CJK6256B简易数控车床的的设计

17页 7100字数+说明书+4张CAD图纸【详情如下】

CJK6256B简易数控车床的的设计论文.doc

主轴箱装配图.dwg

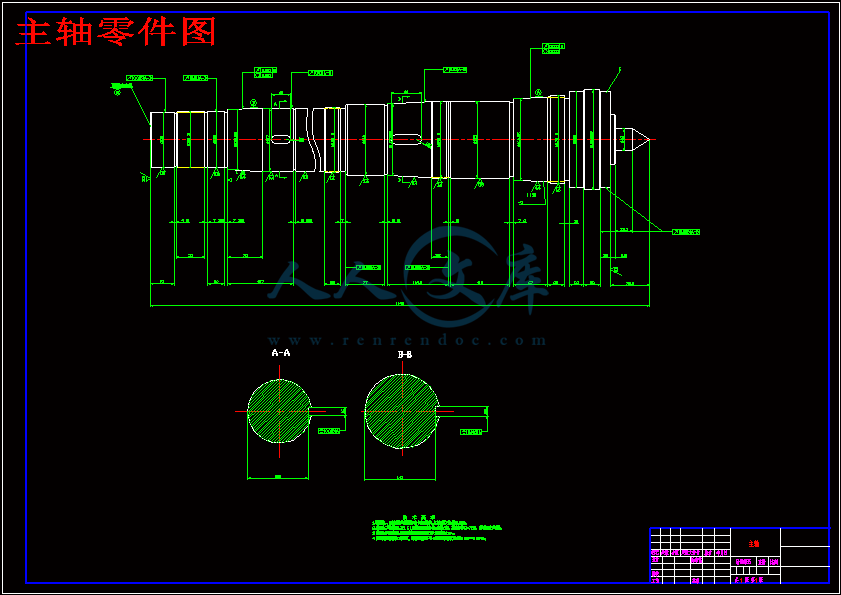

主轴零件图.dwg

自动刀架装配图.dwg

转速图.DWG

前言

随着科学技术的不断发展,机械产品日趋精密、复杂,改型也日益频繁,对机床的性能、精度、自动化程度等提出了越来越高的要求。机械加工工艺过程自动化是实现上述要求的重要技术措施之一,不仅能够提高产品质量和生产率,降低生产成本,还能改善工人的劳动条件。为此,许多企业采用自动机床、组合机床和专用机床组成自动或半自动生产线。但是,采用这种自动、高效的设备,需要很大的初期投资以及较长的生准备周期,只有在大批量的生产条件(如汽车、拖拉机、家用电器等工业主要零件的生产),才会有显著的经济效益。

在机械制造工业中,单件、小批量生产的零件约占机械加工总量的70%~80%。科学技术的进步和机械制造产品市场竞争的日趋激烈,致使机械产品不断改型、更新换代,批量相对减少,质量要求越来越高。采用专用的自动机床加工这类零件就显得很不合理,而且调整或改装专用的“刚性”自动生产线投资大、周期长,有时从技术上甚至是不可能实现的。采用各类仿型机床,虽然可以部分地解决小批量复杂零件的精度很难达到的要求。

为了解决上述问题,满足多品种、小批量,特别是结构复杂、精度要求高的零件的自动化生产,迫切需要一种灵活的、通用的、能够适用于产品频繁变化的“柔性”自动化机床。随着计算机科学技术的发展,1952年,美国帕森斯公司(Parsons)和麻省理工学院(MIT)合作,研制成功了世界上第一台以数字计算机为基础的数字控制(numerical control,简称NC)3坐标直线插补铣床,从而使机械制造业进入了 一个新阶段。

因此,在毕业设计到来时,根据我们专业与企业的要求,在徐卫国老师的指导下,本人选择了数控车床的改造这一课题。通过研究,改造主要有三个部分:

(1)主轴箱

(2)电器

(3)自动刀架

此课题有本人承担,本人改造主轴箱中的主轴部件是机床重要组成部分之一。除了与普通机床一样要求具有良好的旋转精度、静刚度、抗振性、热稳定性及耐磨性外,由于数控机床在加工过程中不进行人工调整,且数控机床要求的转速更高,功率大。所以数控机床的主轴部件在上述几方面要求更高且更严格。在主轴部件的改造方面,本人采取尽可能按原机床传动路线,并选用主轴脉冲发生器来输出主轴转速,主轴转一转,主轴脉冲发生器 发出1024个脉冲。数控车床的电器也很重要,车床的自动化程度也就在此体现。

电器方面,本人参考CJK6256B简易数控车床的电器原理,该结构简单,能较好的实现对主轴电机主轴变频器,刀台电机正反转,风扇等等的控制。

自动刀架也是数控车床与普通车床的重要区别之一,它具有准确的重复定位功能,具有较高的精度。

目录

第一章数控机床的主传动及主轴部

1.1数控机床主传动装置……………………………………………………4-6

1.1.1特点

1.1.2变速方式

1.1.3选择电动机

1.1.4选择带轮

1.1.5确定传动方式

1.2主轴组件设计………………………………………………………………7-9

1.2.1主轴主件类型

1.2.2主轴设计

1.2.3主轴支承

1.2.4主轴停止功能1

1.3中间轴的设计…………………………………………………………………10

1.4输入轴的设计…………………………………………………………………11

1.5主轴箱的装配…………………………………………………………………12

第二章电器…………………………………………………………………………13

第三章自动刀架……………………………………………………………………15

结论……………………………………………………………………16

参考文献……………………………………………………………………………17

附录…………………………………………………………………………………18

第一章数控机床的主传动及主轴组件

1.1数控机床主传动装置

1.1.1特点

数控机床的主传动与普通机床的相比具有以下特点:

(1)主轴传动系统转速高,功率大,能满足数控机床大功率切削和高速切削的要求,实现机床高效率工作。

(2)传动系统调速范围较大,变速迅速可靠,并能实现自动无级调速,使切削工作始终在最佳状态下进行。

(3)为实现刀具的快速或自动装卸,主轴上具有特殊的刀具安装结构。

(4)主轴部件要求有较大的刚度和较高的精度。

1.1.2变速方式

本人根据原机床结构采用双向内齿离合器来使主轴实现四级变速。

1.1.3选择电动机

选用Y160L-4 A型鼠笼转子电动机系列。功率15KW转速1460r/min.额定转矩2.2kn/m。

1.1.4选择带轮

根据电动机的输出功率、输出轴所需的转速、工作时间,选择并校核带轮,确定小带轮与大带轮的基准直径,大带轮如装配图 所示,基准直径为304mm,采用孔板式结构。此结构可以避免齿轮传动时引起的振动与噪声,传动比较准确,传动精度高、平稳、噪声小,维修保养方便,不需润滑。

采用无级变速主轴电机(直流或交流),主轴箱内齿轮变速级数很少(一般最多为四级)。主轴箱内设置齿轮变速,主要目的是重复利用电机的恒功率,输出范围一般多用于大中型机床,一部分小型机床为了获得强力切削也在应用。变速级改变通常是用液压控制齿轮滑移来实现,一般小型数控机床的主轴箱步设置齿轮变速机构其噪声与振动大大减少由于主轴功率特性在不断改进,无齿轮变速的主传动得到越来越多的应用。

液压刀架使用广泛,性能比较稳定,电机带动的刀架没有液压管路,结构简单。

1.1.5确定传动方式

传动路线如下:1.2主轴组件设计

主轴组件由主轴、主轴支承、装在主轴上的传动件和密封件等组成。机床加工时,主轴带动工件或刀具直接参与表面成型运动,所以主轴的精度、刚度和热变形对加工质量和生产效率等有着重要的影响,而且由于数控机床在加工过程中心线的平均空间位置称为瞬时回转中心线。瞬时回转中心线相对于理想回转中心线的距离,就是主轴的回转误差。而回转不进行人为调整,这些影响就更为重要。

(1)回转精度高

回转中心线的空间位置,在理想的情况下应是固定不变的, 称为理想中心线。实际上,由于主轴组件中各种因素的影响,回转中心线的空间位置每一瞬间都是变化的,这些瞬时回转中误差的范围,就是主轴的回转精度。径向误差、角度误差和轴向误差很少单独存在,当径向误差和角度误差同时存在时,构成径向跳动,而轴向误差和角度误差同时存在时构成端面跳动。

(2)刚度大

主轴组件的刚度是指受外力作用时,主轴组件抵抗变形的能力。主轴组件的刚度越大,主轴受力后的变形越小。若主轴组件的刚度不足,在切削力及其它力的作用下,主轴将产生较大的弹性变形,不仅影响工件的加工质量,还会破坏齿轮、轴承的正常工作条件,加快其磨损,降低精度。主轴部件的刚度与主轴的结构尺寸、支承跨距、所选用的轴承类型及其配置形式、轴承间隙的调整、主轴上传动元件的位置关系等有关。

(3)抗振性强

主轴组件的抗振性是指切削加工时,主轴保持平稳运转而不发生振动的能力。若主轴组件抗振性差,工作时容易产生振动,不仅会降低加工质量,而且限制了机床生产率的提高,使就刀具的耐用度下降。

(4)温升低

主轴组件运转中的温升过高会引起两个方面的不良结果:一是主轴组件和箱体因热膨胀而变形,主轴的回转中心线和机床其它元件的相对位置发生变化,直接影响到加工精度;二是轴承等元件会因温度过高而改变已调好的间隙,破坏正常工作,严重时甚至会发生“抱轴”。数控机床为了解决温升问题,一般采用恒温主轴箱。

(5)耐磨性好

主轴组件必须有足够的耐磨性,以便能长期保持精度。主轴上易磨损的地方是刀具或工作安装部位,以及移动式主轴的工作表面。为了提高耐磨性,主轴的上述部位应该淬火硬,或氮化处理,以提高硬度,增加耐磨性。主轴轴承也需要有良好的润滑,以提高其耐磨性。

1.2.1主轴组件的类型

主轴组件按运动方式可分为五类:

(1)只有旋转运动的主轴组件。这类主轴组件结构较为简单,如车床、铣床、和磨床等主轴组件。

(2)既有旋转运动又有轴向进给运动的主轴组件。

(3)既有旋转运动又有轴向调整移动的主轴组件。如滚齿机、部分立式铣床等的主轴组件。主轴在套筒内作旋转运动,并可根据需要随主轴套筒一起作轴向调整运动。主轴组件工作时,用其中的夹紧装置将主轴套筒夹紧在主轴箱内,以提高主轴部件的刚度

(4)既有旋转运动又有径向进给运动的主轴部件。如卧式镗床的平旋盘主轴组件、组合机床的镗孔车端面头主轴组件。主轴作旋转运动时,装在主轴前端面平旋盘上的径向滑块可带动刀具作径向进给运动。

(5)主轴作旋转运动又作行星运动的主轴部件。

1.2.2主轴设计

主轴是主轴组件的重要组成部分,它的结构尺寸和形状、制造精度、材料及其热处理等。对主轴组件的工作性能都有很大的影响,其主要尺寸参数包括如下四个部分:

(1)主轴直径

(2)内孔直径

(3)悬件长度

(4)支承跨距

根据原有结构,本人采用原有主轴,改变主轴支承方案来增强主轴的强度与刚性。

1.2.3主轴支承

根据各段轴的直径,确定主轴支承。前支承用3182132型双短圆柱滚子轴承与8218推力球轴承,后支承采用3182124型双短圆柱滚子轴承,中间辅助支承为128型单列滚珠轴承。这样不仅保证主轴的回转精度,也提高了主轴刚度和抗振性。由于运转中会发热,主轴必然会膨胀,为了吸收这个热膨胀量,希望后支承能沿轴向移动,容易使轴承受损。因此从提高后支承刚性和适应主轴热膨胀的要求来说,前支承采用3182132型双短圆柱滚子轴承为好,右端用端盖顶住,左面用调整螺母来预紧。

参考文献

华东纺织工学院、哈尔滨工业大学、天津大学主编 《机床设计图册》 上海科技技术出版社 1979

范云涨、陈兆年主编 《金属切削机床设计简明手册》

机械工业出版社 1993

许高燕主编 《机械设计手册及课程设计》

中国地质大学出版社 2001

吕慧瑛主编 《机械设计基础》

上海交通大学出版社 2001

成大宪主编 《机械设计手册》

化学工业出版社 1998

王炳实主编 《机床电器控制》

机械工业出版社 1999

彭晓南主编 《数控技术》 机械工业出版社 2001

李宏胜主编 《机床数控技术及应用》

川公网安备: 51019002004831号

川公网安备: 51019002004831号