商务车拉式离合器的设计

47页 14000字数+说明书+外文翻译+3张CAD图纸【详情如下】

A0离合器总装配图.dwg

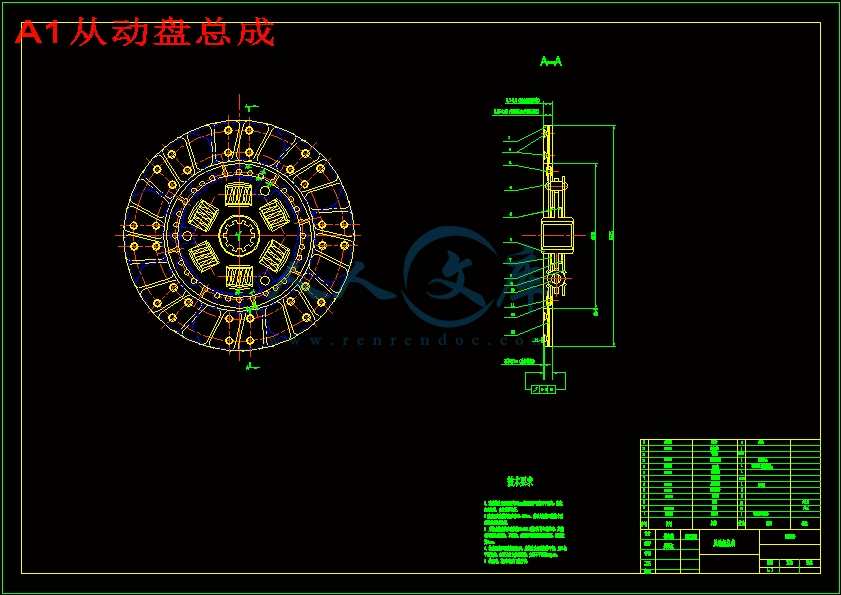

A1从动盘总成.dwg

A1减震盘.dwg

商务车拉式离合器的设计论文.doc

外文翻译--摩擦片式离合器简介.doc

摘要

本次设计题目是FORLAND轻型汽车离合器设计(拉式)

离合器是汽车传动系的重要组成部分,它设计的成功与否,将直接影响到整车性能的好坏。

由本车的发动机扭矩较小,故设计中采用单片膜片弹簧离合器,并采用带扭矩减震器的从动盘。为了使离合器接合平顺,以保证汽车的平稳起步,采用了有轴向弹性的从动片。

本文内容包括:轻型汽车的离合器结构方案论证;离合器工作特性(扭矩传递特性);离合器的基本结构参数设计与选型;强度校核;工艺过程制定和尺寸链计算。

关键词:从动盘 压缩弹簧 制造材料

Abstract

The topic of this sign is design a clutch for FORLAND commercial vehicle(pull_type).

It is the most important part of the light vehicle’s transform-system. The performance of light vehicle is largely relative to the quality of the design.

According to the torque, a single dry-disc diaphragm-spring clutch is used, and a clutch disc with a torsional absorber is fixed. To start the vehicle stability, the clutch must be engaged smoothly, so a plate segment with a axisal elasticity is mounted.

In the paper, I introduced the selection of the possible type of the clutch(torque operation characteristic). The selection of the found a mental parameter and the determination of the main dismensious the structure design of the components and corresponding calculation.

Key words: driven disk compression spring material

目录

绪论1

第一章 结构方案设计2

1.1 总论2

1.2 总成零件结构方案分析4

1.2.1 从动盘数目分析4

1.2.2 压紧弹簧的选择4

1.2.3 从动盘结构方案分析7

1.2.4 从动盘摩擦片结构方案分析9

1.2.5 其他零部件结构方案分析10

第二章 整体性能参数选择与计算12

2.1 摩擦片尺寸计算12

2.2 后备系数的确定13

2.2.1后备系数选择13

2.2.2 性能参数计算14

2.3 第一轴和从动盘毂花键尺寸选取和校验15

2.3.1 花键尺寸d计算15

第三章 膜片弹簧设计17

3.1 拉式膜片弹簧的工作原理17

3.2 拉式膜片弹簧的载荷——变形特性17

3.2.1 接合位置的载荷变形公式18

3.2.2 分离时的载荷变形公式19

3.2.3 小端载荷——变形特性21

3.3 拉式膜片弹簧应力变形特性21

3.3.1 碟形弹簧部分的应力——变形公式21

3.3.2 碟形部分子午剖面上切向应力分布:22

3.3.3 拉式膜片弹簧的应力计算23

3.4 拉式膜片弹簧的设计24

第四章 离合器扭转减震器基本参数选择27

4.1 概述27

4.2 主要性能参数计算和分析27

4.2.1减震器的极限转矩27

4.2.2 计算减震器阻尼力矩28

4.2.3 计算减震器的预紧扭转力矩29

4.2.4 减震弹簧位置半径的确定29

4.2.5 由参考文献提供的列表29

第五章 其余结构参数校核32

5.1 传力片强度校核32

5.2 压盘热容量校核32

第六章 主要零件加工工艺34

6.1 主要零件加工工艺34

6.1.1膜片弹簧的制造工艺34

6.2 工艺尺寸链的计算37

结束语40

致谢41

参考文献42

绪论

我国正处于社会主意初级阶段,主要的工作重点是发展社会生产力,为适应上层建筑的需要,为了使生产关系适应生产力,还要不断的推动科学技术的发展。

现代汽车已成为各国国民经济中不可或缺的一部分,而离合器作为组成汽车的一部分,对其的需求也是愈来愈高。

离合器作为机械传动系的重要组成部分,位于传动系的首端,用于切断和传递传动动力。故汽车离合器设计的好坏,直接关系到汽车是否能够平稳起步;能否可靠的在换挡时将发动机与传动系分离,从而减少变速器中齿轮的冲击,便于换挡;是否能在工作中受到较大载荷时,以打滑的方式保护发动机和传动系不至于过载而损坏。

由于城市道路普遍较窄的现状,车流量的不断增加,导致道路交通情况的日趋复杂,司机在行驶中需要不断的换挡,停车,起步,造成离合器使用频率增高,使用条件日趋严酷,因此设计上应保证离合器有优良的工作性能,即保证其上限工作极限。离合器工作时,温度上升,导致摩擦系数变换,压紧力变化。当散热等系能指标满足时,同时要考虑到国内目前的生产工艺水平,以降低成本和维修费用等。第一章 结构方案设计

1.1 总论

首先应该深入研究对汽车离合器的设计要求,根据离合器在汽车中所处的位置,保证离合器的良好工作性能。一部合格的离合器至少需要满足以下要求:

1.在任何行驶条件下,既能可靠的传递发动机的最大转矩,并有适当的转矩储备,又能防止传动系过载。

2.接合时要完全、平顺、柔和,保证汽车起步时没有抖动和冲击。

3.分离时要迅速、彻底。

4.从动部分转动惯量要小,以减轻换挡时变速器齿轮间的冲击便于换挡和减小同步器的磨损。

5.应有足够的吸热能力和良好的通风散热效果,以保证工作温度不致过高,延长时其使用寿命。

6.应能避免和传动器的扭转振动,缓和冲击和降低噪声的能力。

7.操纵轻便,准确,以减轻驾驶员的疲劳。

8.作用在从动盘上的总压力和摩擦材料的摩擦因数在离合器工作过程中变化要尽可能小,以保证有稳定的工作性能。

9.具有足够的强度和良好的动平衡,以保证其工作可靠、使用寿命长。

10.结构应简单、紧凑、质量小,制造工艺性好,拆装,维修,调整方便等。

离合器的主要功用是切断和实现发动机对传动系的动力传递,保证汽车起步时将发动机和传动系平顺的接合,确保汽车平稳起步;在换挡时将发动机与传动系分离,减少变速器中换挡齿轮之间的冲击;在工作中受到较大的动载荷时,能限制传动系所承受的最大转矩,以传动系各零部件因过载而损坏;有效的降低传动系中的振动和噪声等。

基于以上考虑,下面将选择本设计离合器的传递动力方式。

用于离合器传递动力的方式有摩擦、液力、磁力等几种方式。液力、磁力离合器具有自动适应负载变化,自动变扭等几种优良性能,但其缺点是结构过于复杂,价格较高,体积较大,重量大,维修困难等。鉴于以上几种优点,目前绝大多数汽车上仍使用摩擦式离合器,只有为数不多的高档轿车,及一些工作负荷较大,且工作条件恶劣的重型车,矿山车上使用液力离合器。本设计是轻型汽车,工作条件较好,负荷也较小,采用液力或磁力离合器大可不必。因此,本设计采用摩擦式离合器。

离合器主要由主动部分,从动部分,压紧机构和操纵机构组成。

1、主动部分

?主动部分包括飞轮、离合器盖、压盘等机件组成。这部分与发动机曲轴连在一起。离合器盖与飞轮靠螺栓连接,压盘与离合器盖之间是靠3-4个传动片传递转矩的。

2、从动部分

?从动部分是由单片、双片或多片从动盘所组成,它将主动部分通过摩擦传来的动力传给变速器的输入轴。从动盘由从动盘本体,摩擦片和从动盘毂三个基本部分组成。为了避免转动方向的共振,缓和传动系受到的冲击载荷,大多数汽车都在离合器的从动盘上附装有扭转减震器。

?为了使汽车能平稳起步,离合器应能柔和接合,这就需要从动盘在轴向具有一定弹性。为此,往往在动盘本体园周部分,沿径向和周向切槽。再将分割形成的扇形部分沿周向翘曲成波浪形,两侧的两片摩擦片分别与其对应的凸起部分相铆接,这样从动盘被压缩时,压紧力随翘曲的扇形部分被压平而逐渐增大,从而达到接合柔和的效果。

3、扭转减振器

?离合器接合时,发动机发出的转矩经飞轮和压盘传给了动盘两侧的摩擦片,带动从动盘本体和与从动盘本体铆接在一起的减振器盘转动

?动盘本体和减振器盘又通过六个减振器弹簧把转矩传给了从动盘毂。因为有弹性环节的作用,所以传动系受的转动冲击可以在此得到缓和。传动系中的扭转振动会使从动盘毂相对于动盘本体和减振器盘来回转动,夹在它们之间的阻尼片靠摩擦消耗扭转振动的能量,将扭转振动

参考文献

[1]于骏一,邹青.机械制造技术基础(第一版)[M]. 北京:机械工业出版社,2004年.

[2]濮良贵,纪名刚.机械设计(第八版)[M].北京:高等教育出版社,2006年.

[3]成大先.机械设计手册(第三版)[M].北京:化学工业出版社,1999年.

[4]徐石安,江发潮.汽车离合器/汽车设计丛书[M].北京:清华大学出版社,2005年.

[5]钱大川.新型联轴器、离合器选型设计与制造工艺实用手册[M].北京:北京工业大学出版社,2006年.

[6] 甘永力.精度设计基础[M].长春:吉林人民出版社,2005.

[7] 何少平.机械结构工艺性[M].长沙:中南大学出版社,2003.

[8] 机械结构工艺性[M].北京:机械工业出版社,1997.

[9] 工业机械手设计基础[M].天津:天津科学技术出版社,1979.

[10] 工业机械手图册[M].北京:机械工业出版社,1978.

[11] 沈世德.机械原理[M].北京:机械工业出版社,2002.

[12] MARGHITU, D. B. Mechanical Engineer's Handbook[M] 2001.

[13] MERCER, R. B. Industrial Control Wiring Guide[M].2001.

[14] POPE, J.E.Rules of Thumb for Mechanical Engineers[M]. 1996.

[15]REIMPELL,J.CombinationMachine-EngineeringPrinciples[M].2001.

[16] Ii Z.X.,Qin Z.,Jiang S.et a1.Coordinated motion generation

and real-time grasping force control for multi-fingered manipulation. Proceedings of the IEEE Internationa1 Conference on Robotics and Automation[M].1998.

[17] TANAKA, K. The Science and Technology of CNC[M]. 1999.

川公网安备: 51019002004831号

川公网安备: 51019002004831号