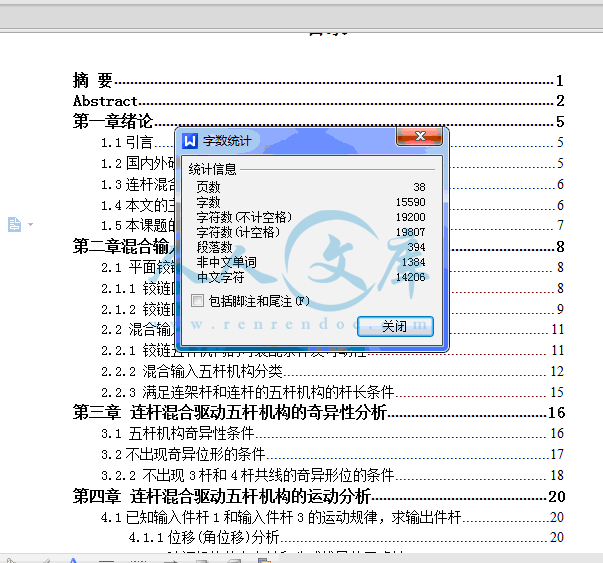

连杆混合驱动五杆机构设计

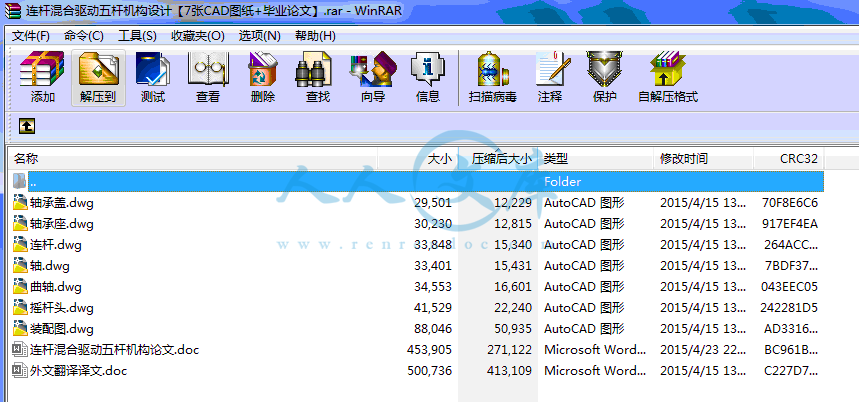

38页 15000字数+说明书+外文翻译译文+7张CAD图纸【详情如下】

外文翻译译文.doc

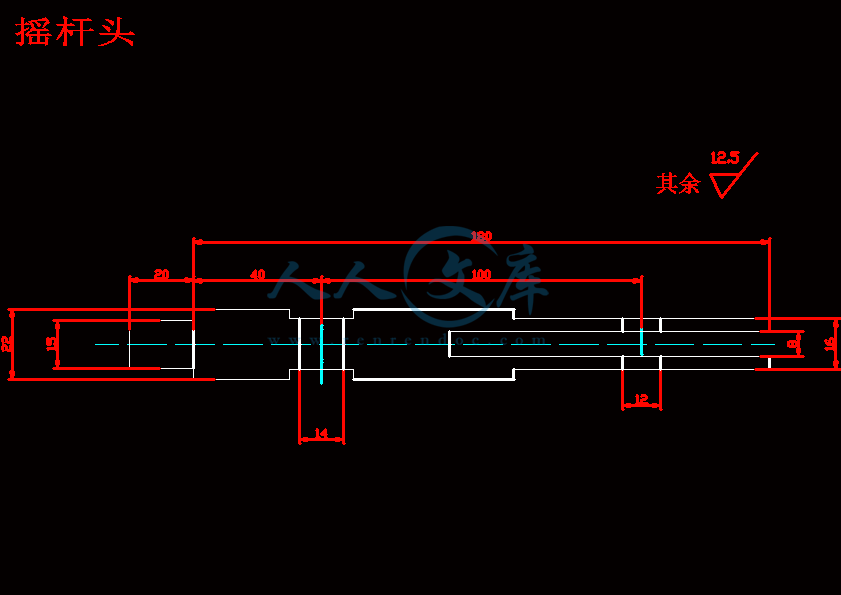

摇杆头.dwg

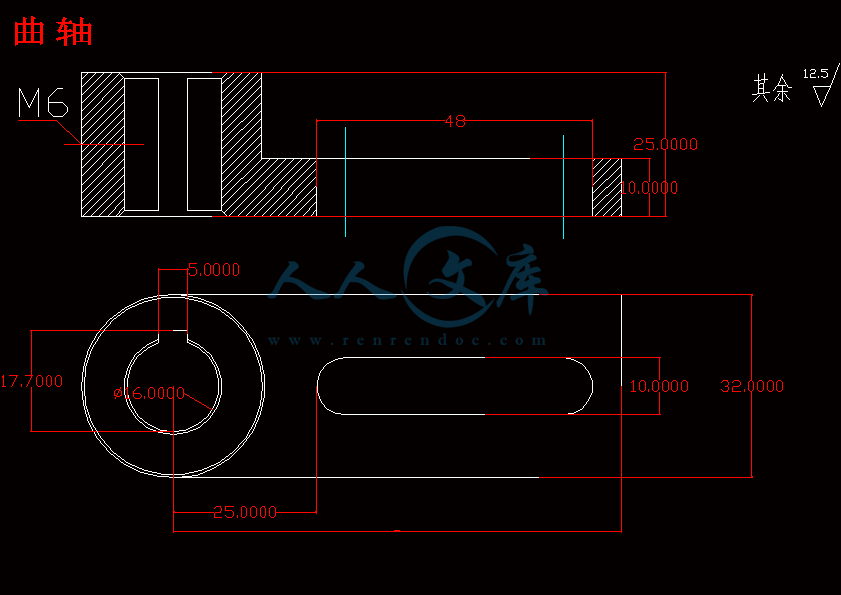

曲轴.dwg

装配图.dwg

轴.dwg

轴承座.dwg

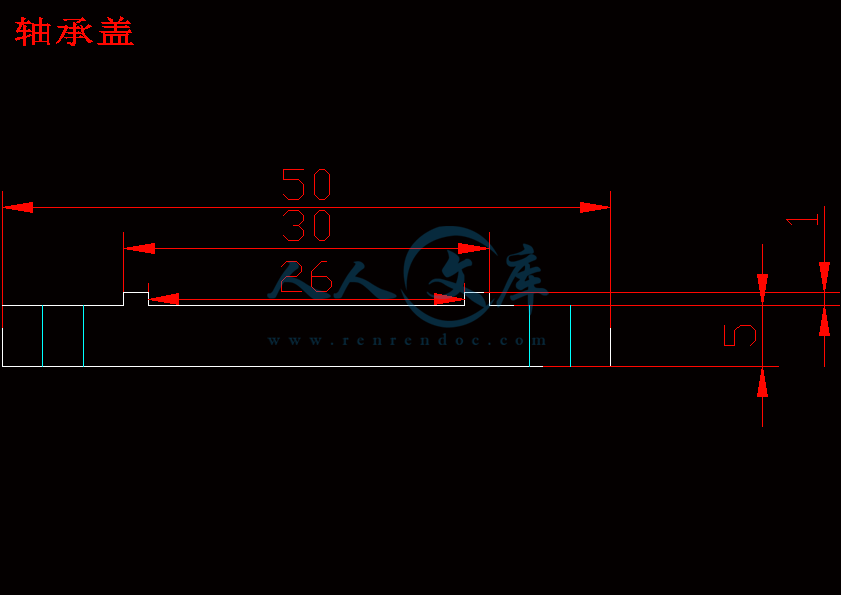

轴承盖.dwg

连杆.dwg

连杆混合驱动五杆机构论文.doc

摘 要

本文以两曲柄分别为连架杆和连杆的一类混合输入五杆机构作为研究对象,围绕此机构对混合驱动可控机构的结构学、运动学和优化综合问题进行了研究。内容为:

1) 从机构的装配条件出发,对机构进行可动性分析,确定了该曲柄— 连杆机构的双曲柄存在条件。

2) 对该机构进行奇异性分析,得出该机构出现奇异位形的两种类型。

3) 分别对机构进行正运动学和逆运动学分析,并通过算例验证机构的存在性和公式推导的正确性。

4) 应用上述分析结果,对该曲柄—连杆机构进行优化综合。针对两种不同的运动类型,分别建立了基于正运动学分析和逆运动学分析的优化综合数学模型,为混合驱动可控机构的优化综合提供了理论方法。并通过实例分析证明了优化后的机构性能有了很大的改善。

关键词:混合输入五杆机构;奇异性分析;运动分析;优化综合

Abstract

In this paper, take the hybrid input five-bar mechanism for double crank

based on link-rack ram and linkage as subject investigated. This research is

mainly around this mechanism. Research content is focused on the followings Firstly, set out from the assembly conditions, them obility of this mechanism was analyzed, the existence condition of this mechanism was determined. Secondly, by analyzing the conditions of singularity, this paper conclude the styles of existing the two kinds of singularity. Thirdly, a nalyse based on for ward kinematic sand inversek in ematics, some examples verify the existence of the mechanism and the correctness of formula deduction. Finally , this paper presents the optimal synthesis of crank-linkage mechanism. Regard two different style as the goal, set up different optimal synthesis model on the base of forward kinematics and inverse kinematics analyses. Offered the theory method for the Optimal shnthesishy brid-drivenand controlled mechanism. The results of optimal synthesis example sverifies the institution performance have a great improvement after optimization

Key kin words: hybrid analyses input five-bar mechanism; analysis of singularity; ematics ; optimal synthes

目录

摘 要1

Abstract2

第一章绪论5

1.1引言5

1.2国内外研究概况5

1.3连杆混合驱动五杆机构的工作原理6

1.4本文的主要工作内容6

1.5本课题的研究意义7

第二章混合输入可控五杆机构的可动性分析及存8

2.1 平面铰链四杆机构类型分析8

2.1.1 铰链四杆机构Grashof准则及可装配条件8

2.1.2 铰链四杆机构的两开链机构工作空间位置关系9

2.2 混合输入铰链五杆机构类型11

2.2.1 铰链五杆机构的可装配条件及可动性11

2.2.2 混合输入五杆机构分类12

2.2.3 满足连架杆和连杆的五杆机构的杆长条件15

第三章 连杆混合驱动五杆机构的奇异性分析16

3.1 五杆机构奇异性条件16

3.2不出现奇异位形的条件17

3.2.2 不出现3杆和4杆共线的奇异形位的条件18

第四章 连杆混合驱动五杆机构的运动分析20

4.1已知输入件杆1和输入件杆3的运动规律,求输出件杆20

4.1.1位移(角位移)分析20

4.1.4验证机构的存在性和公式推导的正确性22

4.1.4.1 使用Mathcad编程进行运动仿真22

4.2速度(角速度)分析24

4.2.1加速度(角加速度)分析24

4.2.2验证机构的存在性和公式推导的正确性24

4.2.2.1使用Mathcad编程进行运动仿真24

4.3传动角Y分析24

第五章 连杆混合驱动五杆机构的优化综合25

5.1基于正运动学分析的优化综合模型27

5.1.1机构优化综合模型的建立27

5.1.1.1混合驱动破碎机优化设计的参数28

5.1.1.2目标函数28

5.1. 1.3 设计变量28

5.1. 1.4 约束条件28

5.2基于逆运动学分析的优化综合模型28

5.2.1机构优化综合模型的建立29

5.2. 1. 1混合驱动破碎机优化设计的参数29

5.2.1.2目标函数29

5.2.1.3设计变量30

5.2.1.4约束条件30

5.3机构优化方法的确立30

5.4机构优化综合实例30

5.4.1基于正运动学分析的优化综合实例30

5.4.2基于逆运动学分析的优化综合实例31

第六章 技术参数33

第七章 小结34

参考文献36

致 谢38

第七章 小结

混合驱动可控机构是目前机构学研究的前沿方面,它既涉及到传统机构学理论和机构创新设计理论,有涵盖机器人特别是并联机器人中的有关理论。本文以曲柄— 连杆混合驱动可控机构作为研究对象,对该机构的结构学、运动学等问题进行深入的分析研究,得到如下的结论:

对于两曲柄分别为连架杆和连杆的混合输入五杆机构,其分析方法不同于两曲柄都是连架杆的混合输入五杆机构。尤其是奇异性分析时不能利用输出杆的速度雅可比矩阵,因为它的输出杆是定轴转动的,其速度雅可比矩阵行列式的值是恒为零的。本文主要是利用一连杆的传力点速度雅可比矩阵,计算它的行列式的值进行分析,并通过作机构运动简图和

运动连续性原理验证了其正确性。2.利用了矢量投影法和复合三角函数的求导法进行了该类机构的角位移、角速度和角加速度的分析。并用Mathcad进行运动仿真得出各曲线都是续的,同时用几何作图法进一

步验证了机构的存在性和公式推导的正确性。3.分别采用正运动学和逆运动学方法对该机构进行优化综合,建立数学模型,包括确定该机构的

目标函数、设计变量和约束条件等。并通过对算例的优化,确定了该机构的最优参数。

由于时间关系及本人知识水平有限,对该类机构的设计与优化综合的研究仅仅是初步的。为了进一步完善设计和优化深度,可以从以下几个方面开展工作。

(1) 在机构的运动学分析的基础上,可以考虑对机构的运动规律进行深入分析,比如各杆长变化、初始相位角的变化和传动比变化等等对伺服电机驱动曲柄的影响;另外,可以通过研究可控机构的结构参数、可调参数对速度特性的影响,比较这些参数对机构速度特性影响的主次关系,找出其中对特征参数影响较大的敏感参数。在优化时,利用这些结论,针对主要因素进行优化,这样可以大大减少优化设计的盲目性,提高优化效率。

(2) 对机构进行动力学分析。在高速机械和重型机械中,运动构件会产生较大的惯性力和惯性力矩,回转机构运转中产生的惯性力会造成很大

的危害。因此必须通过动力学分析,减小惯性力的不良影响。

(3)多目标优化设计目标函数的研究。由于混合驱动机构性能涉及诸多的影响因素,因此有必要对其他更多的目标函数进行研究,获得更有实用意义的优化模型,以利于实际工程应用。比如加入伺服电机的驱动力矩

考察和伺服电机输出功率与常规电机输出功率的比值考察等等。

(4) 优化设计变量的研究。本文仅以运动学性能作为目标函数,故设计变量为机构的结构参数。当研究多目标优化设计目标函数时,应相应增加设计变量的考察,如伺服电机的驱动力矩和功率分配问题等等。

(4) 优化设计变量的研究。本文仅以运动学性能作为目标函数,故设计变量为机构的结构参数。当研究多目标优化设计目标函数时,应相应增加设计变量的考察,如伺服电机的驱动力矩和功率分配问题等等。

参考文献

[1]陈瑞芳,马履中.平面五连杆机构曲柄存在条件及机构类型的判别方法[J]江苏理工大学学报,1998,1 9 (1)

[2]廖汉元,1999 ,等.两白由度机构的可动性条件[J]武汉冶金科技大学学报(自然科学版),22 (1),57-59

[3]李佳,等.五杆两自由度机构可动性的充分条件[J].武汉冶金科技大学学报,1998, 21(3)

[4]周双林.邹惫君,等.混合输入五杆机构构型的分析[J]上海交通人学学报,2001,35(7 )

[5]程光组,贺惠农。两自由度连杆机构精确实现平面轨迹的研究[J].东南大学学报,1990,20 ( 3) :64-67

[6]杨金堂,邵正宇,吴千城.受控五杆机构实现轨迹的“补偿运动”研究[J].武汉冶金科技大学学报。1999,22( 2):171-174

[7]孔建益,W.Funk.具有一个受控原动件的五杆机构精确实现给定函数的研究[J].中国机械工程1996,7 (专刊):106-108

[8]张新华,等混合驱动机械系统建模的理论依据[J]机械科技与技术,2001, 20 (6)

[9]李学刚,等.混合驱动可控机构的研究现状及发展趋势[J].河北理工学院学报,2004,26 ( 3)

[10]方新国,邹葱君,周双林混合驱动平面两自由度五杆机构的完全分类[J]机械科学与技术,2003, 22( 1)

[11]孟宪举,张策.平面五杆机构的尺度分析[J].机械科学与技术,2002, 22 (2)

[12]周双林,郭为忠,姚燕安.混合输入五杆机构柔性:作空间的分析上海交通大学学报,2001,35( 12)

[13]周A林,邹慧君,郭为忠,姚燕安.平面闭链五杆机构柔性-L作空间的分析[J].上海交通大学学报,2000,34( 10)

[14]田汉民.混合输入五杆机构的分析和综合[J].天津:天津大学,2001

[15]张新华.实现轨迹创成的混合驱动可控机构分析和综合[J].天津:天津大学,2002

[16]吴深,褚金奎.用谐波理论和快速傅立叶变换进行五杆机构的轨迹综合[J].机械科学与技术 ,1999,18( 3)

[17]陆永辉,孟彩芳,张策一种新型混合输入式曲柄压力机的研究[J].锻压机械

[18]李辉,孟宪举,等.混合驱动压力机运动设计的初步探[J]机械设计与研究

[19]王生泽,等.可控连杆机构动力学分析的一般方法研究[J].机械设计与研究,2002(增刊)

[20]马承文.邹蔽君,方新国.平面五杆机构的惯性力平衡问题的研究[J].机构设计与研究,2002 , 18 (4)

川公网安备: 51019002004831号

川公网安备: 51019002004831号