空气重介流化床干法选煤机结构改进设计

61页 31000字数+说明书+9张CAD图纸【详情如下】

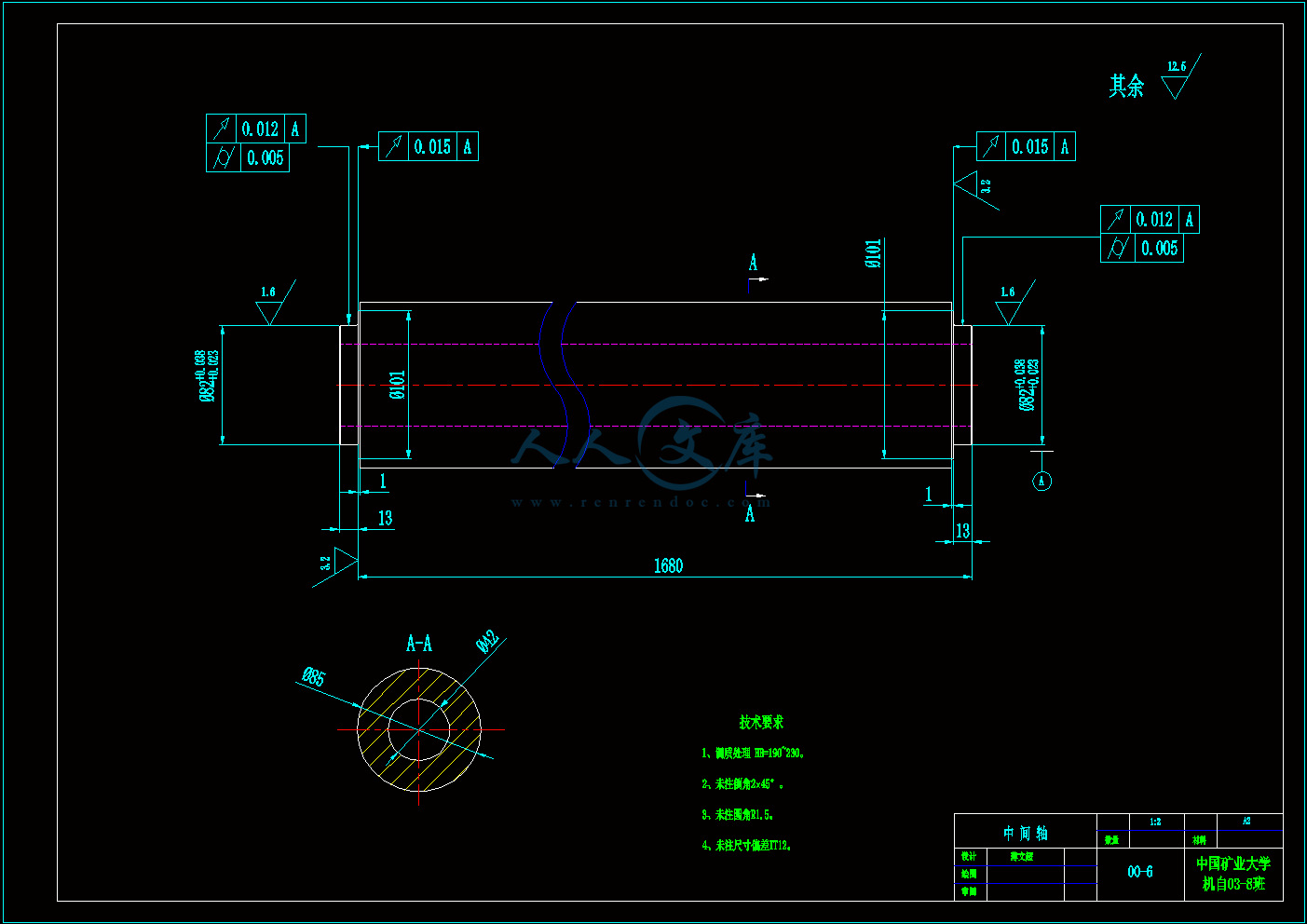

中 间 轴.dwg

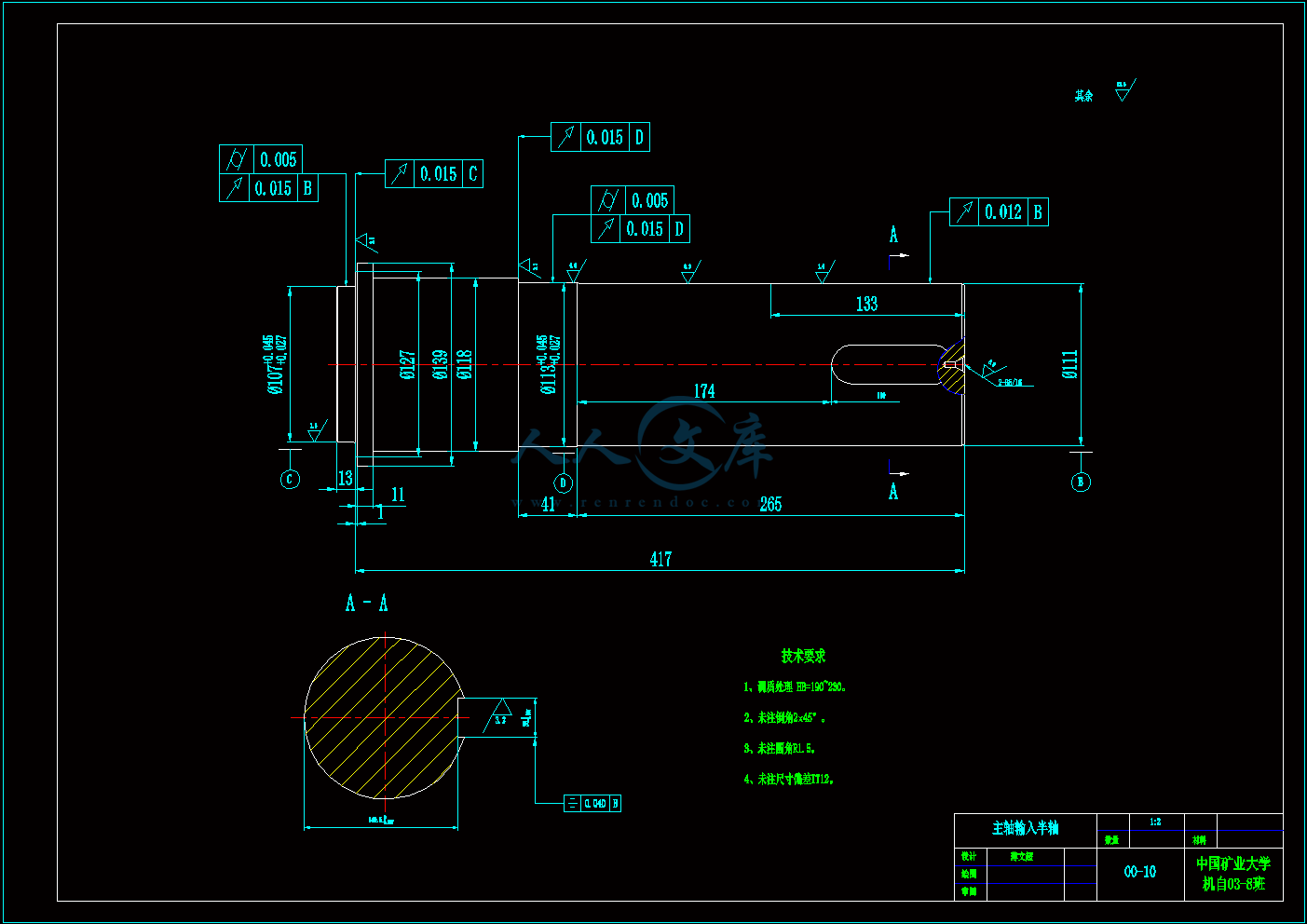

主轴输入半轴.dwg

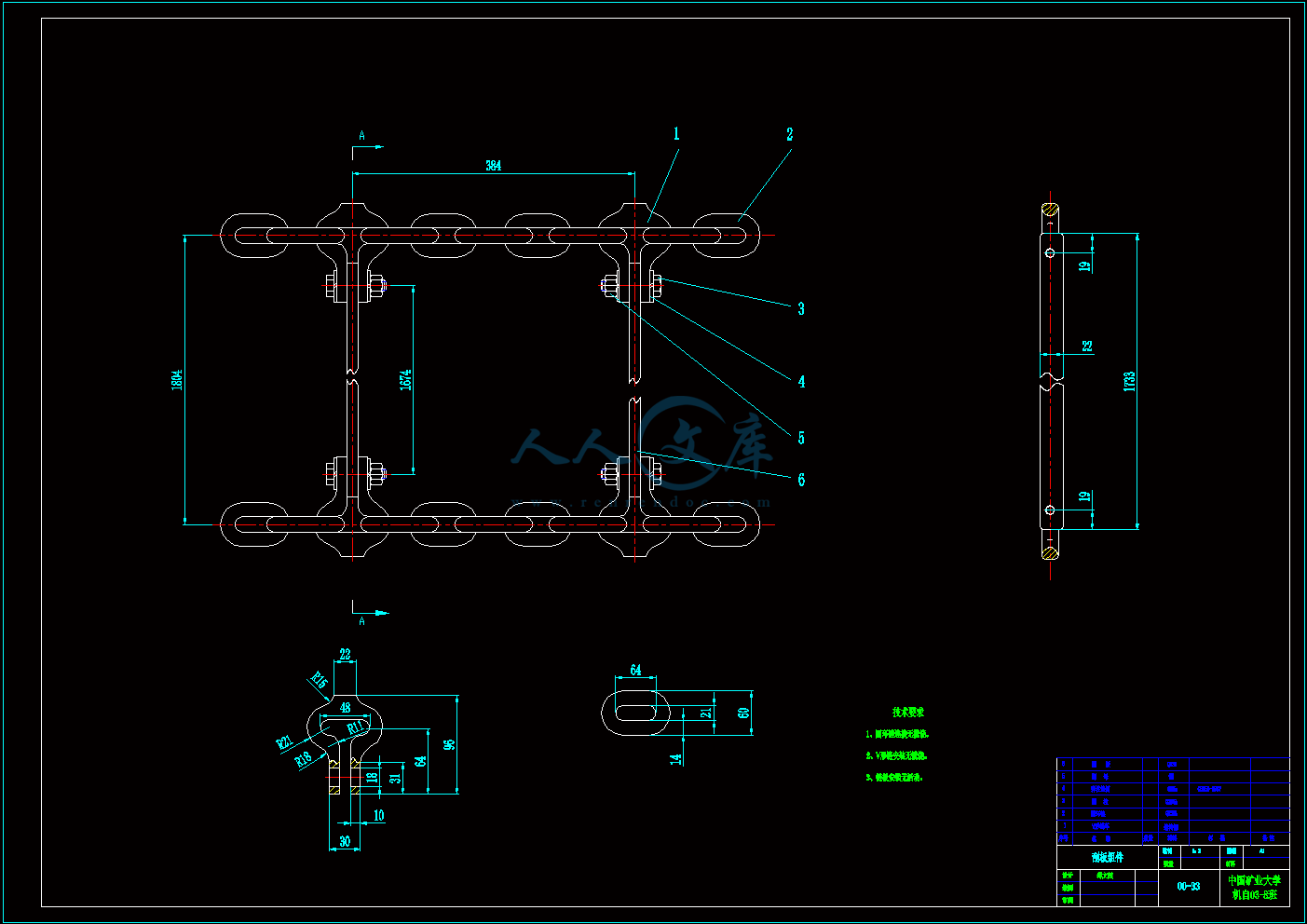

刮板组件.dwg

小 半 轴.dwg

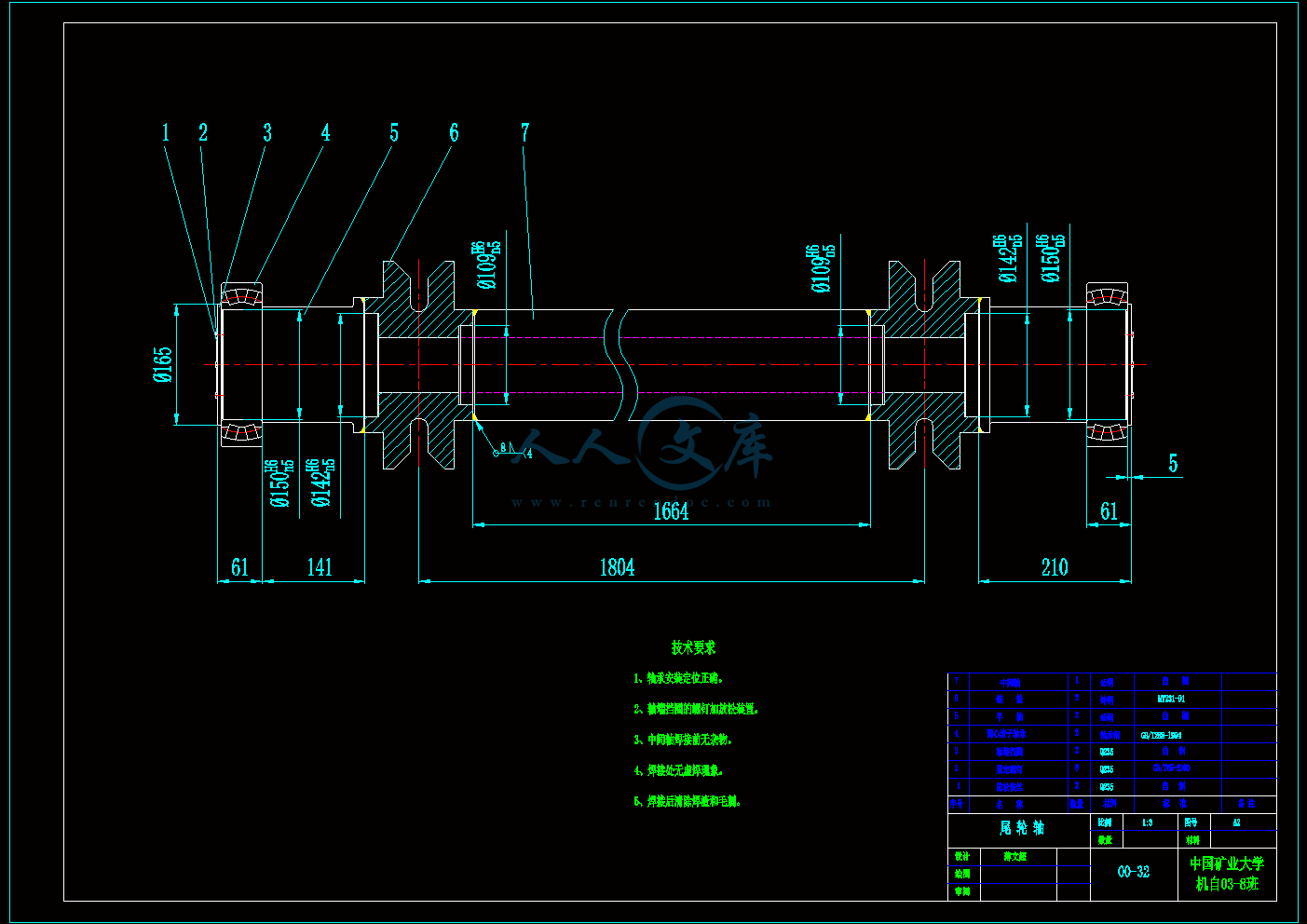

尾 轮 轴.dwg

布 风 板.dwg

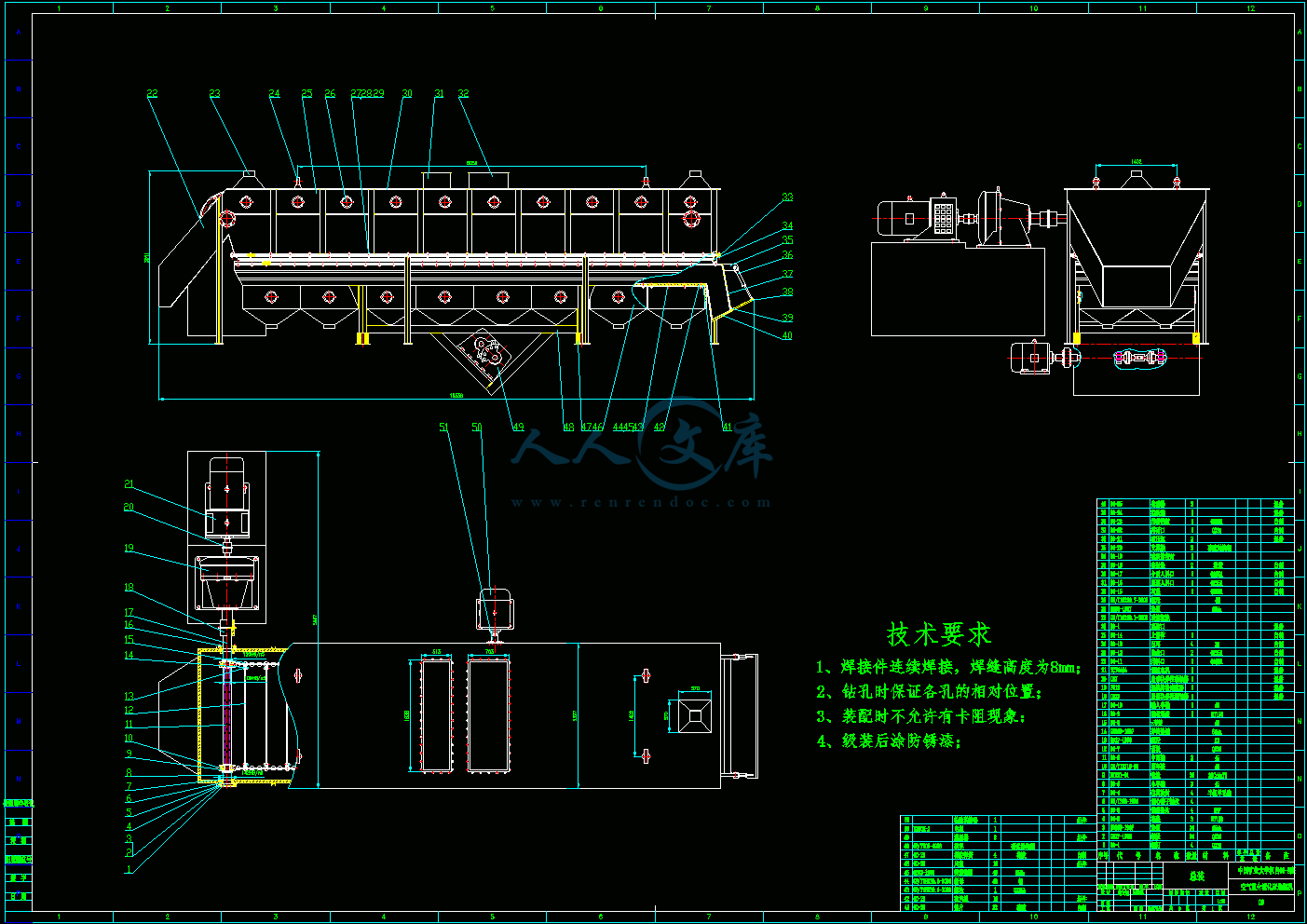

总装图.dwg

扉页.doc

目 录0.doc

空气重介流化床干法选煤机结构改进设计说明书.doc

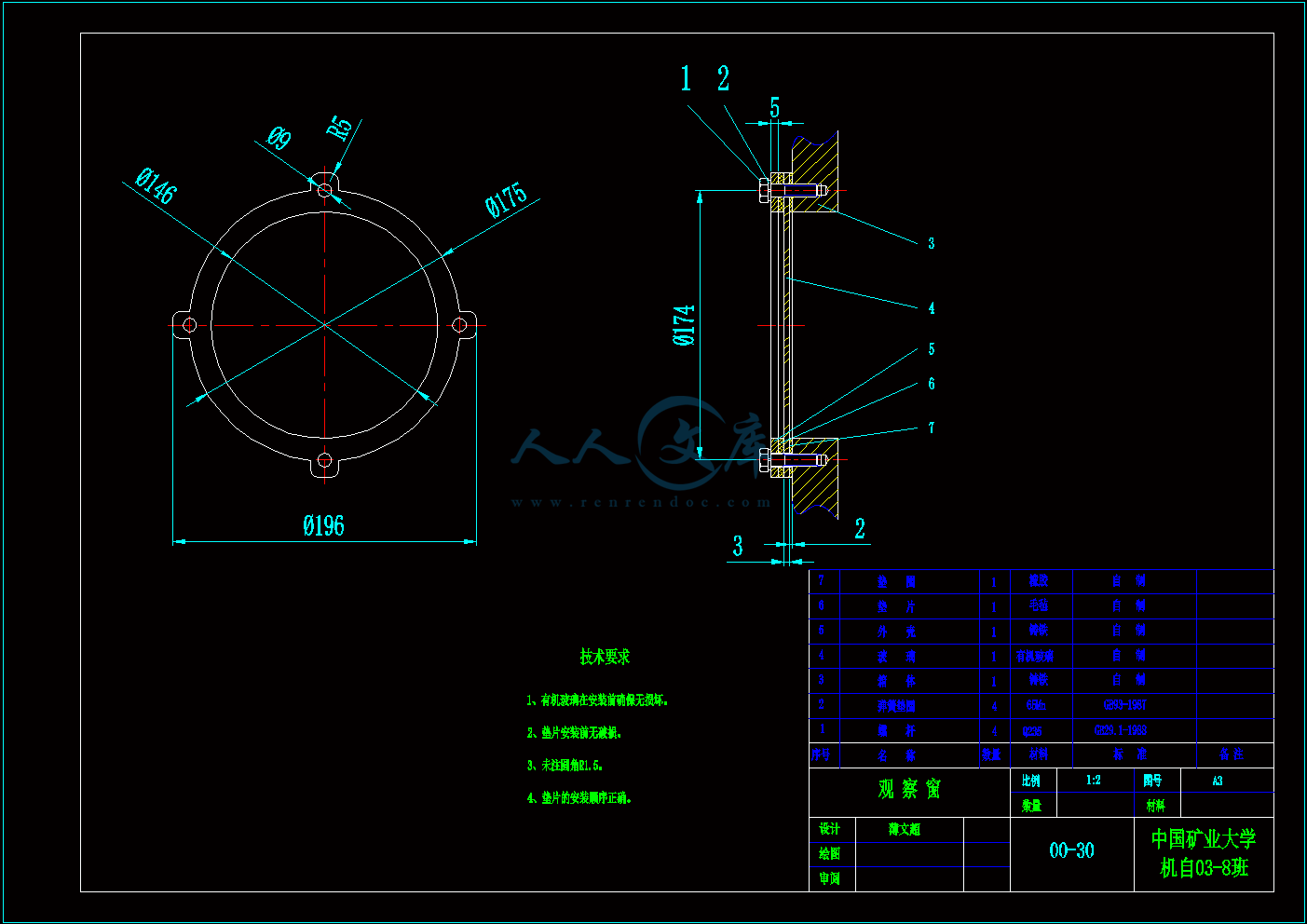

观 察 窗.dwg

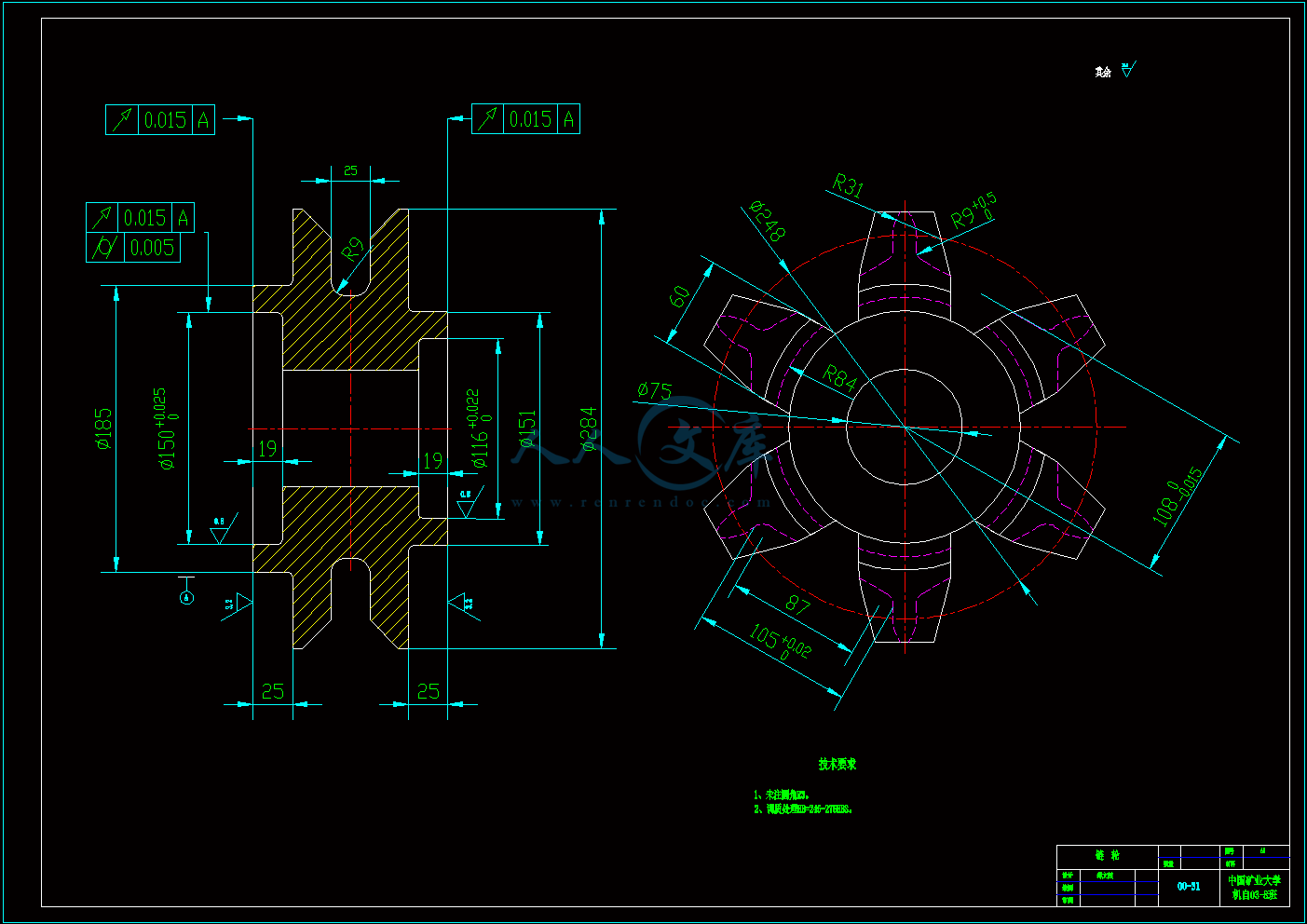

链 轮.dwg

零部件图.dwg

目录

1 绪论

1.1我国能源的现状2

1.2选煤技术简介2

1.2.1选煤技术分类2

1.2.2干法选煤技术的发展过程3

1.2.3研究干法选煤技术的重要意义 6

1.3空气重介干法选煤技术简介7

1.3.1空气重介干法选煤技术的原理7

1.3.2空气重介干法选煤技术的发展7

1.3.3传统空气重介流化床选煤机的结构简介10

1.4传统空气重介流化床选煤机的特点及存在问题 11

1.5 本设计在传统方案上的一些改进14

1.6 本章小结 16

2 空气重介流化床选煤机机构总体设计

2.1排料装置的机构设计17

2.2布风板的结构设计 19

2.3选煤机传动方案的确定 22

2.4本章小结23

3 流化床选煤机刮板运输装置的设计计算

3.1有关原始数据的说明24

3.2输送能力的计算24

3.3刮板的设计计算25

3.4链及链轮的设计计算26

3.5运行阻力的计算30

3.6电动机功率的校核32

3.7紧链力和刮板强度的计算32

3.8链轮轴的设计计算34

3.9本章小结38

4 流化床布风装置的设计计算

4.1布风结构的设计39

4.2布风装置参数的确定43

4.3本章小结44

5 激振装置的设计

5.1结构设计45

5.2主要参数的计算47

5.3激振中心的确定48

5.4激振器的选型50

5.5安装运行51

5.6本章小结51

6 排矸装置的设计

6.1排矸装置的设计52

6.2传感器的选型53

6.3本章小结54

参考文献55

致谢56

摘 要

我国是一个资源分布不平横的国家。近几年西部开发发现了西部的大量煤田。随着选煤工业的发展,传统的湿法选煤对水的要求量极大,不适应西部选煤生产的要求。而传统干法的污染大。在上个世纪我国就开始了空重介流化床选煤技术的研究,取得了很大的成果。随着全粒级煤炭的高效干法分选的实现将促进选煤事及洁净煤技术的进一步发展。

论文讨论了洁净煤分选技术的意义和现状、各种干法分选方法的特点以及空气重介质流化床选煤技术的优越性。在传统空气重介流化床干法选煤机的基础上,针对实际使用中出现的问题, 空气重介质流化床选煤技术具有分选精度高、投资少、环境污染小、分选密度调节范围宽等特点。我在设计中主要设计了选煤机专用刮板输送机、布风板、振动装置。在设计中尝试进行了一些更新。为解决布风不均的问题,设计了一种新型的振动式气体布风板。为了排放矸石,设计了一套排矸装置,可以实现定量排矸。在设计中借鉴了直线振动筛的工作原理、结构设计及主要参数的设计过程。

关键词:洁净煤; 空气重介; 流化床;

ABSTRACT

China is an uneven distribution of resources cross country. In recent years the development of the western region found a large number of western coalfield. Coal industry with the development of the traditional wet coal preparation of the water requirements of the large and does not meet Western Coal production requirements. Moreover, the traditional method of stem pollution. In the last century, China started on the heavy air-fluidized bed coal preparation technology, has made great achievements. The latest development of air heavy medium fluidized bed coal separation technology were discussed. The high efficient coal dry separation of whole size range is expected to come into application and the application will promote the further development of the coal separation undertaking and the coal cleaning technology.

The significance and present situation of clean coal technology were discussed. Characteristics of different dry coal beneficiation methods and advantages of air dense medium fluidized bed were introduced in paper. The air dense_medium fluidized bed technique is of high precision, low investment, wide range of density, and no environment pollution. I designed primarily designed for use exclusively Coal scraper conveyor, the grid plate, vibration device. On the base of previous air dense_medium fluidized bed separator, some renovation is done to solve the problem in use. In order to solve the unequality of the wind when it goes through the wind through board, the design gives a new board which is oscillated. The paper also designs an equipment for the excluding of the refuse, which can let the refuse out of the separator in set quality. I constructive the working principle, structure design and major parameters design process of linear vibrating screen, in this paper.

川公网安备: 51019002004831号

川公网安备: 51019002004831号