液压抓斗式矿井水仓清淤机设计

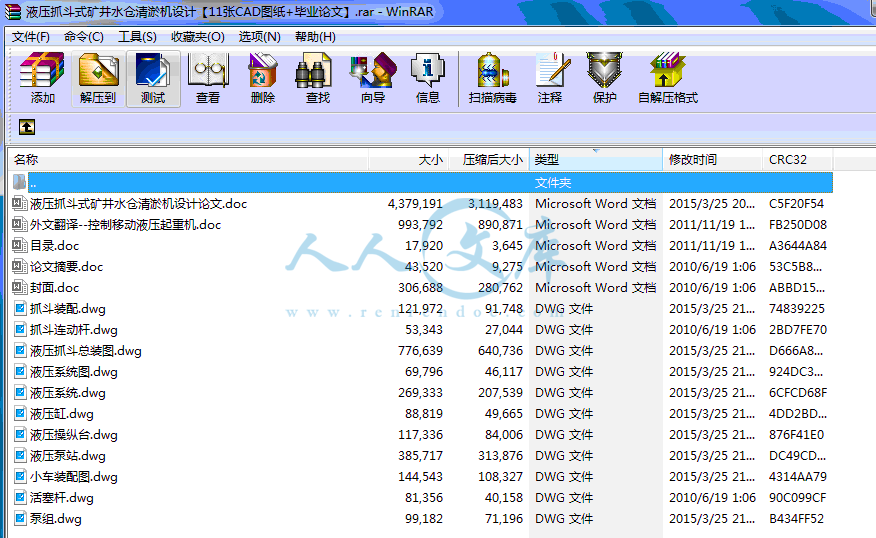

84页 37000字数+说明书+外文翻译+11张CAD图纸【详情如下】

外文翻译--控制移动液压起重机.doc

封面.doc

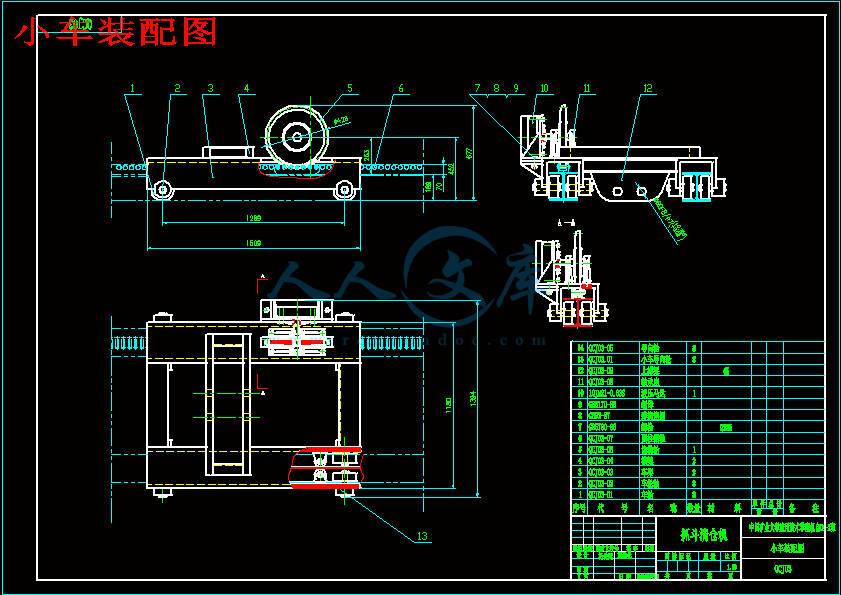

小车装配图.dwg

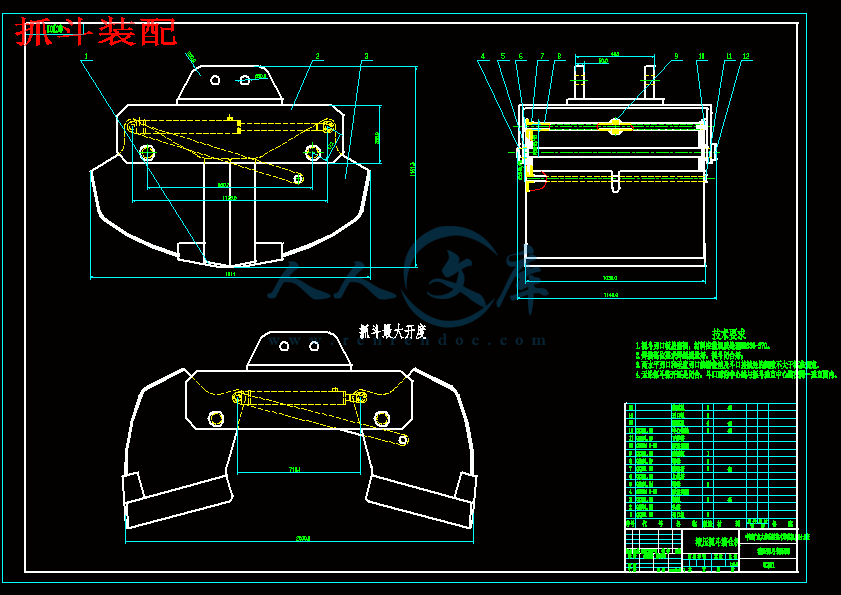

抓斗装配.dwg

抓斗连动杆.dwg

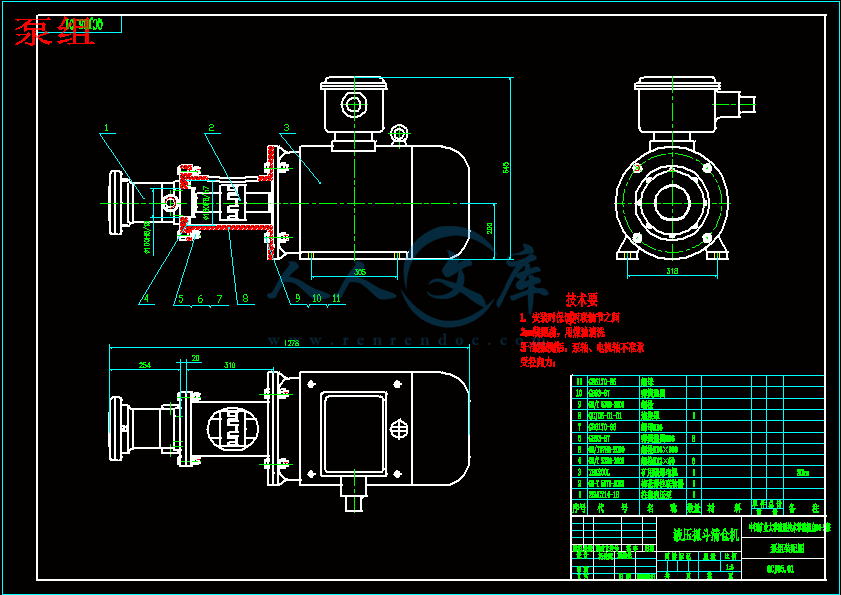

泵组.dwg

活塞杆.dwg

液压抓斗式矿井水仓清淤机设计论文.doc

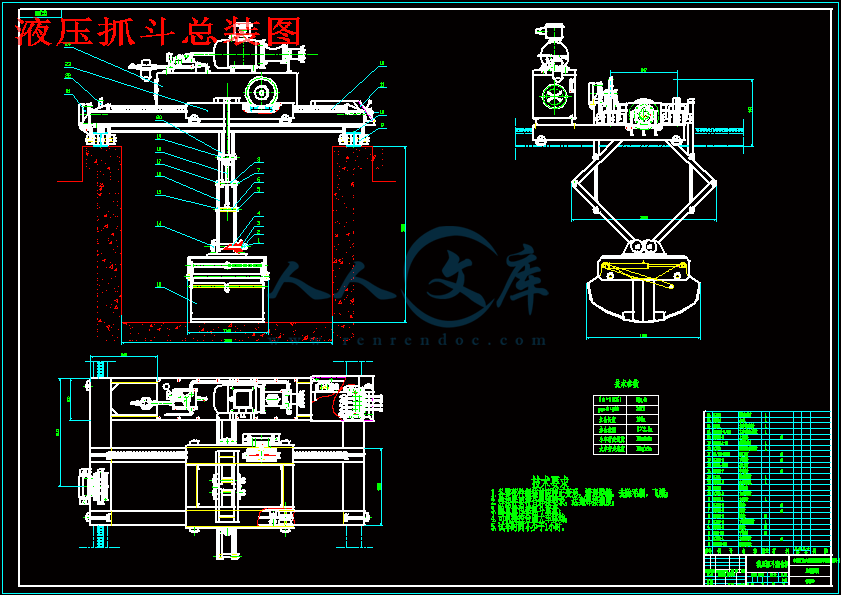

液压抓斗总装图.dwg

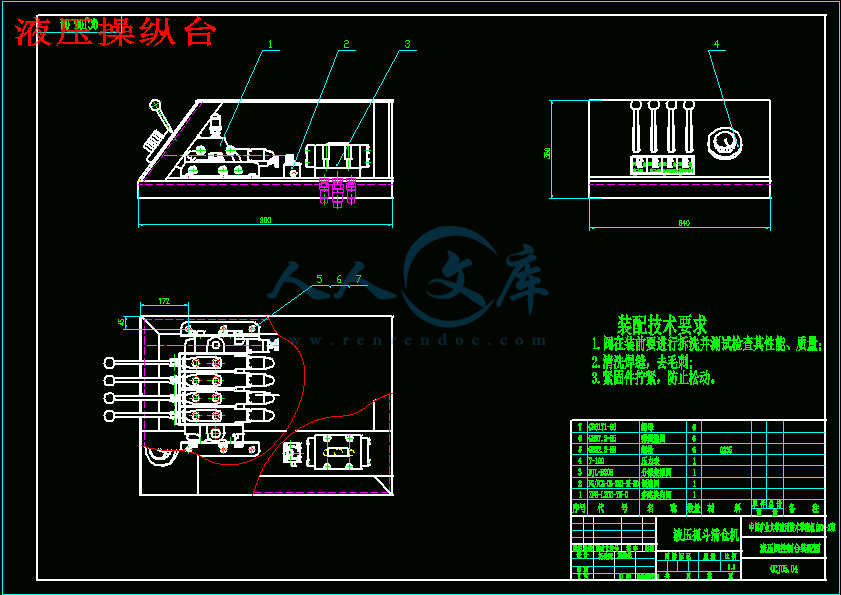

液压操纵台.dwg

液压泵站.dwg

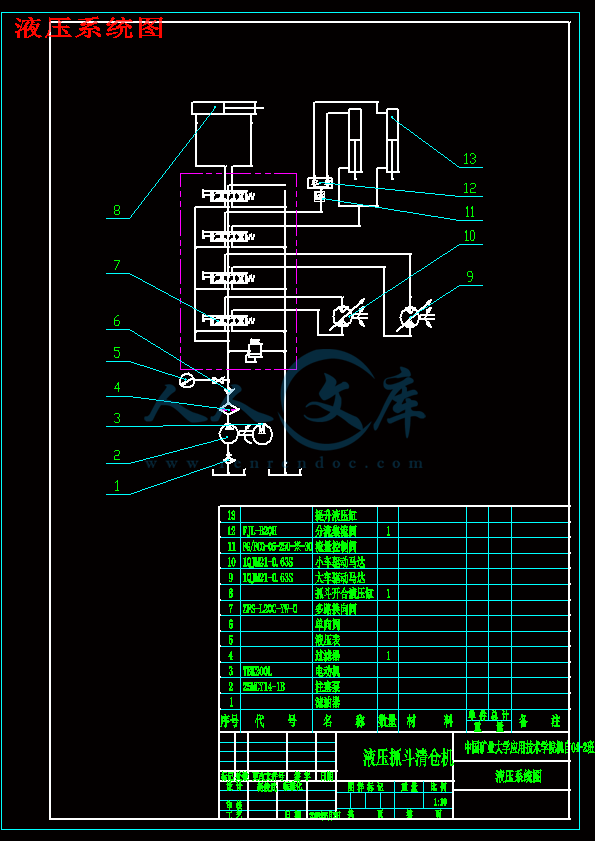

液压系统.dwg

液压系统图.dwg

液压缸.dwg

目录.doc

论文摘要.doc

目 录

1 概 述

1.1起重机械的用途及工作特点

1.2起重机的发展趋势

1.3起重机械的组成和种类

1.4液压抓斗清仓机的基本构成

2 液压抓斗清仓机设计任务书

2.1设计参数

2.2工作条件

2.3设计原则

3 抓斗的设计

3.1抓斗的设计因素?

3.2抓斗的机构原理

3.3抓斗的设计计算

4 小车起升机构和运行机构的计算

4.1升降机构计算

4.2小车运行机构计算

5 大车运行机构的计算

5.1确定传动机构方案

5.2选择车轮与轨道,并验算其强度

5.3运行阻力计算

6液压系统

6.1液压系统总体方案的确定

6.2确定系统工作压力

6.3液压执行元件的设计计算

6.4电动机的选择

6.5联轴器的选择

6.6控制阀的选择

6.7压力表以及压力表开关的选择

6.8液压辅助元件设计

6.9系统的发热及散热计算

6.10过滤器的选择

6.11冷却器的选择

6.12液压管件的选择

6.13阀块设计

6.14 泵站的设计

6.15液压技术的特点和应用情况

7设备液压系统污染的防治

7.1?控制液压系统受污染

7.2加强对液压油品质的控制

7.3结语

结 论

参考文献

摘 要

矿井水仓是煤矿安全生产,防止矿井水灾的重要设施,水仓通常分隔为主仓和副仓,两者轮换清理使用。随着矿井开采深度增大和涌水量增多,水仓内淤积了大量的淤煤,而水仓容积有限,故而必须定期清理。

目前多数煤矿采用人工方式清理,工人们站在煤泥水中,用铁锹及桶刮等方法把煤泥清挖出来,再将煤泥运到附近巷道两旁堆放,待煤泥晾干后再运送上地面,或是将煤泥直接装入矿车中运送到地面。人工清挖不仅劳动强度大,作业效率低,而且清仓周期长,特别在雨水季节还可能会因水仓清理不及时而导致淹井事故。

本文在对现有清仓方法和国内生产或试制过的各种水仓清理设备进行分析研究的基础上,结合液压传动,抓斗起重机械的结构和工作原理介绍了一种用于清理煤矿水仓淤煤的新型水仓清理设备。该设备采用抓斗抓取提升淤煤的工作方式,抓斗的开合及提升全部通过液压缸来实现,抓斗的前移后退及左右移动通过由马达驱动的大小车行走机构带动车架来实现。该设备具有结构简单、动力系统单一,便于安装维护的优点。

关键词:矿井水仓 液压抓斗 清淤设备

ABSTRACT

Wharf coal mine water is safe production, the mine flood prevention essential facilities, water stores are usually separated mainly warehouses and stores of both the use of clean-up rotation. With the increased depth of mining and mine discharge more water stored in a large amount of silt deposition of coal, and the limited volume of water warehouse, therefore must be cleaned regularly.

At present the majority of mine clearance using artificial means, the workers stand in the water slime, and Yong Tieqiao barrel scraping, and other ways to slime-dug up, and then transported to the nearby roadway slime dumped on both sides, to be delivered later on dried slime Ground, or slime in the mine car loaded directly delivered to the ground. Artificial dug not only labor-intensive, low operating efficiency, and the clearing and long cycle, particularly in the rain season also may be cleaning up water stores do not lead to timely and submerged wells accident.

In this paper, the clearing of existing methods and a domestic production or trial production of water equipment to clean up positions on the basis of analysis, the combination of hydraulic, mechanical grab lifting of the structure and working principle of introducing a coal mine for clean-up Coal Wharf silting of water a new water cleaning equipment warehouse. Grab the equipment used to crawl enhance the work of coal silt, grab the Open-and upgrade all through the hydraulic cylinders to achieve, grab the back and around moving forward by the size of the motor-driven vehicles driven cars run institutions - To achieve. The device is simple in structure, power system a single, easy installation and maintenance advantages.

Keywords:Wharf mine water ;Hydraulic grab ;Dredging equipment

1 概 述

1.1起重机械的用途及工作特点

起重机械主要用于装卸和搬运物料,是现代化生产的重要设备。它不仅广泛应用于工厂、矿山、港口、车站、建筑工地、电站等生产领域,而且也应用到人们的生活领域。使用起重运输机械,能减轻工人劳动强度,降低装卸费用,减少货物的破损,提高劳动生产率,实现生产过程机械化和自动化不可缺少的机械设备。

起重机械是以间歇、重复工作方式,通过起重吊钩或其它吊具的起升、下降,或升降与运移重物的机械设备。其工作特点具有周期性。在每一工作循环中,它的主要机构作一次正向及反向运动,每次循环包括物品的装载及卸载,搬运物品的工作行程和卸载后的空钩回程,前后两次装载之间还有包括辅助准备时间在内的短暂停歇。

综合起重机械的工作特点,从安全技术角度分析,可概括如下:

⑴起重机械通常具有庞大的结构和比较复杂的机构,能完成一个起升运动、一个或几个水平运动。例如,桥式起重机能完成起升、大车运行和小车运行三个运动;门座起重机能完成起升、变幅、回转和大车运行四个运动。作业过程中,常常是几个不同方向的运动同时操作,技术难度较大 。

⑵所吊运的重物多种多样,载荷是变化的。有的重物重达几百吨乃至上千吨,有的物体长达几十米,形状很不规则,还有散粒、热融状态、易燃易爆危险物品等,使吊运过程复杂而危险。

结 论

通过此次毕业设计,使我受益匪浅,在将大学期间所学专业基础知识都全面检验一遍的同时更开阔了我的知识面,对我日后的学习和工作都将有很大的帮助。

本文满足设计要求,设计题目主要是针对矿水仓清淤设备及方法所存在的问题,提出了一种具体的设计方案。我主要通过以下几个阶段完成:

1、总体方案的确定

主要对装置的各个部件进行分析。包括机架的结构形式、抓斗装置,提升装置和大小车行走装置等。这个过程是设计的关键所在,方案的好坏直接关系到整个装置性能的优越与否,因而也是我的工作重点。在老师的指导下,最终确定了现有的方案。

2、抓斗的设计

这个过程主要是把总体方案中液压系统应用于抓斗开合升降的构思给表达出来,液压抓斗是整个装置的关键部件,由于设计条件有空间及环境等要求,在对抓斗的设计过程中都要考虑到空间有限的因素,因此抓斗机构采用了液压缸水平布置,及反曲柄联动的机构。此过程完成了抓斗在抓取物料闭合过程中的受力分析及计算。

3、大小车架的设计

车架是承载所有设备的平台,车架结构要求具有足够的刚度、强度和稳定性。。在这个设计阶段,主要的工作是确定了大小车架的结构、承载平台的形式和安装方式,把车架中各个组件、零件以及它们之间的连接形式表示出来,并对车架进行了受力分析及校核

4、液压系统的设计

液压系统是整个装置控制系统的一部分,它和电控系统相结合形成了整个装置的控制系统。在装置中,各个执行元件主要是采用液压驱动的方式。在这个设计阶段,我的主要工作包括液压泵站及其附属器件的设计,各个执行元件的选型设计。

5、零部件的设计

这个过程主要是对装置中一些重要的零部件进行设计。包括驱动装置的设计和液压缸的设计等。

由于时间有限,以及所学知识的局限性,本设计从整体上来说,还存在很多需要改进的地方,其中也存在着或多或少的问题和错误。这也是本次毕业设计的不足之处,对此恳请老师给予批评指正,我将在以后的工作中吸取经验。

参考文献

[1] 起重运输机械,陈道南等编,机械工业出版社,1982年;

[2] 起重机课程设计,陈道南等编,冶金工业出版社,1993年;

[3] 起重机设计手册,张质文等编,中国铁道出版社,1998年;

[4] 起重机课程设计,陈道南等编,冶金工业出版社,1983年;

[5] 起重机设计规范,中华人民共和国国家标准,中国标准出版社,1984年;

[6] 机械设计手册第2卷,成大先等编,化学工业出版社,1996年;

[7] 实用机械设计手册,吴相宪等编,中国矿业大学出版社,1993年;

[8] 起重机械安全技术检验手册,任树奎等编,中国劳动出版社,1993年;

[9] 起重机械,付东明等编,机械工业出版社,1992年;

[10] 起重运输机械设计基础,范祖尧等编,机械工业出版社,1991年;

[11] 起重运输机械计算,沈静宝等译,中国铁道出版社,1982年;

[12] 起重运输机械图册,倪庆兴等编,机械工业出版社,1992年;

[13] 起重机钢结构制造工艺,付荣柏等编,中国铁道出版社,1991年;

[14] 起重运输机械金属结构,王金诺等编,中国铁道出版社,1984年;

[15]现代液压技术应用220例,张利平等编,化学工业出版社,2004年;

[16]机械设计手册第四卷,成大先等编,化学工业出版社,1996年;

[17] 液压设计禁忌,周世昌主编,机械工业出版社,2002年;

[18] 液压技术手册,范存德主编,辽宁科技出版社,2004年;

[19]液压与气压传动,许福玲 陈尧明 等编,机械工业出版社,2004年;

[20] G.A.Manson.Time optimal control of an overhead crane mode1.Optimal Control Applications and Methods,No.3,1982;

[19] W.Singhose,L.Porter and M.Kenison,Effects of hoisting on the input shaping of gantry cranes.Control Engineering Practice,No.2,2000。

川公网安备: 51019002004831号

川公网安备: 51019002004831号