三自由度气动机械手的设计

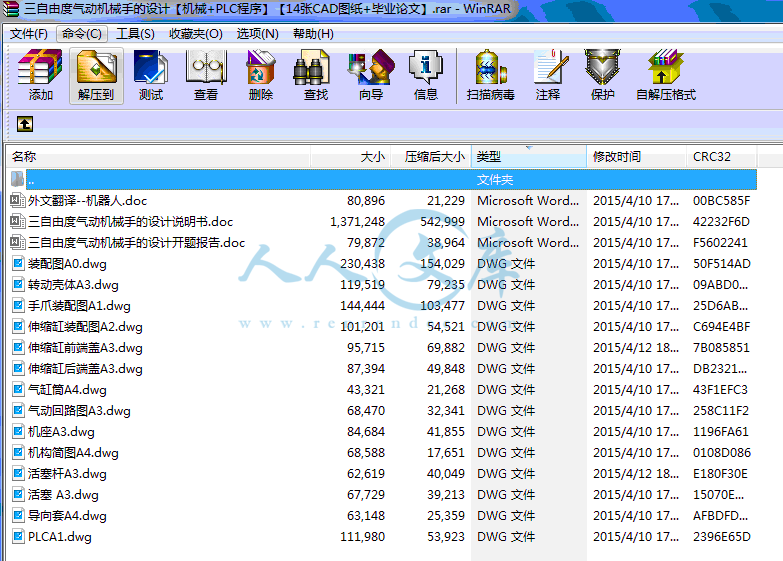

58页 22000字数+说明书+外文翻译+开题报告+14张CAD图纸【详情如下】

PLCA1.dwg

三自由度气动机械手的设计开题报告.doc

三自由度气动机械手的设计说明书.doc

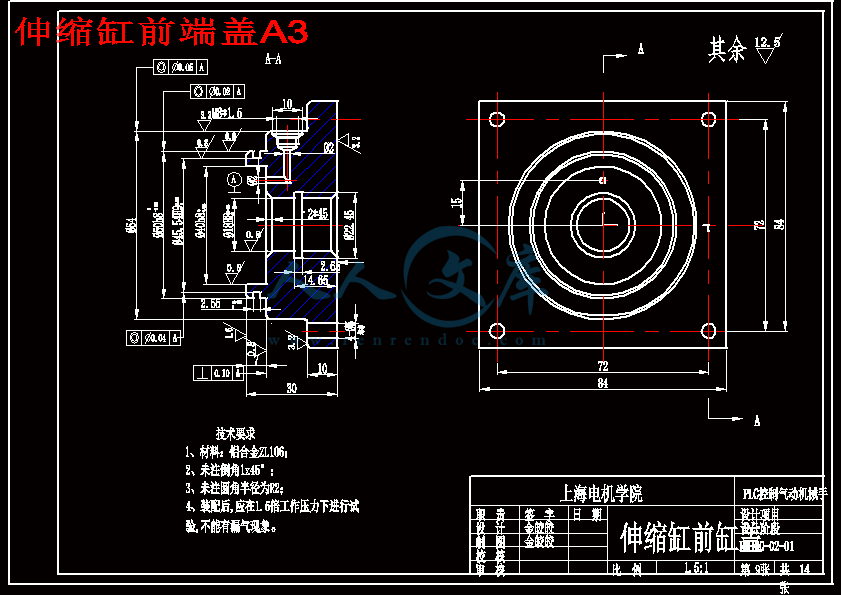

伸缩缸前端盖A3.dwg

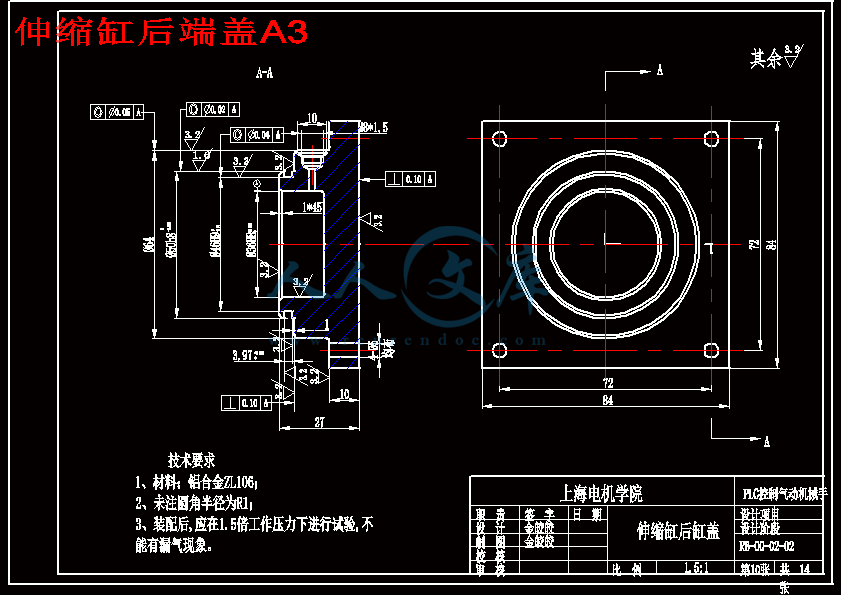

伸缩缸后端盖A3.dwg

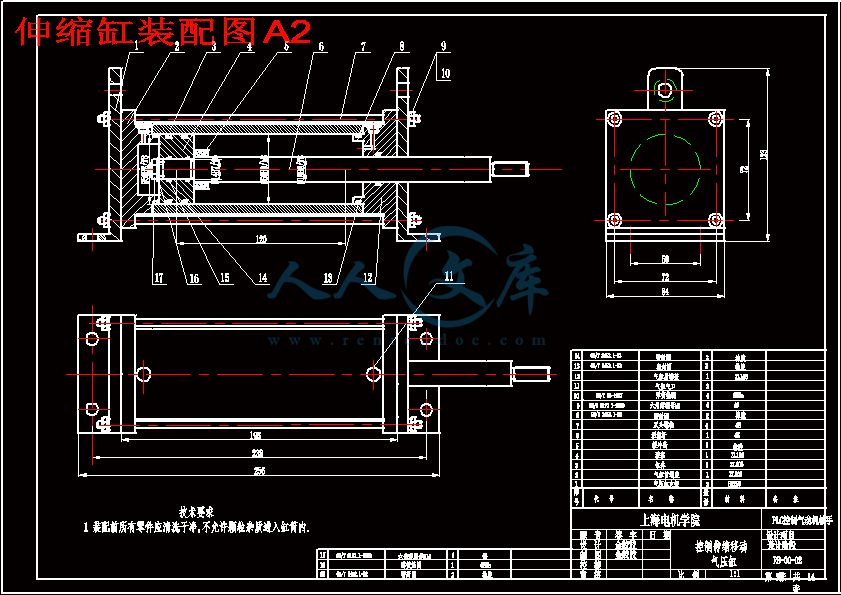

伸缩缸装配图A2.dwg

外文翻译--机器人.doc

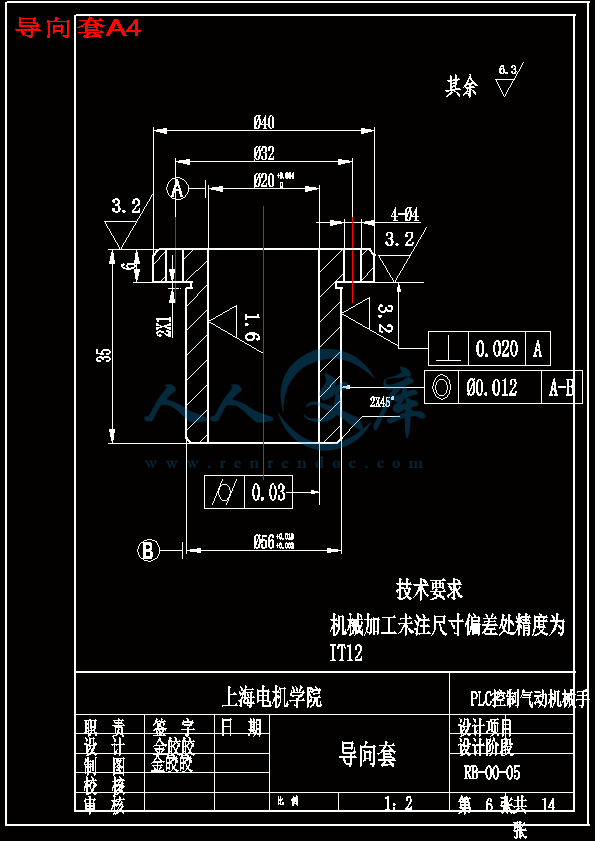

导向套A4.dwg

手爪装配图A1.dwg

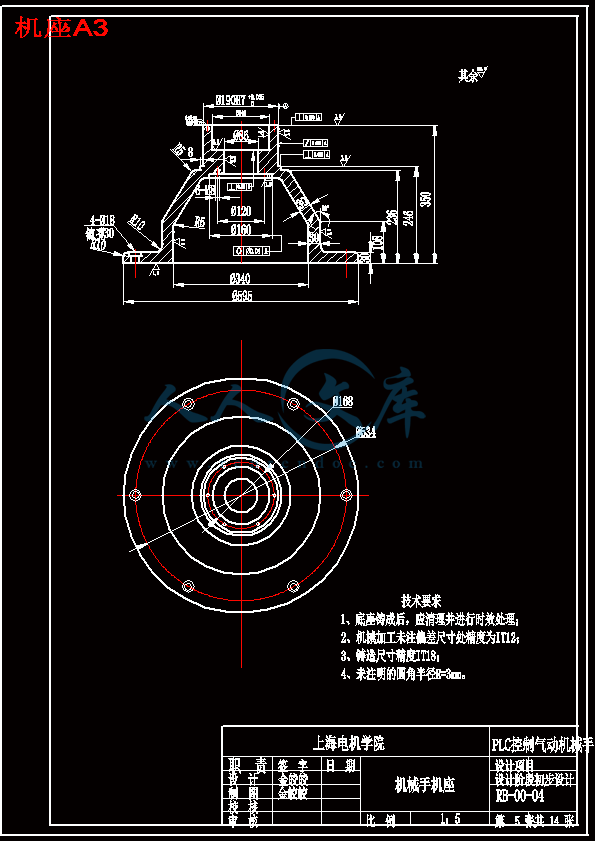

机座A3.dwg

机构简图A4.dwg

气动回路图A3.dwg

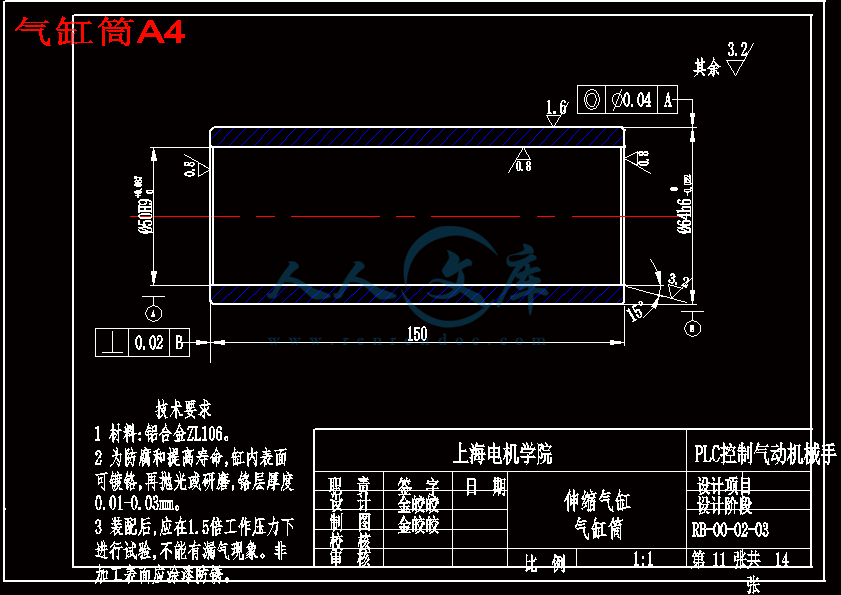

气缸筒A4.dwg

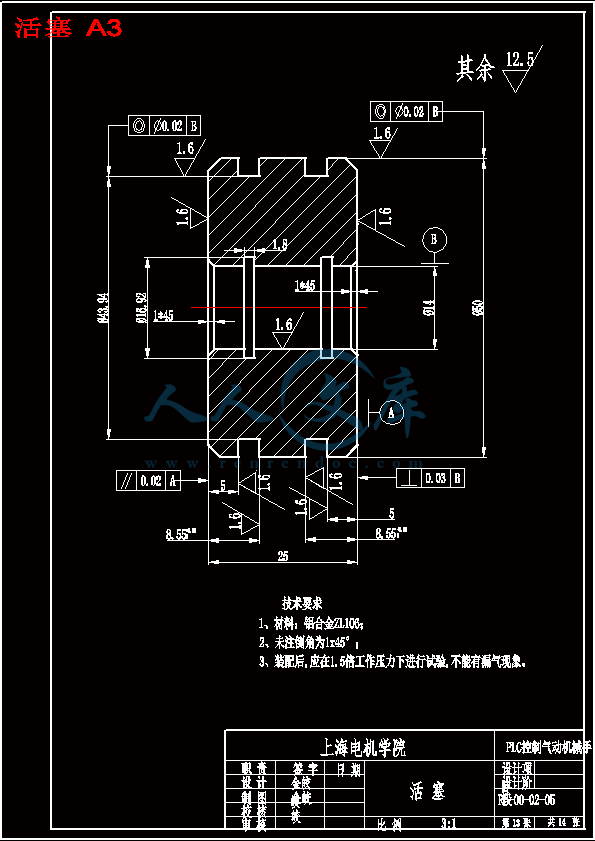

活塞 A3.dwg

活塞杆A3.dwg

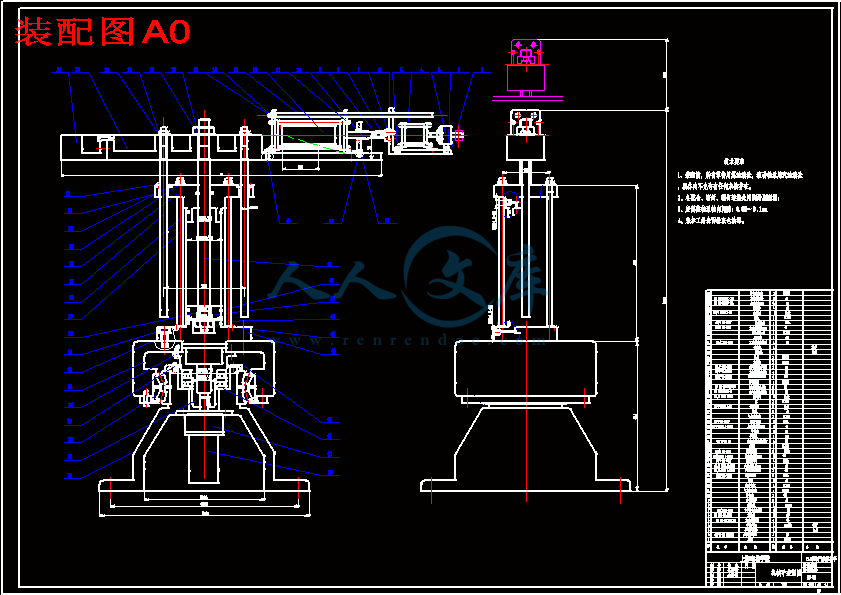

装配图A0.dwg

转动壳体A3.dwg

摘 要

在机械制造业中,机械手已被广泛应用,大大地改善了工人的劳动条件,显著地提高劳动生产率,加快了实现工业生产机械化和自动化的步伐。

本文通过对机械手的组成和分类,及国内外的发展状况的了解,对本课题任务进行了总体方案设计。确定了机械手用三自由度和圆柱坐标型式。设计了机械手的夹持式手部结构;以及设计了机械手的总体结构,以实现机械手伸缩,升降,回转三个自由度及手爪的开合。驱动方式由气缸来实现手臂伸缩和升降,异步电机来实现机械手的旋转。

运用了FX 系列可编程序控制器(PLC)对上下料机械手进行控制, 论述了电气控制系统的硬件设计, 控制软件结构以及手动控制程序和自动控制程序的设计。

关键词:机械手,气缸,可编程序控制器

Abstract

In mechanical manufacturing industry, manipulator has been applied extensively so that the labor condition of worker has been greatly improved , labor productivity raised notably, the step of industrial production mechanization and automation realized rapidly.

This article through to manipulator's composition and the classification, and the domestic and foreign development condition's understanding, has carried on the overall concept design to this topic duty. Had determined the manipulator uses three degrees-of-freedom and the circular cylindrical coordinate pattern. Has designed manipulator's clamp type hand structure; As well as has designed manipulator's gross structure, realizes the manipulator to expand and contract, the fluctuation, rotates three degrees-of-freedom and hand fingernail's opening and closing. The drive type realizes the arm expansion and the fluctuation by the air cylinder, the asynchronous machine realizes manipulator's revolving.

The paper illustrates that the control of the upper and lower material by means of the PLC and also includes the hardware design of the electric control system, the control software structure and the design of the manual and automatic control program.

Key words: manipulator, air cylinder, Programmable controller(PLC)

目 录

1 绪言1

1.1 机械手的概述1

1.2 我国机械手的发展1

1.3 气动机械手的应用现状及发展前景3

1.4 本课题设计要求5

2 机械手的总体设计方案7

2.1 机械手的系统工作原理及组成7

2.2 机械手基本形式的选择8

2.3 驱动机构的选择9

2.4 机械手的技术参数列表9

3 机械手的机械系统设计11

3.1 机械手的运动概述11

3.2 机器人的运动过程分析12

4 机械手手部结构设计及计算13

4.1 手部结构13

4.2 手部结构设计及计算14

4.3 夹紧气缸的设计16

5 机械手手臂机构的设计22

5.1 手臂的设计要求22

5.2 伸缩气压缸的设计22

5.3 导向装置27

6 机械手腰部和基座结构设计及计算29

6.1 结构设计29

6.2 控制手臂上下移动的腰部气缸的设计29

6.3 导向装置33

6.4 平衡装置33

6.5 基座结构设计34

7 气动系统设计37

7.1 气压传动系统工作原理图37

8 机械手的PLC控制系统设计39

8.1 可编程序控制器的选择及工作过程39

8.2 可编程序控制器的使用步骤40

8.3 机械手可编程序控制器控制方案40

9 结论52

参考文献53

致谢54

为了跟踪国外高技术,80年代在国家高技术计划中,安排了智能机械手的研究开发,包括水下无缆机械手,高功能装配机械手(DD驱动)和各类特种机械手,进行了智能机械手体系结构,机构控制,人工智能机器视觉,高性能传感器及新材料的应用研究已取得一批成果。这些技术的实用化将加速我国第二代机械手的发展[2]。

经过80年代尤其是后50年的努力,吸引了160多个单位从事机械手及其相关技术的研究力量,形成了京津、东北、华东、华南等机械手技术地区和十几家优势单位,培养了一支2000多人的工业机械手设计、研制、应用队伍,造就了一批机械手专家,使我国的工业机械手技术发展基本上可以立足于国内。

90年代初期,我国主要开发下列机械手:

(1)喷涂机械手

(2)焊接机械手

(3)搬运机械手

(4)装配机械手

在90年代中期,国家已选择以焊接机械手的工程应用为重点进行开发研究,从而迅速掌握焊接机械手应用工程成套开发技术、关键设备制造、工程配套、现场运行等技术,即以机械手焊接工艺为龙头,开展焊装线总体设计、线体总控及多机通讯,新型焊接机械手用焊接电源、送丝机构、焊缝跟踪系统、机电精度、控制技术等开发及完善化,以及几条焊装生产线的全套应用及其可行性作为主攻目标。

虽然我国的机械手研发工作基本上属于科学研究的项目,但据说,中国科学院目前已造出说话时嘴唇能够活动、眼睛能转动、具视觉功能的机械手,其水准可媲美日本同行,但这台机械手体形甚大,却未能以双脚走路。在日本,机械手能否以二脚行走已成为一个热门及熟练的技术竞赛项目,譬如有“二足机械人竞赛大会”(分等级)。其实,机械手的制作绝对并非只是液压机械与电子产品的混成物,要将机械手造得越来越有人性化,就要兼及生命医学、传感、光学及创造性的文化产业等方面,比如机械手的关节就需要研究中医的经络学、生物学上的神经刺激反应以及文化产品的某种造型特征(其中很重要的是民族特征的外表)等等。英国的科学家甚至预言,到2020年,随着机械手愈来愈精密和使用有机零件制造,它们将会受到“机械手权”的保护。1.4 本课题设计要求

本课题将要完成的主要任务如下:

(1)机械手为通用机械手,因此相对于专用机械手来说,它的适用面相对较广。

(2)选取机械手的座标型式和自由度。

(3)设计出机械手的各执行机构,包括:手部、手臂等部件的设计。

为了使通用性更强,手部设计成可更换结构,不仅可以应用于夹持式手指来抓取棒料工件,在工业需要的时候还可以用气流负压式吸盘来吸取板料工件。

(4)气压传动系统的设计

本课题将设计出机械手的气压传动系统,包括气动元器件的选取,气动回路的设计,并绘出气动原理图。

(5)机械手的控制系统的设计

本机械手拟采用可编程序控制器(PLC)对机械手进行控制,本课题将要选取PLC型号,根据机械手的工作流程编制出PLC程序,并画出梯形图2.4 机械手的技术参数列表

2.4.1 用途

搬运:用于车间搬运

在工业生产线中,机械手具有很广泛的用途。它是工作抓取和装配系统中的一个重要组成部分。它的基本作用是从指定位置抓取工件运送到另一个指定的位置进行装配。机械手臂代替了人工的繁杂劳动,并且操作精度高,提高了产品质量和生产效率。

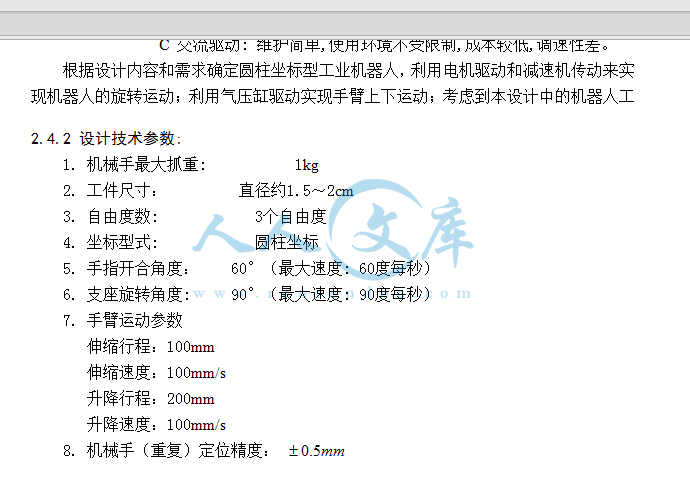

2.4.2 设计技术参数:

1. 机械手最大抓重: 1kg

2. 工件尺寸: 直径约1.5~2cm

3. 自由度数: 3个自由度

4. 坐标型式: 圆柱坐标

5. 手指开合角度: 60°(最大速度: 60度每秒)

6. 支座旋转角度: 90°(最大速度: 90度每秒)

7. 手臂运动参数

伸缩行程:100mm

伸缩速度:100mm/s

升降行程:200mm

升降速度:100mm/s

8. 机械手(重复)定位精度:

参考文献

[1]吴振彪.工业机器人.武汉:华中理工大学出版社,1997

[2]郭洪红.工业机器人技术.西安:西安电子科技大学出版社,2006.3

[3]王天然.机器人.北京:化学工业出版社,2002

[4]白井良明[日].机器人工程.北京:科学出版社,2001

[5]大熊繁[日].机器人控制.北京:科学出版社,2002

[6]陆鑫盛,周洪.气动自动化系统的优化设计[M].上海:上海科学技术文献出版社,2000.5

[7]SMC(中国)有限公司.现代实用气动技术.第二版.北京:机械工业出版社,2003.10

[8]郑洪生.气压传动及控制,第二版[M].北京:机械工业出版社,1992

[9]林文坡.气压传动与控制[M].西安:西安交通大学出版社,1992

[10]成大先.机械设计手册.第五卷.第四版[M]. 北京:化学工业出版社,2002

[11]机械设计手册编委会.机械设计手册.气压传动与控制.北京:机械工业出版社,2007.2

[12]气动工程手册编委会.气动工程手册[M].北京:国防工业出版社,1995

[13]王积伟,章宏甲,黄谊.液压与气压传动.第二版.北京:机械工业出版社,2005

[14]吴宗泽,罗圣国.机械设计课程设计手册.北京:高等教育出版社,2006.5

[15]何铭新,钱可强.机械制图.北京:高等教育出版社,2004.1

[16]张建明等.机电一体化系统设计.第二版.北京:北京理工大学出版社,2008.6

[17]王信义.机电一体化技术手册.第二版.北京:机械工业出版社,2000

[18]张建民.机电一体化原理和应用.北京:国防工业出版社,1992

[19]高钟毓.机电控制工程.北京:清华大学出版社,1994

[20]钟福金,吴晓梅.可编程序控制器[M].南京:东南大学出版社,2003

[21]李建兴.可编程序控制器应用技术.北京:机械工业出版社,2004.7

[22]Yuan Shihua , Hu Jibin. The research on the efficiency of multirange hydro-mechanical transmission[J]. Journal of Beijing Institute of Technology,1998

[23]Goo Bong Chung and Byung-Ju Yi etl. Design and analysis of a spatial 3_DOF Micromanipulator for tele-operation[A].Proceed-ings of the IEEE/RST International conference on Inellligent Robots and System[C].USA,2001

[24]Tim King and Michele Pozzi and Angelo Mannara, Piezoactuators for real-world applications[J]. Power Engineering Journal,2000

川公网安备: 51019002004831号

川公网安备: 51019002004831号