货车制动系液压系统设计

35页 16000字数+说明书+外文翻译+开题报告+6张CAD图纸【详情如下】

中文标题.doc

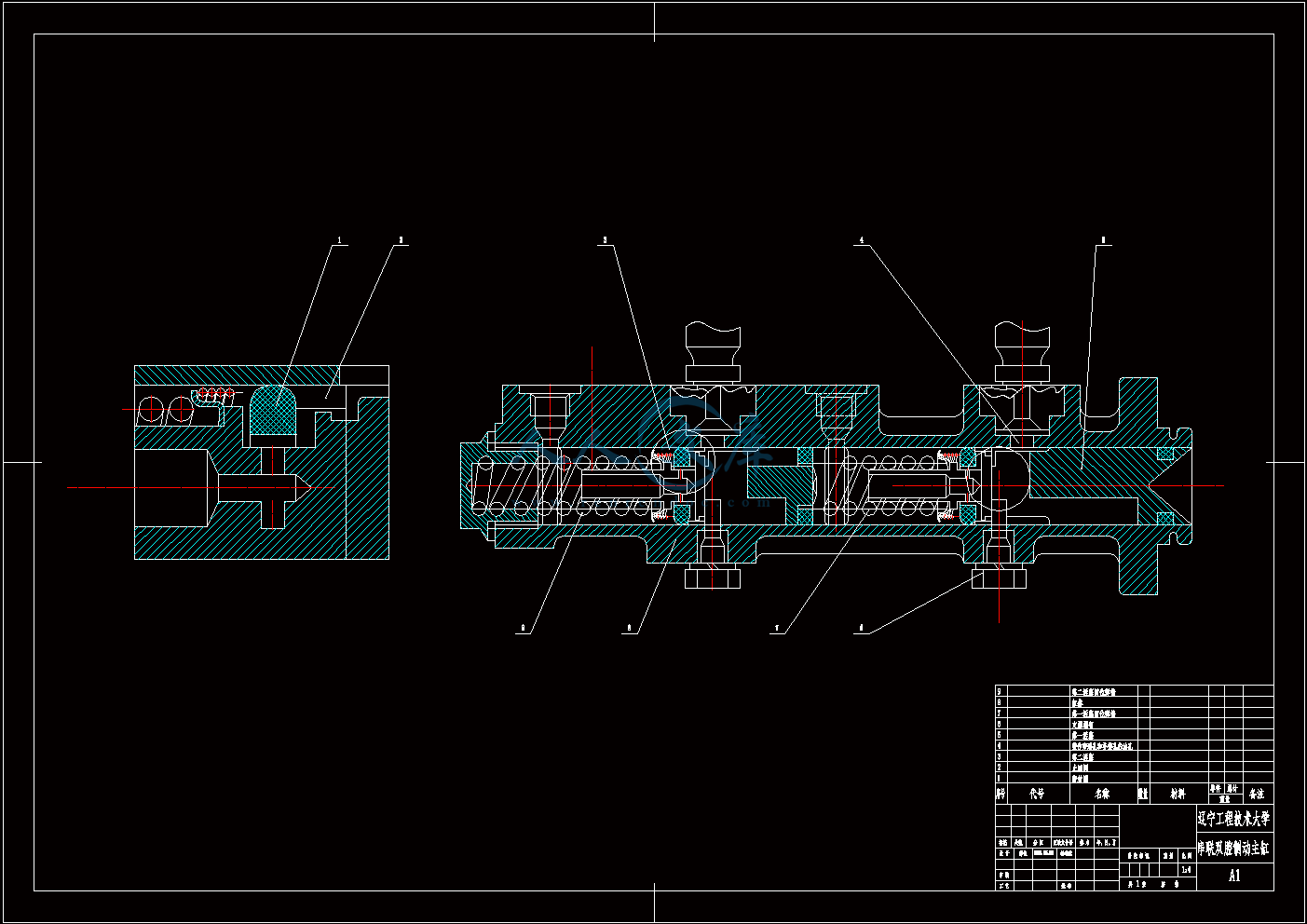

制动主缸.dwg

回路图.dwg

外文翻译--未来汽车制动控制系统的新技术及其发展趋势.doc

摘要.doc

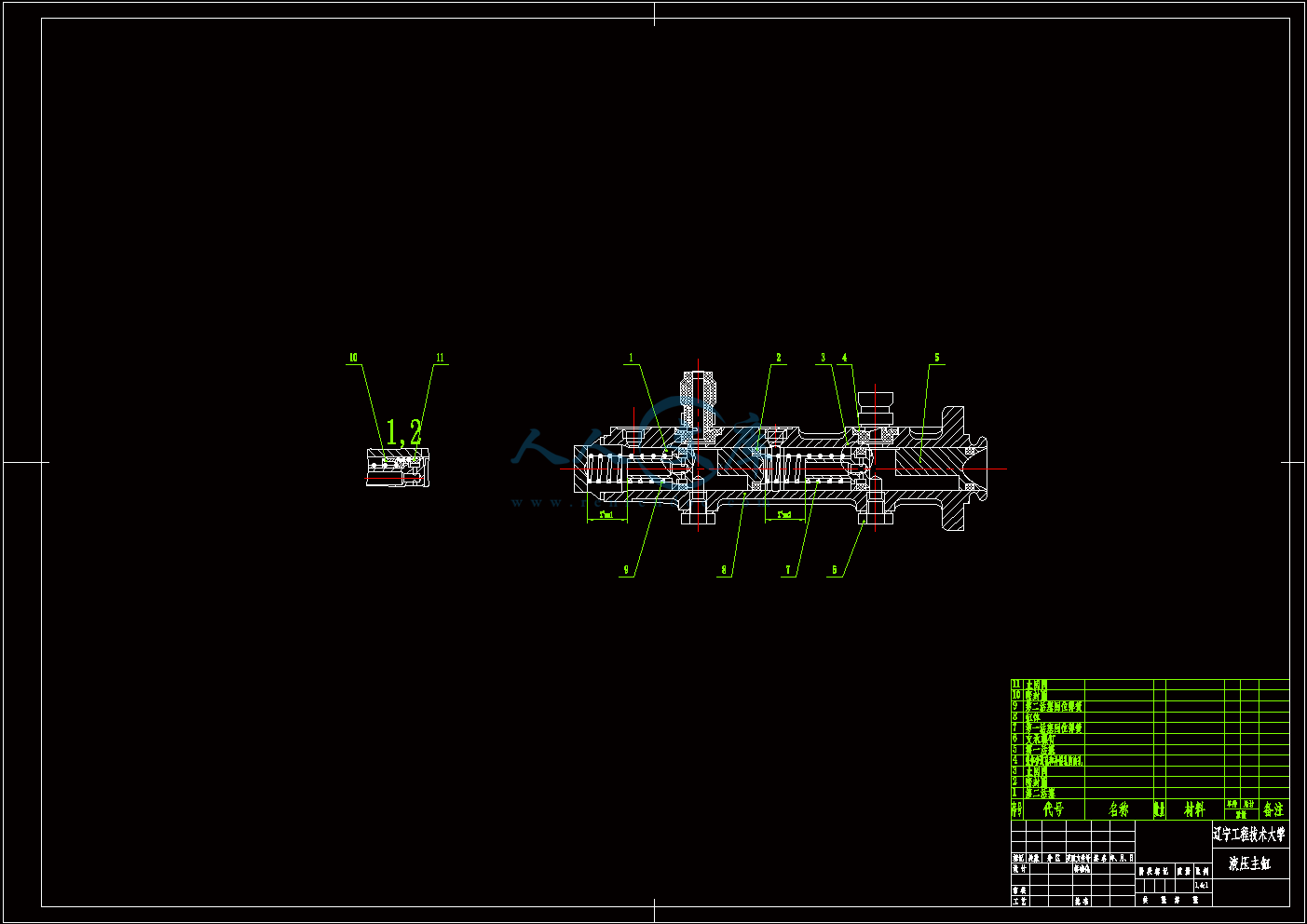

液压主缸.dwg

目录.doc

系统结构示意图.dwg

货车制动系液压系统设计说明书.doc

货车制动系统液压设计开题报告.doc

蹄.dwg

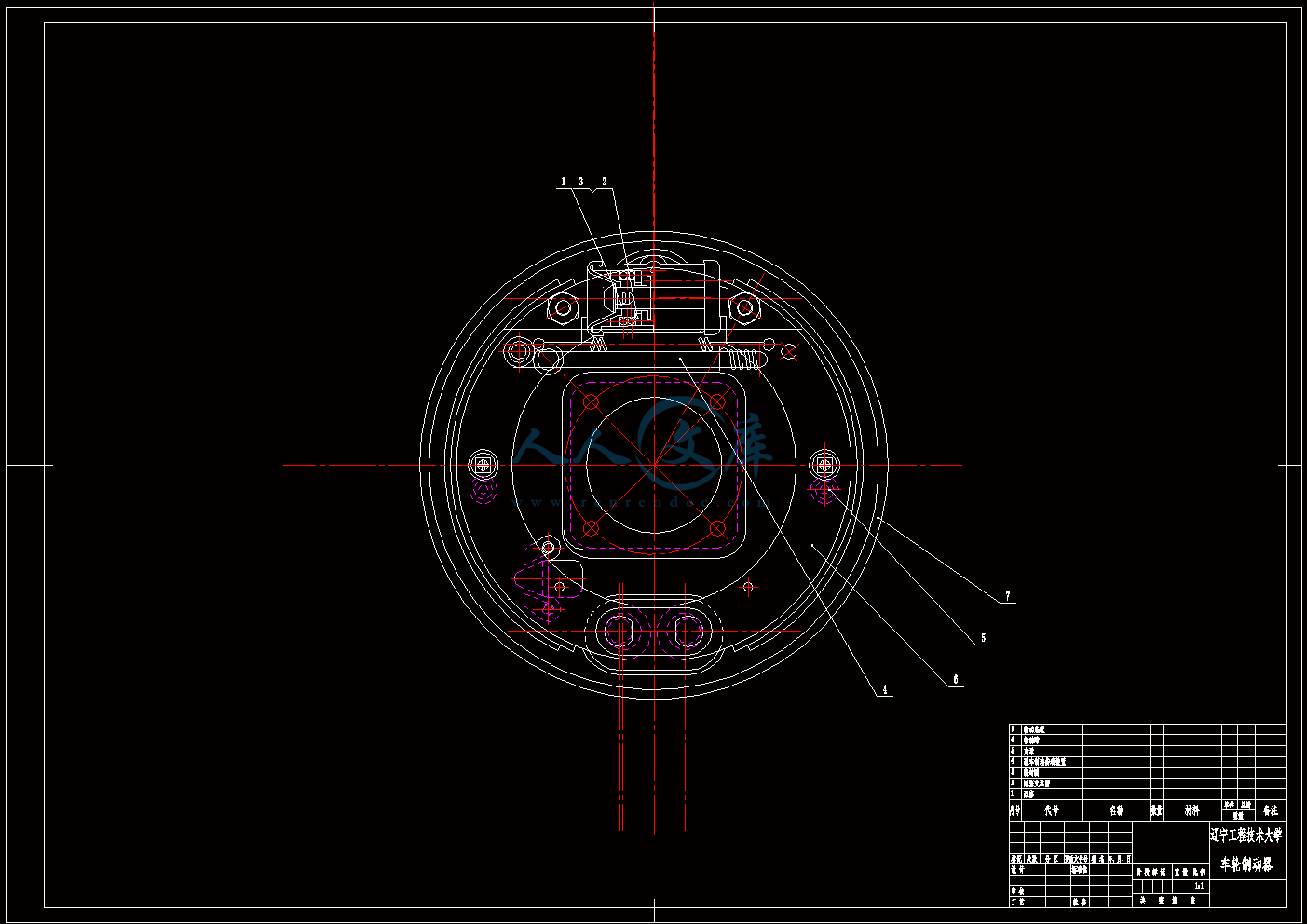

车轮制动器.dwg

目录

前言1

1制动系要求6

2制动系的选择9

2.1汽车总质量9

2.2轴荷分配和质心位置的计算9

2.3同步附着系数12

2.4制动强度和附着系数利用率15

2.4.1制动器最大制动力矩18

2.4.2制动器因数18

2.4.4制动器主要零件的结构设计21

3制动器驱动机构的结构型式选择及设计计算23

3.1制动驱动机构的结构型式选择24

3.1.1液压制动驱动机构的设计计算25

3.2制动力分配的调节装置27

4液压系统计算及工作原理28

4.1汽车制动装置的工作原理28

4.2制动缸液压传动装置的工作原理28

4.3液压优点与缺点29

4.3.1液压优点29

4.3.2液压的缺点29

4.4轮缸的计算29

4.4.1前轮轮缸的活塞作用面积29

4.4.2方向控制换向阀31

4.4.3对换向阀的性能要求31

4.4.4换向阀用于以下目的31

4.4.5手动换向滑阀的结构和工作原理31

4.5压力控制阀32

4.3.1对安全阀的性能要求32

4.3.2对稳压阀的性能要求32

5结论33

致谢34

参考文献35

附录A36

附录B42

摘要

汽车制动系是用以强制行驶中的汽车减速或停车、使下坡行驶的汽车保持稳定以及使已停车的在原地(包括在斜坡上)驻流不动的机构对制动器的效能、制动效能的恒定性。使驾驶员敢于发挥出汽车的高速行驶能力,从而提高汽车运输的生产率。制动时的方向稳定性有着具体的要求。随着高速公路的迅速发展和车速的提高以及车流密度的日益增大,为了保证行车的安全性,汽车制动系的工作可靠性显得日益重要,也只有制动性能良好、制动系工作可靠的汽车,才能充分发挥其动力性能。液压制动系统提高了汽车制动的安全性,增加了安全行驶性,研究液压制动系统是为了更好的保证汽车的行驶性能的可靠性,研究范围主要包括系统中各个部件的压力,流量,和功率,充分发挥制动性能。提高制动效率。减低流量的损失。

关键词: 制动效率 制动系统 流量 功率

Abstract

The automobile braking system was uses to force in the travel the automobile to decelerate or the parking, to make the downhill travel the automobile to maintain stabilizes as well as causes to stop in-situ in (including in pitch) the standing current motionless organization to the brake potency, the brake potency constancy.。Causes the pilot to dare to display the automobile high speed travel ability, thus enhances motor transport the productivity. Time the brake yawing stability has the concrete request。Increase day by day along with the highway rapid development and the vehicle speed enhancement as well as the stream of vehicles density, in order to guarantee the driving the security, the automobile braking system operational reliability appears day by day importantly, also only then braking quality good, braking system work reliable automobile, can display its power performance fully.。The hydraulic brake system enhanced the security which the automobile applies the brake, increased the security of service, the research hydraulic brake system is for the better guarantee automobile driving quality reliability, the research scope mainly includes in the system each part pressure, the current capacity, with the power, displays the braking quality fully. Enhances the brake efficiency. Decreases the current capacity the loss.

Key word: Brake efficiency Braking system Current capacity Power

制动系的选择

货车的主要参数为:

长宽高() 489419302085

轴 距() 2800

前 轮 距() 1480

后 轮 距() 1470

最小离地间隙()186

整车整备质量()1985

最大装载质量()1500

前满载轴荷分配()1057

后满载轴荷分配()2797

最 高 车 速不底于90

1 制动系要求

能适应有关标准和法规的规定。各项性能指标除应满足设计任务书的规定和国家标准、法规规定的有关要求外,也应考虑销售对象国家和地区的法规和用户要求。

具有足够的制动效能,包括行车制动效能和驻车制动效能。行车制动效能是用在一定的制动初速度下或最大踏板力下的制动减速度和制动距离两项指标来评定。欧、美、日等国的有关标准或法规对这两项指标的规定。综合国外有关标准和法规,可以认为:进行制动效能试验时的制动减速度j,载货汽车应为4.4~5.5相应的最大制动距离货车为0.15+/115,式中第一项为反应距离;第二项为制动距离,的单位为 m;的单位为km/h.

工作可靠,汽车至少应有行车制动和驻车制动两套制动装置,且它们的制动驱动机构应是各自独立的。行车制动装置的制动驱动机构至少应有两套独立的管路,当其中一套失效时另一套应保证汽车制动效能不底于正常的30%;驻车 制动装置应采用工作可靠的机械式制动驱动机构。

制动效能的热稳定性好。汽车的高速制动、短时间内的频繁重复制动,尤其是下长破时的连续制动,都会引起制动器的温升过快,温度过高特别下长坡时的频繁制动可使制动器摩擦副的温度达3000C~4000C 有时甚至高达7000C..此时,制动摩擦副的摩擦系数会急剧减小,使制动效能下降而发生热衰退现象。制动器发生热衰退后,经过散热、降温和一定次数的和缓使用使摩擦表面得到磨合,其制动效能可重复恢复,这称为热恢复。提高摩擦材料的高温摩擦稳定性,增大制动鼓、盘的热容量,改善其散热性或采用强制冷却装置,都是提高抗热衰退的措施。

制动效能的水稳定性好。制动器摩擦表面浸水后,会因水的润滑作用使摩擦系数急剧减少而发生所谓的“水衰退”现象。一般规定在出水后反复制动5~15次,即应恢复其制动效能。良好的摩擦材料吸水率低,其摩擦性能恢复迅速。也应防泥沙、污物等进入制动器工作表面,否则会使制动效能降低并加速磨损。某些越野车为了防止水和泥沙浸入而采用封闭的制动器。

制动时的操作稳定性好。即使任何速度制动,汽车都不应当失去操作性和方向稳定性。为此,汽车前、后轮制动器的制动力矩应相同。否则当前轮抱死而侧滑时,将失去操作性;后轮抱死而侧滑甩尾,会失去方向稳定性;当左、右轮的制动力矩差值超过50%时,会发生制动时汽车跑偏。

制动踏板和手柄的位置和行程符合人—机工程学的要求,即操作方便性好,操作轻便,舒适,能减少疲劳。踏板形成;对货车应不大于160~200mm。各国法规规定,制动的最大踏板力一般为150N(轿车)~700N(货车)。设计时,紧急制动(约占制动总次数的5%~10%)踏板力的选取范围:货车为350~550N,采用伺服制动或动力制动装置时取其小值。应急制动时的手柄拉力以不大于400~500N为宜。

作用滞后的时间要尽可能地短,包括从制动踏板开始动作至达到给定制动效能水平所需的时间(制冻滞后时间)和从放开踏板至完全解除制动的时间(解除制动滞后时间)。

制动时不应产生震动和噪音。

与悬架、转向装置不产生运动干涉,在车轮跳动或汽车转向时不会引起自行制动。制动系中应有音响或光信号等警报装置以便能及时发现制动驱动机件的故障和功能失效;制动系中也有必要的安全装置,例如一旦主、挂车之间的连接制动管路损坏,应有防止压缩空气继续漏失的装置;在行驶过程中挂车一旦脱挂,亦应有安全装置驱动使驻车制动将其挺驻。

能全天候使用,气温高时液压制动管路不应有气阻现象;气温低时液压制动管路不应出现结冰。制动系的机件应使用寿命长、制造成本低;对摩擦材料的选择也应考虑到环保要求,应力求减小制动时飞散到大气的有害于人体的石棉纤维

川公网安备: 51019002004831号

川公网安备: 51019002004831号