液压防爆提升机设计

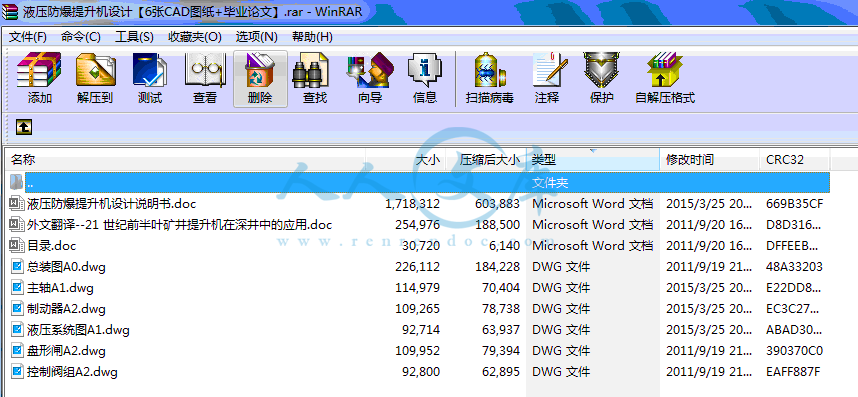

84页,42000字数+说明书+外文翻译+6张CAD图纸【详情如下】

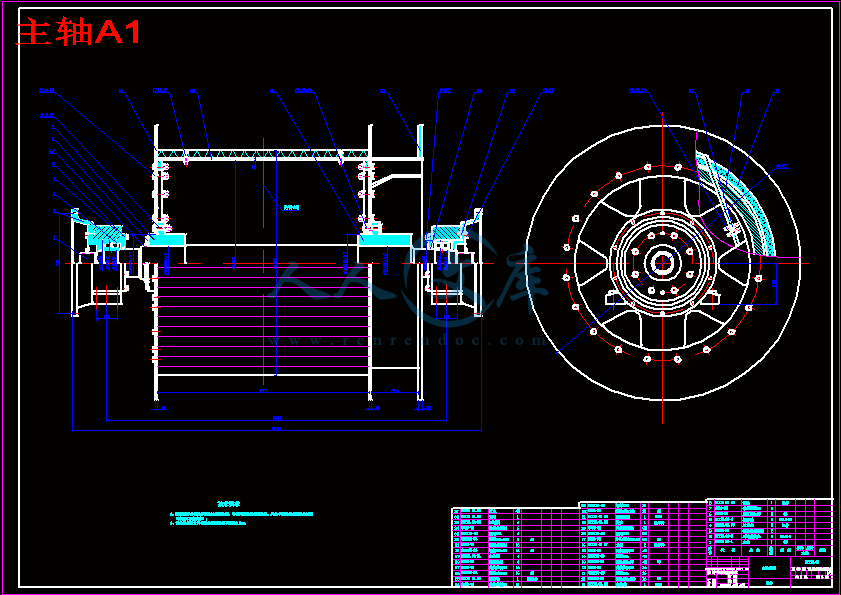

主轴A1.dwg

制动器A2.dwg

外文翻译--21 世纪前半叶矿井提升机在深井中的应用.doc

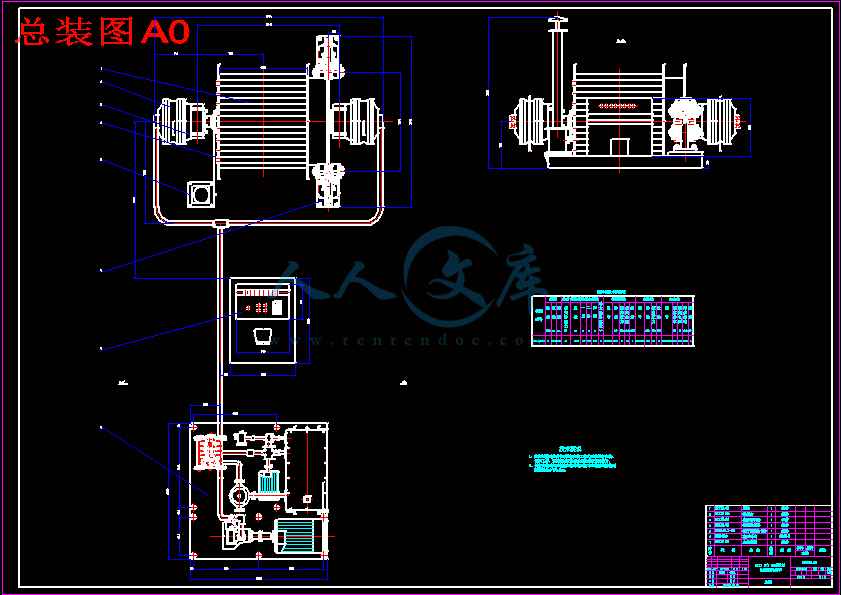

总装图A0.dwg

控制阀组A2.dwg

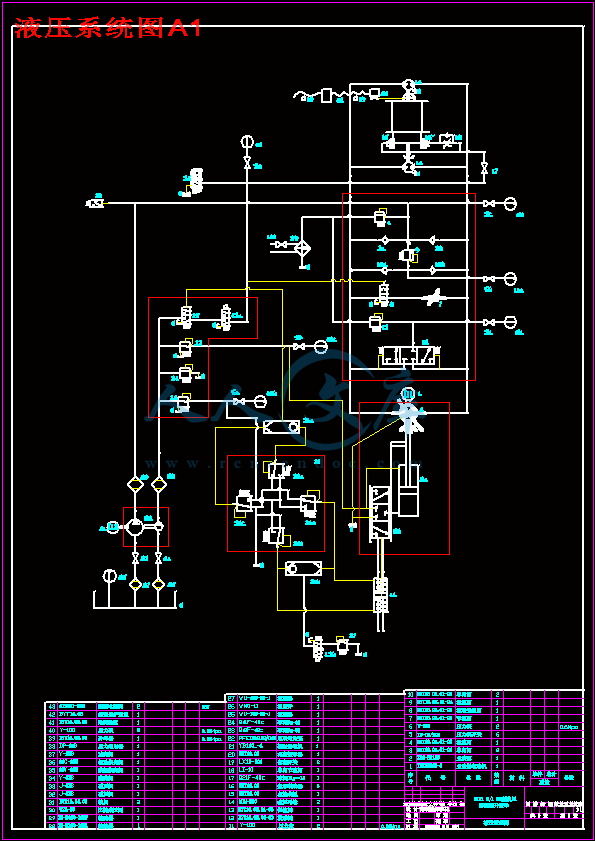

液压系统图A1.dwg

液压防爆提升机设计说明书.doc

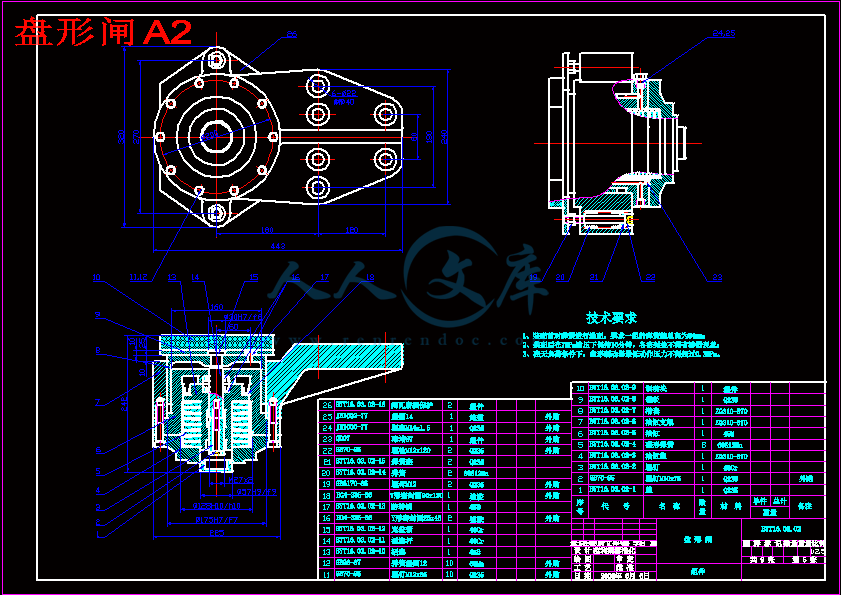

盘形闸A2.dwg

目录.doc

目录

1 绪论……………………………………………………………………………1

1.1液压防爆提升机概述……………………………………………………1

1.1.1引言……………………………………………………………………1

1.1.2液压防爆提升经济的用途、工作原理、类型…………………………1

1.2液压防爆提升机的方展历程……………………………………………3

1.2.1国外发展历程…………………………………………………………3

1.2.2国内发展历程…………………………………………………………4

1.3技术特点…………………………………………………………………5

1.4液压传动的优缺点………………………………………………………7

1.5液压系统设计方案的确定………………………………………………8

1.5.1概述……………………………………………………………………9

1.5.2方案确定………………………………………………………………9

2 钢丝绳的选择和卷筒尺寸的确定…………………………………………10

2.1钢丝绳的选择……………………………………………………………10

2.1.1钢丝绳的结构…………………………………………………………10

2.1.2钢丝绳的分类…………………………………………………………10

2.1.3钢丝绳的选择…………………………………………………………11

2.1.4钢丝绳在卷筒上的固定方式…………………………………………12

2.2卷筒尺寸的确定…………………………………………………………12

2.2.1卷筒结构………………………………………………………………12

2.2.2卷筒尺寸的确定………………………………………………………13

3 液压马达、主液压泵及其电机的选择………………………………………16

3.1液压马达…………………………………………………………………16

3.1.1概述……………………………………………………………………16

3.1.2液压防爆提升绞车常采用的几种液压马达…………………………16

3.2液压泵……………………………………………………………………22

3.2.1概述……………………………………………………………………22

3.2.2液压防爆提升绞车常采用的几种液压泵……………………………22

3.3液压马达、主液压泵及其电机的选择…………………………………30

4 主轴装置的设计……………………………………………………………32

4.1概述………………………………………………………………………32

4.2主轴装置的结构设计……………………………………………………32

4.3主轴装置的计算…………………………………………………………32

4.3.1变位质量计算…………………………………………………………32

4.3.2筒壳强度计算…………………………………………………………35

4.3.3主轴强度和刚度计算…………………………………………………35

4.3.4主轴承强度计算………………………………………………………50

5 制动装置的设计……………………………………………………………51

5.1概述………………………………………………………………………51

5.2制动装置的结构设计……………………………………………………52

5.3制动装置的设计计算……………………………………………………56

5.3.1盘形制动闸正压力计算………………………………………………56

5.3.2松闸时作用在活塞上的液压力计算…………………………………58

5.3.3盘形制动闸工作油压计算……………………………………………59

6 液压系统的设计……………………………………………………………59

6.1液压系统各液压回路的设计……………………………………………59

6.1.1引言……………………………………………………………………59

6.1.2各液压回路的设计……………………………………………………60

6.2液压阀组及油箱的设计…………………………………………………62

6.2.1液压阀组的设计………………………………………………………62

6.2.2油箱的设计……………………………………………………………64

7 液压提升机的安装与调试…………………………………………………65

7.1液压提升机的安装………………………………………………………65

7.1.1安装前的准备工作和设备运搬………………………………………65

7.1.2液压提升机的安装……………………………………………………66

7.2液压提升机的调试………………………………………………………69

8 液压提升机的运转、维护与检修……………………………………………71

8.1液压提升机的操作与运转………………………………………………71

8.2液压提升及的维护与检修………………………………………………73

结论……………………………………………………………………………77

参考文献………………………………………………………………………78

翻译部分

英文原文……………………………………………………………………79

中文译文……………………………………………………………………87

致谢……………………………………………………………………………94

摘 要

本设计首先对液压防爆提升机的用途、工作原理、类型及其发展历程进行了概述,通过对液压传动优缺点的分析以及与其它类型提升机进行比较确定了液压系统的设计方案。然后通过对其工作环境和技术特点的分析,并参考目前国内液压防爆提升机的结构,对液压防爆提升机的整体结构进行了设计,包括钢丝绳的选择、卷筒的设计、主轴装置的设计、制动装置的设计、液压系统的设计以及计算与校核。本设计由防爆电动机、低速大扭矩液压马达、轴向柱塞泵、双联叶片泵、多种控制阀、盘形制动器、卷筒、支承轴等部件组成。由于液压系统部分比较复杂,为了使提升机的结构紧凑,提高液压系统的性能和指标,将其主回路部分和其它部分分别组合在一起,构成主阀组和控制阀组。此液压提升机的特点是:采用液压传动、采用无级调速、结构紧凑、操纵简单、采用液压控制、制动安全可靠,其最大的优点是防爆功能。本液压提升机用于矿山、港口、码头等需要搬运物料的场所,尤其在煤矿井下等含有瓦斯或其它易燃易爆气体的场所广泛应用。

关键词:液压提升机; 设计; 计算; 阀组

Abstract

The first design of the hydraulic hoist the use of explosion-proof, principle, type and its development process was outlined by the advantages and disadvantages of hydraulic and other types of analysis and comparison determine elevator hydraulic systems design. Then through their work environment and the technical characteristics of the analysis, and refer to the current domestic hydraulic elevator explosion-proof structure of the hydraulic elevator explosion-proof structure of the overall design, including the choice of wire rope, roll the design, spindle Equipment design, the design of the braking system, hydraulic system design and calculation and verification. The design by the explosion-proof motor, a low-speed torque hydraulic motors, axial piston pump, double-blade pump, a variety of control valves, disc brakes, drum, the support shaft and other components。As part of the hydraulic system more complicated, in order to hoist the compact structure, improve the performance of the hydraulic system and indicators, its main circuit and other parts of the portfolio together, constitute the main valve block and control valve block. This hydraulic hoist features: The hydraulic transmission, a stepless speed regulation, compact and simple manipulation, the use of hydraulic control, brake safe and reliable, its biggest advantages is the explosion-proof function. The hydraulic hoist used for mining, ports, terminals and other necessary materials handling establishments, particularly in the coal mine gas, such as containing flammable and explosive gases or other places widely used.

Key words:Hydraulic hoist; design; Computation; Valve group

1.1.2液压防爆提升机的用途、工作原理、类型

(1)用途

液压防爆提升机主要用于有沼气、煤尘爆炸危险的煤矿井下,作为提升和下放人员、煤、矸石及运输材料、设备之用。也可供其它有易燃气体和爆炸危险,要求使用防爆电气设备的场所作起重运输用.在煤矿主要是用于采区上、下山运输,同时也可用于井下暗立井、暗斜井和掘进时的提升运输及井下辅助运输.

(2)工作原理

液压防爆提升机由机械、液压传动、电气部分等组成。采用鼠笼型防爆主电机驱动双向变量主油泵;主油泵和二台内曲线低速大扭矩液压马达组成闭合回路、衡扭矩液压调速系统;二台液压马达分别布置在主组装置两侧与主组联接,拖动提升机运转。提升机有二台辅助油泵,一台工作、一台备用。辅助油泵中,其大泵作补油泵用,给主液压传动补油;小泵作控制用,给制动系统、操作系统、调绳系统供油。

提升机采用远距离液控操纵方式。司机通过操作液压式比例先导伐给主油泵的比例油缸输入由低到高的压力油,使主油泵的行程调节器动作,改变主油泵摆动的缸体的倾角来改变主油泵的流量,以改变液压马达的转速,使提升机起动,加速运转。司机通过操作液压式比例先导伐的手柄扳到不同角度,就可使主油泵输出不同的流量,使提升机得到不同的提升速度。当液压式比例先导伐的手柄扳到最大位置时,提升速度最大。当液压式比例先导伐的手柄扳到中立位置时,提升机停车。当手柄反方向扳动时,提升机反方向运行。

提升机采用盘型闸制动,以实现提升机的正常和紧急制动。正常制动的制动力靠液压传动装置本身产生的。提升时负荷成为制动力。下放重物时液压马达变为泵。液压泵变为液压马达。使电动机产生发电反馈制动。盘型制动器不参与工作制动。只是在提升机卷筒停止运转后作为保险装置来使用。提升机在运行中出现故障,保险装置自动工作,也可由司机用脚踏开关进行紧急制动停车。

提升制动系统有压力油时,盘型闸制动打开,没有压力油盘型闸制动。司机操作的液压式比例先导阀共有4个减压阀,其中两个减压阀操纵主油泵正反向供油,另两个减压阀控制盘型闸的开起,当司机操作液压式比例先导伐时,同时压下两个阀,一个阀输出的压力油进主泵的比例油缸,使主泵向液压马达供油并使其运转。另一个阀输出的压力油供制动系统的液控换向阀,使制动系统向盘型制动器供油,盘型闸制动打开、使提升机运转。当司机扳回液压式比例先导伐的手柄扳到中立位置时,(比例油缸向中位返回)主泵流量逐渐减小到零,液压马达停止运转。同时液控换向阀由于没有压力油而复位,提升机制动。这样就实现了开始提升运转时,盘型制动闸同时打开,提升机停止运转时,盘型制动闸同时立刻制动,保征了提升机的安全运行。 1.5液压系统设计方案的确定

1.5.1概述

液压绞车的液压系统是液压绞车的核心部分。液压绞车液压系统的任务是将电动机产生的机械能转换为液压能,再将液压能转变为机械能对外作功拖动外负载。

液压绞车的液压系统一般由以下四个部分液压元件组成:

(1)动力元件。液压泵是液压系统的动力元件,其作用是将原动机的机械能转变为液压能供给液压系统。

(2)执行元件。液压马达是液压系统的执行元件,其作用是将液压系统提供的液压能转变为机械能,拖动外部负载做机械运动

(3)控制元件。液压系统用阀作控制元件,执行机构的运动都具有一定的力、速度和方向,这三个要素都是由阀来控制的。阀可分为压力控制阀、流量控制阀和方向控制阀。

(4)辅助元什。除了上述三类元件外,其他元件均为辅助元件。它们主要用于液压油的储存、油管的连接和密封,油液的滤清、冷却、液压系统某些参数的显示等。

液压绞车液压系统主要元件的动力传递关系如图1.6所示。电动机将机械能输入液压系统,由液压动力元件—液压泵转变为液压能,通过控制元件—液压阀凋整控制压力油的方向、流量和压力的大小,然后传递给执行元件—液压马达,使其按照一定的方向、速度和出力带动负载运动和工作,构成液压系统。

图1.6液压绞车液压系统的动力传递关系

1.5.2方案确定

液压系统按照液流循环方式不同分为开式系统和闭式系统。矿用防爆液压提升绞车一般常采用闭式系统,采煤工作面的液压安全绞车一般常采用开式系统。其主要理由是:

(1)考虑到闭式系统能够满足防爆液压提升绞车提升重物的工作要求。在提升时能可靠地支承住重物,不会自行下落,在重物下降时能有效的控制下降速度,并且能量可以通过电动机发电反馈电网回收。

(2)考虑到防爆液压提升绞车的功率大,闭式系统比开式系统的效率高,可节省电耗。—般开式系统常用定量泵或单向变量泵,它的换向、凋速由阀或泵、阀联合控制,压力过高时,多余的油自溢流阀流回油箱,造成效率损失。而闭式系统一般采用双向变量泵,通过改变变量泵输出油液的方向和流量,控制液压马达的运动方向和速度,回路中压力的高低取决于负载的大小。因而没有过剩的压力和多余的流量,故效率较高。同时,闭式系统可以将开式系统回油背压所造成的能量损失及工作部件换向时的能量损失回收。开式系统为了保证工作部件运动的平稳性,常常特意在液压马达的回油管路上用节流阀或压力阀形成背压。这样回油背压的压力能便白白消耗在节流阀或压力阀内的节流损失上,并转变为热能,引起油液温度升高。但在闭式系统中,液压马达的回油直接流入油泵的进油腔,如果液压马达的排油腔有背压P2,则油泵的进油腔也受到油压P2的作用,而作用在油泵吸油腔的这个压力是帮助电动机推动油泵转动的,因此节省了电动机的一部分动力,使液压系统效率较高。

(3)考虑到防爆液压提升绞车换向较频繁,闭式系统起动,换向工作比较平稳,效率较高。开式系统工作部件的换向,要靠换向阀来实现,换向制动过程中,工作部件的动能便完全消耗在换向阀关闭回油所产生的节流损失上。如果开式系统采用的油泵是定量泵时,工作部件换向制动时不需要油泵供给动力,但是由于油泵的流速一定,压力一定(由溢流阀凋定),所以油泵仍然耍输出功率,这些功率便白白浪费在大量油液经溢流阀流回油箱时所发生的节流损失上了。而闭式系统一般是采用双向变量油泵来控制工作部件的换向,通过一定的控制方式,使油泵的斜盘或斜轴倾角从凋定的某一数值逐渐减少,一直减到零,然后逐渐向反方向增大到所需数值。这样在换向时.油泵输出的功率便相应减少,工作平稳,效率高。

(4)考虑到开式系统结构较简单,油液可在油箱中很好地冷却和沉淀杂质,散热良好,故较适应采煤工作面液压安全绞车使用。而闭式系统结构较复杂,为了补偿泄漏需要设置油箱和补油泵;为了使液压系统的油得到冷却需要设置油冷却器,不断将系统中的一部分热油置换出来,经油冷却器再回到油箱以进行冷却;同时又将油箱中冷却了的油液输入到系统中去。

参考文献

[1] 吴辉海.液压绞车.北京:煤炭工业出版社,1989

[2] 洪晓华主编.矿井运输提升.徐州:中国矿业大学出版社,2005

[3] 余发山.国内外矿井提升的现状与发展.煤矿机电,1995(3)

[4] 张兰俊.电控防爆和液压防爆提升机比较分析.煤矿机械,1999(3)

[5] 彭佑多.大惯量液压提升机液压系统.液压与气动,2000(5)

[6] 能源部编.煤矿安全规程.北京::煤炭工业出版社,1992

[7] 官忠范主编.液压传动系统.北京:机械工业出版社,1989

[8] 王占林.近代液压控制.北京:机械工业出版社,1997

[9] 雷天觉主编.液压工程手册.北京:机械工业出版社,1990

[10] 机械设计手册编委会编著.机械设计手册[第二卷].北京:机械工业出版社,

2004

[11] 机械设计手册编委会编著.机械设计手册[第二卷].北京:机械工业出版社,

2004

[12] Hitoshi shiraishi.CMAC Neural Network Controller for Fuelinjection System .IEEE

Transactions on Control Systems Technology.Vo1.3,no1,march,1995

[13] 张延宝.对副井使用液压提升机的建议.山西煤炭,1998(4)

[14] 方明华.浅论液压防爆提升绞车的经济技术比较.煤矿设计,1996(5)

[15] 刘长年.液压伺服系统分析与设计.北京:科学出版社,1987

[16] World Mining Equipent,Mike Woof looks at the hoisting market ,2000(11)

[17] 陈维健,齐秀丽.矿井运输及提升机械.徐州:中国矿业大学出版社,1989

川公网安备: 51019002004831号

川公网安备: 51019002004831号