带式输送机伺服调偏装置设计

35页 18700字数+说明书+开题报告+5张CAD图纸【详情如下】

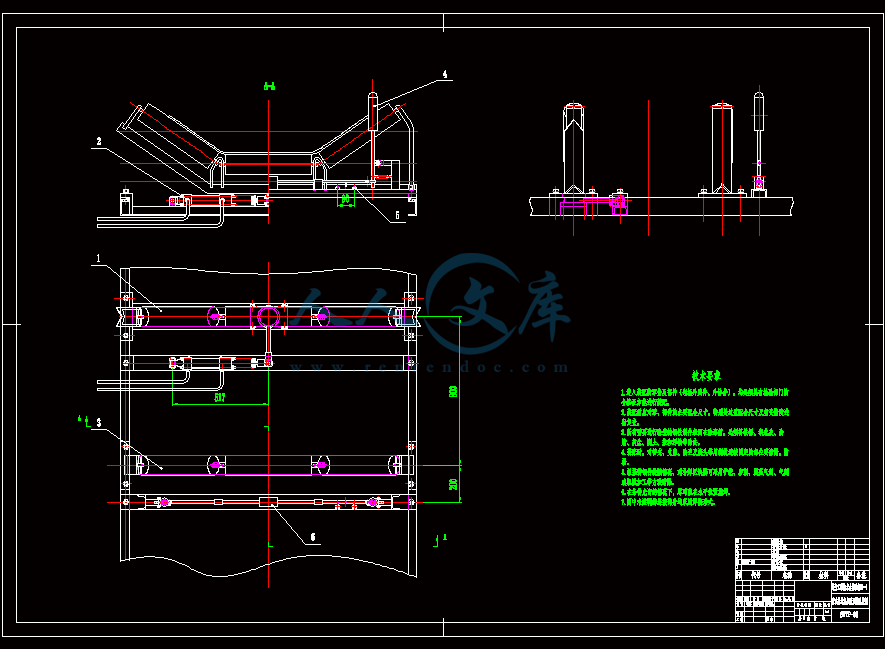

单耳.dwg

双耳.dwg

封皮.doc

带式输送机伺服调偏装置设计开题报告.doc

带式输送机伺服调偏装置设计说明书.doc

摘要.doc

液压系统图.dwg

液压缸装配图.dwg

目录.doc

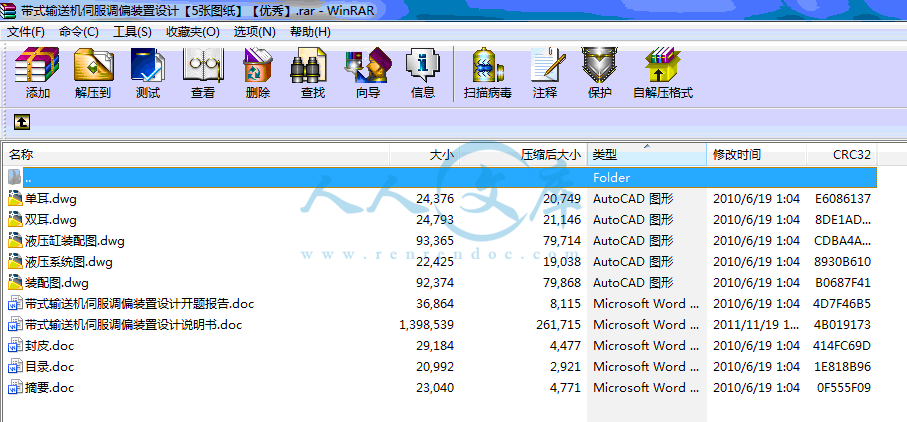

装配图.dwg

目录

引言1

1 带式输送机2

1.1 带式输送机的特点2

1.2 带式输送机的分类3

1.3 带式输送机在国内应用情况4

1.4 国内外带式输送机技术的差距5

2 带式输送机胶带跑偏的研究8

2.1 带式输送机胶带跑偏的危害8

2.2 带式输送机胶带跑偏的原因8

2.3 带式输送机胶带跑偏的主要调整方法10

2.4 目前常用的几种主要调偏托辊装置12

2.5 另外几种常用的调偏方法13

3 带式输送机胶带跑偏结构设计15

3.1 方案设计15

3.2 总体结构设计15

3.2.1 胶带的运动分析15

3.2.2 胶带在托辊表面的运动分析15

3.2.3 胶带调偏的原理18

3.2.4 跑偏装置介绍19

3.3 主要元件的设计计算及校核23

3.3.1 元件的设计计算23

3.3.2 强度校核26

3.4 结构设计28

4 结论29

致谢30

参考文献31

附录A 译文32

附录B 外文文献42

摘要

近年来,随着国民经济的发展,特别是大型露天矿的开发,带式输送机广泛应用于机械设备中,工作中经常会遇到输送带跑偏的情况发生,所以必须对跑偏现象进一步研究。

本文介绍了带式输送机跑偏的原因及调整的方法,在分析传统调偏装置的基础上,本文的主要采用伺服系统、调心托辊、立辊、检测装置、行程开关等来完成对带式输送机胶带跑偏的调整和控制。伺服系统用来调节调心托棍,使其转动一定的角度,要在设备安装允许的范围内,利用摩擦力来平衡跑偏时所引起的力,而检测装置能更好的控制带的跑偏。当带发生跑偏时,胶带会向一侧倾斜,利用立辊,再通过控制盒的控制,使信号发给了伺服系统,并启动了阀,使整个系统开始运行,完成胶带跑偏的调整。

本文采用的调偏装置可有效地调整胶带的跑偏,使其达到允许的范围内,从而延长带的寿命,提高其工作效率。

关键词:带式输送机;胶带; 跑偏;托辊

Abstract

In recent years, with the national economy development, specially the developm-

ent of large-scale strip mine. The belt conveyer is widely applied in the mechanical device, it will always happen that the conveyer belt runs out of way. Therefore, we must have a further study of this phenomenon.

This article introduces the reason of the belt conveyer’s run-out and the method to adjust this phenomenon, on the basis of analyzing traditional adjustment equipment, it mainly use the servo-system, the idler, the vertical idler, examined equipment, the limit switch and so on to complete the run-out adjustment and control to it. The servo system is used to adjust the idler to turn a certain angle, and use the friction to balance the run-out force within the permission scope of the installation, so that the examined equipment can control the belt deviation better. When the run-out occurs, the rubber belt can incline to one side, by using the vertical idler and controlling box to send the signal to the servo-system and start the valve, mading the whole system start to move and completing the adjustment of belt deviation.

The equipment in this article can adjust the belt’s deviation effectively, make it achieve the permission scope, lengthen the belt’s life, and enhance its working efficiency.

Key words: Belt conveyor; rubber belt; belt deviation; idler

川公网安备: 51019002004831号

川公网安备: 51019002004831号