高楼火灾逃生器设计

36页 14000字数+说明书+外文翻译+8张CAD图纸【详情如下】

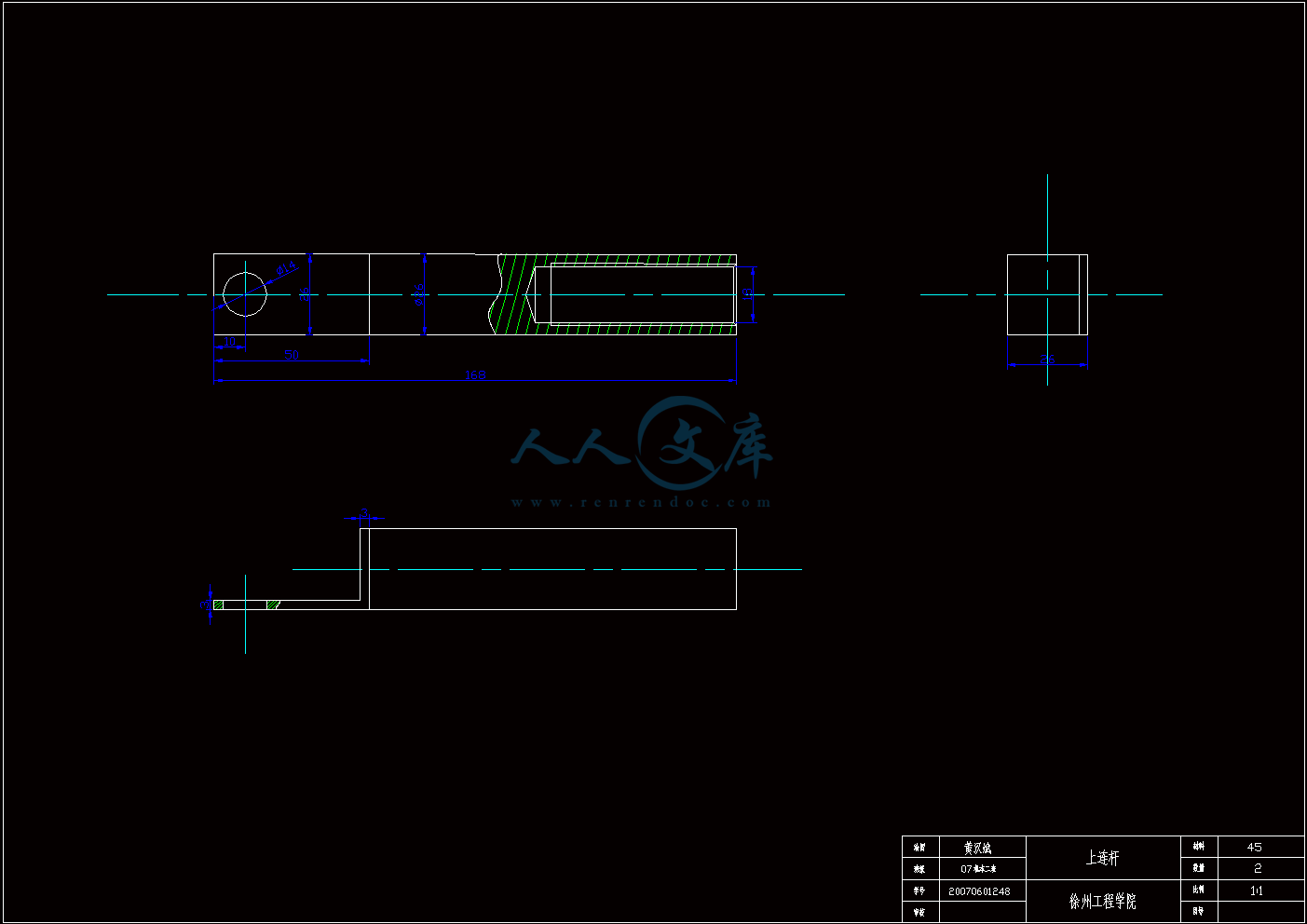

上连杆.dwg

中连杆.dwg

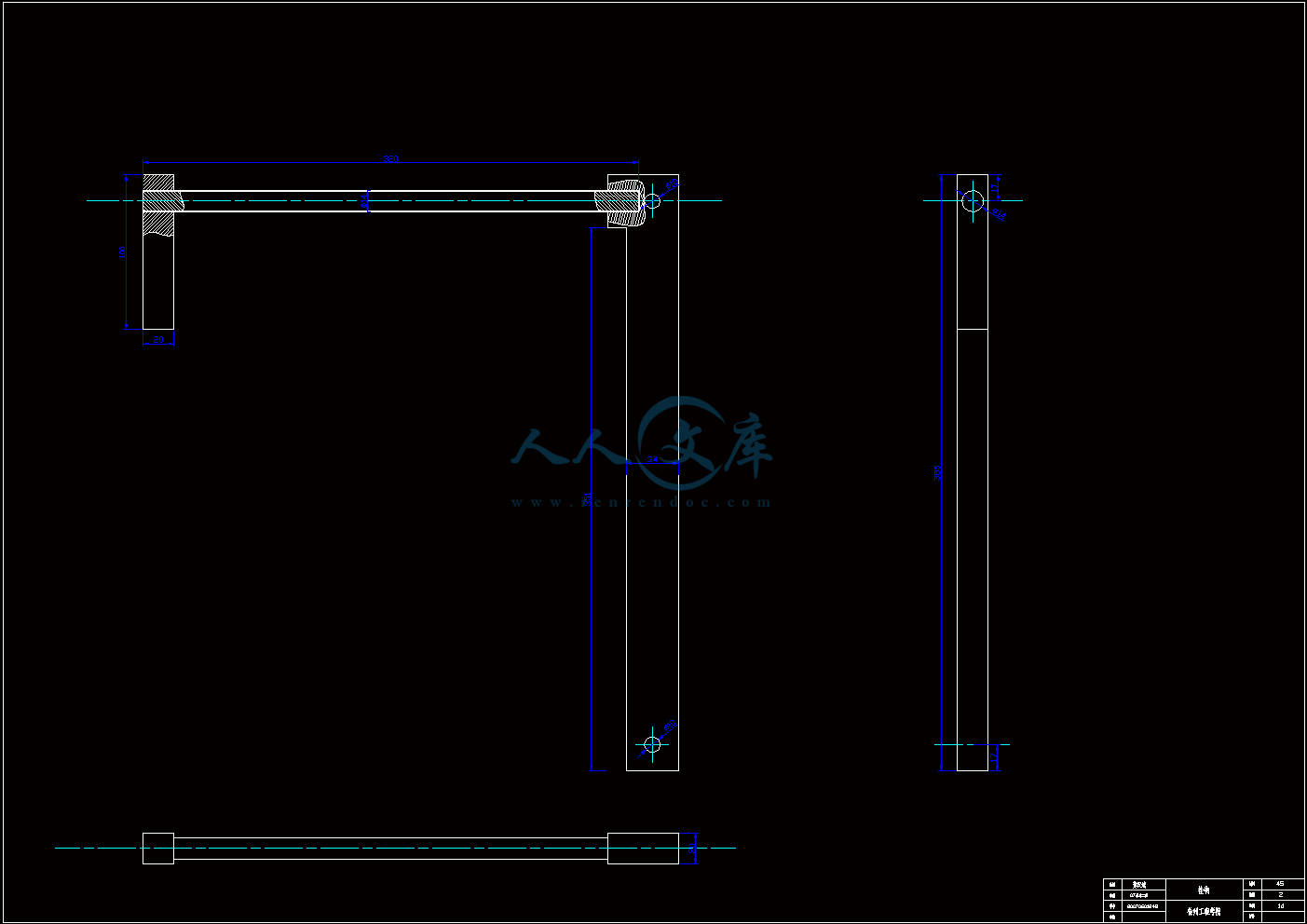

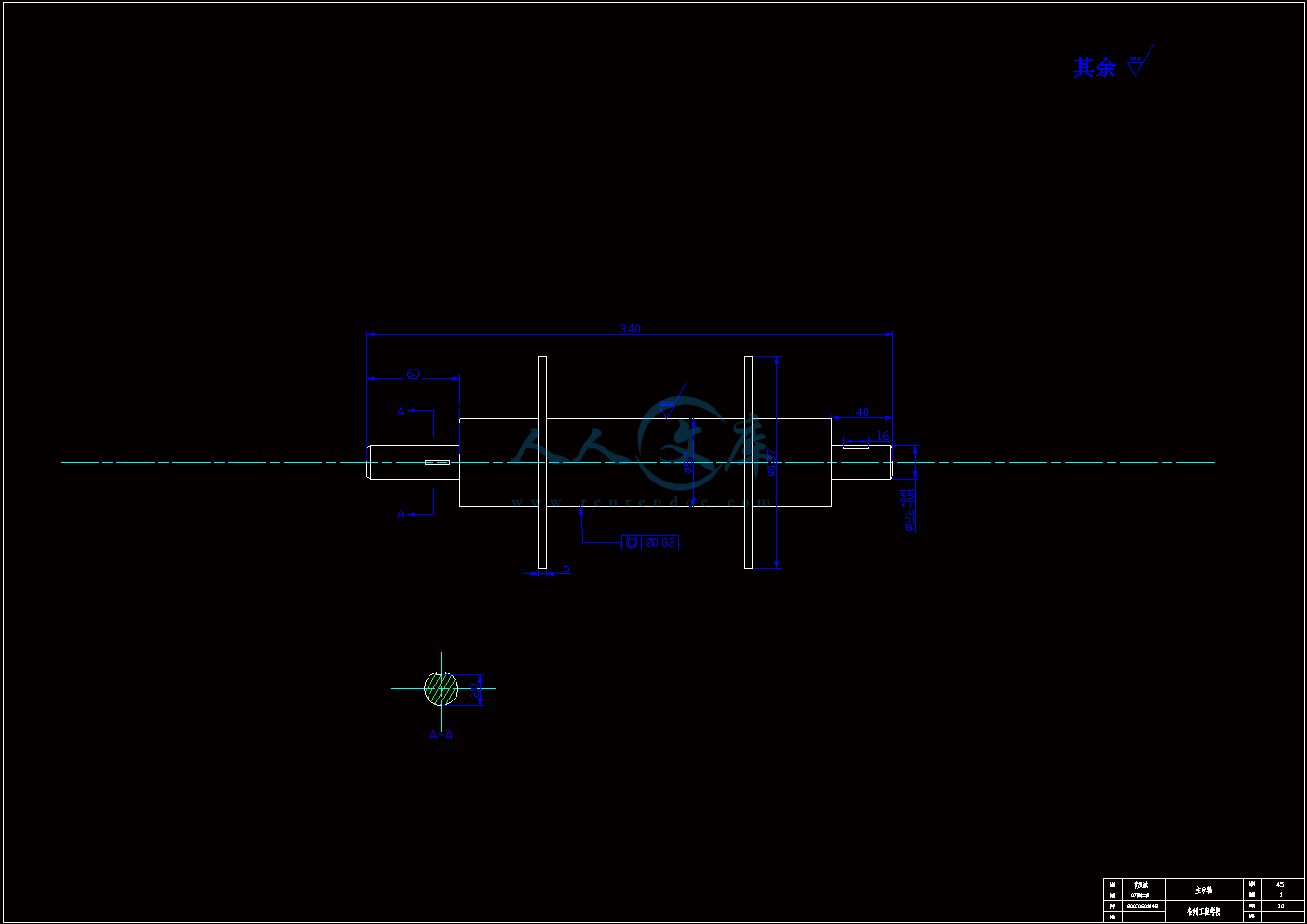

主动轴.dwg

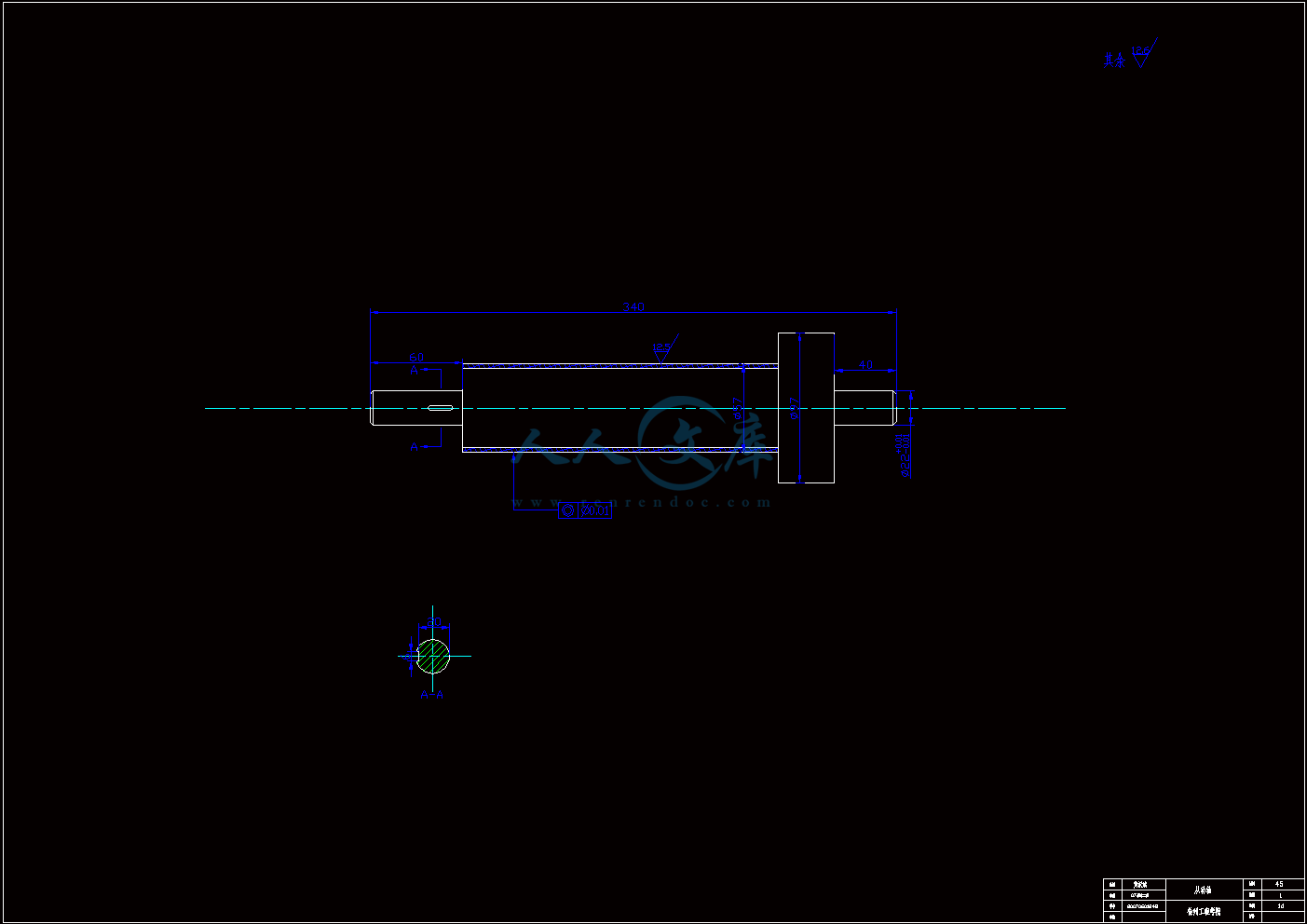

从动轴.dwg

外文翻译--以知识为基础的方法在机械产品设计任务中的实施.doc

挂钩.dwg

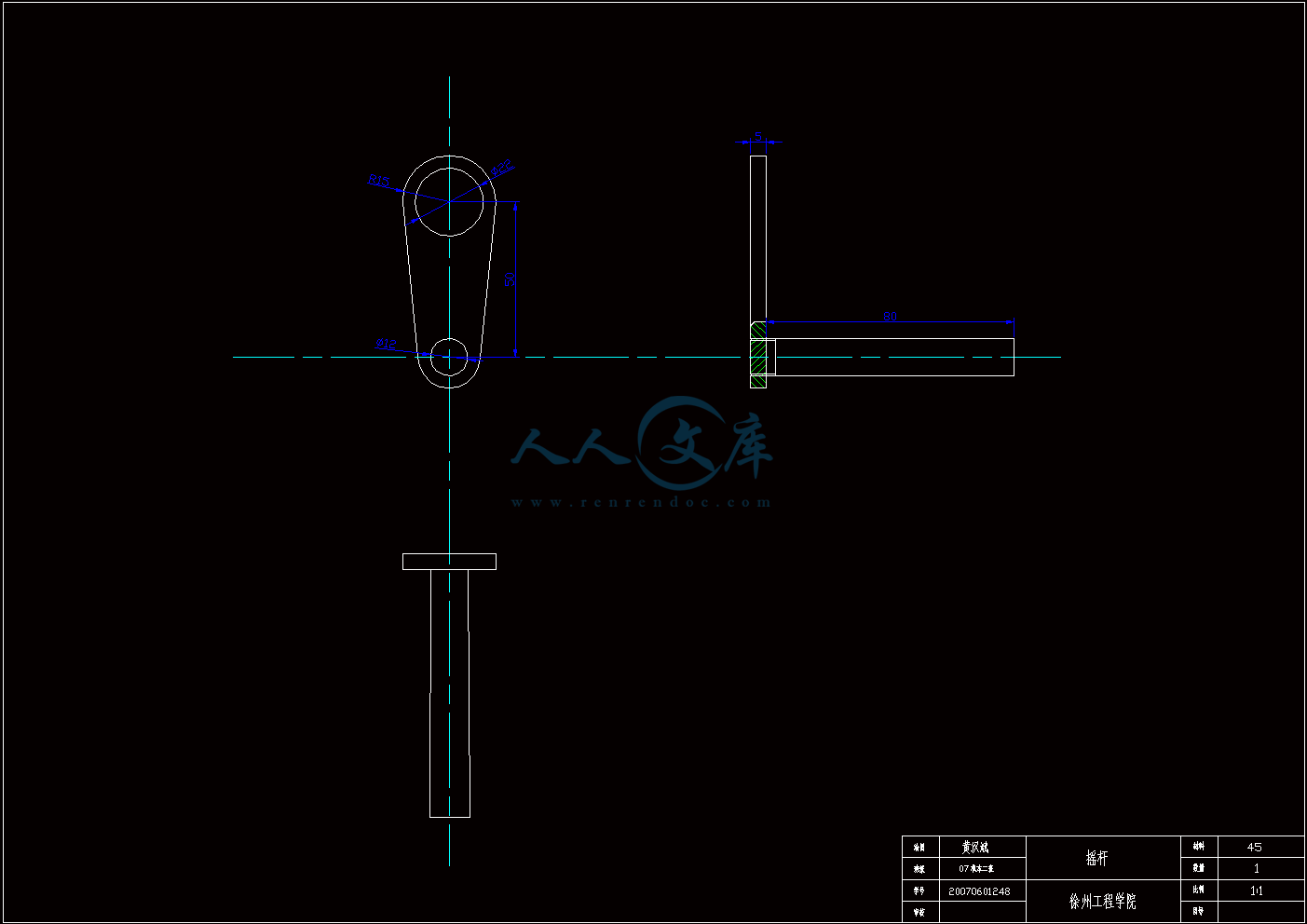

摇杆.dwg

板件.dwg

装配图.dwg

说明书.doc

高楼火灾逃生器设计说明书.doc

目 录

摘要II

AbstractIII

1 绪论1

1.1 设计背景及意义1

1.2 国内外研究概况2

1.3 高楼火灾逃生器的实例3

1.3.1 内凸轮式高楼火灾逃生器3

1.3.2 涡轮蜗杆式高楼火灾逃生器4

1.3.3 钢丝绳防滑逃生装置4

1.3.4 心摩擦式高楼火灾安全逃生器5

2 整体方案设计6

2.1 方案构设6

2.1.1 方案一6

2.1.2 方案二9

2.1.3 方案三11

2.2 方案的比较与选择12

3 装置零部件设计13

3.1 轴的设计13

3.1.1 轴的概述13

3.1.2 主动轴的设计14

3.1.3 从动轴的设计15

3.2 齿轮的设计16

3.2.1 齿轮的概述16

3.2.2 齿面接触疲劳强度和齿根弯曲强度设计16

3.3 棘轮的设计20

3.3.1 棘轮的概述20

3.3.2 棘轮的设计21

3.4 其他零部件的设计选择22

3.4.1 标准件的选择22

3.4.2 安全座椅的选择23

3.4.3 挂钩的设计24

4 计算和验证24

4.1 静力学平衡计算25

4.2 绕绳的计算26

4.3 速度计算26

结论29

致谢30

参考文献31

摘要

本文从开始介绍了高楼逃生装置的背景和研究意义,并对现有的一些高楼逃生装置进行了分析和对比,发现大多数的装置有成本高、机构复杂、安全系数低等一些不足之处。本设计根据机械创新理论,设计出一种基于负反馈闭环系统的高楼逃生装置,该装置具有成本低、操作简单、安全系数高、纯机械无电气结构等优点,最后通过对设计机构的零部件进行计算,得出整个机构的图形,在多次试验和计算之后,确定了不论是小孩还是老人都能从高楼平安降落到地面,达到了本次设计的目的。

关键词 高楼火灾逃生器;机械创新理论;往复;可控

1 绪论

1.1 设计背景及意义

随着建筑高度的增加和日趋密集,建筑的安全隐患也越来越多,即使在发达国家的高楼遇有火灾、爆炸等事件时,由于时间、空间等诸多因素的限制,人员自救逃生也是一个急待解决的重要问题。高楼火灾的有效救援和应急逃生,已经成为人们高度关注的社会问题。高层建筑一般功能较多,内部通道和外部环境情况复杂,一旦发生火灾,由于烟囱效应,火势和浓烟就会迅速扩大,很短时间内蔓延到内部楼梯和走廊,封锁正常的疏散通道,至使楼上被困人员无法逃生。所以逃生人员自救是一个亟待解决的重要问题。高楼突然失火或其他灾难发生时 ,电梯不能用,楼梯阻塞,而一般地面救援装备的举高和投射能力又远远的落后于高层建筑的高度发展而且装备体积庞大受道路交通,建筑周边环境等方面的影响因而延误救援时机,这样的情况每年都有发生 ,也有很多人因无法逃生而遇难,所以怎样快速有效的逃离火灾建筑成了决定生死的问题,而高楼逃生装置在这样的环境下应运而生。然而在人们将越来越多的精力和时间都投入到对安全问题保障研究的同时,却忽略了最基础的一种手段 ,在人们越来越多的用到各种高科技和现代手法进行安全保障的同时,却忽略意外事件的发生,是不可以借助外力和各种现代手段解决的 ,要靠最基础和最简单的方式 ,也就是机械传动的方式才是最安全和稳定的。

本课题要求针对高层建筑实际情况,设计一种在发生火灾情况下,能帮助人方便、快捷的逃生的工具。要求设计出的逃生器能适合各种结构的建筑物,运行实现自动化,并且要求操作方便,可以折叠,体积和重量在一个人可以操作的限度范围内。可以多次往返高层建筑进行营救。从而能最大限度的减少火灾中的人员伤亡。通过分析比较现有的一些高楼逃生器,大多数装置虽然能达到高楼逃生这一功能,但其结构原理复杂,操作繁琐,安全性差,生产成本高,部分装置还需要电力控制,局限性大(发生地震或火灾时很有可能断电,也不允许操作人员进行复杂的操作)。所以本设计采用一种基于负反馈闭环系统的高楼逃生装置,装置结构简单,操作简便,且无需电力或其他能源驱动,纯机械结构。其原理是利用逃生人员的重力,通过机构的转换,产生阻止逃生人员快速下落的阻力,随着下降中绕绳层数的减少,包角增大,阻力增大,使逃生人员依次有加速、匀速、减速下降的过程,最终以安全速度到达地面。装置的仰角大小可以人为调节。当从动轴与安全绳的粗糙度、安全绳的直径发生改变时可以通过改变仰角的大小使装置仍然可以正常使用,适应了各种环境。通过计算,结果达到预期要求,借助本装置逃生人员可以以安全的速度平稳的下落到地面。因而可以在灾难发生的时候保证人的生命安全。符合设计要求。

1.2 国内外研究概况

在我国,目前主要的救生设备有逃生缓降器,这种设备主要针对普通家庭和个人使用,其构造由调速器、安全带、安全钩、钢丝绳等组成。每次可以承载约100公斤重的单人个体自由滑下,其下滑速度约为每秒1.5米,从二十层楼上降到地面约需40多秒/每人,根据人体重量的不同,略有差异。40秒虽然在平时看似不多,但在火灾逃生分秒必争的情况下还是略显漫长。目前这种逃生缓降器的使用状况不甚理想,其原因除家庭消防意识、经济因素之外,主要是难以适用老幼病残者,多户同时使用可能发生相互缠绕,以及安装问题、定期保养等,难以走进百姓家门。

还有一个主要的设备是救生气垫,它主要是一种利用充气产生缓冲效果的高空救生设备。一般采用高强度纤维材料,经缝纫、粘合制成,其气源一般采用高压气瓶。但是救生气垫仅限于高度为3-4层的楼房使用,随着高度的增加,其缓冲效果、作用面积也将大打折扣,同时此装备要求有相当大的窗户作为人们逃生的出路,在一定程度上受到很大的限制。因此应用范围非常有限,当然对于高楼逃生就有很大的危险性。

川公网安备: 51019002004831号

川公网安备: 51019002004831号