带钢跑偏机的分析设计

51页 17000字数+说明书+外文翻译+3张CAD图纸【详情如下】

图表插图.doc

外文翻译--电液控制阀.doc

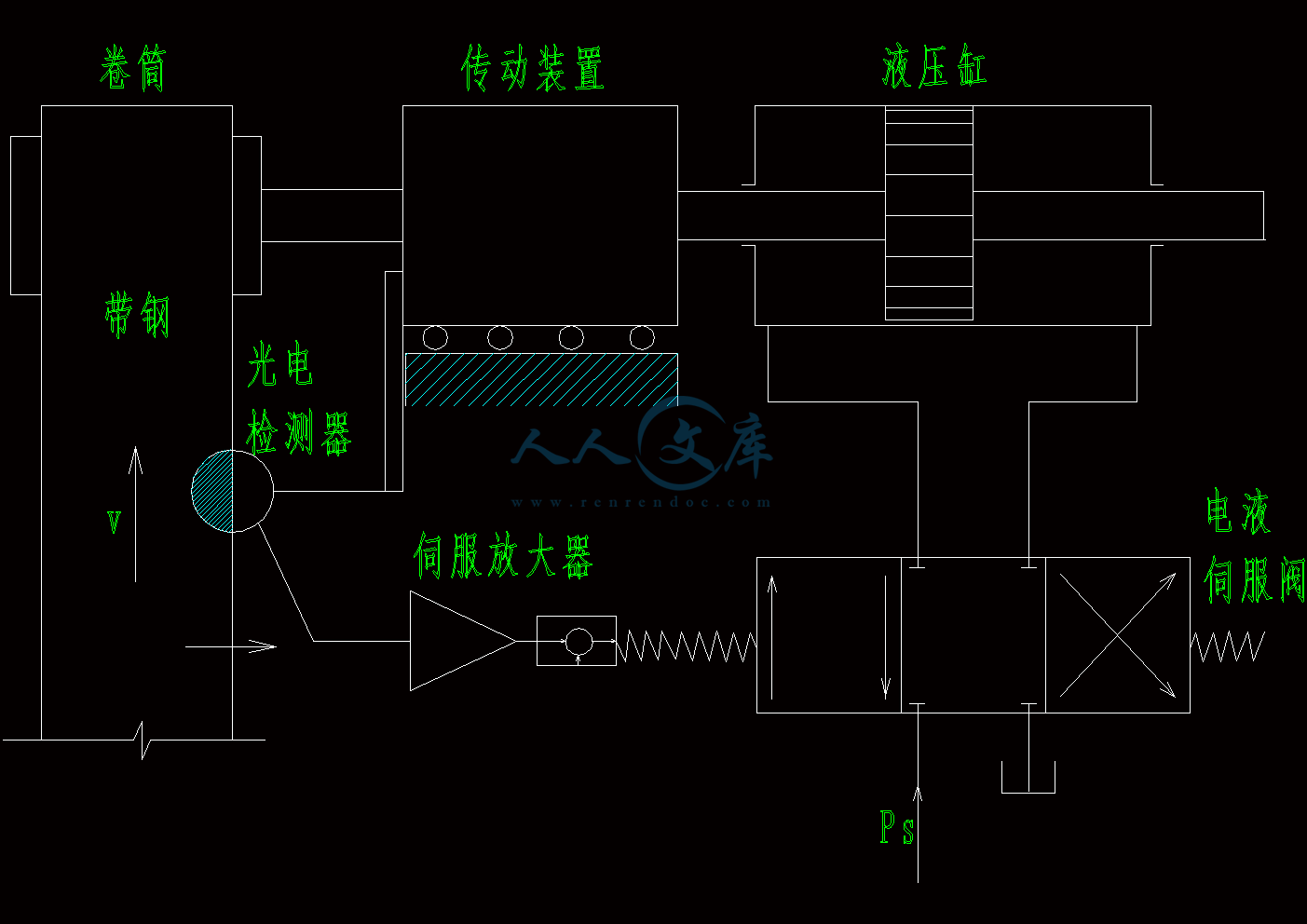

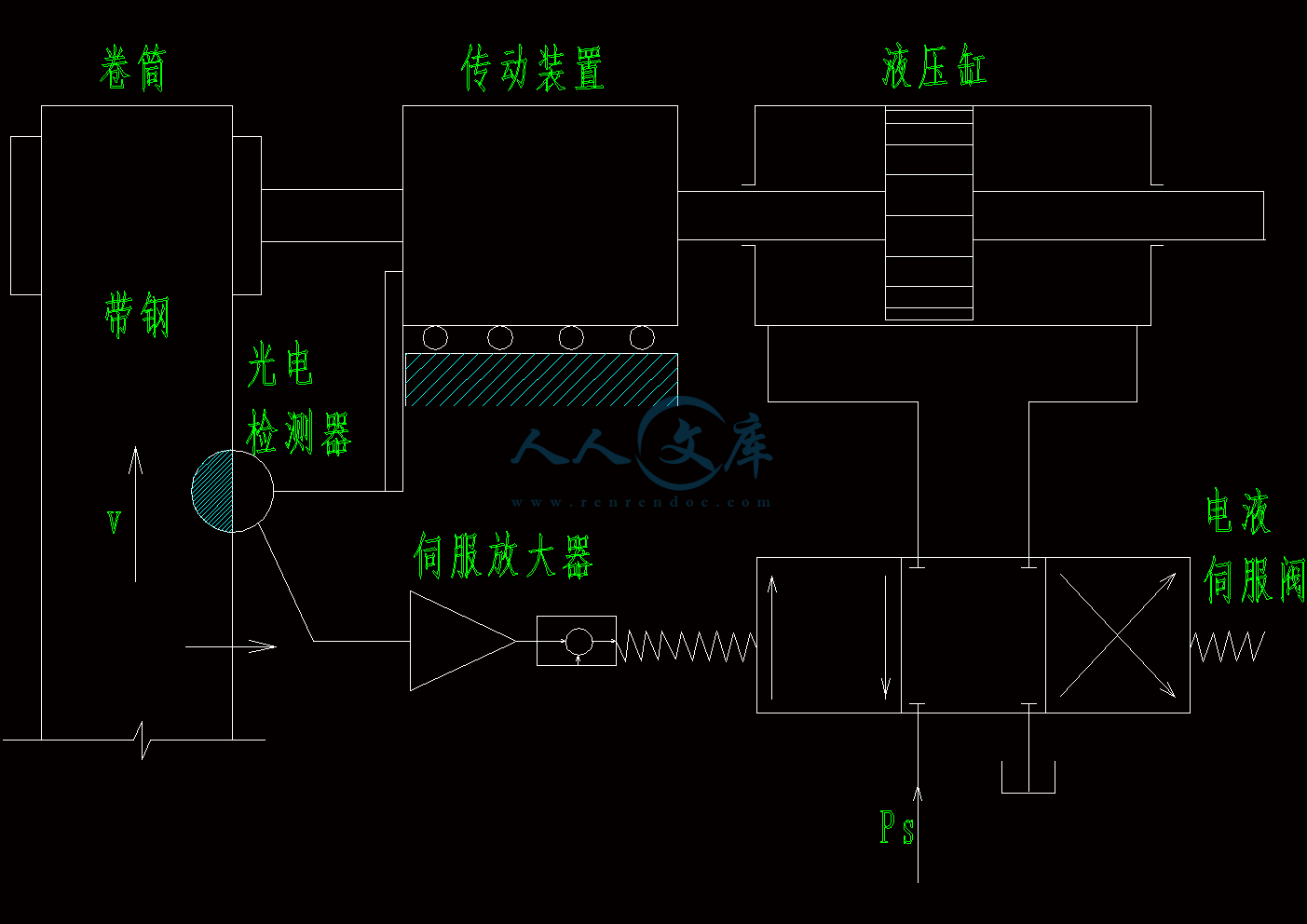

带钢跑偏控制原理图.dwg

带钢跑偏机的分析设计说明书.doc

摘要.doc

目录.doc

跑偏控制系统原理图.dwg

跑偏控制系统负载轨迹.dwg

目录

前 言1

1 绪 论2

1.1 液压控制系统的组成2

1.2 液压控制系统的分类3

1.2.1 按偏差信号的产生和传递介质不同分类3

1.2.2 按液压控制元件不同分类3

1.2.3 按被控物理量的不同分类3

1.2.4 按输入信号的不同分类3

1.3 液压控制系统的特点4

1.4 电液伺服控制系统的发展概况4

2 设计要求及方案的选择7

2.1 设计要求7

2.2 方案选择7

2.2.1 方案一:机、液型带钢跑偏控制装置7

2.2.2 方案二:电、液型带钢跑偏控制装置9

3 电液伺服机构的分析11

3.1 电液伺服阀11

3.1.1 电液伺服阀的组成11

3.1.2 电液伺服阀的静态特性11

3.1.3 电液伺服阀的传递函数13

3.2 电液伺服液压缸的分析15

3.3 电液伺服系统的数学模型17

3.4 电液位置伺服系统的特点18

3.5 电液位置伺服系统的设计原则19

3.5.1 确定主要性能参数的原则19

3.5.2 确定参数间适当的比例关系20

3.5.3 应考虑的其它因素22

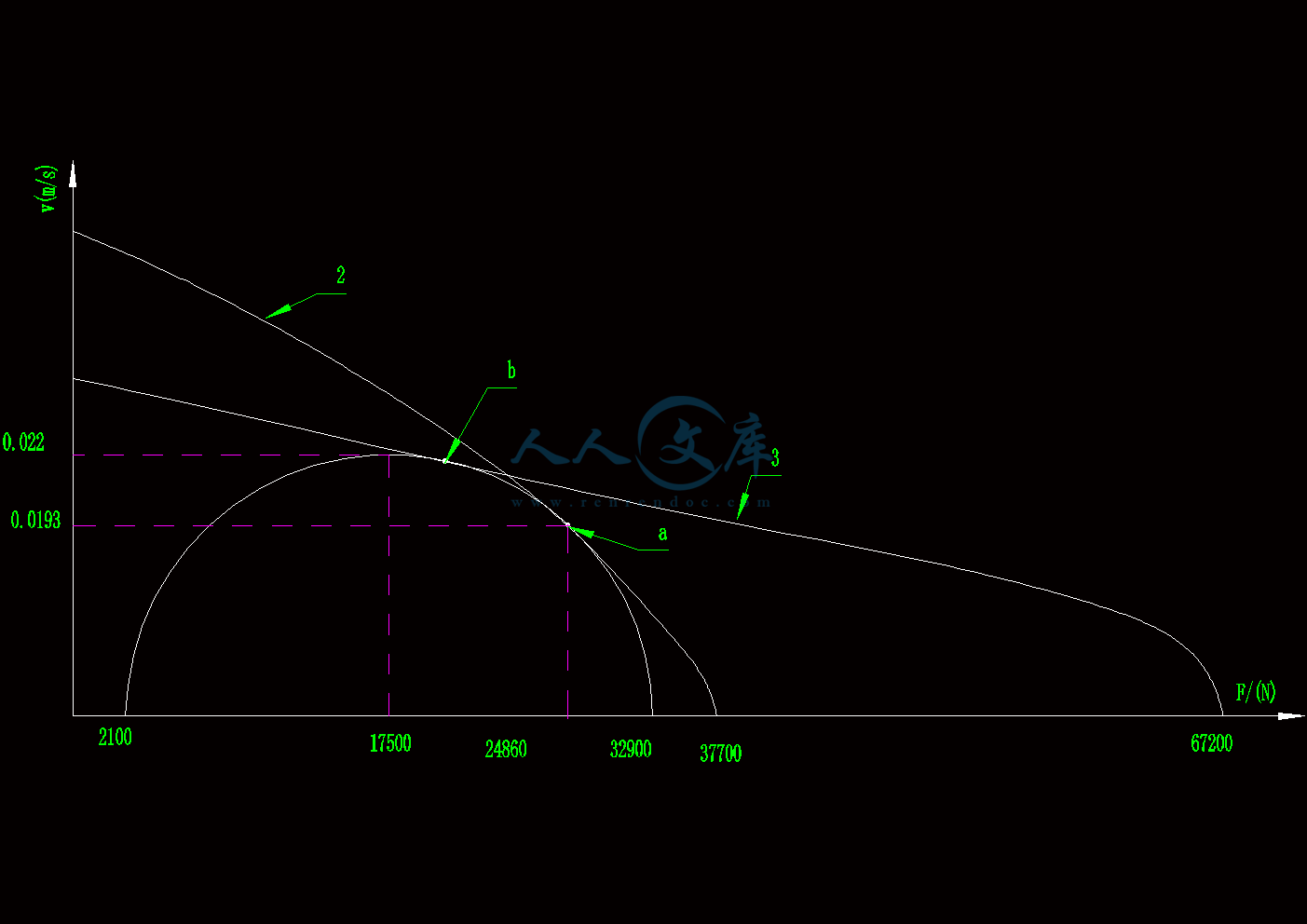

4 静、动态计算及分析23

4.1 静态计算23

4.1.1 确定供油压力23

4.1.2 根据负载轨迹或负载工况确定、23

4.1.3 选取伺服阀25

4.2 动态分析与计算26

4.2.1 求取各元件的传递函数26

4.2.2 绘制系统方块图26

4.2.3 根据系统精度或频宽要求初步确定开环增益27

5 系统的校正28

5.1 修改动力机构参数,改善系统性能28

5.1.1 确定活塞面积28

5.1.2 重新选择伺服阀28

5.1.3 系统稳定性和动态特性核验29

5.1.4 计算各项稳态误差30

5.2 系统的校正31

5.2.1 校正系统的动态分析32

5.2.2 校正后系统的误差33

6 液压能源参数选择34

7 系统的仿真35

7.1 系统PID控制器对系统的影响(I=0;D=0)36

7.1.1 取P=100时36

7.1.2 取P=150时36

7.1.3 取P=208.9时37

7.1.4 取P=300时37

7.2 改变液压缸阻尼比对系统的影响38

7.2.1 取=0.1时38

7.2.2 取=0.3时38

7.2.3 取=0.5时38

7.2.4 取=0.6时39

7.2.5 取=0.7时39

7.3 修改液压缸活塞面积对系统的影响40

7.3.1 取=1时40

7.3.2 取=时40

7.3.3 取= 3时40

7.4 无阻尼液压固有频率对系统的影响41

7.4.1 当=50时41

7.4.2 当=65.6时41

7.4.3 当=88时42

7.4.4 当=95时42

8 结论43

致 谢44

参考文献45

摘要

目前,随着电脑技术,液压控制技术的发展,电液伺服控制系统也出现了突飞猛进的成果。

带钢经过连续轧制或酸洗等一系列加工处理后须卷成一定尺寸的钢卷,由于辊系的偏差及带材厚度不均和板材不齐等种种原因,使带材在作业线上产生随机偏离现象。它使卷取机卷成的钢卷边缘不齐,直接影响包装,运输及降低成品率。所以有必要做防跑偏的控制系统,以提高工作效率。

本文在通过对带钢跑偏机理的分析设计,阐述了有关电液伺服控制系统元件的组成、结构、工作原理及发展状况,并运用现代电液伺服控制技术设计控制方案,采用MATLAB仿真,不断调节使系统达到高效、稳定的自动跑偏控制的目的。

关键词:电液伺服控制系统;仿真

液压控制技术在军事工业中,用于飞机的操作系统、雷达跟踪和舰船的舵机装置、导弹的位置控制、坦克火炮的稳定装置等。在民用工业中,用于仿形或数控机床,船舶舵机和消摆系统,冶金方面的带钢跑偏控制、张力控制、工程车辆转向系统,汽车的无人驾驶、自动变速、主动悬挂,试验装置方面的抗震试验台、材料试验机、道路模拟实验系统等。总之,液压控制技术应用愈来愈加广泛,在各个工业部门发挥着重要作用。尤其是在计算机的应用促使液压控制技术得到更迅速的发展和更广泛的应用。

2 设计要求及方案的选择

2.1 设计要求

带钢经过连续轧制或酸洗等一系列加工处理后须卷成一定尺寸的钢卷,由于辊系的偏差及带材厚度不均和板材不齐等种种原因,使带材在作业线上产生随机偏离现象。它使卷取机卷成的钢卷边缘不齐,直接影响包装,运输及降低成品率。所以有必要做防跑偏的控制系统,以提高工作效率。

已知条件与要求:

机组最大卷取速度 =5

最大钢卷质量 =15000

卷取机移动部分质量 =20000

卷取误差

移动距离

导轨摩擦系数

工作环境 冷轧车间

根据对同类机组的实测数据及统计资料,经分析确定系统的性能指标为

系统误差

系统频宽

最大工作速度

最大加速度

2.2 方案选择

根据主机参数及其控制系统要求,现在对现有两种控制方案进行对比:

2.2.1方案一:机、液型带钢跑偏控制装置

该跑偏控制装置由两个先导阀、主阀(液动型零开口四通滑阀)、双出杆对称液压缸、无外动力液压油源等组成。其工作原理如图2-1所示。

两个锥阀既作为检测带钢对中与否的传感器, 又是主阀的先导阀。其结构见图2-2。先导阀阀芯为带平衡活塞式结构, 靠弹簧复位; 滑轮及连杆靠螺纹与阀芯相联并可调零; 主阀为液动型零开口四通滑阀, 其结构见图2-3。

川公网安备: 51019002004831号

川公网安备: 51019002004831号