高空作业车上车工作装置设计

50页 22000字数+说明书+外文翻译+10张CAD图纸【详情如下】

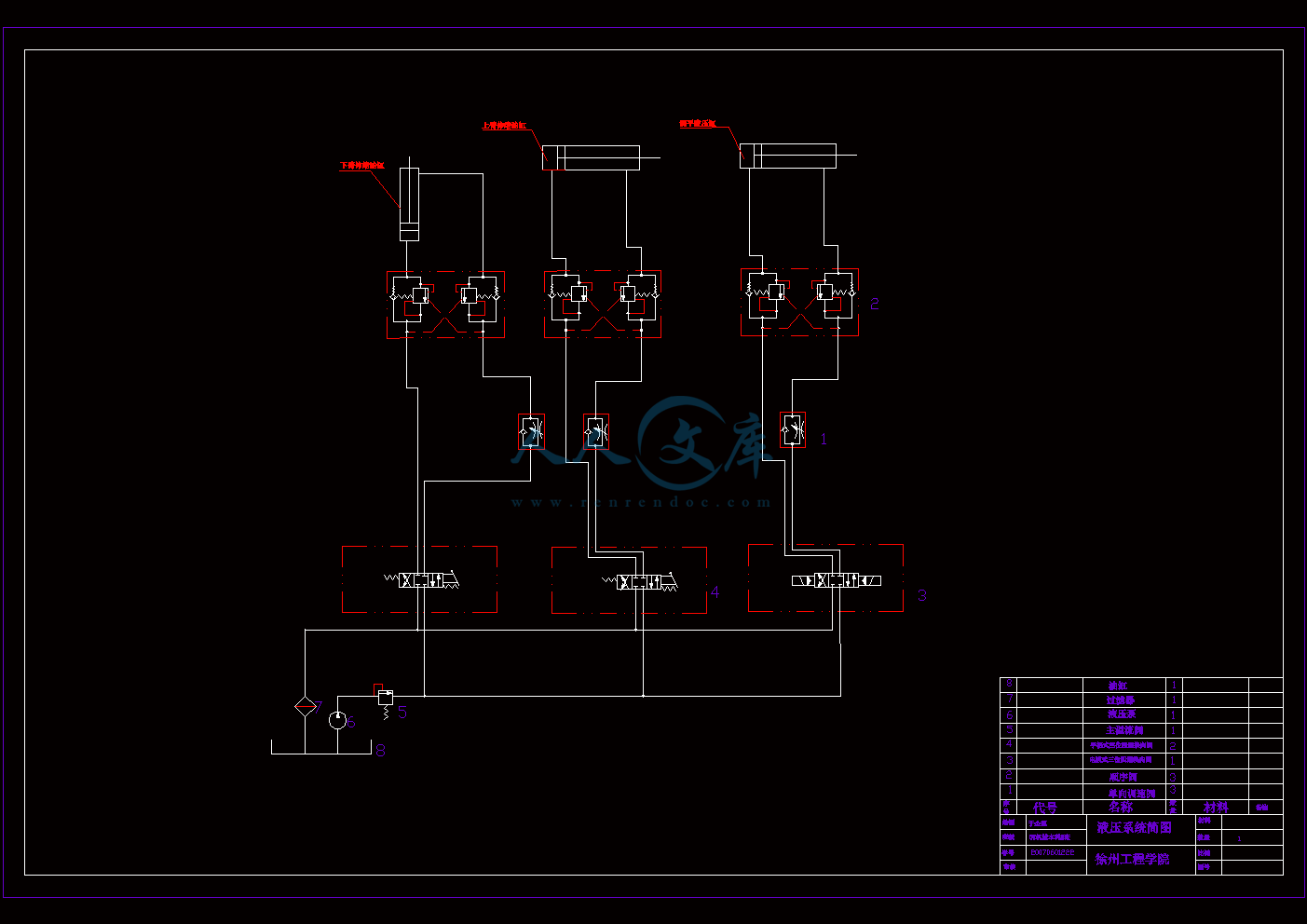

上臂.dwg

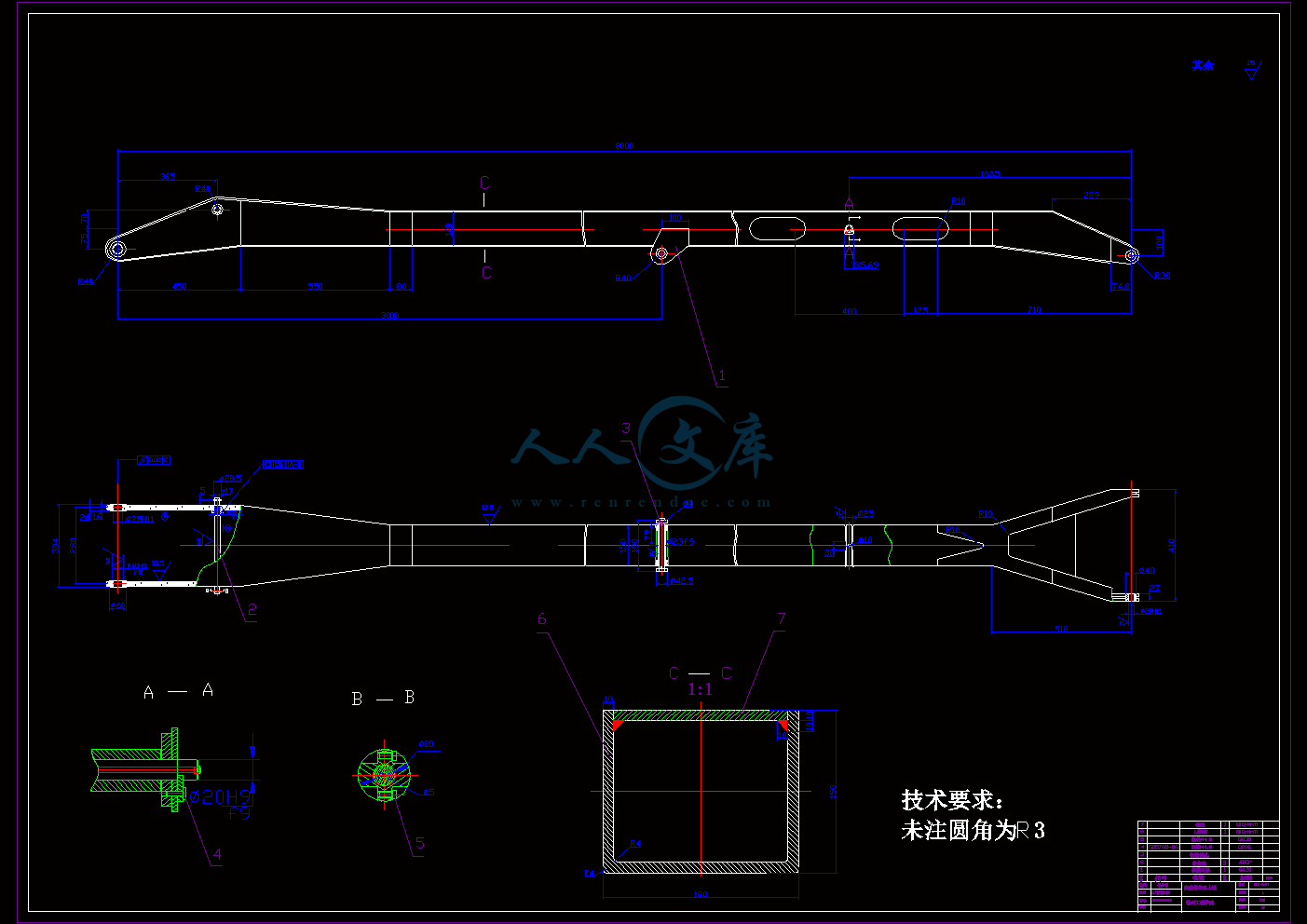

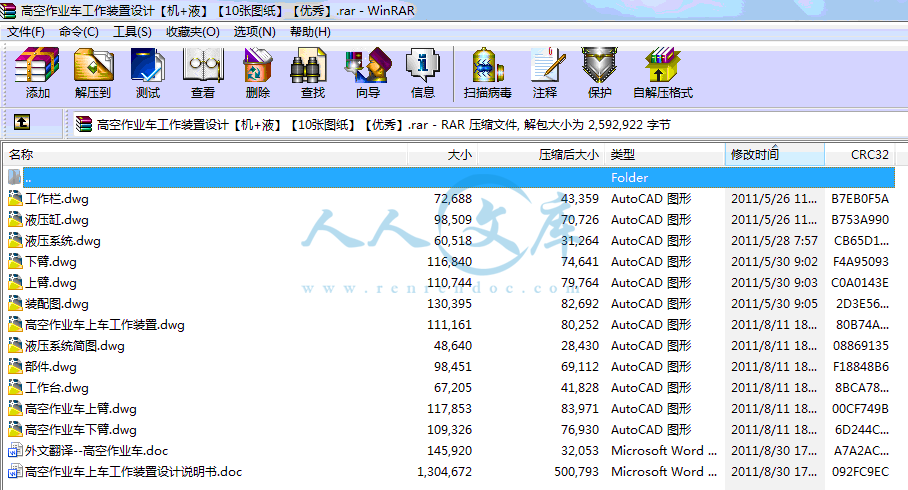

下臂.dwg

外文翻译--高空作业车.doc

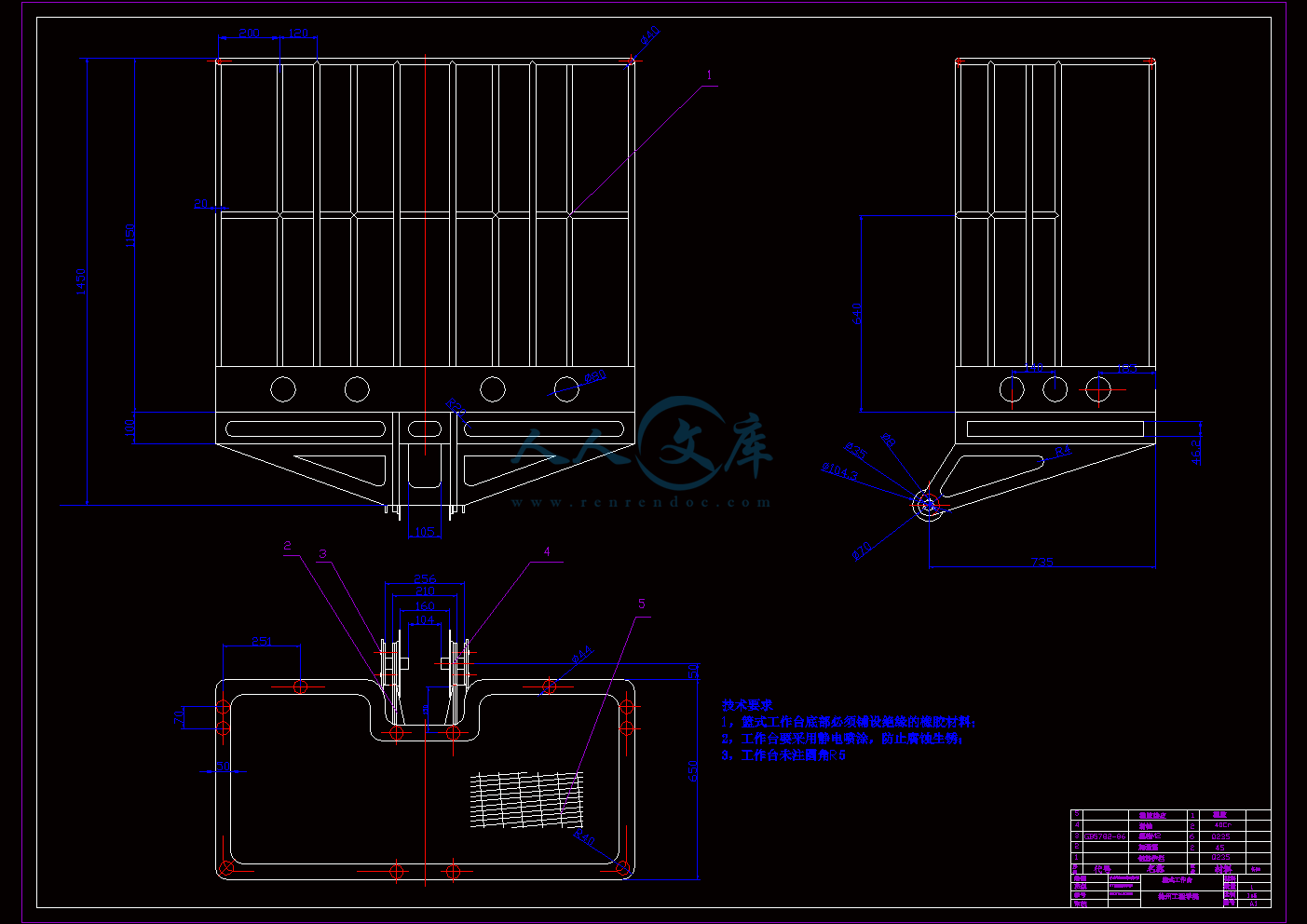

工作台.dwg

工作栏.dwg

液压系统.dwg

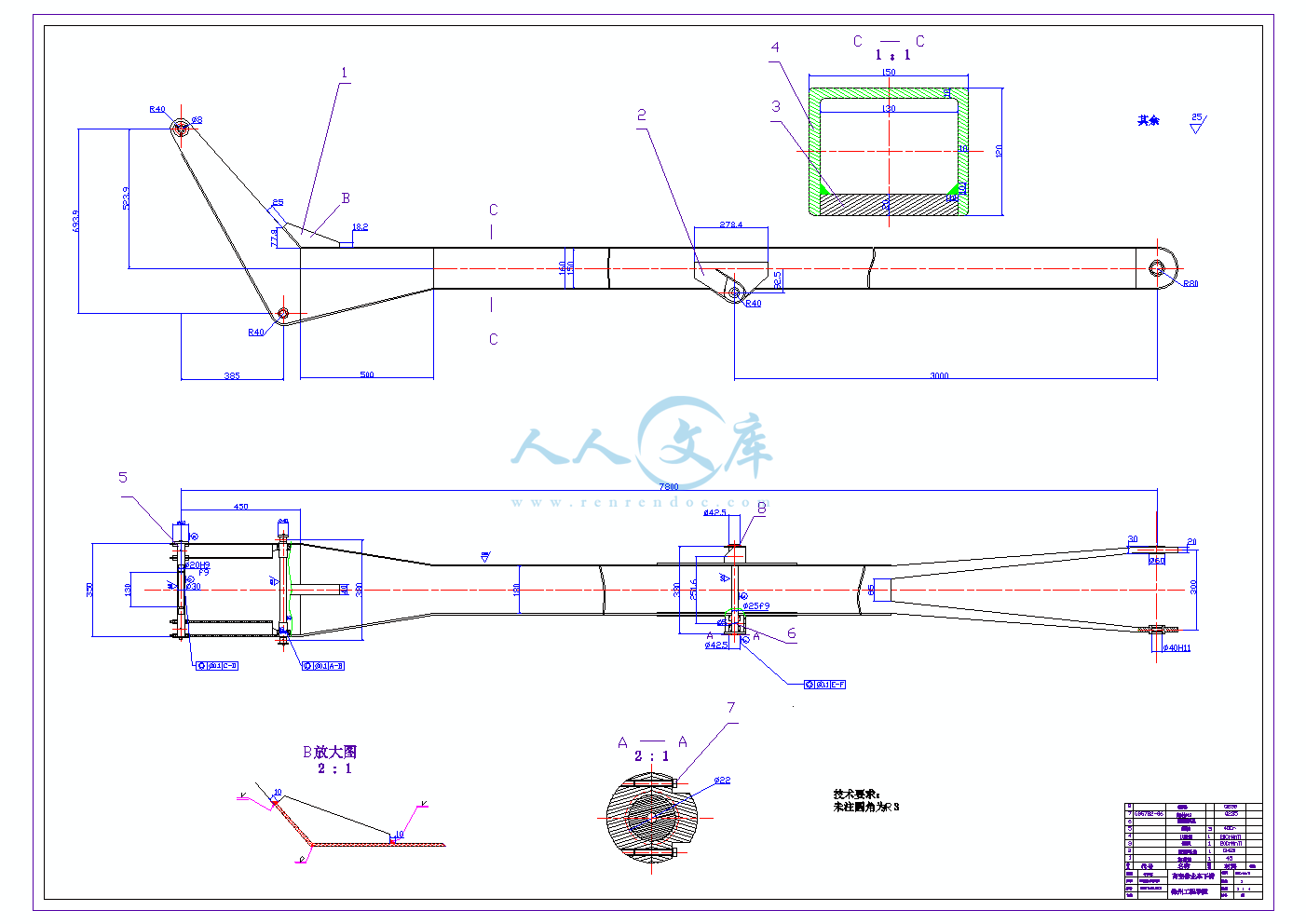

液压系统简图.dwg

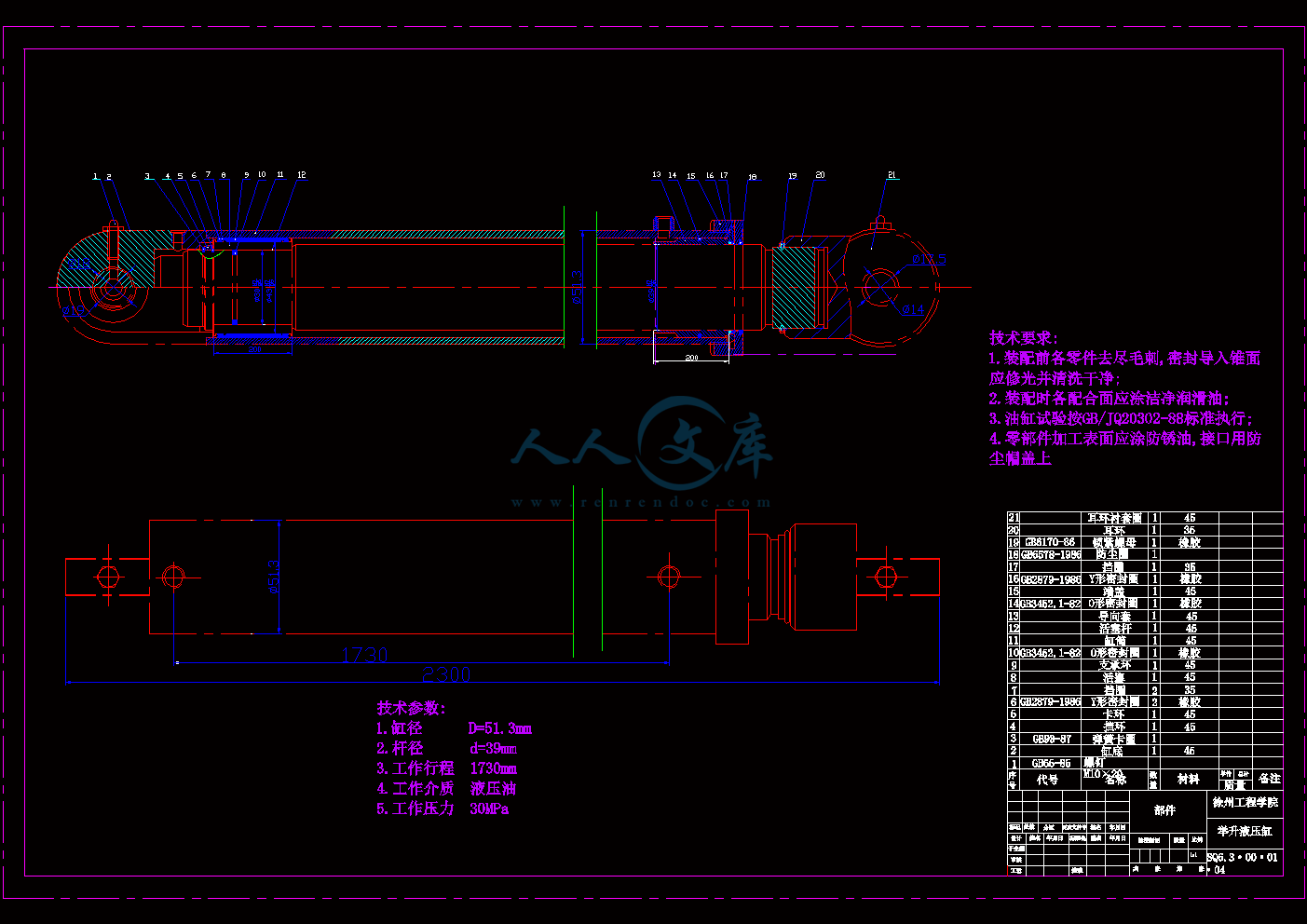

液压缸.dwg

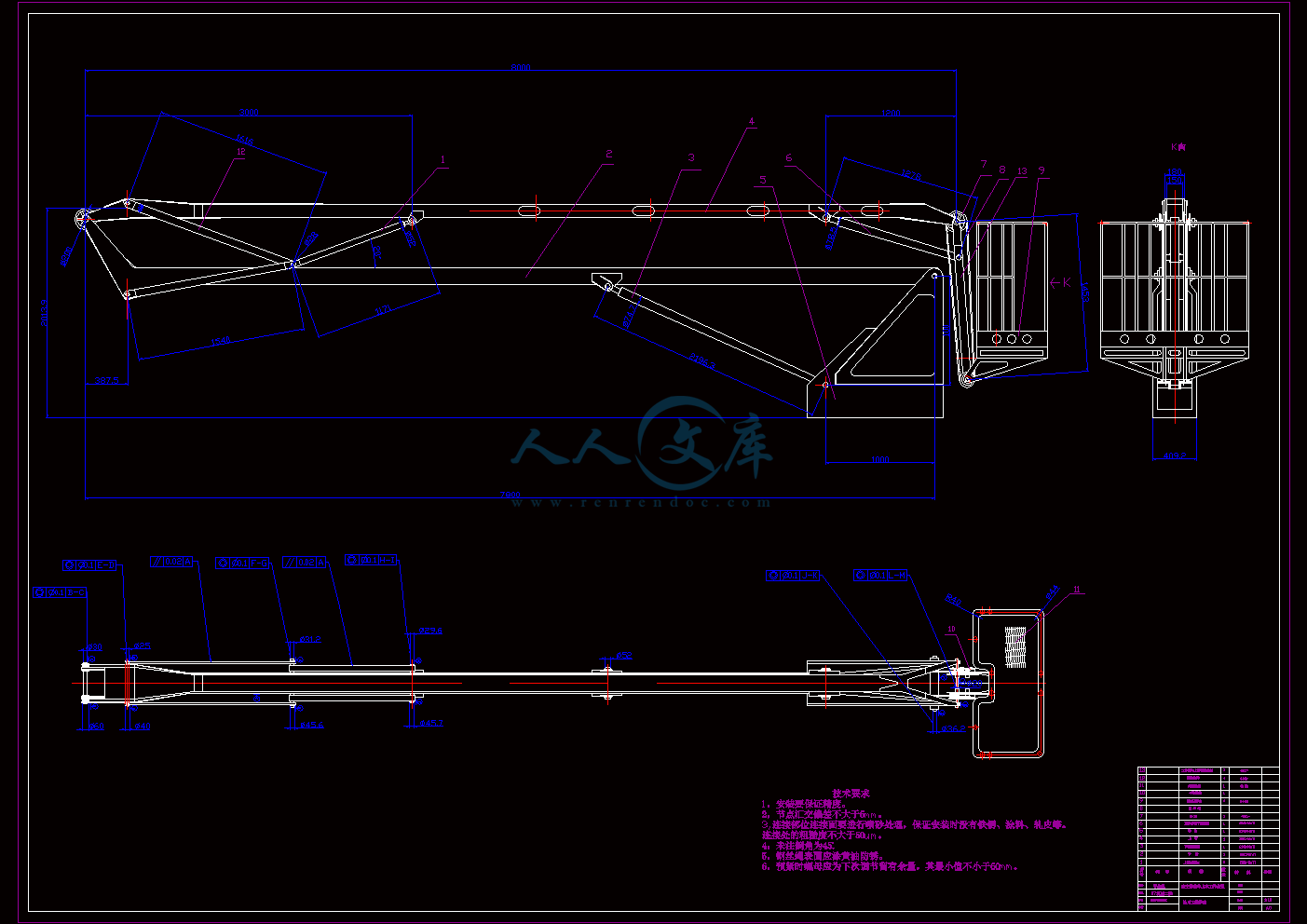

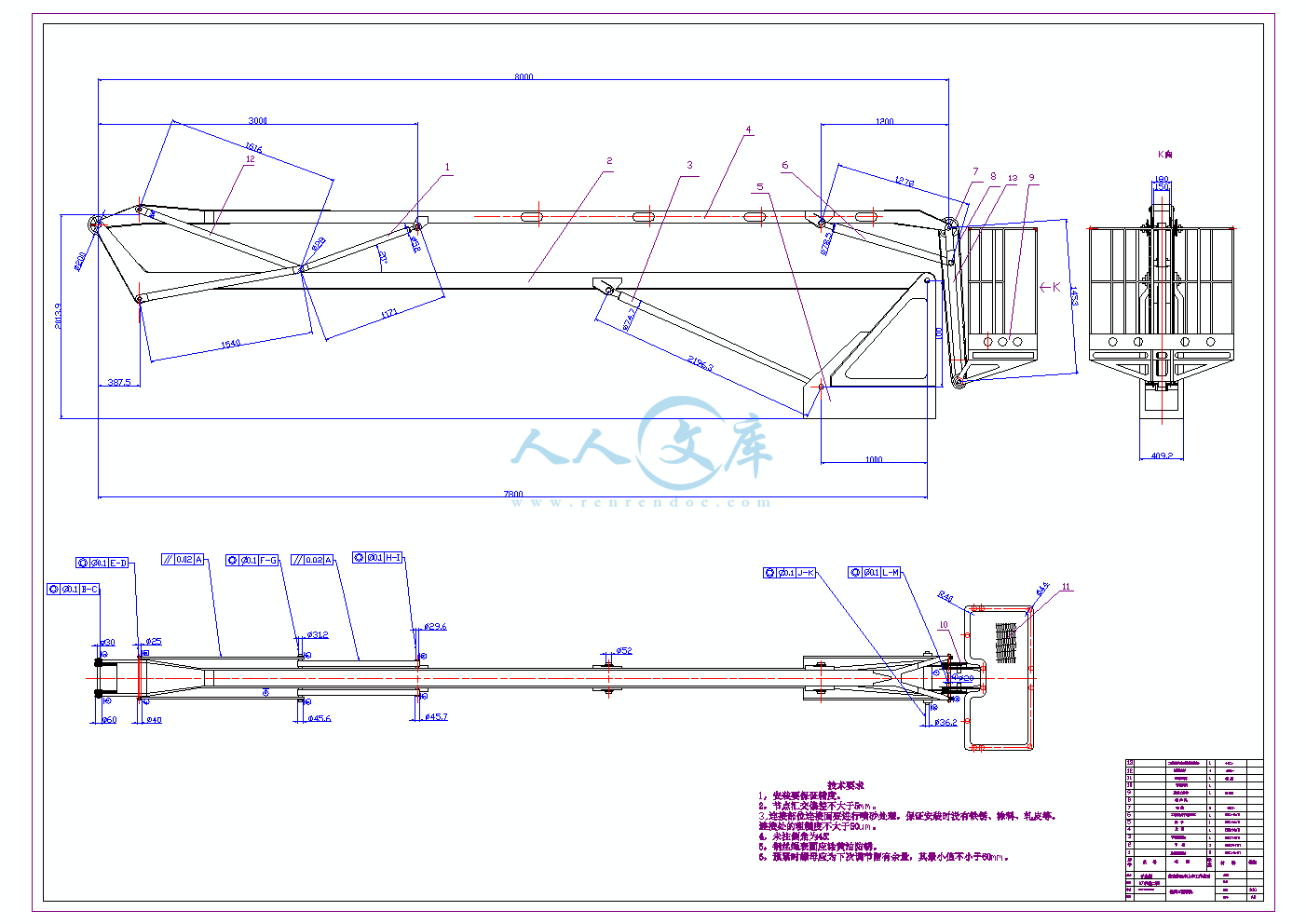

装配图.dwg

部件.dwg

高空作业车上臂.dwg

高空作业车上车工作装置.dwg

高空作业车上车工作装置设计说明书.doc

高空作业车下臂.dwg

目录

摘要I

AbstractII

1 绪论1

1.1高空作业车的作用和意义1

1.1.1高空作业车简介1

1.1.2高空作业车用途1

1.1.3高空作业车的技术特点1

1.1.4选题意义2

1.1.5外国高空作业车的发展概况2

1.1.6国内高空作业车发展状况3

2上车机构的机械原理设计和分析6

2.1上车机构的组成部分6

2.2上车结构图6

2.3机械设计分析7

3 上车机构传动结构设计8

3.1上车机构的受力分析8

3.2参数确定9

3.2.1杆长确定9

3.2.2确定参数的范围9

3.2.3初定断面尺寸10

3.3可靠性设计12

3.3.1臂L强度校核13

3.3.2臂L强度校核15

3.3.3铰接旋转轴的强度校核17

4 液压系统设计18

4.1液压系统的构成18

4.2液压系统设计概述18

4.3设计依据18

4.4主要机构简述18

4.5高空作业车起升机构的液压回路设计18

4.5.1动作分析18

4.5.2液压回路设计18

4.5.3优缺点分析20

4.6高空作业车回转机构液压回路20

4.6.1动作分析20

4.6.2液压回路设计20

4.7高空作业车变幅机构液压回路设计21

4.7.1动作分析21

4.7.2液压回路设计21

4.8整体液压回路设计21

4.9上臂油缸的设计22

4.9.1缸筒壁厚的计算24

4.9.2缸体的外径计算25

4.10下臂油缸的设计与计算26

4.10.1缸筒壁厚的计算27

4.10.2缸体的外径计算27

4.10.3流量的计算28

4.11起升机构液压马达设计计算28

4.12液压泵的确定29

4.12.1液压泵的最大工作压力P的确定:29

4.12.2液压泵的流量Q的计算30

4.13油箱的选择30

5工作台水平调整机构设计32

结论36

致谢37

参考文献38

附录39

附录139

6高空作业车的操作保养与维修39

6.1高空作业车的操作行为规范39

6.2高空作业车的保养与维修40

6.3高空作业车的常见故障及排除方法42

摘要

高空作业车主要应用于路灯、电力、交通、高速公路、造船修船、通信、建筑、园林、广告、机场、港口、有线电视等行业,使用面广、作业效率高、安全方便,拥有巨大的市场潜力。本课题主要是对其上车部分进行理论分析、计算并进行结构设计。

高空作业车是由两个机械臂组成,合理确定其一些基本尺寸,运用理论力学知识对其受力分析,用材料力学知识进行强度校核,确定其他尺寸。根据负载条件,选择液压元件,设计液压系统。运用绘图软件Pro-e , CAD,画出零件图和装配图。

可靠性设计可以保证高空作业车有足够的强度,有利于保证生产的安全。

关键词 受力分析;强度校核;液压系统;零件图和装配图

1 绪论

1.1高空作业车的作用和意义

1.1.1高空作业车简介

1.1.1.1高空作业车的含义

高空作业车是指3米以上,由液压或电动系统支配多支液压油缸,能够上下举升进行作业的一种车辆。采用液压传动的载人高空作业车,是当代先进的物种机械设备。施工人员借助高空作业车升空工作,只要正确使用,安全得到保证。但操作不妥或安全措施未落实,它又是一种十分危险的主空作业规程,要制定一定的行为规范。

1.1.1.2高空作业车的分类

高空作业车大体有折叠臂、伸缩臂、混合臂、自行式、剪叉式等五个系列, 东风小霸王高空作业车、东风多利卡高空作业车、东风145高空作业车,江铃高空作业车,庆铃高空作业车,奥铃高空作业车。 高空作业车的颜色以工程黄的颜色为主,不论是在白天和黑夜,黄色比较醒目。另提供多种选择。

1.1.2高空作业车用途

主要应用于电力,通讯,路灯,交警,高速公路,有线电视,修造船,建筑,园林,广告,摄景,大型企业等行业.

1.1.3高空作业车的技术特点

(1)新型的全液压自行式专用底盘。研制的具有完全自主知识产权的自行式高空作业升降平台车,采用了机电液一体化、可靠性设计和计算机辅助设计等技术,成功地研制了一种全液压驱动、自行式专用底盘,突破了以往国内高空作业升降平台车只能采用汽车或起重机底盘改装设计的限制。

(2)带载行驶、作业稳定性好。底盘结构突破了传统的设计理论和方法,通过优化上车平台总体布局与载荷分布,减少了重心偏移。采用独特的大角度后仰式铰点结构,合理设置多种配重模块,有效地平衡了工作力矩。采用H型变截面复合箱梁剐性车架和高负荷实心橡胶轮胎,增加了底盘整体刚度,保证了整机行驶、作业过程的稳定性,实现了高空作业升降平台车带载行驶的功能。

(3)多功能、多用途的作业装置。通过大臂前端托架,可以快速安装举升装置或载人平台,实现物料举升、起重吊装和载人高空作业等功能,同时为扩展作业装置以及各种工作装置的快速切换提供了接口。

(4)独特的三维旋转托举装置。设计的三维旋转托举装置,既能够自动保持被举升物料的姿态,又可以实现举升物料在空间内任意高度、任意位置和任意方向的调整要求,速度控制精确灵敏,微动性能好,满足了大型洞库内高空作业与通风管道安装的要求。 曲臂式高空作业车能悬伸作业、跨越一定的障碍或在一处升降可进行多点作业;平台载重量大,可供两人或多人同时作业并可搭载一定的设备;升降平台移动性好,转移场地方便;外型美观,适于室内外作业和存放。适用于车站、码头、商场、体育场馆、小区物业、厂矿车间等大范围作业。 拖车式折臂高空作业车,移动方便,折臂结构紧凑,采用新型优质型钢,强度高、重量轻、直接接入交流电或采用本身直流电源启动,架设速度快,工作台即可升高又可水平延伸,还可旋转,易于跨越障碍物到达工作位置,是理想的高空作业设备。 在作业斗内和回转座上均设有操纵装置, 远距离控制发动机的启动/停止、高速/低速,采用电液比例阀控制臂的动作,平稳性好,工作臂可左、右360°连续旋转,靠连杆机构自动维持作业槽水平,主泵出现故障时可操纵应急泵下降作业槽,具备夜间照明,可起吊重物。产品被广泛用于电力、路灯、市政、园林、通信、机场、造(修)船、交通、广告、摄影等高空作业领域。 新型的全液压自行式专用底盘研制的具有完全自主知识产权的自行式高空作业升降平台车,采用了机电液一体化、可靠性设计和计算机辅助设计等技术,成功地研制了一种全液压驱动、自行式专用底盘,突破了以往国内高空作业升降平台车只能采用汽车或起重机底盘改装设计的限制。 带载行驶、作业稳定性好,底盘结构突破了传统的设计理论和方法,通过优化上车平台总体布局与载荷分布,减少了重心偏移。采用独特的大角度后仰式铰点结构,合理设置多种配重模块,有效地平衡了工作力矩。采用H型变截面复合箱梁剐性车架和高负荷实心橡胶轮胎,增加了底盘整体刚度,保证了整机行驶、作业过程的稳定性,实现了高空作业升降平台车带载行驶的功能。多功能、多用途的作业装置,通过大臂前端托架,可以快速安装举升装置或载人平台,实现物料举升、起重吊装和载人高空作业等功能,同时为扩展作业装置以及各种工作装置的快速切换提供了接口。 独特的三维旋转托举装置设计的三维旋转托举装置,既能够自动保持被举升物料的姿态,又可以实现举升物料在空间内任意高度、任意位置和任意方向的调整要求,速度控制精确灵敏,微动性能好,满足了大型洞库内高空作业与通风管道安装的要求。

1.1.4选题意义

川公网安备: 51019002004831号

川公网安备: 51019002004831号