【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

包钢烧结φ250卸灰阀设计

摘 要

电动蘑菇头式双层卸灰阀是烧结厂专用的一种卸灰装置,烧结机双层卸灰阀的作用是在保证不漏料的情况下,把台车底部从风箱漏下的烧结矿料粒,定时排到除尘皮带运输机上。它的使用性能直接影响到烧结机产量、作业率能否进一步提高。而φ250电动蘑菇头式双层卸灰阀结构简单、工作效率高、除尘量较大(3t/h)、具有双层结构密封性能好、占地面积小、适合在恶劣的环境中工作。因此,电动蘑菇头式双层卸灰阀在各钢铁厂得到广泛的应用。

在这次毕业设计中,主要是对电动蘑菇头式双层卸灰阀的传动部分进行设计,具体设计步骤分成一下几部分:进行传动方案的总体设计、传动零件的设计、轴系部件的设计以及金属的热处理和零件的磨损、密封与润滑。

关键词:卸灰阀;蘑菇头式;除尘;主传动

Design of sintering Φ250 dust valve in Baotou Steel Factory

Abstract

Electric cone type double dust valve is a special type of dust device in sintering plant. The double dust valve of the sintering machine is used to pledge not to leak materials,the sintering meterial from the Bellows which is at the bottom of the machine ,should be transport to the Belt Conveyor on time. It's direct influence of performance characteristics goes to sintering machine production and that whether work rates have a further raising. Φ250 electric cone type double dust valve have simple structure,high working efficiency, comparatively large dust-clearing quantity ( 3t/h) , it have double structural sealing that can be good , little area of occupancy , and it suits to work in bad environment. Therefore, electric cone type double dust valve gets extensive application in each steel factory.

In this graduated design , it’s major is the design of the part of the transmission to Electric cone type double dust valve, specific design step is divided into some parts of: the general design of transmission scheme, the design of transmission parts, the design of shaft parts as well as the heat treatment ,and of the wear of metal, the part of the seal and lubrication.

Keyword: Dust valve; Cone type; dust-clearing; Main transmission device

设计卸灰阀的有关参数

项目

序号设备性能参数数值单位备注

1烧结散料粒 度0~10mm

温 度<150℃

密 度1.7t/

2处理量3t/h

3阀工作周期28.6s

4重锤量46Kg

目 录

摘 要I

AbstractII

第一章 绪 论1

1.1 课题来源及课题设计的意义1

1.1.1 烧结厂粉尘来源1

1.1.2 烧结厂生产工艺中废气的产生2

1.1.3 污染物特点及其技术参数2

1.2 烧结厂废气治理所采取的措施3

1.2.1 烧结机废气除尘3

1.2.2 烧结机烟气中二氧化硫的治理3

1.2.3 烧结机尾除尘4

1.2.4 整粒系统除尘5

1.2.5 球团竖炉烟气治理5

1.2.6 生产工艺流程的改革6

1.2.7 烧结厂烟气冷却机废气的余热回收方式6

1.2.8 除尘技术装备水平和效果普遍提高7

1.2.9 烧结厂粉尘二次污染控制采取的措施7

1.2.10加强设计工作适应生产要求7

1.2.11加强操作和设备维护8

1.3 卸灰阀的分类及其工作原理8

1.3.1 卸灰阀的选用原则8

1.3.2 常见卸灰阀的结构及其工作原理9

第二章 传动装置的总体设计13

2.1 确定传动方案13

2.1.1 传动装置的组成13

2.1.2 合理确定传动方案13

2.1.3 确定减速器结构及其零部件13

2.1.4 选择电动机的型号14

第三章 传动零件的设计17

3.1 摆线针轮行星传动设计17

3.1.1 特点17

3.1.2 减速器的选择18

3.1.3 设计计算18

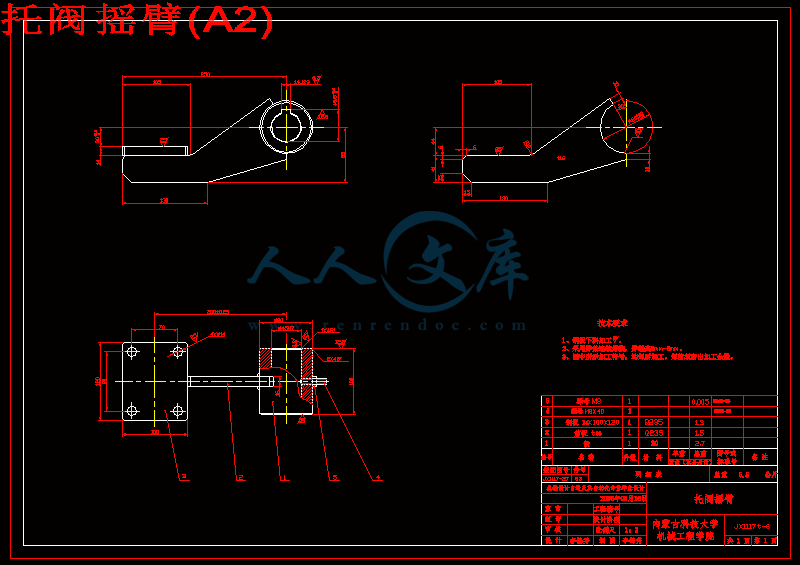

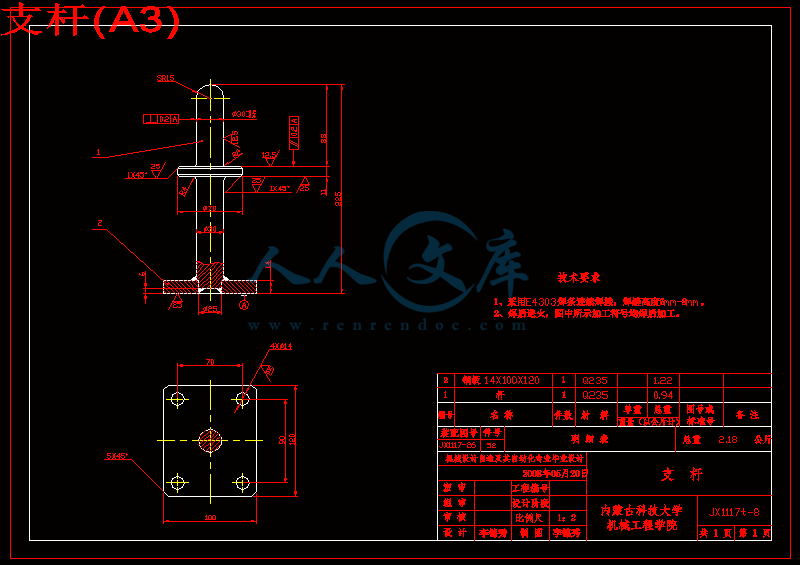

3.2 传动托阀摇臂轴的设计21

3.3 圆柱螺旋压缩弹簧的设计计算30

第四章 其余零部件的设计35

4.1 键的选择和键联结的强度计算35

4.1.1 减速器与拨盘轴静联结所用键35

4.1.2 上拨杆与轴静联接所用键35

4.1.3 托阀摇臂与轴联接所用键35

4.2 轴承选择与校核36

4.2.1 托阀摇臂轴左端轴承选择与校核36

4.2.2 托阀摇臂轴右端轴承选择与校核37

第五章 主要部件结构设计及金属的热处理38

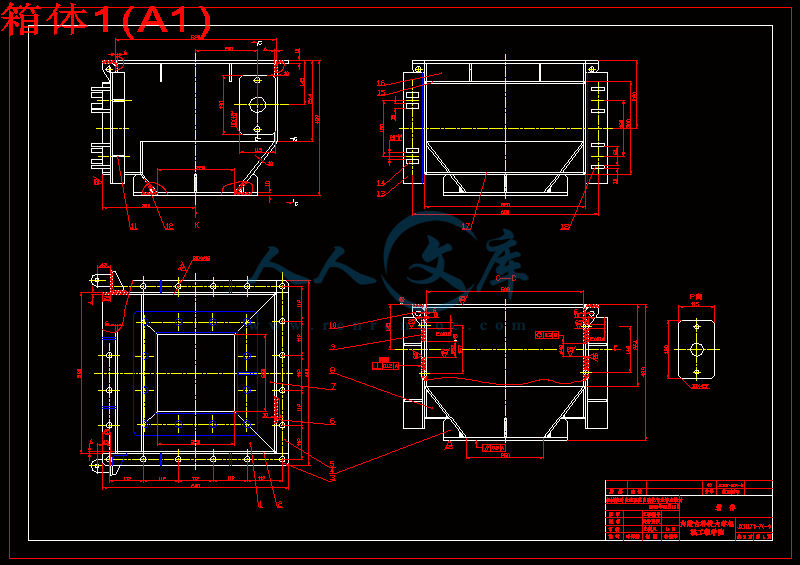

5.1 箱体(焊接件)38

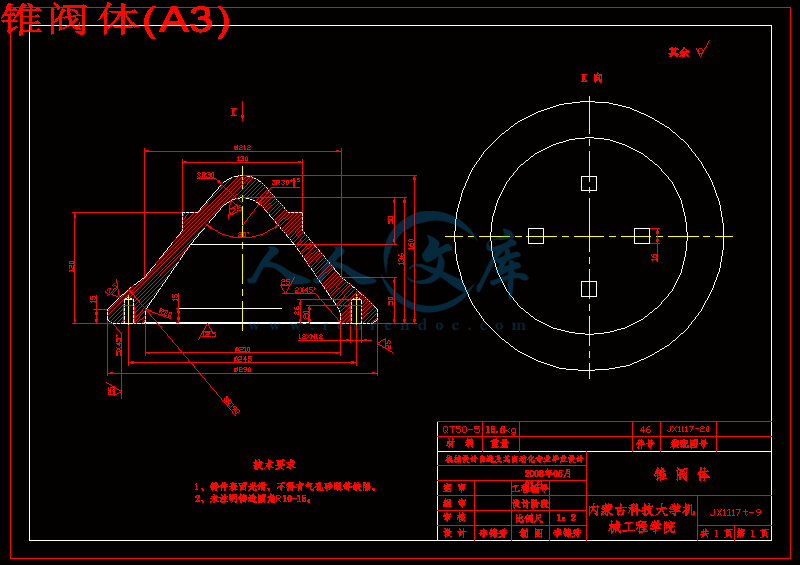

5.2 锥阀体(QT50-5)38

5.3 弹簧39

第六章 磨损、润滑与密封41

6.1 影响开启阀磨损的各种因素41

6.2 密封42

6.3 润滑(轴承的润滑)43

结 束 语45

参考文献47

第一章 绪 论

1.1 课题来源及课题设计的意义

烧结厂所产生的颗粒物对人体健康会产生一定的影响,其影响程度取决于颗粒物的浓度和在其中暴露的时间。研究数据表明,因上呼吸道感染、心脏病、支气管炎、气喘、肺炎、肺气肿等疾病而到医院就诊的人数的增加与大气中颗粒物浓度的增加是相关的。对患呼吸道疾病和心脏病的老人的死亡率研究表明,在颗粒物浓度一连几天异常高的时期内,死亡率就有所增加。[1]

粉尘(dust)一般指悬浮于气体介质中的微小固体颗粒,在重力作用下沉降,但在一段时间(甚至相当长时间)内能保持悬浮状态。它通常是由固体物质的破碎、研磨、分级、输送等机械过程,或土壤、岩石的风化等自然过程形成的。颗粒的形状往往不规则。颗粒的尺寸范围一般为1~200μm左右。其不仅对于人体、生物有生理危害,对机器设备也同样有害。[1]

川公网安备: 51019002004831号

川公网安备: 51019002004831号