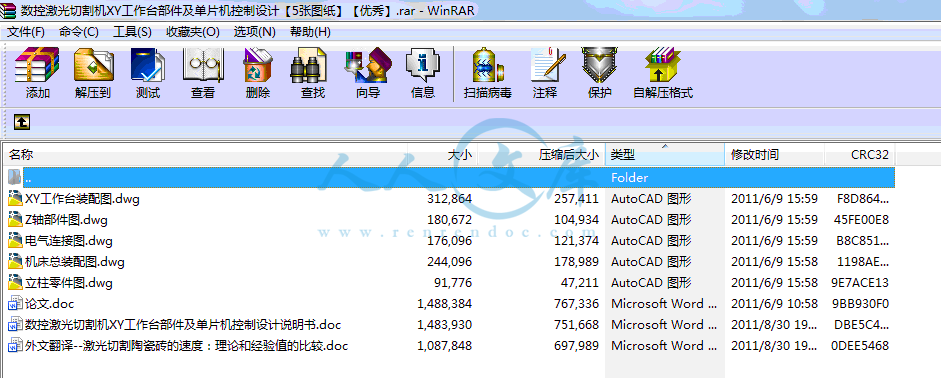

数控激光切割机XY工作台部件及单片机控制设计

54页 19000字数+说明书+外文翻译+5张CAD图纸【详情如下】

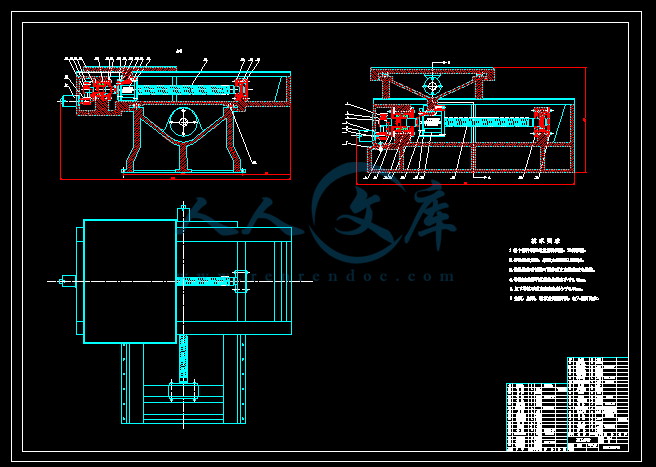

XY工作台装配图.dwg

Z轴部件图.dwg

外文翻译--激光切割陶瓷砖的速度:理论和经验值的比较.doc

数控激光切割机XY工作台部件及单片机控制设计说明书.doc

机床总装配图.dwg

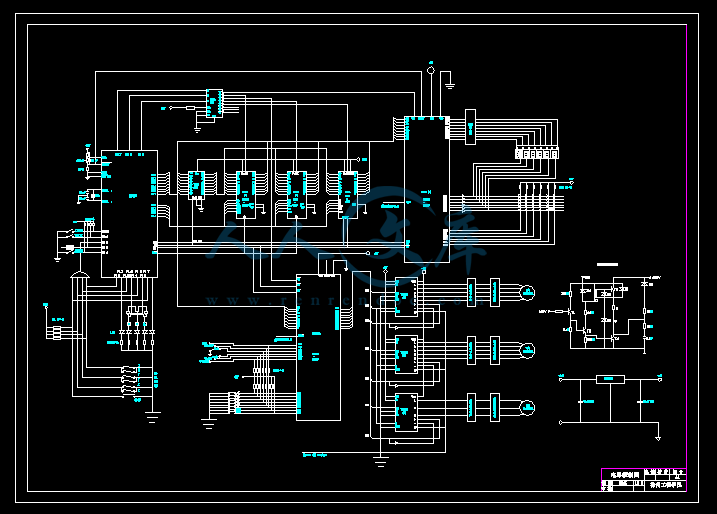

电气连接图.dwg

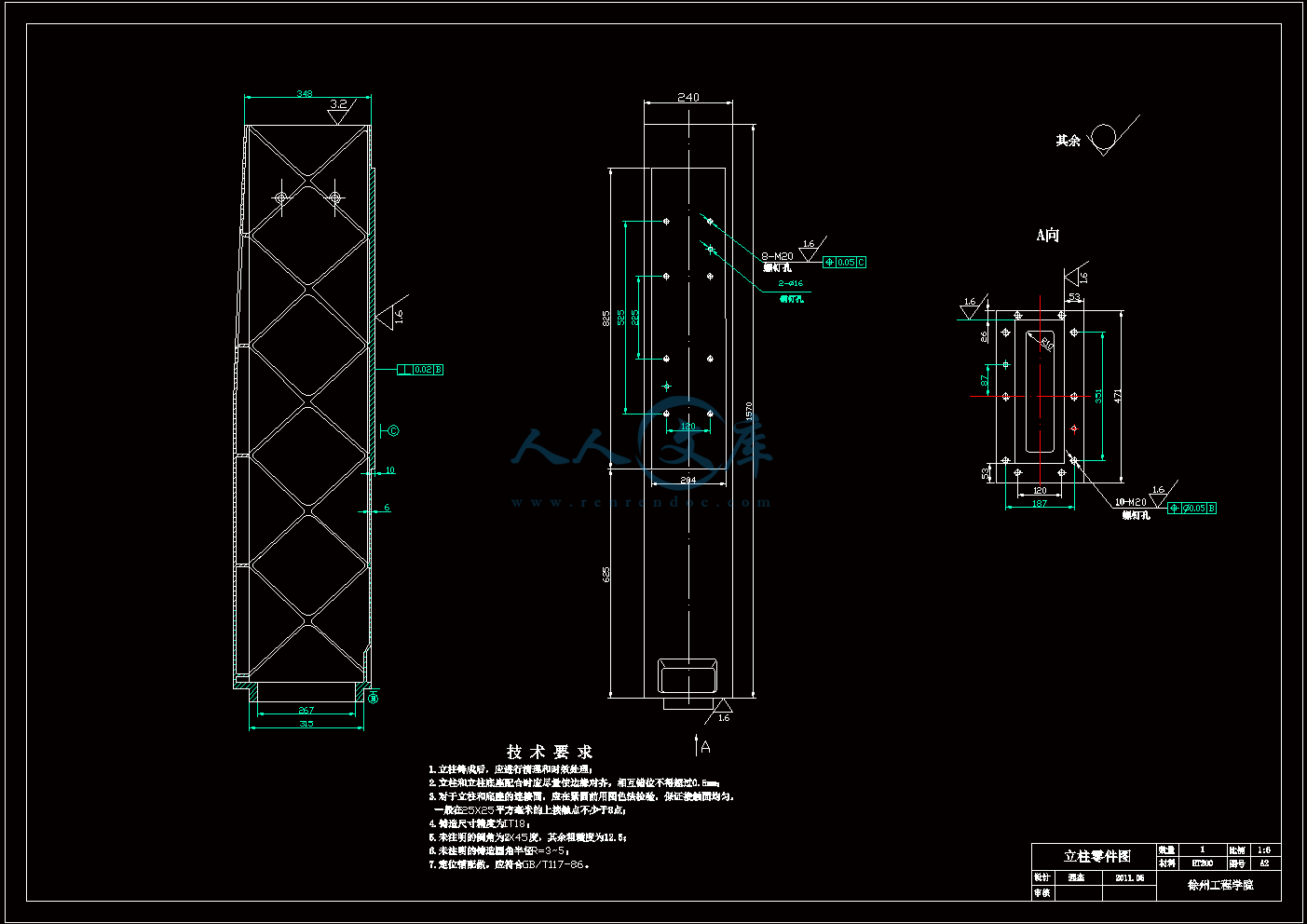

立柱零件图.dwg

论文.doc

目录

摘要I

AbstractII

1 绪论1

1.1激光技术概述1

1.2激光切割技术的应用1

1.3设计任务2

1.4总体设计方案分析2

2 工作台机械结构设计5

2.1 XY工作台的设计5

2.1.1 X-Y工作台结构设计总述5

2.1.2主要设计参数及依据5

2.1.3 XY工作台部件进给系统受力分析6

2.1.4初步确定XY工作台尺寸及估算重量6

2.2 Z轴随动系统设计6

2.3 机座的设计7

2.3.1 机座的结构设计7

2.3.2机座材料的选择8

3 传动系统的设计9

3.1丝杠的选型9

3.1.1 丝杠的介绍9

3.1.2丝杠螺母副的选择10

3.1.3丝杠的校核11

3.2 滚珠丝杠支承的选择13

3.2.1 支承方式的选择13

3.2.2 轴承的选择13

3.3导轨的选型及计算13

3.3.1 导轨的组成种类及其应满足的要求13

3.3.2导轨材料的选择及热处理13

3.3.3导轨的选型及长度估算14

3.3.4导轨副的额定寿命计算15

3.3.5滚动导轨副的技术要求17

3.4 步进电机的选择17

3.4.1步进电机的特点17

3.4.2 步进电机的选型17

3.4.3步进电机惯性负载的确定19

3.4.4 步进电机接口及电路驱动20

3.5齿轮传动机构的确定23

3.5.1传动比的确定23

3.5.2齿轮结构主要参数的确定23

3.6传动系统刚度的确定24

4 消隙方法与预紧26

4.1 消隙方法26

4.2预紧27

5 控制系统设计29

5.1 确定机床控制系统方案29

5.2 主要硬件配置29

5.2.1主要芯片选择29

5.2.2 主要管脚功能29

5.2.3 EPROM的选用30

5.2.4 RAM的选用31

5.2.5 89C51存储器及I/O的扩展31

5.2.6 8155工作方式查询32

5.2.7状态查询33

5.2.8 8155定时功能33

5.2.9 芯片地址分配34

5.3 总体程序控制35

5.3.1流程图35

5.3.2主程序35

5.4 键盘设计36

5.4.1键盘定义及功能36

5.4.2 键盘程序设计37

5.5 显示器设计38

5.5.1显示器显示方式的选用38

5.5.2显示器接口38

5.5.3 8155扩展I/O端口的初始化38

5.6 插补说明39

5.7光电隔离电路41

5.8越界报警电路42

结论43

致谢44

参考文献45

附录46

主要设计参数及依据

本设计的XY工作台的参数定为:

①工作台行程:横向300mm,纵向400mm

②工作台最大尺寸(长×宽×高):900×900×500mm

③工作台最大承载重量:120Kg

④脉冲当量:0.001mm/pluse

⑤进给速度:XY轴均为0.05米/秒

⑥表面粗糙度:Ra0.8~1.6

⑦设计寿命:每天工作8小时,工作12.5年,250工作日/年

1 绪论

1.1激光技术概述

激光被誉为二十世纪最重大的科学发现之一,它刚一问世就引起了材料科学家的高度重视。1971年11月,美国通用汽车公司率先使用一台250W CO2激光器进行利用激光辐射提高材料耐磨性能的试验研究,并于1974年成功地完成了汽车转向器壳内表面(可锻铸铁材质)激光淬火工艺研究,淬硬部位的耐磨性能比未处理之前提高了10倍。这是激光表面改性技术的首次工业应用。多年以来,世界各国投入了大量资金和人力进行激光器、激光加工设备和激光加工对材料学的研究,促使激光加工得到了飞速发展,并获得了巨大的经济效益和社会效益。如今在中国,激光技术已在工业、农业、医学、军工以及人们的现代生活中得到广泛的应用,并且正逐步实现激光技术产业化,国家也将其列为“九五”攻关重点项目之一。“十五”的主要工作是促进激光加工产业的发展,保持激光器年产值20%的平均增长率,实现年产值200亿元以上;在工业生产应用中普及和推广加工技术,重点完成电子、汽车、钢铁、石油、造船、航空等传统工业应用激光技术进行改造的示范工程;为信息、材料、生物、能源、空间、海洋等六大高科技领域提供崭新的激光设备和仪器。

数控化和综合化把激光器与计算机数控技术、先进的光学系统以及高精度和自动化的工件定位相结合,形成研制和生产加工中心,已成为激光加工发展的一个重要趋势。

1.2激光切割技术的应用

激光切割是用聚焦镜将CO2激光束聚焦在材料表面使材料熔化,同时用与激光束同轴的压缩气体吹走被熔化的材料,并使激光束与材料沿一定轨迹作相对运动,从而形成一定形状的切缝。从二十世纪七十年代以来随着CO2激光器及数控技术的不断完善和发展,目前已成为工业上板材切割的一种先进的加工方法。在五、六十年代作为板材下料切割的主要方法中:对于中厚板采用氧乙炔火焰切割;对于薄板采用剪床下料,成形复杂零件大批量的采用冲压,单件的采用振动剪。七十年代后,为了改善和提高火焰切割的切口质量,又推广了氧乙烷精密火焰切割和等离子切割。为了减少大型冲压模具的制造周期,又发展了数控步冲与电加工技术。各种切割下料方法都有其有缺点,在工业生产中有一定的适用范围。

激光切割机是光、机、电一体化高度集成设备,科技含量高,与传统机加工相比,激光切割机的加工精度更高、柔性化好,有利于提高材料的利用率,降低产品成本,减轻工人负担,对制造业来说,可以说是一场技术革命。

激光切割的适用对象主要是难切割材料,如高强度、高韧性、高硬度、高脆性、磁性材料,以及精密细小和形状复杂的零件。激光切割技术、激光切割机床正在各行各业中得到广泛的应用。因此研究和设计数控激光切割有很强的现实意义。微机控制技术正在发挥出巨大的优越性。

川公网安备: 51019002004831号

川公网安备: 51019002004831号