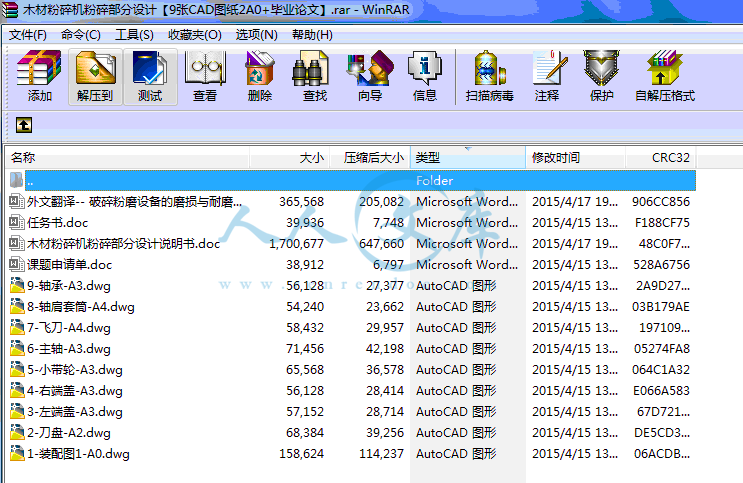

木材粉碎机粉碎部分设计

41页 14000字数+说明书+任务书+外文翻译+9张CAD图纸【详情如下】

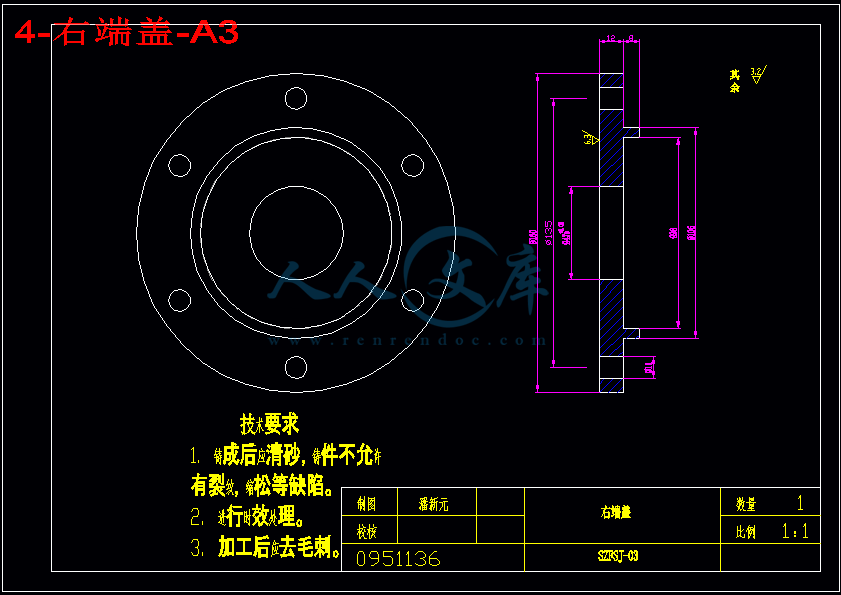

4-右端盖-A3.dwg

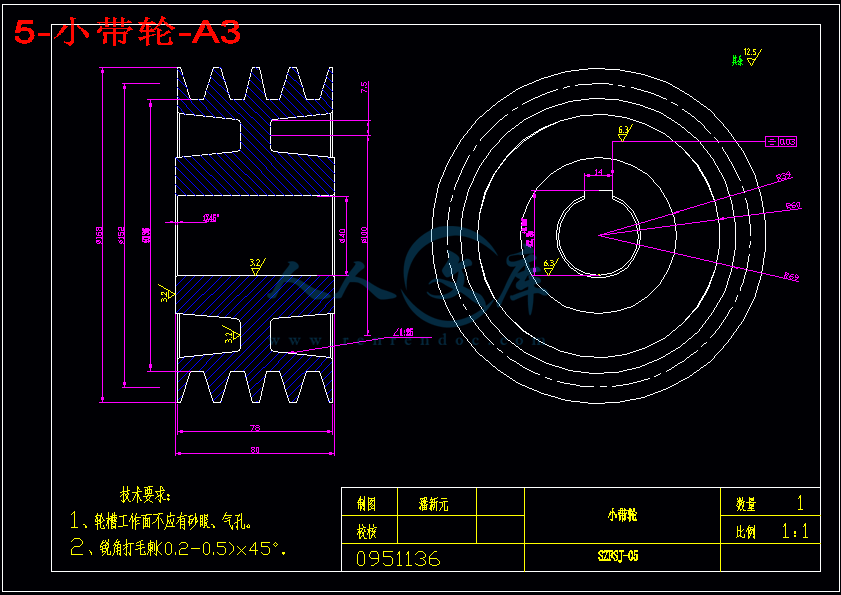

5-小带轮-A3.dwg

6-主轴-A3.dwg

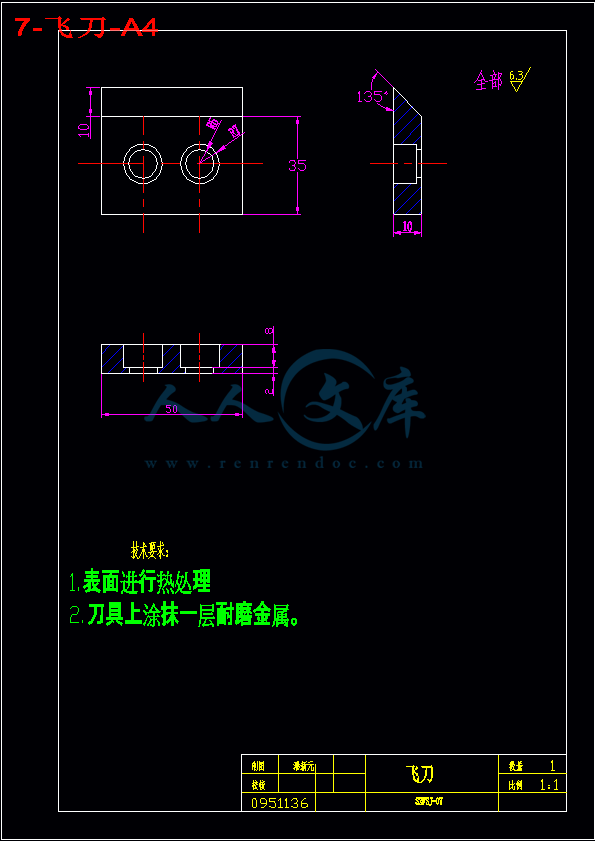

7-飞刀-A4.dwg

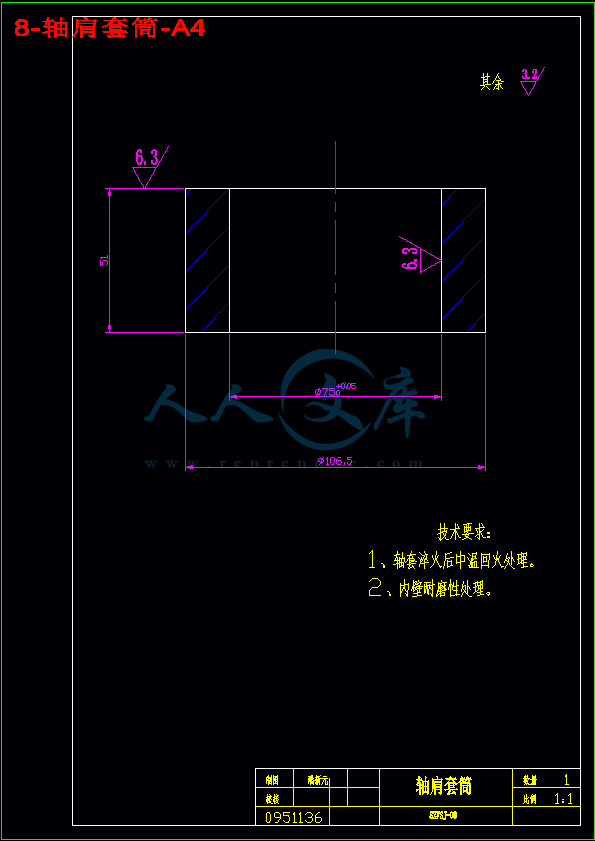

8-轴肩套筒-A4.dwg

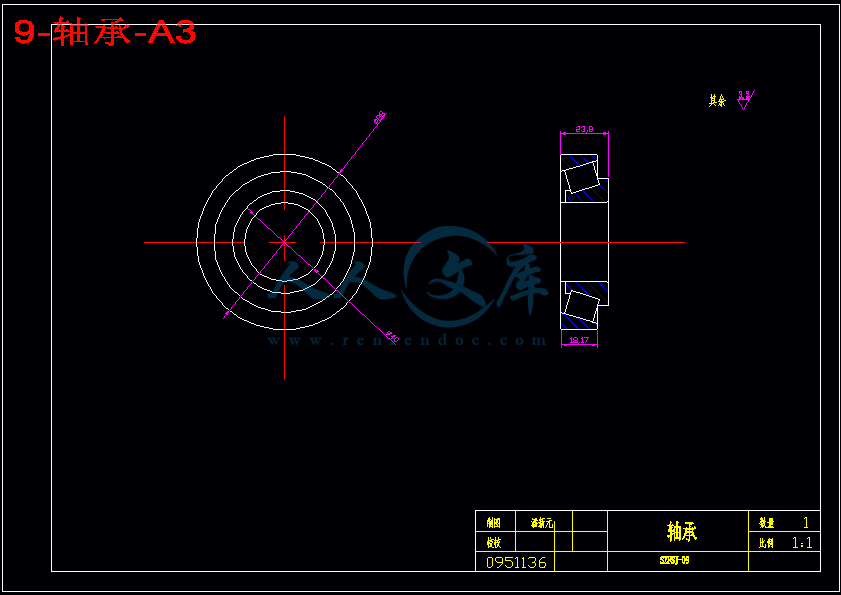

9-轴承-A3.dwg

任务书.doc

外文翻译-- 破碎粉磨设备的磨损与耐磨材料的发展.doc

木材粉碎机粉碎部分设计说明书.doc

课题申请单.doc

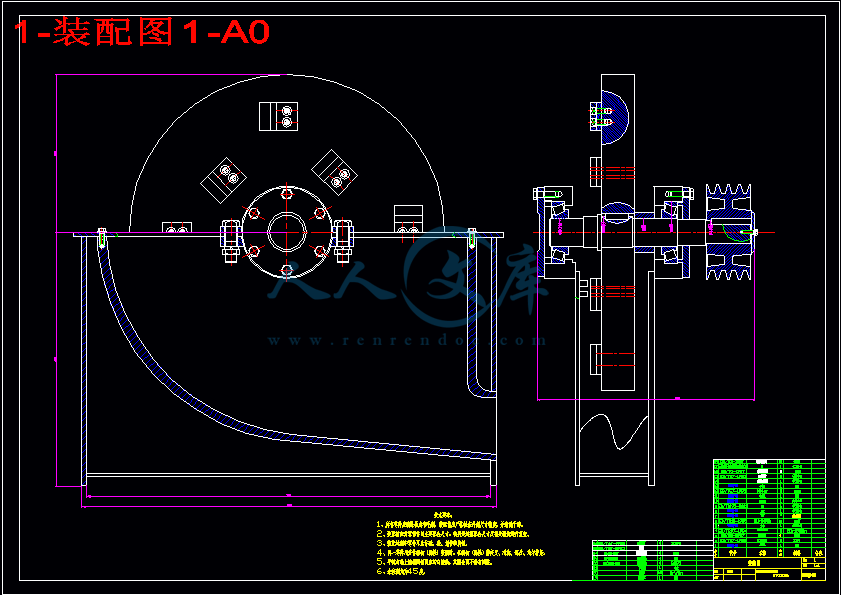

1-装配图1-A0.dwg

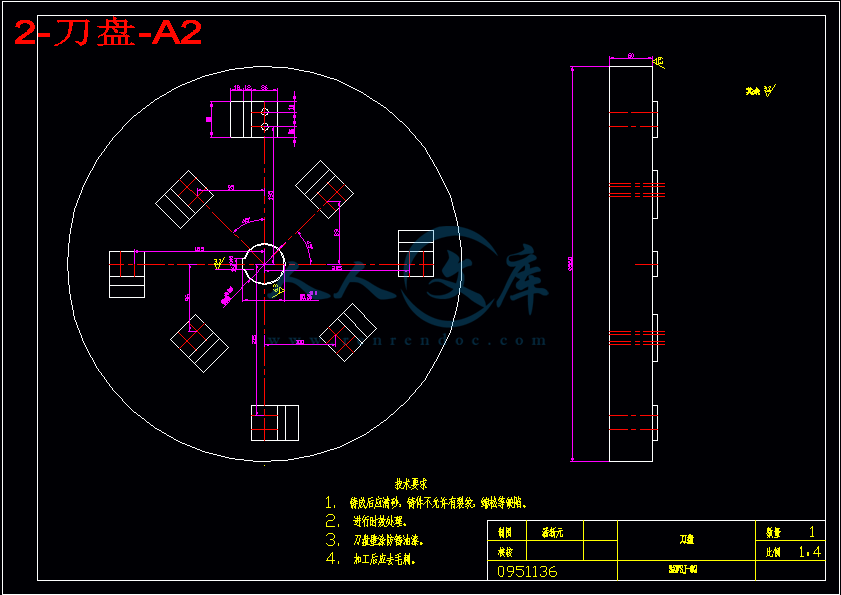

2-刀盘-A2.dwg

3-左端盖-A3.dwg

摘要

近年来,随着我国经济建设的发展,在很多领域的生产实际中,对各种木质物料粉碎机的需求越来越大。根据木质物料粉碎机用途的不同,研制出满足各种要求的木质物料粉碎机已成为目前迫在眉睫的紧要任务。

本机的机架、上盖都采用了铸件,降低了整机的重心;发动机和主轴之间通过皮带传动,缓和了载荷冲击;主轴通过两个圆锥滚子轴承与机架连接;刀盘和主轴之间采用平键联接;飞刀用垫块和螺栓固定。飞刀采用螺旋曲面方式依次摆放多把短刀。

关键词: 树枝粉碎机 园林绿化 削片机 木材加工

ABSTRACT

Abstract:In recent years, with the economic development in our country, and in many fields in the actual production, for a variety of wooden material grinder increasing demand. According to the wooden material grinder of different applications, developed to meet the various requirements of the wooden material grinder has become the urgent task for current imminent.

The fly cutter uses the bolt and cushion to be fixed, Reliable and stable, The fly cutter stretches out the quantity to be able to adjust,And advantageous for disassembling and the replacement. Rack is equipped with wheels, can be driven by the traction machine,Suitable to use in the urban green residues and the trail level lumber processing.

Key words: Branch Chipper Landscaping Chipper Wood Processing

目录

绪 论1

第一章 枝桠粉碎机介绍2

1.1枝桠粉碎机的分类特点及其工作原理2

1.2 选题的设计思想,设计方法及改进4

1.3 本章小结4

第二章 移动式枝桠粉碎机的总体设计5

2.1 枝桠粉碎机设计任务5

2.2 普通盘式枝桠粉碎机的结构5

2.3盘式枝桠粉碎机的削片原理7

2.4本章小结9

第三章 主要技术参数的确定和计算10

3.1 生产能力的确定10

3.2 飞刀数量的确定10

3.3切削力的计算11

3.3.1主切削力的理论分析与计算11

3.3.2主切削力的经验公式13

3.4切削功率的计算17

3.6 本章小结19

第四章 主要部件的设计计算20

4.1盘式短刀与长刀削片机比较20

4.2刀盘结构设计及尺寸的确定21

4.2飞刀平面布置22

4.3主轴的结构设计24

4.3.1 轴的最小直径计算24

4.3.2轴的结构设计25

4.4滚动轴承的选择26

4.5 键连接的设计26

4.5.1带轮与输入轴间键的选择及校核26

4.5.2输出轴与齿轮间键的选择及校核26

4.6飞刀的设计27

4.7本章小结27

第五章 主要部件的校核和验算28

5.1 主轴强度的校核28

5.1.1求轴上的载荷28

5.1.2按弯扭合成应力校核轴的强度29

5.1.3 精确校核轴的疲劳强度29

5.2 滚动轴承的校核32

5.3本章小结33

5.4最后完成图33

结论34

参考文献35

致谢36

第一章 枝桠粉碎机介绍

1.1枝桠粉碎机的分类特点及其工作原理

树枝粉碎机是将原木、采伐与抚育剩余物(枝桠、梢头木、树根、小径木等)以及木材加工剩余物(如板皮、板条、碎单板、木芯等)加工成一定规格长度木片的设备。它属于备料设备,但也是十分重要的。其切削特征是纵端向切削,主要参数是削出木片的长度。对枝桠粉碎机的主要工艺要求是:削出的木片长度应均匀一致,其合格率应在允许范围内,且应厚度均匀,切口大而平滑,产生的碎料少,削出的木片的尺寸规格依使用要求而定。

随着人造板工业的发展和原木资源的日益缺乏,利用各种剩余制品削制工艺木片作为充分利用木材资源、提高木材综合利用率的主要手段的观点,已得到了人们的普遍赞同,削片机的种类也随之而日益增多。

树枝粉碎机按切削机构的形状可分为鼓式和盘式,它们的结构简图如下图:要把枝桠加工成碎片, 首先需要人工将枝桠材放进料斗, 木材在人力或进料机构的压力作用下进入削片机, 当木材的端面碰到飞刀刀盘端面时, 进给停止, 飞刀转到切削位置开始切削, 由于飞刀有一定角度, 当切入木材一定深度时, 木材受到飞刀切削面的分力、刀盘和料斗( 或底刀)的阻碍作用, 局部沿木材纤维方向崩裂成木片, 从前刀面飞出。切削过程中, 木材在压力和飞刀切削分力的作用下,向刀盘方向进给, 使切削加工得以连续进行, 完成整根木材的加工。

鼓式枝桠削片机机座采用高腔度钢板焊接而成,是整台机器的支承基础;刀辊上安装两把飞刀,用专门制造的飞刀螺栓,通过压力块,把飞刀固定在刀辊上;根据被切削原料的不同厚度,上喂料辊总成可以借助液压系统在一定范围内上下浮动;切削下来的合格木片通过网筛孔落下,有底部排处,大的片料将在机内再进行切削。鼓式削片机的结构简图如下图2所示。

1.主轴 2.锁紧装置 3.飞刀 4.飞刀螺栓 5.压刀块

6.飞刀座 7.刀辊 8.上喂料辊 9.下喂料辊 10.底刀

图1-2 鼓式枝桠粉碎机结构简图

一般而言,盘式树枝粉碎机由于飞刀运动时的切削平面固定不变,飞刀和底刀可以很好的形成剪切作用,所以盘式枝树枝碎机的木片比鼓式枝树枝碎机的木片质量好,生产率高;适宜加工原木、劈木、木芯、较厚的板皮和成捆的枝桠材,因其进料槽为方形或圆形,可充分发挥其生产能力,主要用于生产规模较大的人造板企业和造纸企业。鼓式枝桠粉碎机由于飞刀的切削平面随飞刀位置的变化而变化,削片过程中不能形成有利的剪切作用,其进料槽沿刀鼓方向为长方形,适用于加工板皮、板条、碎单板、小径木、枝桠材等厚度较小、径级不大的木料和竹材,这种削片机主要用于中小型人造板企业;现在经改进的鼓式削片机的削片质量完全能够满足人造板生产的工艺要求。盘式枝桠粉碎机大多数采用自由进料,而鼓式枝桠粉碎机大多数采用强制进料,水平进料的适宜加工较长的原料,而加工较短的原料通常采用倾斜进料。总之,枝桠粉碎机的结构形式主要取决于原料的特征和对削片质量及生产率的要求。

对于中小型树枝粉碎机而言,由于其削制的原料大多数是枝桠、板皮等剩余物,材径较小,采用平面盘式机削片时,对平面盘式的削片长度的均匀性影响不大,而其制造成本低廉,易于推广。因此,中小型枝桠粉碎机采用平面刀盘结构是一个发展方向。

水平进料可防止原料撞击刀盘轴,操作方便,安全可靠;而倾斜进料便于投料,可保证合理的切削参数。1.2 选题的设计思想,设计方法及改进

普通盘式削片机的飞刀为长直刀, 在刀盘上呈径向布置, 切削木材时, 飞刀要切削整个原木端面, 导致动态载荷( 切削力、切削功率) 波动大、切削过程不平稳、功率消耗大、振动噪声大.为改善这种情况, 国内外科研人员曾做过很多研究 , 一是力图搞连续切削, 在刀盘上增加飞刀数量, 这样虽然使切削情况有所改善, 但飞刀在切削过程中切削原木的宽度仍然是变化的, 而且增加刀数导致功率成倍地增长; 二是将飞刀后面和刀盘面制造成螺旋面,这样切削平稳,加工出来的木片质量好。这里我采用螺旋面切削方式,并对它进行了均衡性切削改进,力图减小削片过程中切削力和切削功率的波动。

1.3 本章小结

本章主要介绍了课题研究的目的及其意义、国内外枝桠粉碎机的发展现状和趋势、枝桠粉碎机的分类特点及其工作原理、选题的设计思想,设计方法及改进等

参考文献

[1]顾正平,沈瑞珍.盘式短刀枝桠削片机设计参数的影响因素[J].北京林业大学学报.2002(1):183-186 .

[2]濮良贵,纪名刚主编.机械设计[M].北京:高等教育出版社,2006.

[3]刘灏主编.机械设计手册[S].北京:机械工业出版社,1998.

[4] 牛晓华,吴兆迁,樊涛.木质物料粉碎机的设计[J].林业劳动安全,2008(3):14-17.

[5]李黎.木材切削原理与刀具[M].北京:中国林业出版社,2005.

[6]罗迎社.材料力学[M].武汉:武汉理工大学出版社,2001.

[7]濮良贵,纪名刚,陈国定,吴立言.机械设计[M]. 北京:高等教育出版社2006.

[8]苏旭平.工程材料[M].湖南:湘潭大学出版社,2008.

[9]朱思红,付东荔,缪小红.树枝粉碎机的研制[J].南京大学学报,2004,27(3):111-113.

[10]张晓文,顾正平,沈瑞珍.盘式木材削片机均衡切削的研究[J].北京林业大学学报.1999,第21卷.

[11]Collacoff RA.Mechanical Fault Diagnosis and Condition Monitoring .London :Chapman and Hall .1977.89页.

[12]Kuehnle M R .Toroidal Drive Combines Concepts .Product Engineering .Aug. 1979.261页.

[13]B.D.Choat.Jigs and Fixtures Design,The Institution of Production Engineers,1973.

川公网安备: 51019002004831号

川公网安备: 51019002004831号