ZFS10000-25-45中位放顶煤液压支架设计

1000页 34000字数+说明书+任务书+外文翻译+6张CAD图纸【详情如下】

ZFS10000-25-45中位放顶煤液压支架设计说明书.doc

任务书.doc

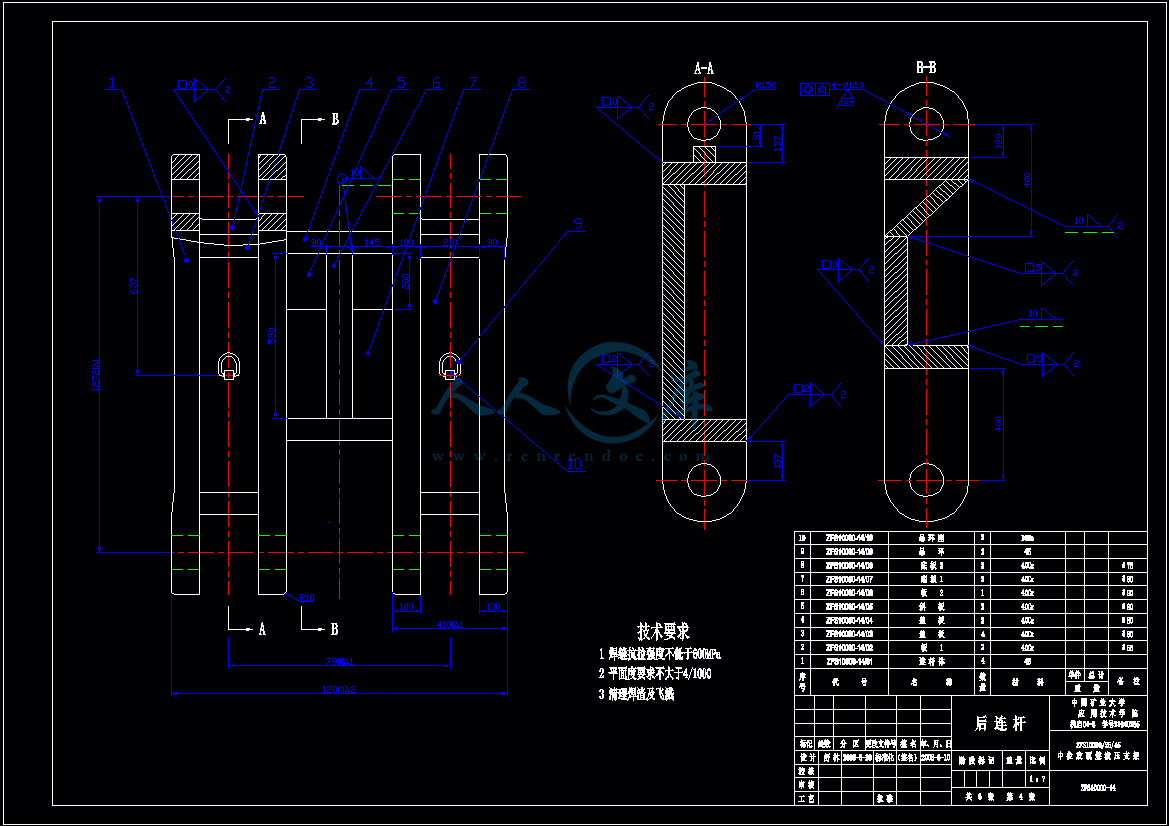

后连杆A2.dwg

外文翻译--液压支架.doc

封皮.doc

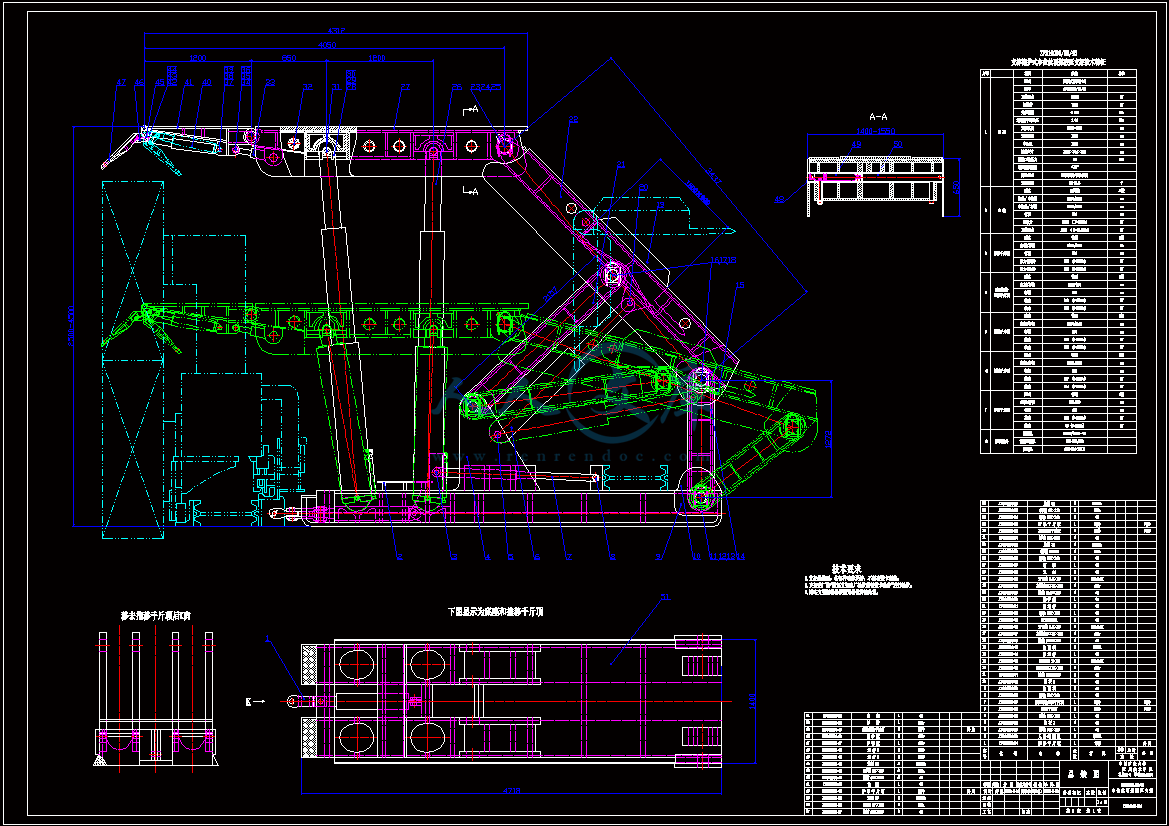

底座装配图A0.dwg

总装图A0.dwg

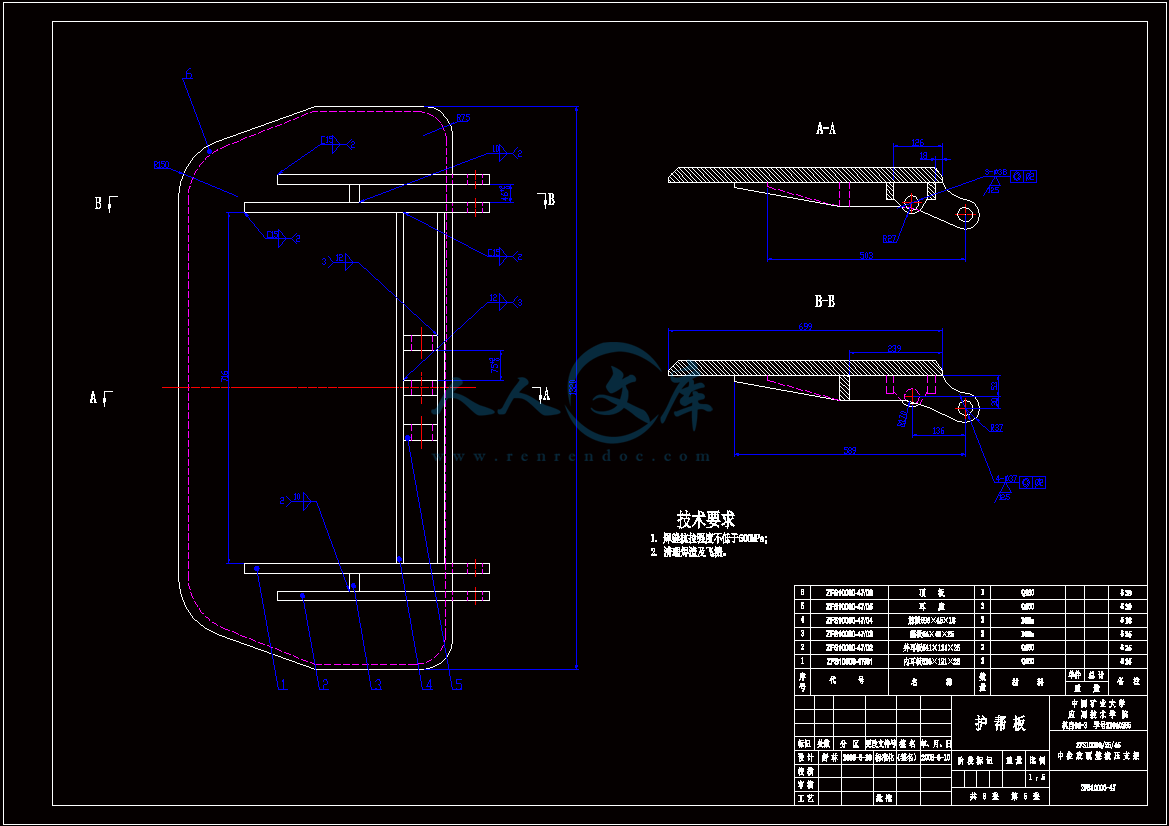

护帮板A2.dwg

摘要.doc

液压系统图A3.dwg

目录.doc

顶梁装配图A0.dwg

目录

1 序论 1

1.1 国内外液压支架的现状1

1.1.1 国外液压支架现状1

1.1.2 国内液压支架技术现状2

1.2支护设备的用途和种类3

1.3液压支架工作原理3

1.4液压支架的分类6

1.5液压支架结构9

1.5.1支撑式支架9

1.5.2掩护式支架10

1.5.3支撑掩护式支架11

1.5.4放顶煤液压支架12

1.6 液压支架的设计目的、要求和基本参数14

1.6.1设计目的14

1.6.2对液压支架的基本要求14

1.6.3设计液压支架必需的基本参数15

2 液压支架的结构设计15

2.1 液压支架的主要尺寸的确定15

2.1.1液压支架以及配套设备的型号15

2.1.2支架高度和伸缩比16

2.1.3支架间距的确定17

2.1.4顶梁尺寸的确定17

2.1.5底座尺寸的确定19

2.1.6立柱布置19

2.2四连杆机构的确定19

2.2.1四连杆机构的作用19

2.2.2四连杆机构的设计要求20

2.2.3四连杆机构设计方法的选择21

2.2.4求解过程23

2.3支架在工作面的通风断面积验算26

2.4各部件结构选择27

2.4.1顶梁27

2.4.2立柱29

2.4.3掩护梁和四连杆机构31

2.4.4底座31

2.4.5侧护板34

2.4.6千斤顶35

2.5液压支架性能参数的确定37

2.5.1支护强度37

2.5.2支护面积38

2.5.3支架的有效工作阻力38

2.5.4确定立柱的技术参数38

2.5.5泵站压力的确定39

2.5.6千斤顶参数的确定39

3 液压支架的强度设计39

3.1概述39

3.1.1液压支架工作状态39

3.1.2计算载荷的确定40

3.2液压支架受力分析与计算41

3.2.1支架整体受力分析43

3.2.2顶梁的受力分析与计算43

3.2.3掩护梁的受力分析与计算46

3.2.4底座的受力分析与计算48

3.3顶梁载荷分布49

3.4底座接触比压50

4 液压支架的强度计算53

4.1强度条件53

4.2液压支架的强度校核54

4.2.1前梁强度校核54

4.2.2主顶梁强度校核58

4.2.3底座强度校核64

4.2.4 掩护梁的强度校核69

4.2.5 前梁千斤顶的强度验算73

4.2.6立柱强度校核75

4.2.7 前连杆强度校核及对应销轴 82

4.2.8 后连杆强度校核及对应销轴 84

5 液压支架的液压系统 85

5.1立柱和千斤顶86

5.2支架液压阀87

5.2.1液控单向阀87

5.2.2安全阀87

5.2.3操纵阀88

5.3液压支架液压原理图88

5.4液压支架的控制方式89

5.4.1手动控制89

5.4.2自动控制89

5.5液压系统安装、调试、保养89

5.5.1安装89

5.5.2调试92

5.4.3保养93

结论94

参考文献95

摘 要

中位放顶煤液压支架的放煤口位于支架高度的中部,即掩护梁上。工作面为双输送机,一前一后分别运输采煤机的落煤和放落的顶煤。由于工作面有两套独立的出煤系统,采煤和放煤间干扰较少,可以实现采、放平行作业,提高工作面生产率。中位放顶煤液压支架是当前我国应用数量较多,分布面较广的综放支护设备。它已不仅是一种单纯维护工作面空间的支护设备,还是一种依靠矿山压力破碎煤体,具有放煤功能的综采设备。

本次设计的四连杆中位放顶煤液压支架ZFS10000/25/45,有顶梁、底座、掩护梁、立柱、前后连杆等几部分组成。放煤口设在掩护梁上,采用两部输送机,架型为支撑掩护式,适用于厚煤层的开采。由于该支架采用了四连杆机构,因而受力状态好,抗扭能力强。因此,该四连杆型式的放顶煤支架适合于倾角较大煤层的放顶煤开采。

此支架具有受力状态好,抗扭能力强,不易倒架,不易损坏且煤尘较小等优点,其不足之处为:(一)后输送机置于底座上,挡煤板与架间浮煤易损坏中部槽,人工清理浮煤劳动强度大,效率低;(二)由于掩护梁不能摆动,仅靠放煤机构对跨落下来的大块煤进行二次破煤的能力欠佳。

关键词:四连杆; 中位放顶煤; 液压支

ABSTRACT

The position puts against the coal powered supports to put the coal mouth to be located in the middle of supports, on the caving shield.The working surface has two conveyors, tandem separately transport the loader to fall the coal and to put against the coal.Because the working surface has two set of independent coal systems, mining coal and puts the coal room disturbance to be few, may realize pick and put on parallel operations, enhances the working surface productivity.The position puts against the coal powered supports are now adopt most in our country, the distribution are abroad synthesis of support and protect equipments. Not only it was already one kind of pure maintenance work space of support and protection equipments, one kind of dependence underground pressure broken pulverized coal body, had puts the coal function the synthesis to pick the equipment.

In this design four-bar the position puts against coal powered support ZFS10000/25/45. It consists of canopy, base plate, caving shield, hydraulic legs, front and rear lemniscate bars and so on. The coal mouth is located in the caving shield, uses two conveyors, the support type is chock shield, is suitable in thick seam mining.Because the support has used four-bar mechanism, the stressful condition is good, has stable torsional ability. Therefore, the four-bar type puts against the coal support to suit in the big inclination angle coal puts against coal mining.

This support has the good stressful condition , has stable torsional ability, not easy to lose face, not easy to damage also the coal dust is small and so on,.Its deficiency is: (1) Back conveyor puts base plate, keeps off the coal board and the bay floats the coal easily to damage the trough, the hand cleaning floats the coal labor intensity to be big, the efficiency is low; (2) Because caving shields are not able to swing, only depends on put the coal organization to the big lump coal which cross falls down to carry on two times broken coal abilities unsatisfactory.

Keywords:Four-bar; put the coal in the middle of supports; powered supports支护设备的用途和种类

回采工作面支护设备用于支撑工作面顶板、阻挡顶板冒落的岩石窜入作业空间,以保证工作面内机器和人员安全生产。

目前回采工作面使用的支护设备有金属摩擦支柱、单体液压支柱和自移式液压支架,它们与采煤机和工作面输送机分别组成“普采”、“高档普采”和“综采”。

金属摩擦支柱和单体液压支柱与金属铰接顶梁配套使用(统称单体支护设备),它们的支撤和移动都靠人工操作,故劳动强度大、安全性较差、支撤速度慢、工作面产量和效率较低。

近年来新发展的切顶支柱和滑移顶梁支架为进一步改善普采工作面的劳动条件和技术经济效益提供了途径。

液压支架是以高压乳化液作为动力,使支架的支撑、切顶、移架和输送机推移等工序全部实现了机械化。因而大大改善了回采工作面的作业环境,使矿工们从笨重的体力劳动中解放出来,有效地提高了劳动安全性,并为工作面实现自动化创造了条件。同时也大大提高了回采工作面的技术经济效益。但液压支架的初期投资较大。

木支柱在机械化采煤工作面仅用于临时性辅助支护,如处理顶板事故等。

1.3 液压支架工作原理

液压支架的主要动作有升架、降架、推移输送机和移架。这些动作是利用乳化液泵站提供的高压液体,通过液压控制系统控制不同功能的液压缸来完成的。每架支架的液压管路都与工作面主管路并联,形成各自独立的液压系统(图1—1),其中液控单向阀和安全阀设在本架内,操纵阀可设在本架

内,前者为本架操作,后者为邻架操作。

川公网安备: 51019002004831号

川公网安备: 51019002004831号