【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘 要

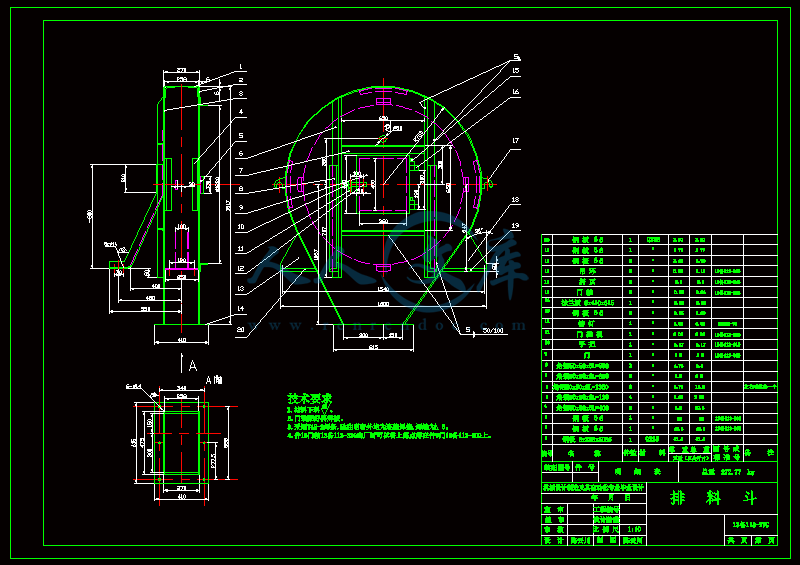

圆筒混合机是烧结厂主要设备之一。一次混合机主要作用是将物料混匀及湿润,二次混合机主要是对物料进行制粒,使物料满足成分均匀、水分适中、透气良好的要求。混合料的进料由皮带机和漏斗两种形式,将料送入圆筒混合机的进料端,通过筒体的旋转,物料在筒体内呈螺旋状运动,在运动的过程中使混合料形成“滚落”状,从而完成物料的混合、湿润、制粒、混匀,通过圆筒混合机排料端的溜槽排到皮带输送机上。

阐述了混和、制粒时物料的运动过程,对圆筒混合机内物料运动的几种状态进行分析。描述了影响圆筒混合机混匀、制粒的因素。分析了圆筒混合机筒体各部分的力学性能,提供了相应的受力的计算方法。然后阐述了圆筒混合机传动装置的受力分析和计算方法,主要是对轴的安全性能的校核,保证传动的可靠性。

关键词 圆筒混合机;传动;受力分析;校核

Abstract

Drum blender is one of the most important equipments in modern iron and steel corporation. The primary role of the first mixer is mixing materials and humid. The Mixer of second major is used to proceed granulation. Uniform material to meet constituents, moderate water, good ventilation requirements. Mixture of feed material from the belt and a funnel in two forms, Will be expected into the cylinder-feed mixer Through the revolving cylinder Materials in the cylinder show a spiral movement movement in the process of mixture formation is tumble accusation .Thus completing the mixed materials、 humid、 granulation and blending, Through mixing drum nesting end of the chute into the conveyor belt.

The mixing and rolling process of material is explored. Several characteristics of material motion in drum blender are carefully analysis. Influence factors on material mixing and balling is described. Analysis of the mixing drum cylinder parts of the mechanical properties. To provide the corresponding force method of calculation. Then the mixing of the Transmission stress analysis and calculation method are explored the main to the axis is checking at the safety performance, Ensure the reliability of transmission.

Keywords Drum blender; transmission; stress analysis; check

目录

摘要…………………………………………...……………………I

Abstract.............................................................................................II

第一章 绪论...................................................................................1

1.1 引言 ....................................................................................1

1.2 圆筒混合机的发展.......................................................................1

1.2.1圆筒混合机概述........................................................................3

1.2.2 圆筒混合机的工作原理.................................................................3

1.2.3 一次混合机..................................................................................3

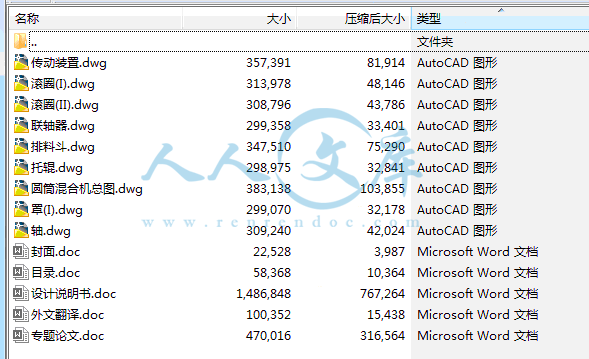

1.3 圆筒混合机的结构.......................................................................4

1.3.1 入料装置.....................................................................................4

1.3.2 筒体部分.....................................................................................4

1.3.3 传动装置.....................................................................................5

1.3.4 支撑装置.....................................................................................5

1.3.5 给料装置.....................................................................................5

1.4 圆筒混合机的工艺布置...............................................................5

1.4.1支撑形式.....................................................................................6

1.4.2传动形式.....................................................................................6

1.5 影响物料混合及造球的因素.......................................................6

1.5.1原料性质的影响...........................................................................6

1.5.2加水润湿方法..............................................................................6

1.5.3混合、制粒效果..........................................................................7

1.5.4混合制粒时间..............................................................................7

1.5.5混合机的安装倾角及充填率.........................................................7

1.5.6添加物........................................................................................8

1.6 作用及意义...................................................................................8

第二章 圆筒混合机电机功率计算..............................................9

2.1 混合机传动总功率的分析...........................................................9

2.2 圆筒混合机内物料运动过程分析..............................................10

2.2.1物料转动所消耗功率的计算.........................................................10

2.2.2一次混合机的最佳参数选择.........................................................12

2.2.3二次混合机的最佳参数选择.........................................................12

2.3 计算物料重心上移所消耗的功率..............................................13

2.3.1计算物料滚动时内摩擦所消耗的功率...........................................15

2.3.2计算转动物料所消耗的功率........................................................15

2.4 计算克服支承系统的摩擦所消耗的功率..................................15

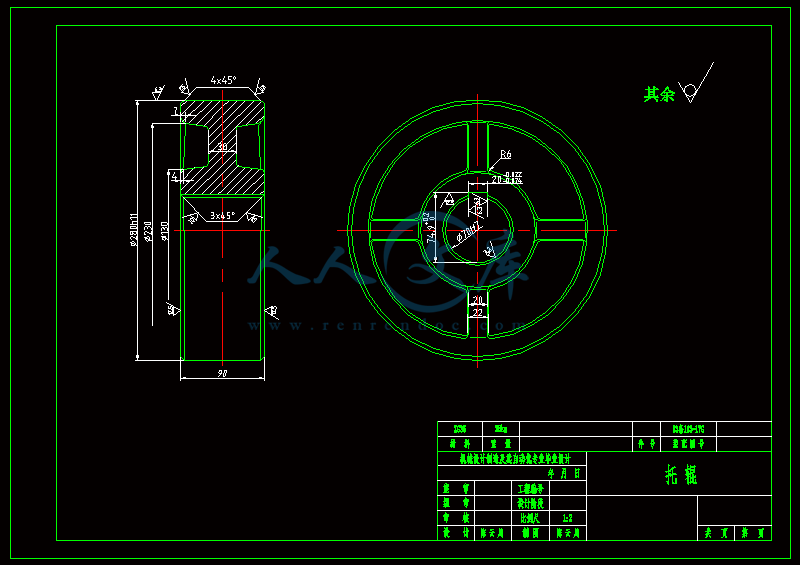

2.4.1计算托轮上所消耗的功率............................................................16

2.4.2计算挡轮上所消耗的功率............................................................17

2.4.3计算支承系统所消耗的总功率.....................................................17

2.5 计算总功率..................................................................................17

2.5.1圆筒混合机的电机功率计算.........................................................18

2.6 本章小结......................................................................................19

第三章 传动装置的总体设计...........................................................21

3.1 分析传动装置的工作情况..........................................................21

3.1.1传动装置示意图..........................................................................21

3.1.2传动形式....................................................................................21

3.2 根据传动装置的组成和特点确定传动方案..............................21

3.2.1圆柱齿轮减速器传动布置形式.......................................................22

3.3 初步确定减速器结构和零部件类型..........................................23

3.3.1确定传动装置的总传动比和分配各级传动比................................23

3.3.2计算传动装置的运动和动力参数..................................................24

3.3.3减速器的选择.............................................................................24

3.3.4减速器的校核.............................................................................25

3.3.5圆柱齿轮减速器箱体设计注意事项..............................................26

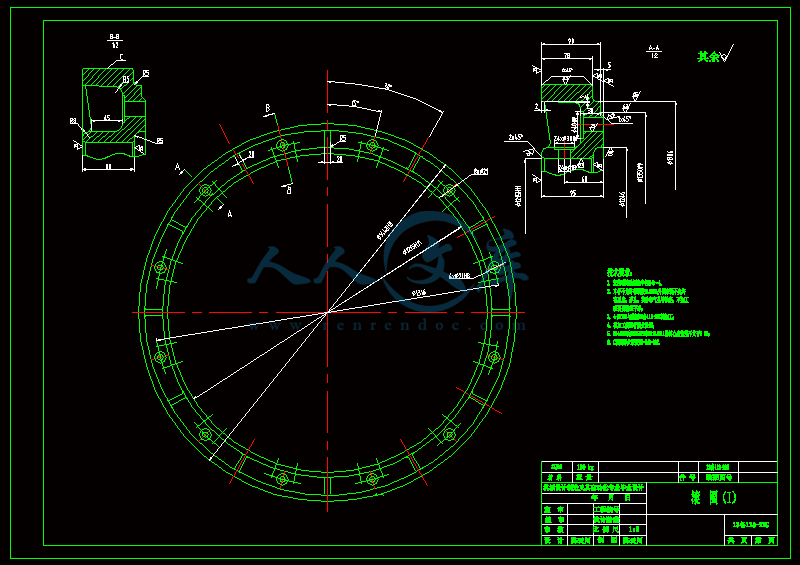

3.4 联轴器的选择.............................................................................26

3.4.1联轴器的附加力矩的计算............................................................26

3.4.2类型选择的条件..........................................................................27

3.4.3与电机轴相连的联轴器型号选择..................................................27

3.4.4与减速器输出轴相连的联轴器型号选择........................................27

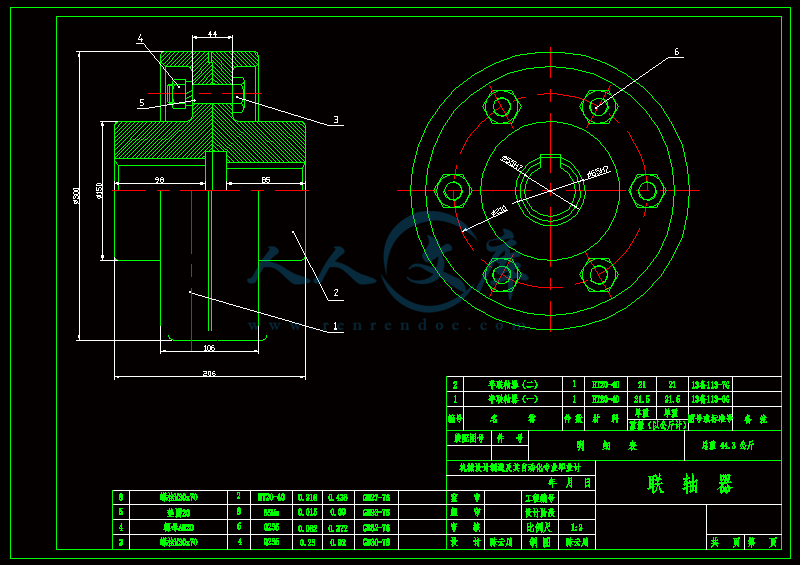

3.5 传动齿轮和齿圈的设计.............................................................28

3.5.1 选定齿轮类型、精度等级、材料及齿数......................................28

3.5.2 按齿面接触强度设计..................................................................28

3.5.3 按齿根弯曲强度设计..................................................................30

3.5.4 几何尺寸计算............................................................................32

3.6 轴的结构设计.............................................................................32

3.6.1 轴结构设计的一般原则.............................................................32

3.6.2 初步确定轴的形状及外形尺寸...................................................33

3.6.3 初步选择滚动轴承....................................................................34

3.6.4 确定轴上圆角和倒角尺寸..........................................................35

3.6.5 求轴上的载荷...........................................................................35

3.6.6 按弯扭合成应力校核轴的强度...................................................39

3.6.7 精确校核轴的疲劳强度..............................................................39

3.7 本章小结....................................................................................42

第四章 设备的使用和维护..............................................................43

4.1 设备的使用................................................................................43

4.2 设备的维护................................................................................43

第五章 结束语.................................................................................44

参考文献..............................................................................................45

川公网安备: 51019002004831号

川公网安备: 51019002004831号