连续式履带装煤机装运部设计

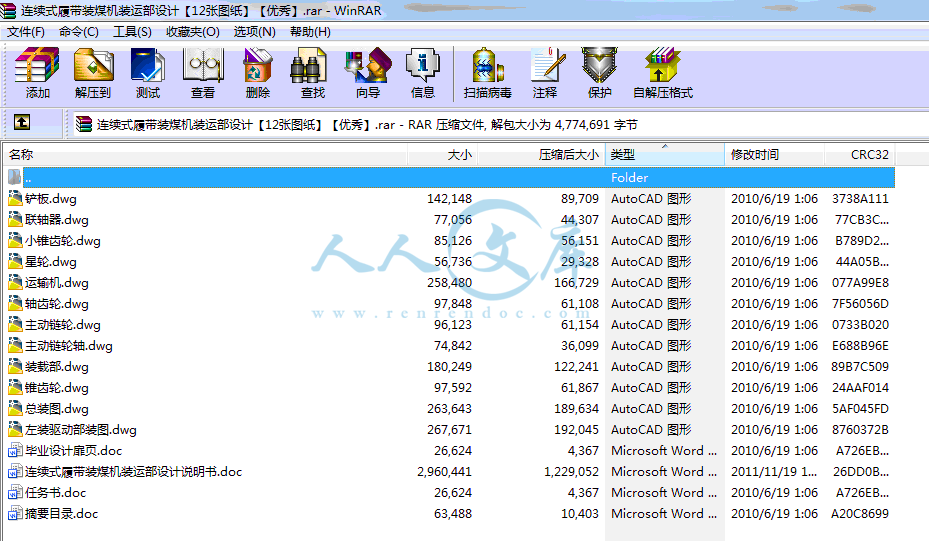

82页 22000字数+说明书+任务书+12张CAD图纸【详情如下】

主动链轮.dwg

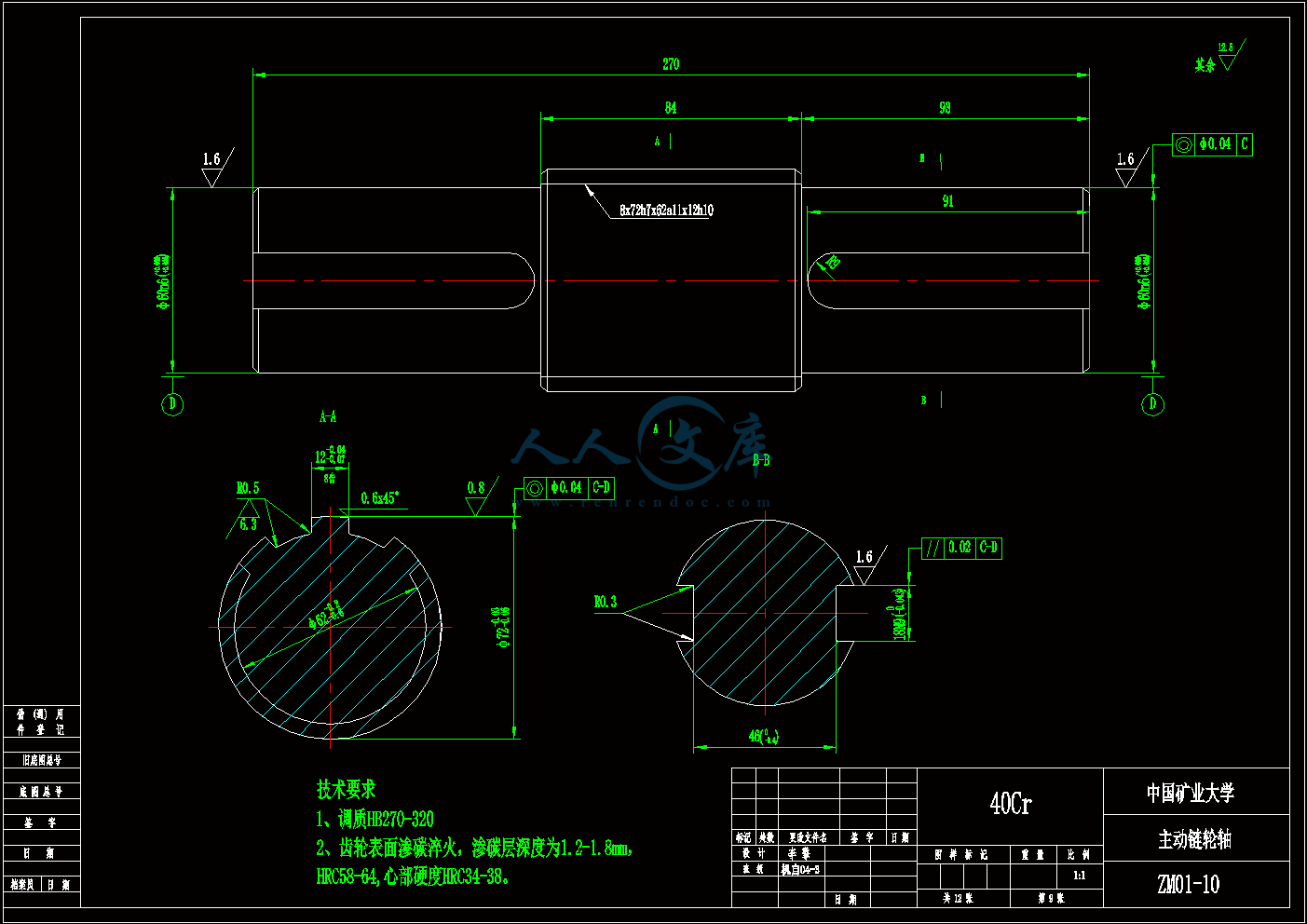

主动链轮轴.dwg

任务书.doc

小锥齿轮.dwg

左装驱动部装图.dwg

总装图.dwg

摘要目录.doc

星轮.dwg

毕业设计扉页.doc

联轴器.dwg

装载部.dwg

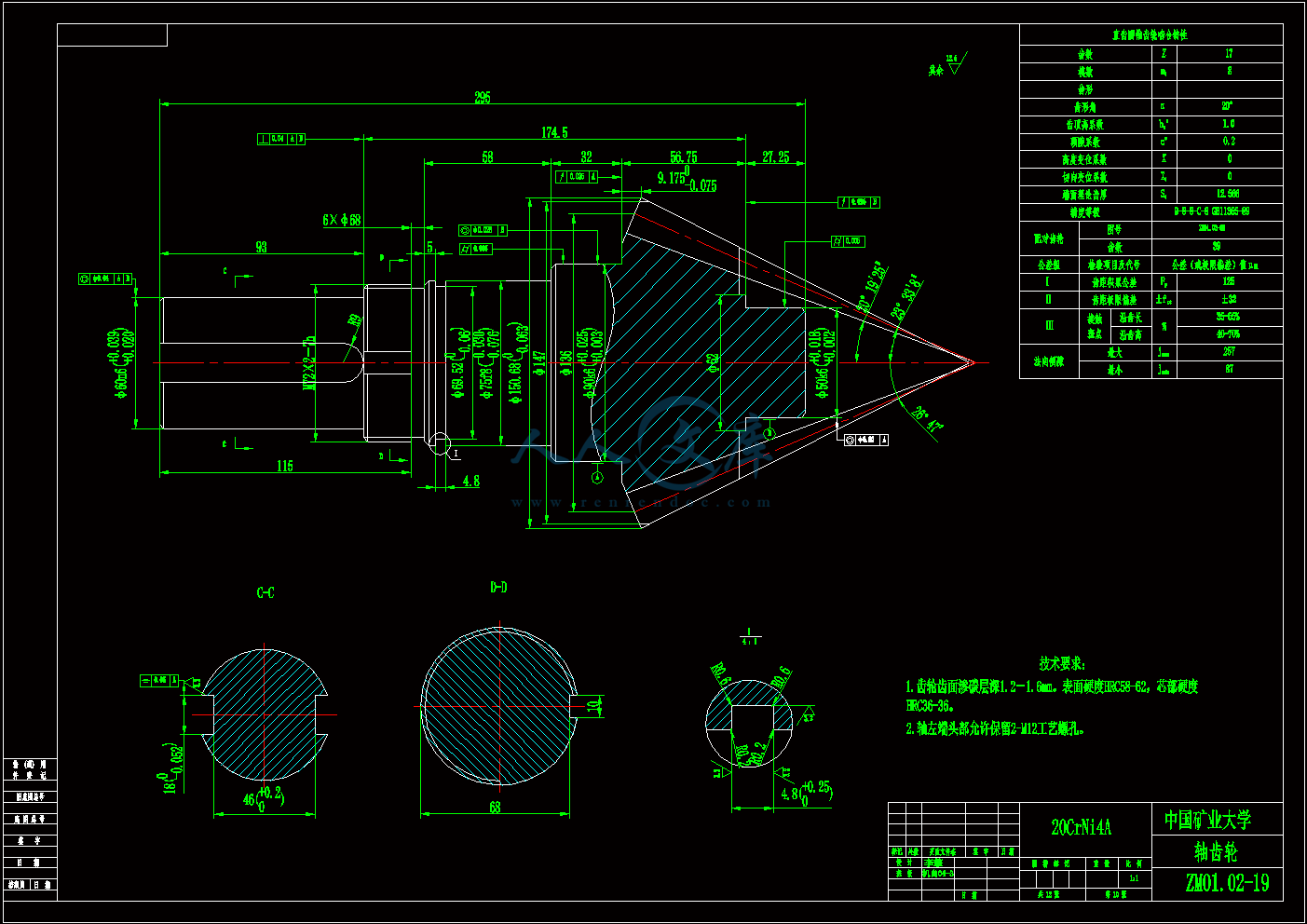

轴齿轮.dwg

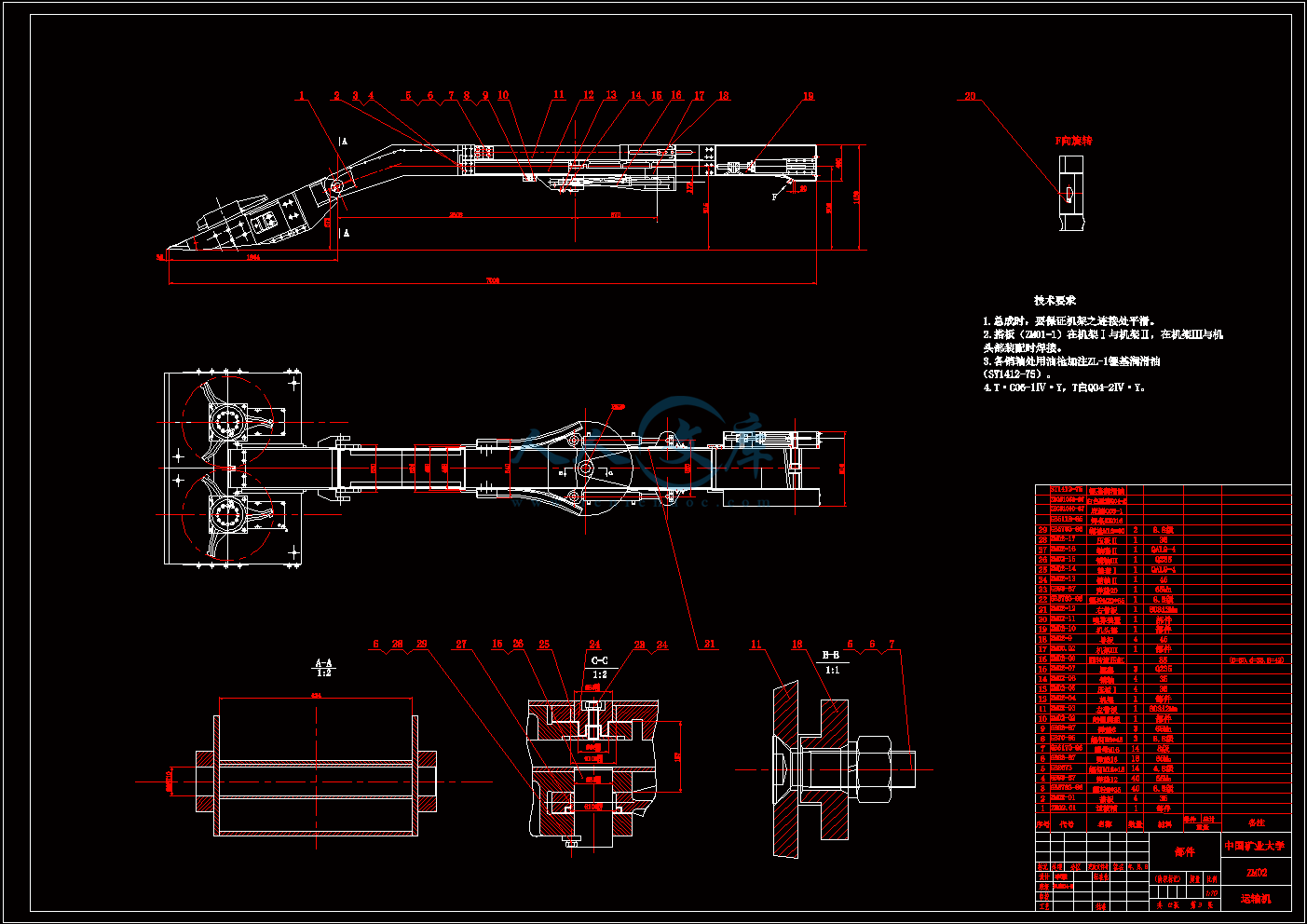

运输机.dwg

连续式履带装煤机装运部设计说明书.doc

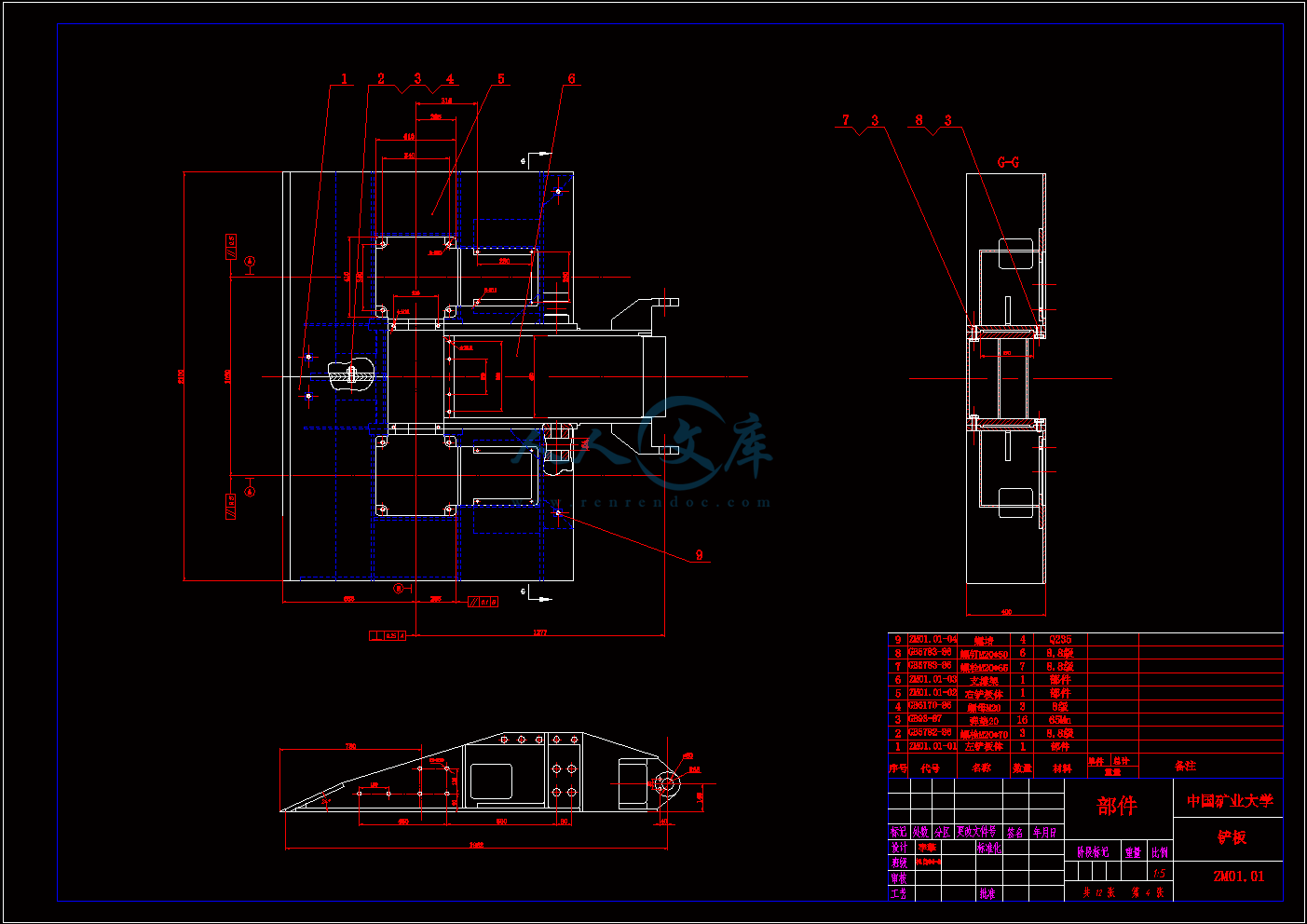

铲板.dwg

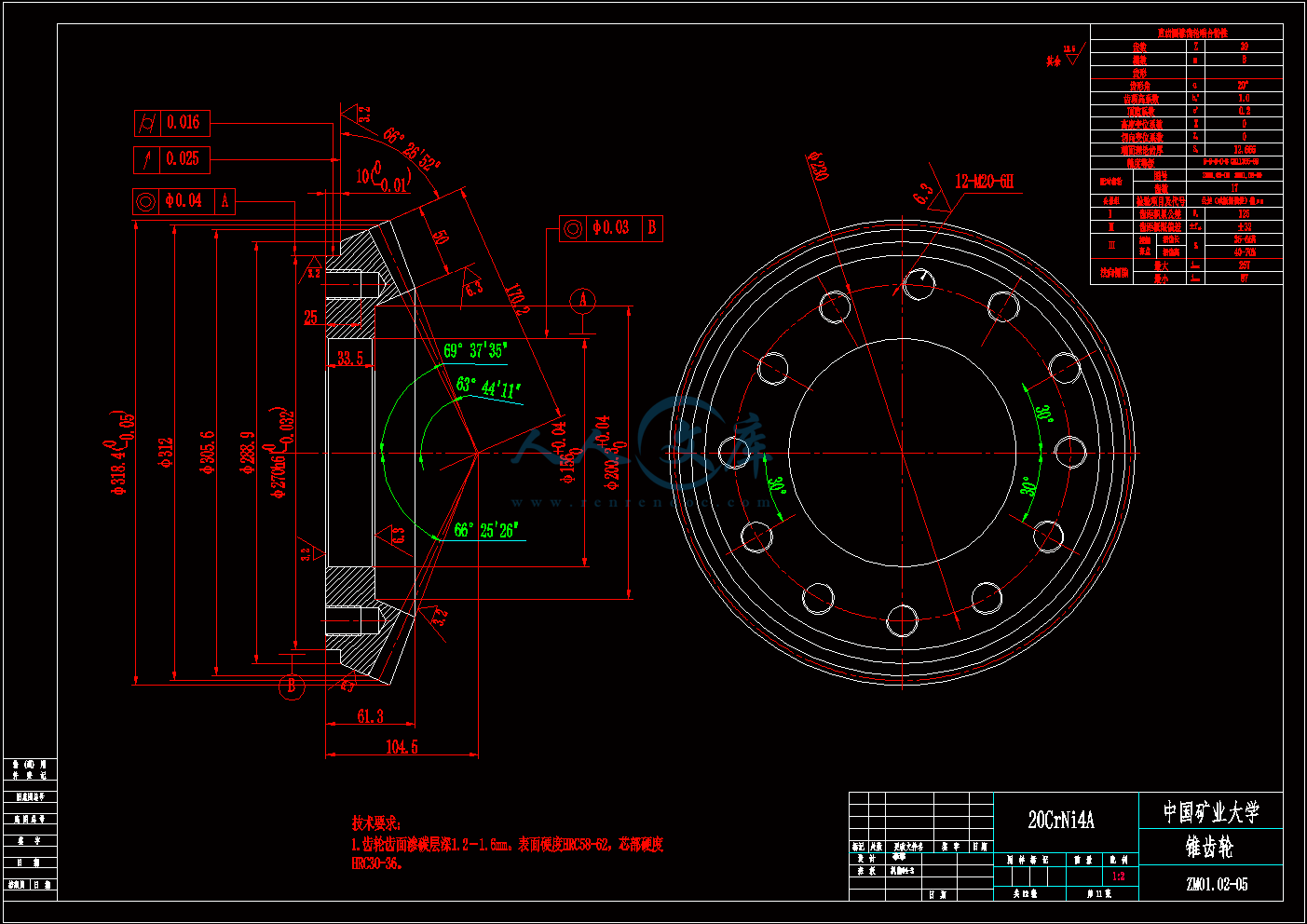

锥齿轮.dwg

目录

1绪论1

1.1矿山装载作业现状1

1.2装煤机的分类1

1.3装载机械的发展史3

1.4装载机械的发展趋势4

2总体设计5

2.1设计总则5

2.2设计要求5

2.2.1总体5

2.2.2装载部5

2.2.3液压系统6

2.2.4供电电压6

2.3主要结构及工作原理6

2.3.1用途及适用范围6

2.3.2耙斗装置7

2.3.3装载部8

2.3.4装运部星轮传动装置8

2.3.5运输部9

2.3.6主体部11

2.3.7液压系统11

2.4设计步骤12

2.5主要部件设计方案13

2.5.1装载部星轮设计方案13

2.5.2运输部设计方案13

2.6主要部件外形尺寸的估算14

3装载部设计15

3.1星轮机构的特点15

3.2星轮外形尺寸的确定15

3.3星轮转速的确定18

3.4星轮装载所需功率的计算20

4运输部设计22

4.1输送能力计算22

4.2运行阻力23

4.3刮板链张力25

4.4刮板输送机所需功率25

4.5刮板链的预紧力和紧链力26

4.6刮板链的安全系数27

4.7主动链轮28

4.8刮板输送机主动链轮的主要尺寸30

5驱动装置设计31

5.1液压马达的选型31

5.2星轮、刮板输送机的传动装置设计32

5.2.1传动方案设计32

5.2.2锥齿轮的计算33

5.2.3齿根弯曲疲劳校核计算37

5.3齿轮主要数据38

6主要部件校核40

6.1星轮轴的计算40

6.2主动链轮轴的校核48

6.3齿轮Z3的轴的计算56

6.4联轴器的校核65

7机器的使用与维护67

7.1操作程序67

7.2使用注意事项67

7.3维护保养与故障排除68

7.4电气装置74

7.5机器的解体、安装与调整74

7.5.1解体74

7.5.2井下安装75

7.5.3安装后检查和调试75

7.6机器的调整76

小结78

参考文献79

摘 要

随着现代科技的不断发展、进步,我们的矿用机械的科技水平也有了进一步的提高。连续式履带装煤机就是近几年发展起来的新型矿用装煤机械,连续式履带装煤机是集装载、运输、行走于一体的全液压装载设备。可进行连续的作业,还可与矿车、刮板输送机和带式输送机配套使用。即可在井下使用,也可用于地面煤场做装载。本设计是对连续式履带装煤机的装运部进行设计,装载部采用的是星轮装载,运输系统采用刮板输送机,装载部和运输部共用一组液压马达驱动,取消装载减速器,使机器结构更加紧凑,运转更加协调,减少了故障。星轮装载是近几年发展起来的,与蟹爪式相比有明显的优点。运输部根据需要选用的圆环链为中单链,以适应井下复杂多变的巷道情况,可以进行水平方向的转动。本设计主要是对装载部星轮、刮板输送机以及驱动装置进行了科学的设计。正文中首先介绍了装煤机的各种类型和发展趋势,对本次设计中的装煤机原理进行了介绍,其次是三个主要部分的设计计算,并对关键部分进行了强度校核。最后讲解了连续式履带装煤机的安装、使用和维护等方面的注意事项。

关键词:

装载; 星轮; 刮板输送机; 锥齿轮;

Abstract

with the unceasing development and improvement of modern science and technology , our mineral machinery technical level has got the further enhancement.The continuous-type caterpillar band coal loading-machine is the new mineral coaling machinery which begins to develop in recent years, the continuous-type caterpillar band coal loading-machine is entire hydraulic charging equipment which is the collection of loading, the transportation and walks in a body.It can not only do the continual work, but also be used with the mine car, the scraper conveyer and the belt conveyer .That is to say,it may use in mine shaft, also use in the ground coal field to load. The design mains design about the loading-machine department of continuous-type caterpillar band coal-loading machine, the loading department uses the spider loading, the transportation system uses the scraper conveyer, the loading department and the department of transportation uses in common a group of oil motor to actuate, to take the place of the reduction gear, which makes the machine structure to be more compact and the revolution to be more coordinated, reduced the breakdown.The spider loading develops in recent years.Compared with the the crab claw type,it has the obvious merits . According to the need,the round endless chain used in the department of transportation is the single chain so as to adapt the complex changeable tunnel situation in mine shaft. It may rotate in the horizontal direction .The design mainly design about the spider of the load department , the scraper conveyer as well as the drive The main text first introduced each kind of type and the trend of development of coal loading-machine, it introduced coal loading-machine principle, next is design calculations about three main part, and carried on the intensity examination to the essential part. Finally it explained continuous-type caterpillar band coal loading-machine installment, use and maintenance and so on.

Key word:

Loading; Spider; Scraper conveyer; Bevel gear;

2.1 设计总则

(1)要符合煤矿和设计标准。

(2)煤矿生产,安全第一。

(3)满足矿用需求,能与矿车、刮板输送机等运输设备配套使用。

(4)保证机器质量。

2.2设计要求

本设计是对ZMY100/45M型装煤机装运部进行设计。

2.2.1总体

生产能力 100 t/h

总功率 45 KW

适应巷道断面 ≥5㎡

爬坡能力 ±16°

外形尺寸(长×宽×高) 900*2100*2400

机器调动速度 10m(min)

整机重量 9.5 t

供电电压 660V/1140V

机器左右偏转角度 ±36°

机器左右偏转宽度(刮板机中心线) ±1.45m

机器升降高度 700-1621mm

2.2.2装载部

铲板顶尖抬起 350mm

铲板顶尖卧底 200mm

装载形式 星轮

星轮转速 48(40)r.p.m

2.2.3运输部

运输机形式 单中圆环链刮板式

刮板链规格 φ14×50圆环链

运输机槽宽 420 mm

链速 0.94(0.77)m/s

运输能力 100 t/h

川公网安备: 51019002004831号

川公网安备: 51019002004831号