基于虚交点的圆锥体端面尺寸数显量具的研制设计

22页 12000字数+说明书+9张CAD图纸【详情如下】

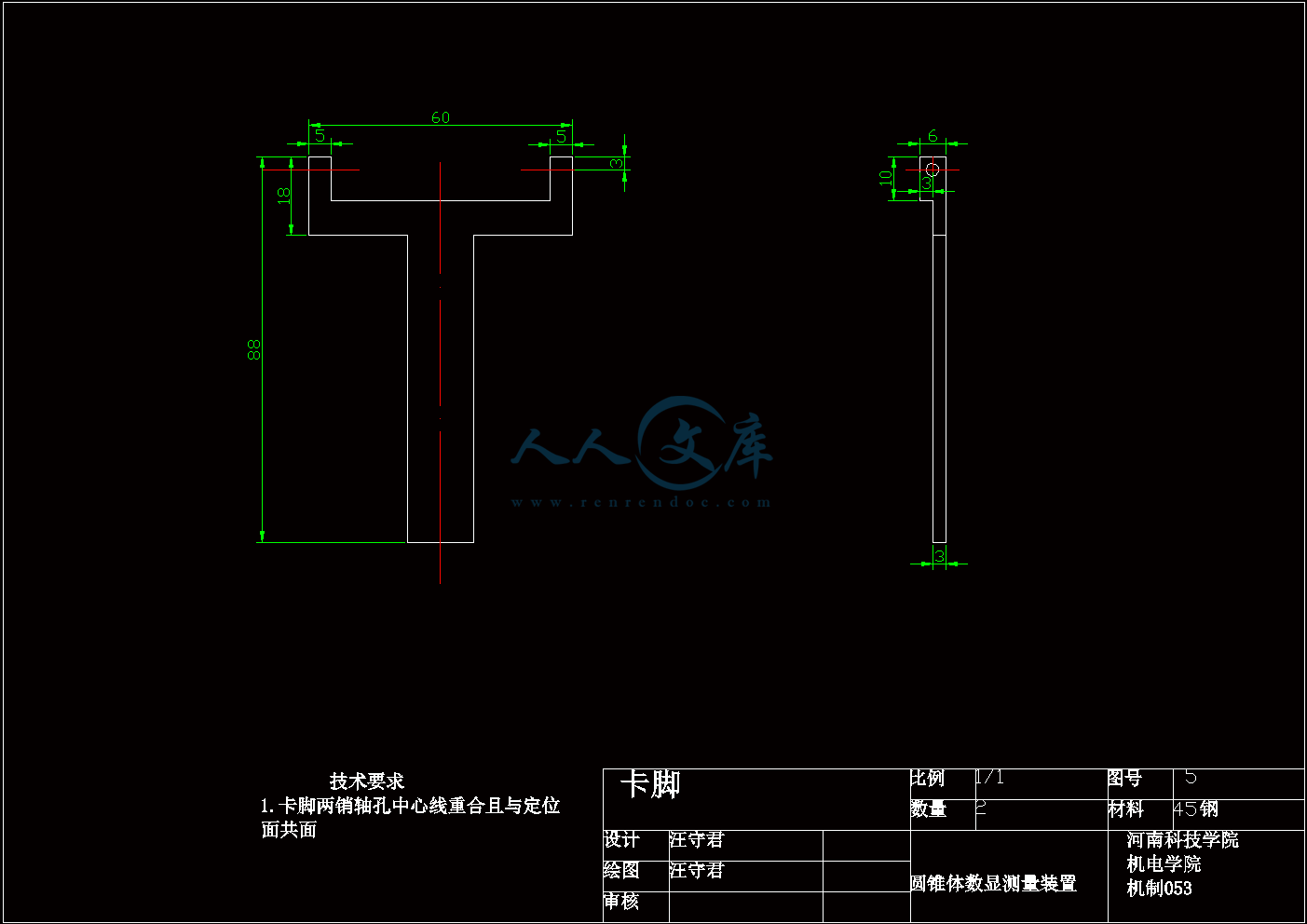

卡脚.dwg

基于虚交点的圆锥体端面尺寸数显量具的研制设计说明书.doc

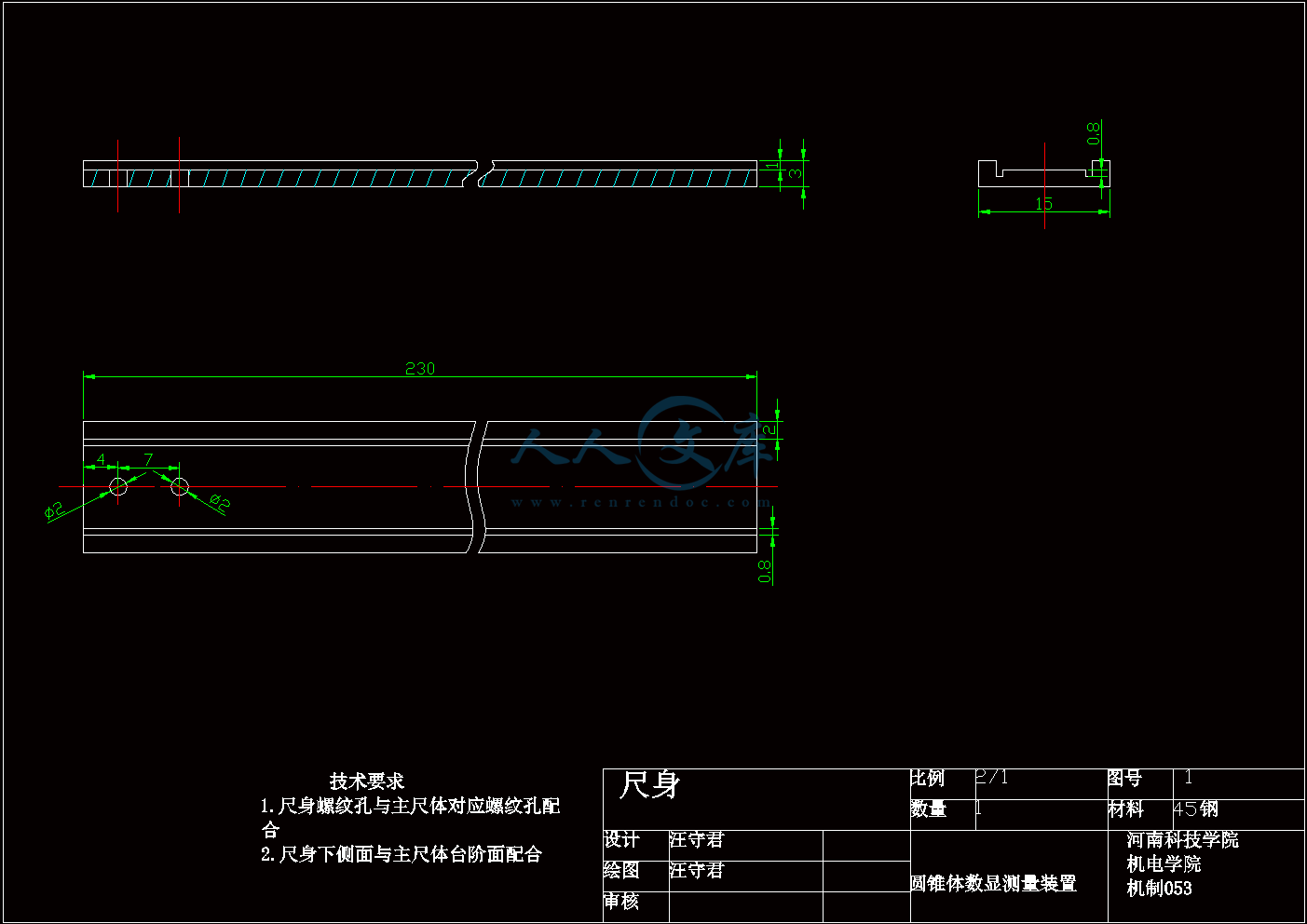

尺身.dwg

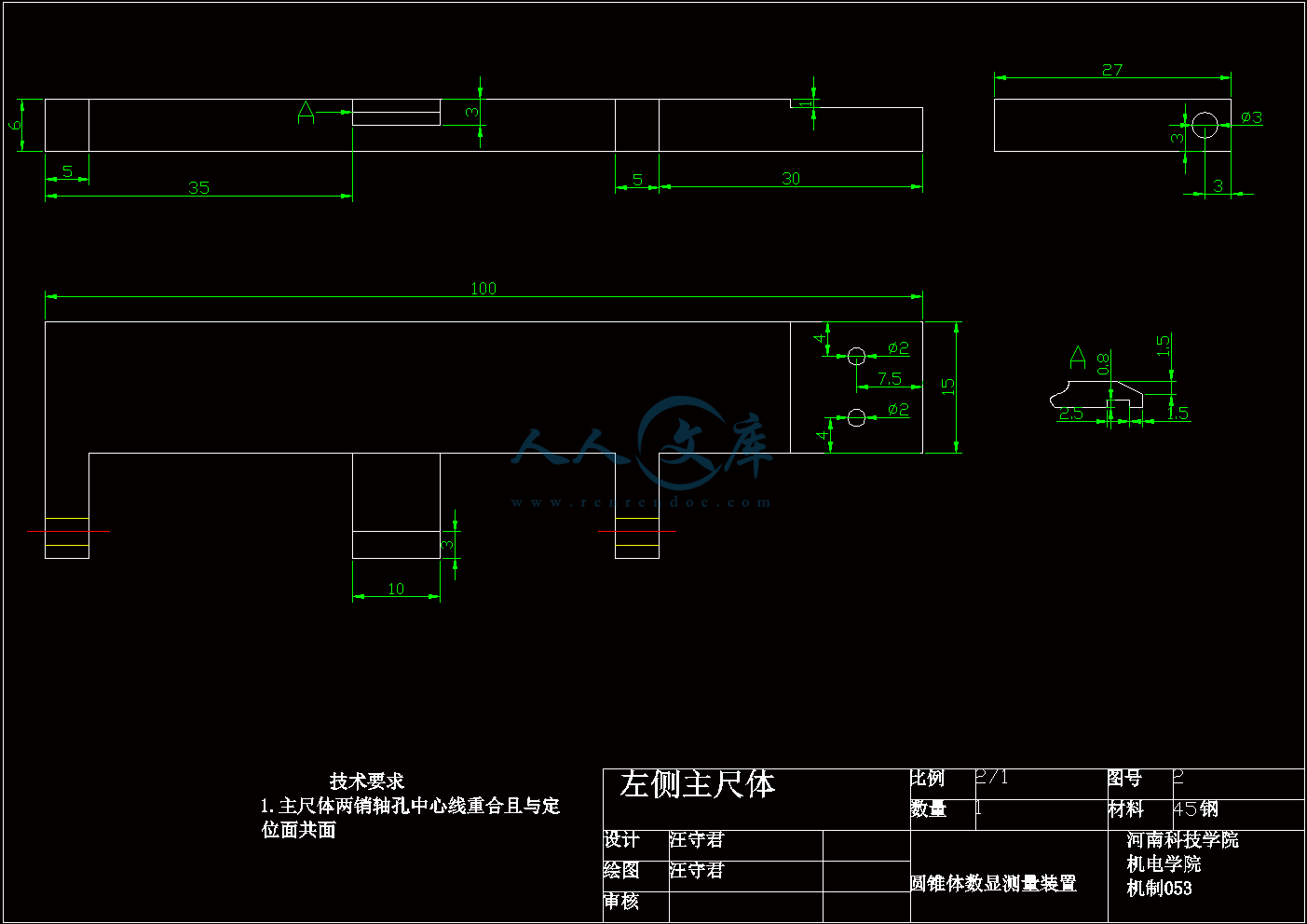

左侧主尺体.dwg

游标.dwg

游标体.dwg

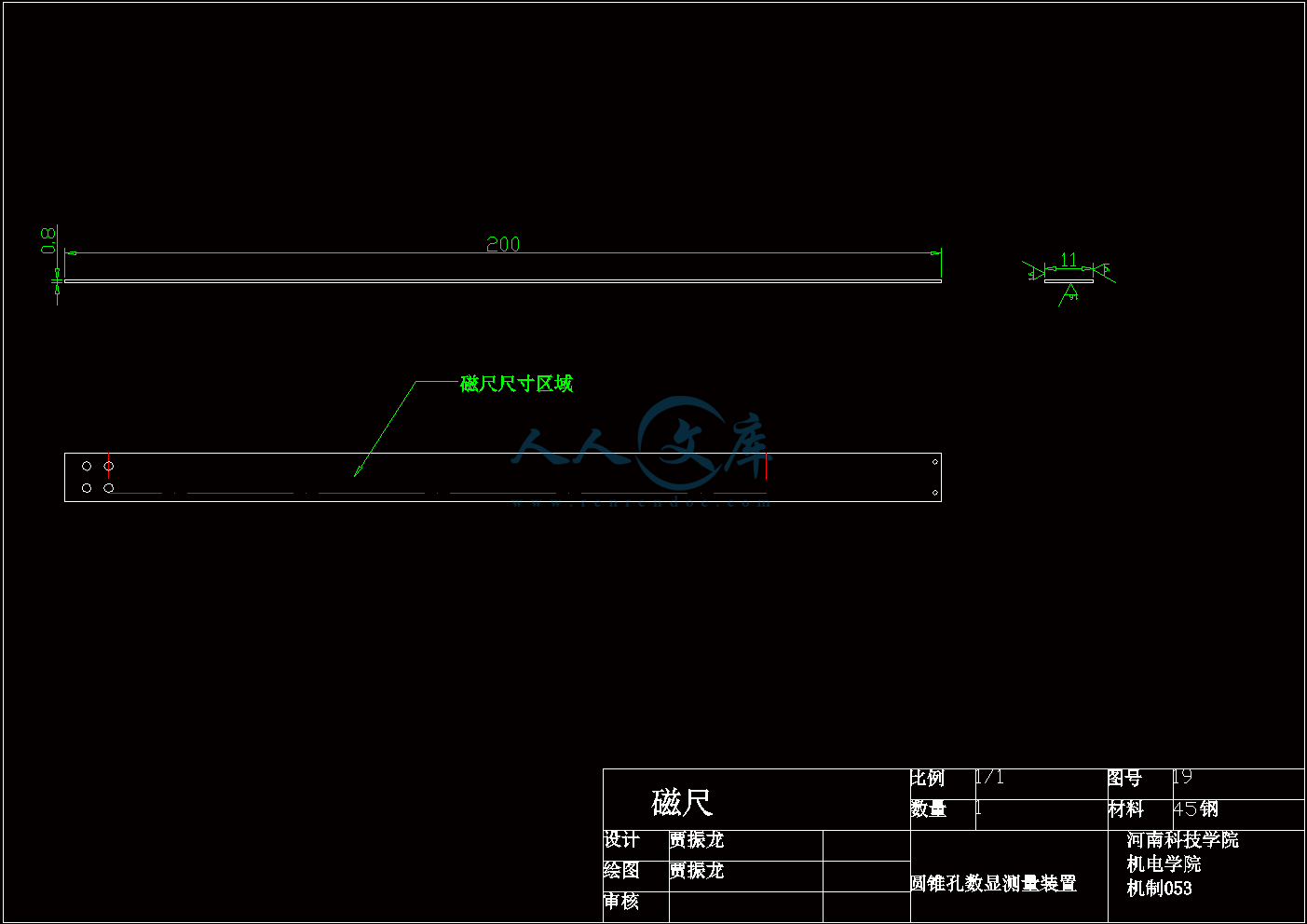

磁尺.dwg

被测零件.dwg

装配图.dwg

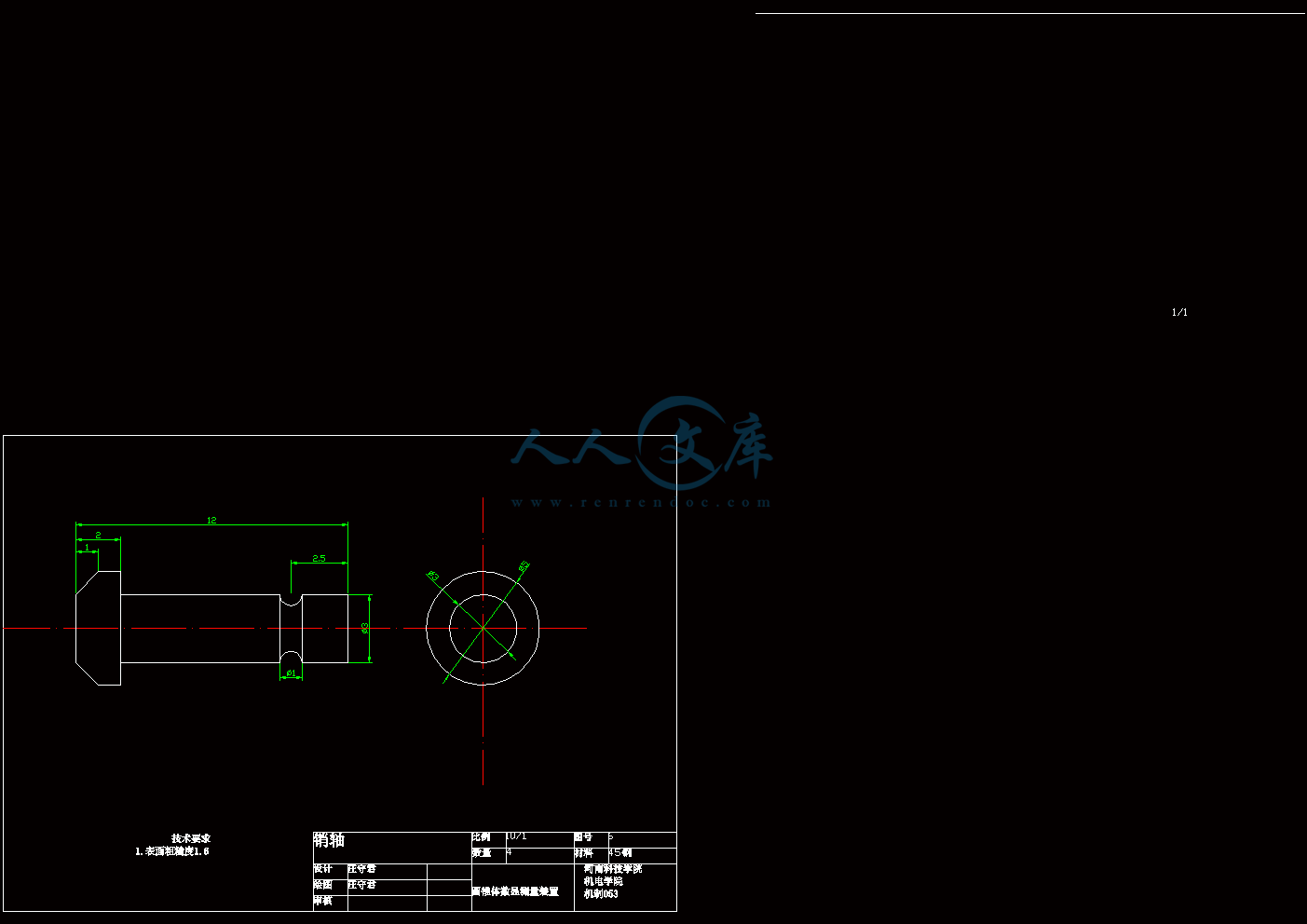

销轴.dwg

目 录

1 绪论1

1.1 目前对锥体端面直径量具的研究现状1

1.2 本次设计的意义和主要内容1

2 装置的测量原理和结构1

2.1 装置的测量原理1

2.2 装置的结构2

3 装置的测量范围分析3

3.1 最小测量直径的确定3

3.2 最大测量直径的确定3

4 装置各零件的加工工艺分析和工艺路线的设计4

4.1 主尺体的工艺分析和设计6

4.1.1 工艺路线方案一6

4.1.2 工艺路线方案二7

4.1.3 工艺路线方案的比较分析8

4.2 测量卡脚的工艺分析和设计10

4.3 尺身和游标的加工工艺分析和工艺路线的设计11

5 对装置测量精度的分析和改善的措施13

5.1 主尺体铰链中心线与主尺体定位面不共面(误差为δ1)对测量精度的影响13

5.2 主测量卡脚铰链中心线与主测量卡脚工作面不共面(误差为δ2)对测量精度的影响14

5.3 改善和提高装置测量精度的措施15

6 量具使用应该注意的事项16

7 结束语17

致谢17

参考文献18

摘 要

圆锥体由于结构的特殊性导致其端面直径不易测量。而检测锥体的方法,最常用的是使用圆锥套规,这种检测方法一般只是用来判断工件是否在规定的极限尺寸内,以确定工件是否合格,但不能测出零件锥体实际尺寸。特别当锥度较大时,过端刻线与止端刻线、过端面与止端面将相距很近,并难以区分;也有借助辅助工具间接测量的,但此测量方法操作麻烦,测量时间也较长,不利于缩短工时,提高生产率,且不能直接测出数据,需利用所得数据进行计算,当尺寸精度要求较高时,使用上述量具在生产现场很难实现对该尺寸的精确测量。本文设计一种基于虚交点的圆锥体端面尺寸数显量具,可在机直接测量,不需计算,数显直读,且结构简单,测量范围大,有效地解决了生产现场检测锥体端面直径的问题,并利用电子数显卡尺和不锈钢板材等现有材料对该装置各零件进行工艺规程设计,最后进行样品试制。

关键词:圆锥体端面直径,测量装置,精度分析,工艺分析设计

Development of Digital Display Device for Measuring the End Size for the Cone Based on Virtual Intersection

Abstract

Because the cone has structural specificity, which causes its end face diameter not easy to be measured. Cone and detection methods, the most common is the use of cone sets of regulations, this detection method is generally used to judge whether the workpiece size within the limits of the provisions to determine whether the workpiece qualified, but you can not measure the actual size parts cone. Particularly when the taper is larger, had carved lines and only client-side engraved lines, had faces and will only end in close proximity, and it is difficult to distinguish; also aids with the indirect measurements, but this measurement method is cumbersome, time measurements are more long, is not conducive to shorten working hours, increased productivity, and can not be directly measured data, to be calculated using the data, when higher dimensional accuracy, the use of the above-mentioned scene in the production of measuring is very difficult to achieve accurate measurement of the size. In this paper, the design of a virtual point of intersection of the cone-end digital display measuring size, can be directly measured in the machine, without calculation, direct-reading digital display and simple structure, measuring range, and effectively address the production-site detection of end-diameter cone , and the use of electronic digital calipers and stainless steel sheet material, such as the existing parts of the device design process planning, the final sample trial.

Keywords:End Face Diamter of Cone, Measuring Tool, Precision Analysis, Process Analysis and Design

1 绪论

1.1 目前对锥体端面直径量具的研究现状

目前,对于圆锥体端面直径的测量装置及方法主要有以下几种:

(1)在万能工具显微镜上测量[7],但此方法测量步骤繁琐,且测量设备成本较高,经济性较差;

(2)借助辅助工具间接测量的方法,主要有:在正弦尺上测量[6]、用60°靠铁和正弦尺测量、在平台上测量(有单球法、双球法、圆柱圆球法、量块圆球法、圆锥量规法、圆柱双球法、四球法、双圆柱法)[7]等等,这些方法都需要根据所得数据由计算得出结果,受辅助工具本身制造误差和计算误差的影响,得出的尺寸精度较低,而且需要将工件从加工设备上卸下来,操作比较麻烦;

(3)也有使用圆锥套规[2],但套规不具有通用性,必须针对被测工件进行一对一设计,制造成本高,加工周期长,在生产的效率上和经济上都不好,不利于精益生产,而且无法测量出工件的具体尺寸。

川公网安备: 51019002004831号

川公网安备: 51019002004831号