细石混凝土搅拌机设计

45页 14000字数+说明书+外文翻译+10张CAD图纸【详情如下】

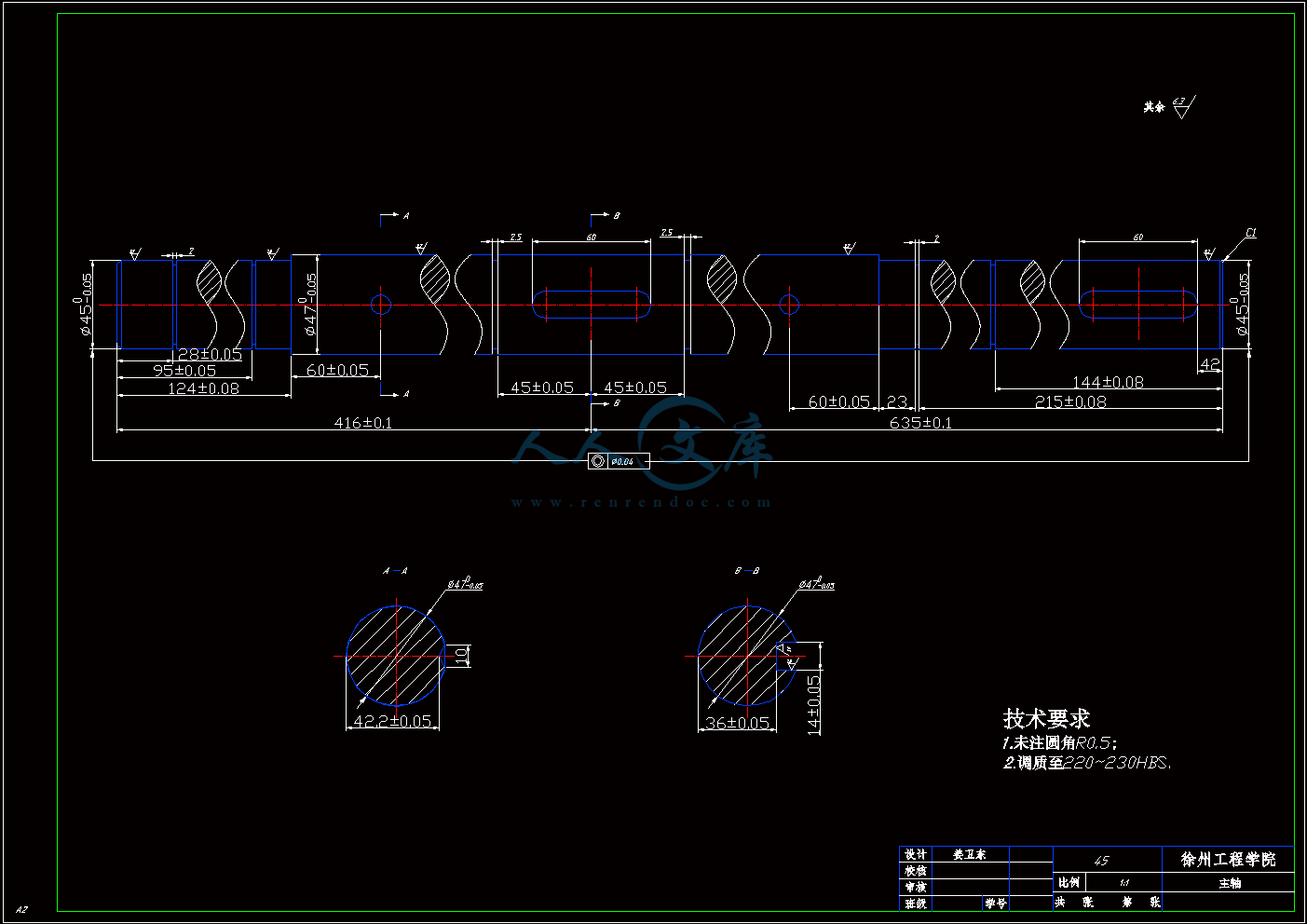

主轴.dwg

减速装置.dwg

外文翻译--混合性能单轴构件式搅拌机 中文版.doc

外文翻译--混合性能单轴构件式搅拌机 英文版.pdf

搅拌机装配图.dwg

搅拌杆.dwg

料筒.dwg

机架.dwg

细石混凝土搅拌机设计说明书.doc

说明书.doc

轴承座.dwg

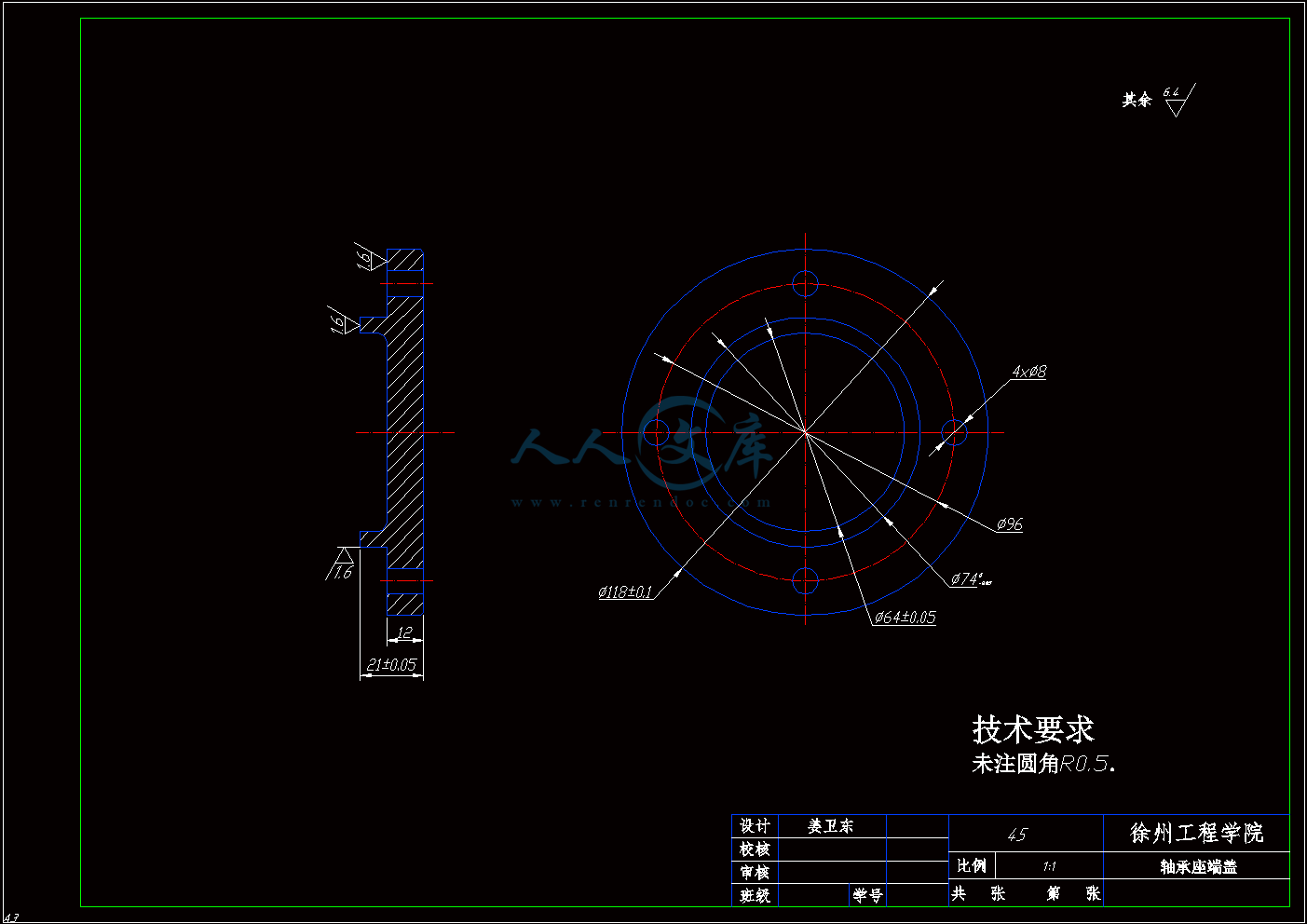

轴承座端盖.dwg

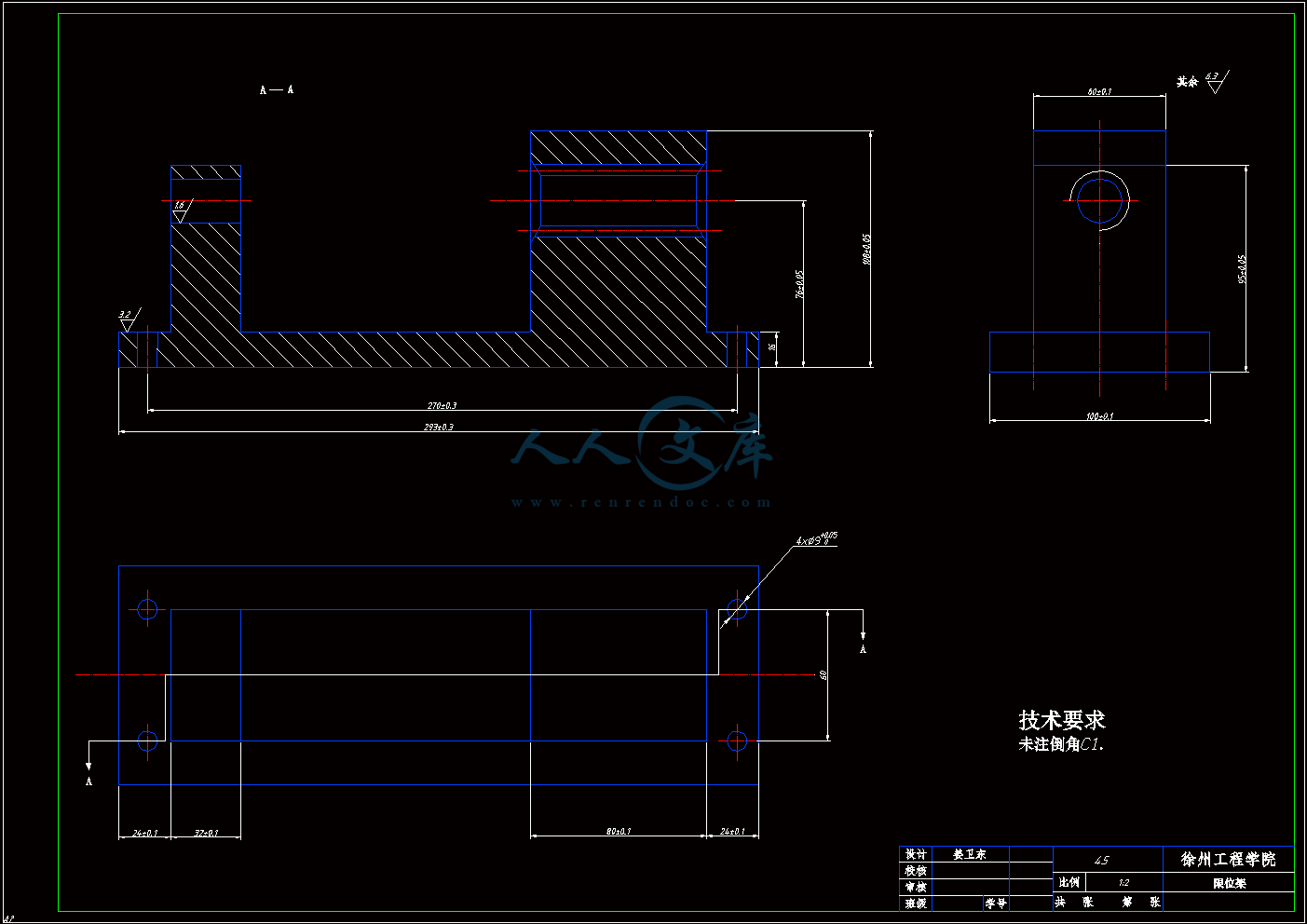

限位架.dwg

限位销.dwg

目录

摘要I

AbstractII

1 绪论1

1.1 混凝土搅拌机械1

1.2 混凝土搅拌机结构和工作原理3

2传动部分设计4

2.1电动机的选择4

2.2传动比的分配7

2.3计算传动装置的运动和动力参数8

2.4第一级齿轮传动的设计10

2.4.1材料的选择10

2.4.2确定齿轮主要尺寸13

2.5第二级齿轮传动的设计16

2.5.1材料的选择16

2.5.2确定齿轮主要尺寸18

2.6减速器的润滑和密封21

2.6.1传动的润滑21

2.6.2轴承润滑22

2.6.3密封装置22

3 搅拌机的工作原理23

3.1 搅拌机的结构组成23

3.1.1搅拌机料筒24

3.1.2搅拌机叶片24

3.1.3搅拌机轴承24

3.1.4搅拌机联轴器27

3.1.5搅拌机轴28

3.1.6搅拌机支架34

3.2 工作过程35

3.3电路控制36

4.1搅拌机使用的注意事项37

4.2搅拌机的日常保养37

结论39

致谢40

参考文献41

1 绪论

1.1 混凝土搅拌机械

混凝土施工机械的发展状况是影响建筑工程施工机械化程度的重要因素之一。因为建筑技术与建筑工程的现代化已经使建筑物的基础、梁、柱、板等主要构件几乎都是混凝土浇筑而成的.如果工程中所用的大量混凝土,其生产过程中的各道工序(即贮料、装料、配料、搅拌、运输、浇筑和振捣)都采用人工操作,则不仅需要大量的劳动力,而且劳动强度高、效率低、混凝土的质量差。为此,必须十分重视混凝土施工机械的发展和应用,并作为提高建筑施工机械化程度的主要技术措施之一。当前,我国建筑工程中混凝土的加工虽已基本机械化,但分散件很强,尚不能走向较高程度的工业化,商品混凝土应用的程度还很小。今后一段时间内,要把注意力放在混凝土施工地机械化体系的配套上,使之更加完善。

混凝土搅拌机是将一定配合比的水泥(胶结材料)、砂、石(骨料)和水(有时还加入一些混合材料)拌和成匀质混凝土的机械。同人工拌和混凝土相比,混凝土搅拌机具有生产率高,拌和质量好,减轻工人劳功强度等优点,如今它是建筑施工现场、混凝土构件厂及商品混凝土供应站生产混凝土的重要机械设备之一。

混凝土搅拌机按搅拌混凝土的原理来分有自落式和强制式两种。

自落式混凝土搅拌机工作机构是筒体,沿筒内壁圆周安装若干搅拌叶片。工作时,将物料投入搅拌筒内,筒体绕其自身轴旋转,靠搅拌筒的旋转,由筒内的搅拌叶片将物料推到一定的高度后,物料靠自重坠落下来,反复对物料进行搅拌而加工成匀质混凝土。这种搅拌机特点是搅拌强度不大,效率低,只适合加工普通塑性混凝土,对骨料的粒径要求不严格,广泛地应用于各种中小型建筑工地。是现在建筑行业中应用较为广泛的一种混凝土搅拌机。

强制式混凝土搅拌机的搅拌机构是水平式设置在筒内的搅拌轴,轴上安装搅拌叶片,工作时,强制式混凝土搅拌机的搅拌筒固定不动,是由筒内转轴的带动叶片旋转来对物料进行强制式的剪切,挤压、翻转的强制搅拌作用,使拌合料在剧烈的相对运动中达到均匀拌和。这种搅拌机搅拌质量好,效率高,适合加工普通塑性和半硬性的混凝土。由于受构造上的限制,对粗骨料粒径的要求较为严格,施工现场的混凝土搅拌站和混凝土预拌工厂的搅拌楼中使用的搅拌机均系此种类型。

混凝土搅拌机,按其外形又可分为鼓形、锥形和盘形二种;按所用动力装置不同又分为电动式和内燃式两种;由搅拌量的不同,又将搅拌机分成多种容量型号,目前世界上的混凝上搅拌机已有200种以上。我国混凝土搅拌机的容量、规格的发展也很迅速,容量仅在3000L以下的就合11种之多,它们是;50,100,150、200,250,350,500,750,1000,1500和3000L这些搅拌机都同属周期作业式,随着混凝土施工工艺的发展和对搅拌机要求的提高,必将很快推出各种新型的混凝土搅拌机械。

根据搅拌机搅拌筒容量参数的小同,又常把混凝土搅拌机划分为大型(出科容量为1—3)、中型(出料容量为0.35—0.75)和小型(出料容量为0.5一0.25)三种。

我国混凝土搅拌机的生产业已定型,并自成系列,其代号和主要技术参数的意义:

J——搅拌机:

G——鼓形自治式混凝土搅拌机;

Z——锥形反转出料式混凝土搅拌机;

F——锥形顿翻出料式混凝1:搅拌机;

D——单卧轴强制式混凝土搅拌机;

JG250型混凝土搅拌机——表示鼓形自落式混凝土搅拌机,电动机驱动,出料容量并经捣实后的混凝土体积为250L。

混凝土搅拌机其主要组成部分有:

搅拌机构.它是混凝土搅拌机的主要工作机构,由搅拌筒、搅拌叶片等组成。

传动装置它是向搅拌机各工作机构传递力和速度的系统。—般有由带条、摩擦轮、齿轮,、链轮和轴等传动元件组成的机械传动系统和由液压元件组成的液压传动系统两大类。

川公网安备: 51019002004831号

川公网安备: 51019002004831号