burden vehicle tension equipment to tighten. Now belt conveyer’s development towards to long distance, high belt speed, great power and high transportation, and the advantage of this kind of conveyer realizes easily, make extensive application in coal industry.

Keyword Belt conveyer two cylinder drive tight

1.1 前言

带式输送机自1795年被发明以来,经过两个世纪的发展,已被电力、冶金、煤炭、化工、矿山、港口等各行业广泛采用。特别是第三次工业革命带来了新材料、新技术的采用,使带式输送机的发展步入了一个新纪元。当今,无论从输送量、运距、经济效益等各方面来衡量,以成为全国争先发展的行业。随着我国工业生产自动化程度的不断提高,带式输送机这一类古老、经济适用而又现代化的连续输送机械,是国民经济中不可缺少的关键设备[1]。

1.2 带式输送机的发展史

皮带运输机有着200多年的发展史,影响深远。自1972年圆管胶带输送机诞生后就在国外迅速普及,到2004年已有余种运输机在世界各地生产并使用。进入21世纪,我国发明了可伸缩、可升降的圆管胶带输送机;气垫式圆管胶带输送机;中摩式圆管胶带输送机和圆管胶带输送机用高温耐热胶带、无缝托辊组[12]。

1.2.1国外带式输送机的发展

国外带式输送机技术发展的很快,其主要表现在个方面:一方面是带式输送机的功能多元化、应用范围扩大化;另一方面是带式输送机本身的技术与装备有了巨大的发展,尤其是长距离、大运量、高带速等大型带式输送机已成为发展的主要方向。其核心技术是开发应用于了带式输送机动态分析与监控技术,提高了带式输送机的运行性能和可靠性。

川公网安备: 51019002004831号

川公网安备: 51019002004831号