道路地下打孔机设计

80页 30000字数+说明书+任务书+14张CAD图纸【详情如下】

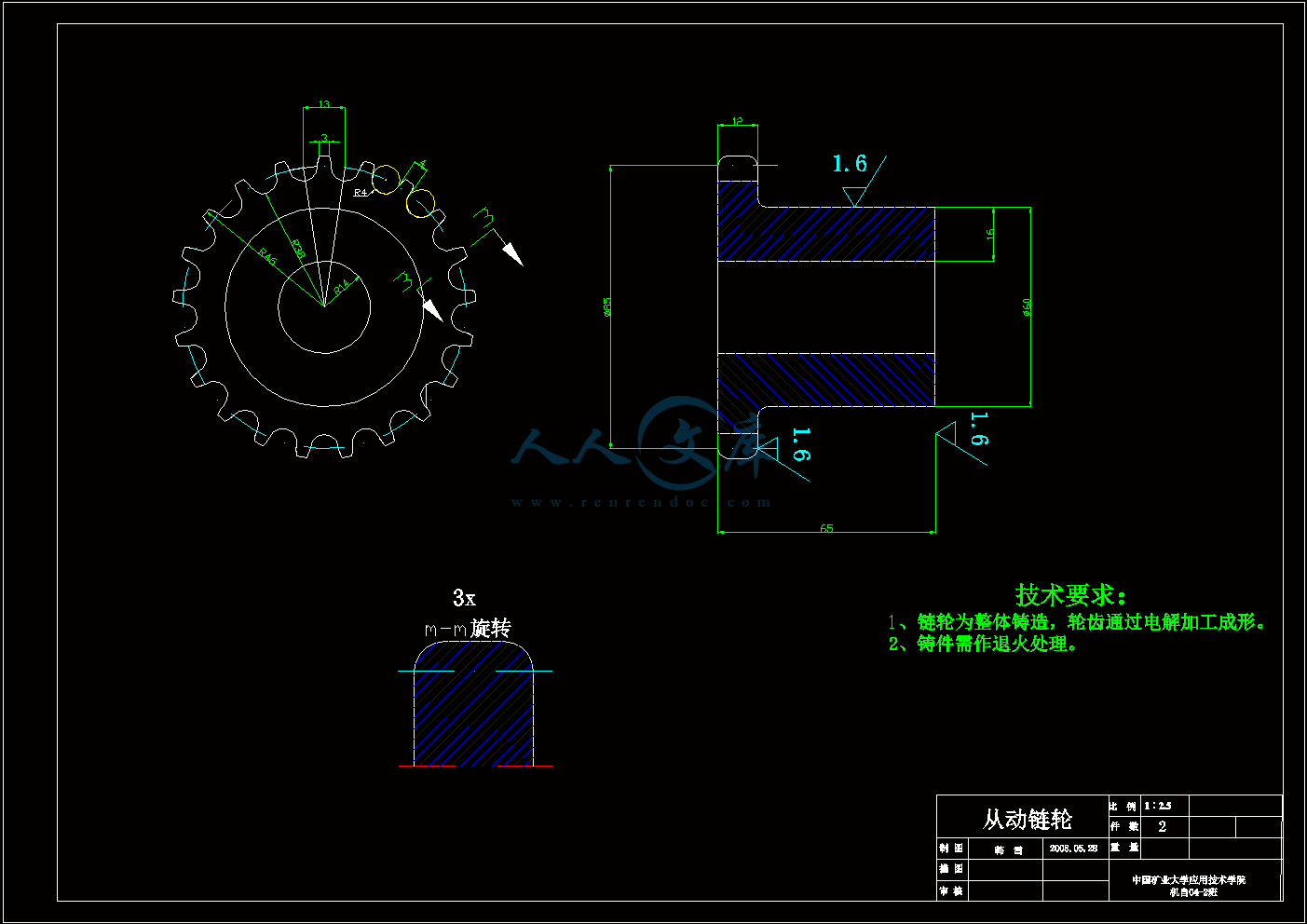

从动链轮.dwg

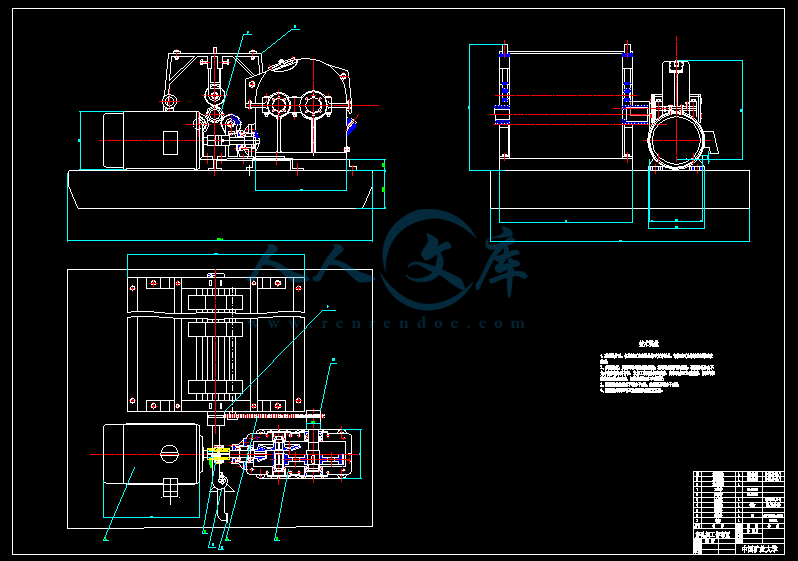

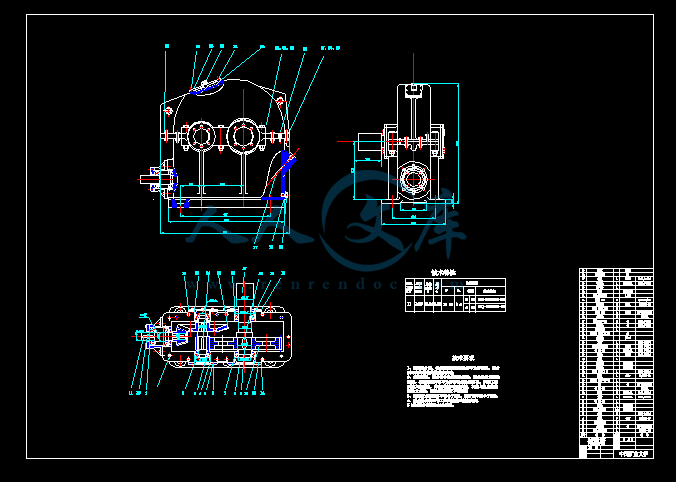

减速箱.dwg

封皮.doc

总装图.dwg

摘要任务书,目录.doc

支架.dwg

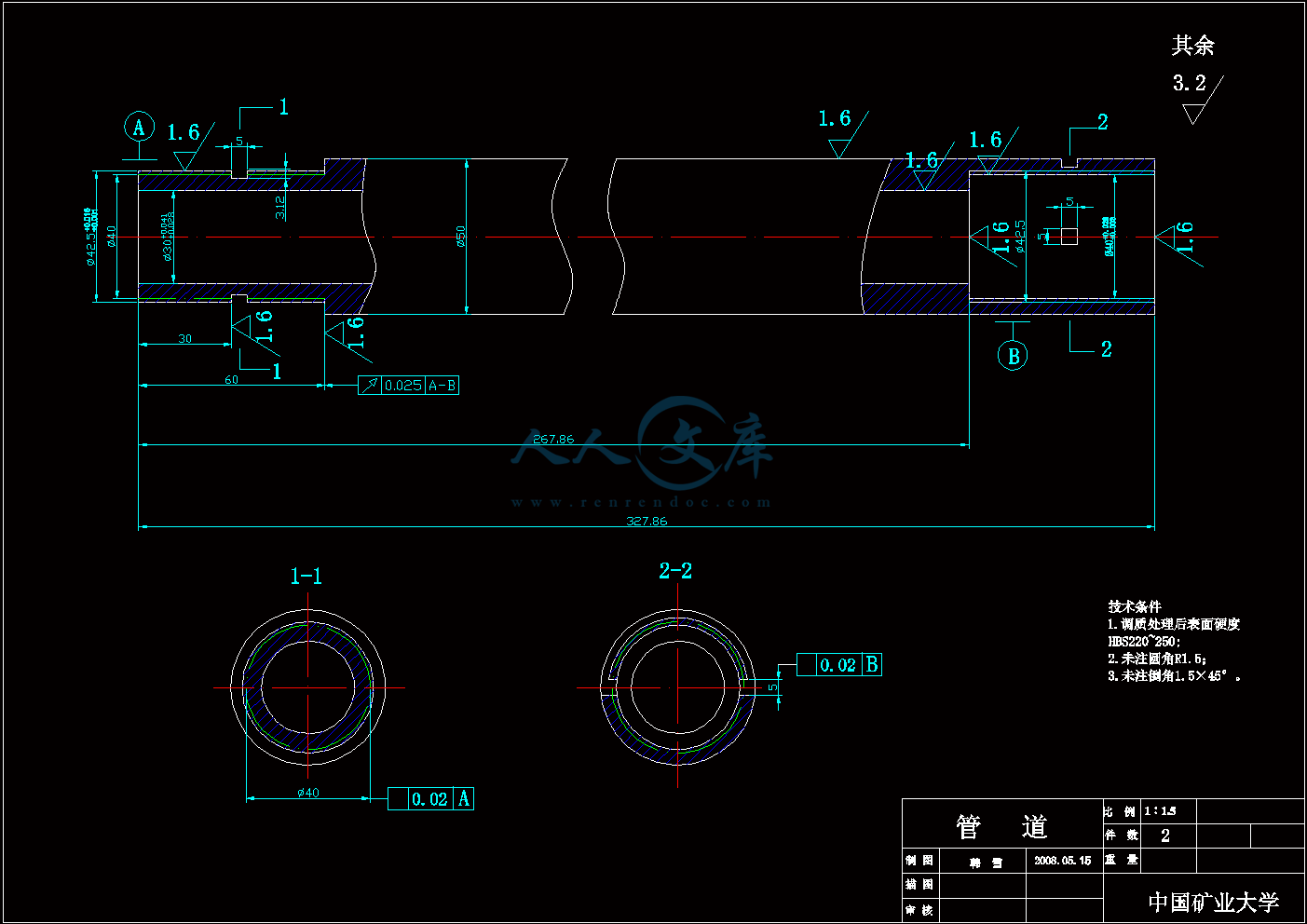

管道.dwg

输入轴.dwg

道路地下打孔机设计说明书.doc

钻头.dwg

锥齿轮.dwg

目 录

一、绪论2

1.1打孔机简介与种类2

1.2打孔机得发展情况4

1.3.研究得背景与意义4

二、总体设计方案确定及动力元件选择6

2.1总体设计的要求6

2.2机型与传动形式得选择6

2.2.1机型得选择6

2.2.2传动形式的选择7

2.3打孔机的整体布局7

2.3.1打孔机得总体布局7

2.3.2打孔机的驱动和动力输入方式7

2.3.3打孔机整体参数确定8

2.4钻机的功能单元及实现方法11

2.4.1钻具11

2.4.2回转机构11

2.5电动机的选型12

三、减速装置设计13

3.1传动比确定及各级传动比分配13

3.2运动参数及动力参数计算14

3.2.1计算各轴转速14

3.2.2计算各轴的功率14

3.2.2计算各轴的功率15

3.3齿轮传动的设计计算15

3.3.1第一级齿轮传动副的设计计算15

3.3.2第二级齿轮传动副的设计计算18

3.3.3三级齿轮传动副的设计计算22

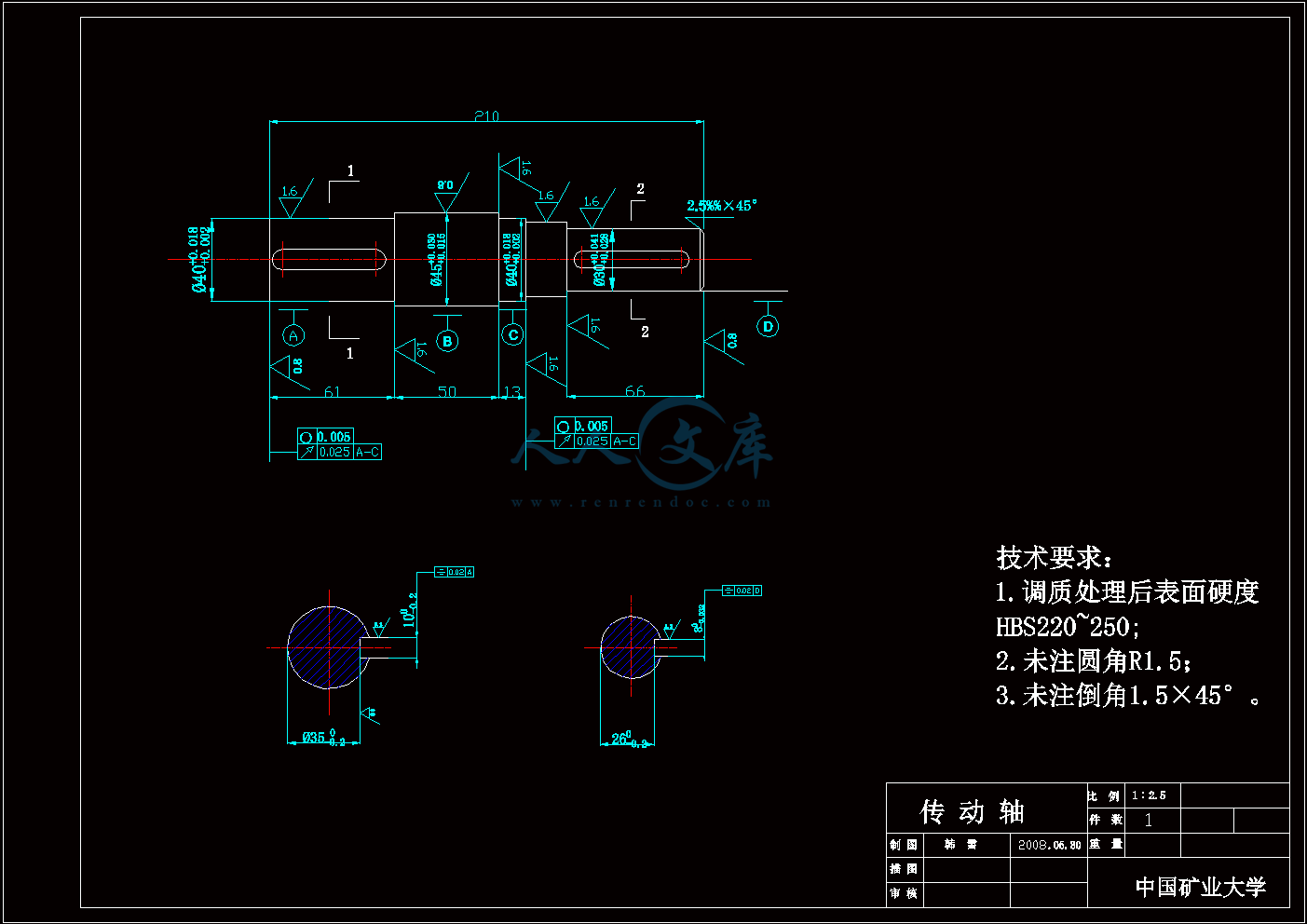

3.4传动轴的设计25

3.4.1第一传动轴的设计及计算25

3.4.2第二轴的结构设计及计算29

3.4.3三轴的结构设计及计算35

3.5减器箱体结构尺寸39

3.5.1结构尺寸39

3.5.2油标41

3.5.3通气罩41

3.5.4.螺塞42

四、链传动设计42

4.1链传动的特点42

4.2链的类型43

4.3链传动选择44

五、支架的设计50

5.1.机架设计准则50

5.2.支架的效核51

5.3梁的效核53

5.4传动轮的设计53

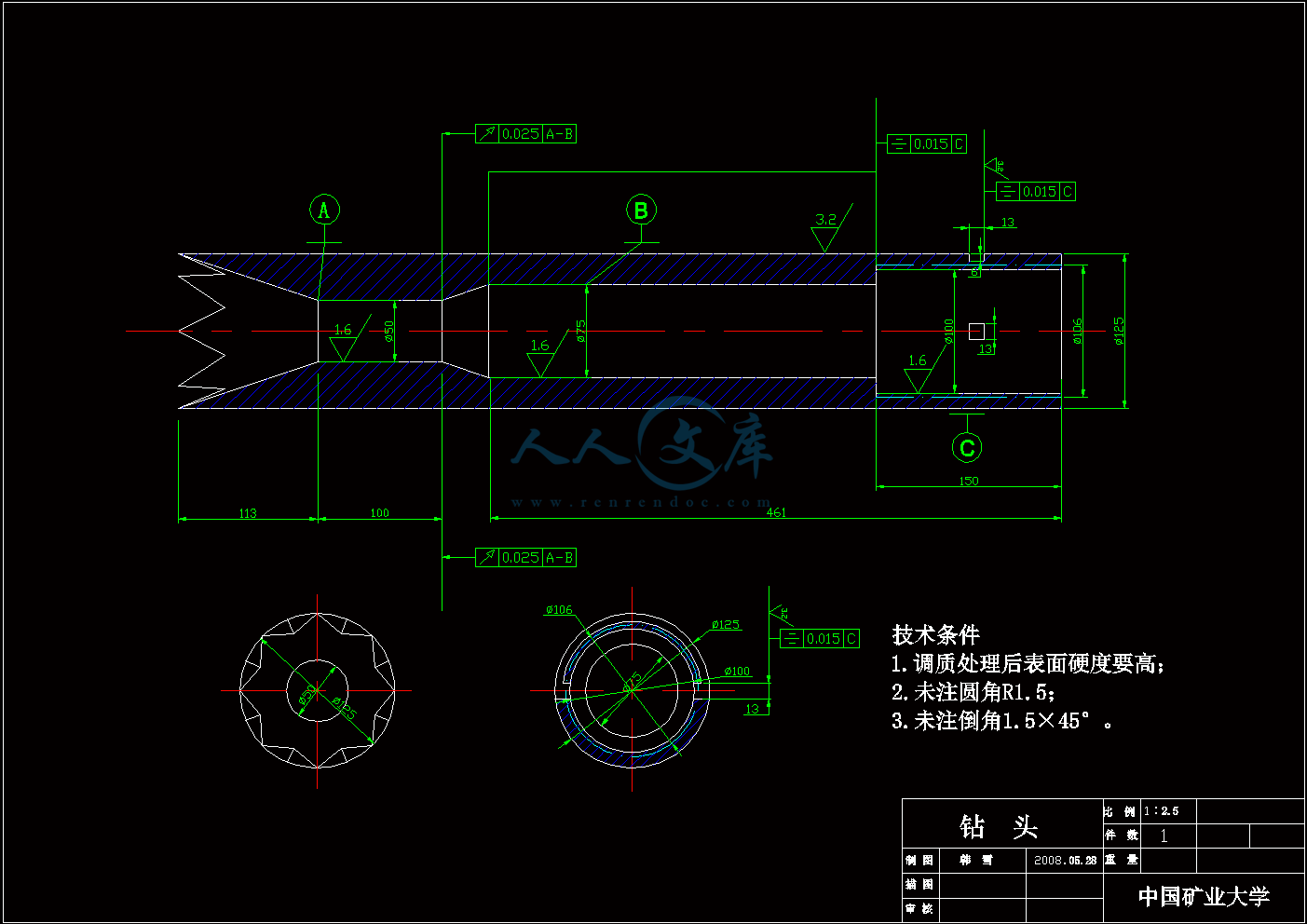

六、钻杆钻头的设计54

6.1钻杆在扩孔时的作用55

6.2扩孔器55

6.3转速的确定56

6.4钻进液量的确定56

6.5管线回拖工艺57

6.6导向钻进58

6.6.3泥浆的蓦本性能60

6.6.4泥浆处理剂61

6.7冲击回转钻进原理61

七、钻头的设计66

7.1吹洗孔和排粉槽67

7.2钻头体硬度68

7.3钻头布齿68

7.4扩孔钻头70

7.5力学模型中的几个简化处理量72

7.6模型建立72

7.7小结76

八、底座的设计77

结束语79

参考文献79

翻译部分80

英文原文80

中文译文86

致谢89

摘 要

道路地下打孔机是用于地下钻孔的机器。它广泛用于地质侦探、矿产侦探、水文水井钻凿、工程建筑的基础施工、矿山开采及其他各种用途的钻探生产中。目前,打孔机已发展成为品种众多、门类较齐全的专业机械。

设计钻机时,首先应以保证设计的打孔机能高效、优质、安全、低耗完成打孔为前提,使设计的钻机技术先进、经济合理,具有良好的经济技术指标。

本次设计的打孔机,是针对于小规模的打孔。综合考虑了所有相关问题,设计的一款地下打孔机。本文从理论到实践对水平定向道路地下打孔机设技技术及方法进行了系统的分析和研究,特点是针对当前的定向钻进施工过程中在应用方面存在的

问题进行了较深入的分析,从工程实施的角度出发,着重论述了如何提高定向钻

机在地下管线铺设中的安全性和施工质量,即采用钻机铺设地下管线应以前期的

资料收集、地层分析及地下管网探测为前提和基础,以定向轨迹的设计和计算为理论依据。

定向钻孔的施工是关键,个组件满足使用条件是重要保证。

关键词:打孔机、钻头、钻杆

ABSTRACT

Road underground drilling machine is used for underground drilling machines. It is widely used geological detective, Detective mineral, water well drilling, construction of the foundation construction, mining and other purposes, drilling production. At present, the drilling machine has developed into many species, the professional classes more complete machinery.

Design rig, the first should be to ensure that the design of the drilling mechanism efficient, high quality, safe, low completion of drilling as the prerequisite to the design of the rig technologically advanced, economically rational, has a good economic and technical indicators.

The design of the drilling machine, is to address small-scale drilling. Comprehensive considered all the relevant issues, a design of the underground drilling machines. This article from theory to practice on the ground floor level of road directional drilling technology and technology-based methods for the analysis and research system, characterized by a view of the current construction of directional drilling in the process of the application Issue a more in-depth analysis, from the perspective of the project, focused on how to improve the Directional Drilling Machine in the laying of underground pipeline in the safety and construction quality, that is used to rig the laying of underground pipeline to the pre -Data collection, analysis and formation detect underground pipe network as the prerequisite and basis for directional path to the design and theoretical basis for the calculation.

Directional drilling the construction is the key, component meet the conditions of use is an important guarantee

Key words: drilling machine, drill, drill pipe

川公网安备: 51019002004831号

川公网安备: 51019002004831号