【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

文档包括:

说明书一份,46页,20300字左右.

翻译一份.

图纸共11张:

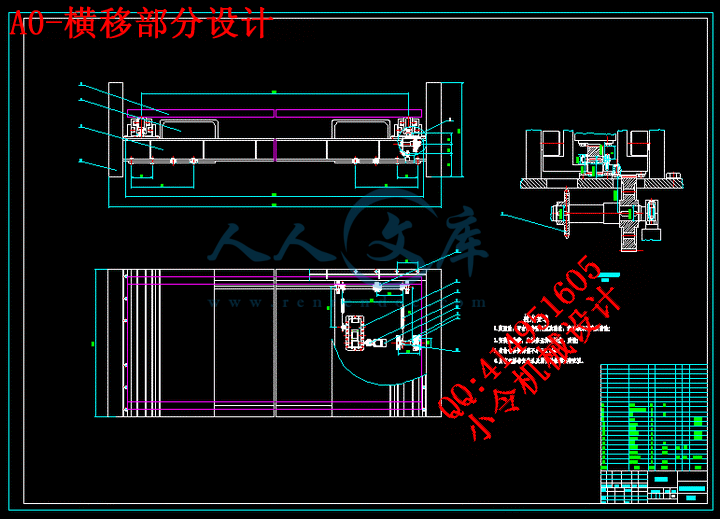

A0-横移部分设计.dwg

A0-滑叉装配图.dwg

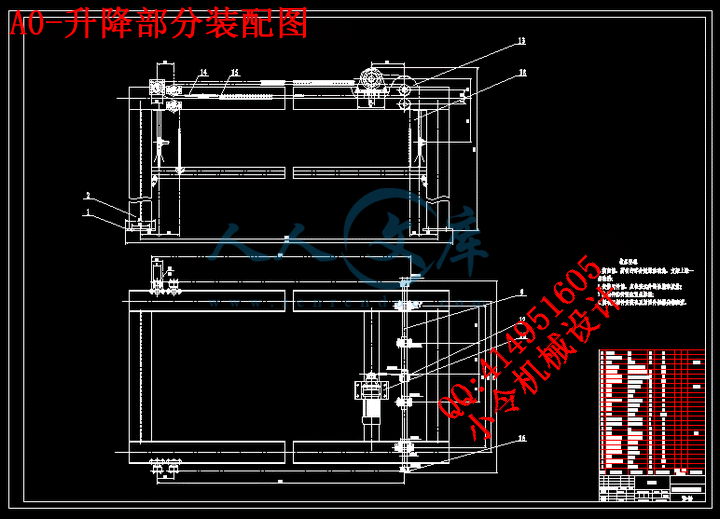

A0-升降部分装配图.dwg

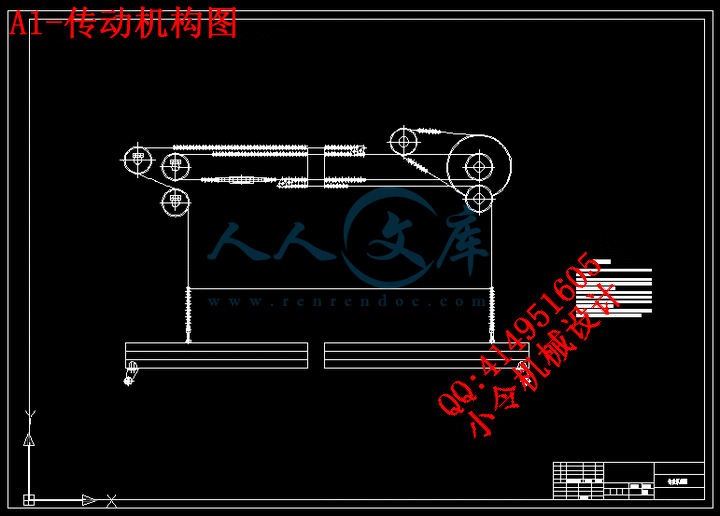

A1-传动机构图.dwg

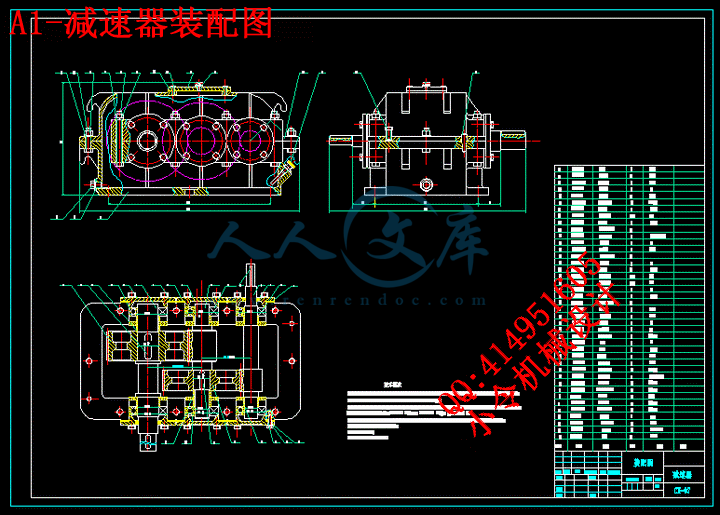

A1-减速器装配图.dwg

A1-升降架.dwg

A2-减速器大齿轮.dwg

A2-减速器低速轴.dwg

A2-链轮.dwg

A2-链轮组件图.dwg

A2-轴零件图.dwg

摘要3

Abstract4

第1章 绪论5

1.1课题的来源,目的及意义5

1.2立体车库概述5

1.3几种机械停车设备的特点及比较7

1.4 总体方案确定8

第2章 链驱动双层升降横移式车库技术参数12

2.1传动机构的组成12

2.2 传动机构的主要参数12

第3章 机械系统传动设计13

3.1传动链和链轮的选择13

3.2链的设计计算13

3.2.1设计标准13

3.2.2传动的计算14

3.3 链轮的设计计算16

3.3.1 设计链论尺寸16

3.4 滚子链的静强度计算22

3.5 链条的使用寿命计算23

3.6 链条的耐磨工作能力计算24

3.7 电动机的选择25

3.8减速器的选择26

3.9轴承的选择27

3.10轴的选择27

3.10.1 选择材料27

3.10.2 初步估算轴径27

3.10.3轴的结构设计28

3.10.4 轴上的受力分析28

3.10.5轴的强度校核30

第4章 经济分析35

4.1 机会研究35

4.1.1社会需求程度35

4.1.2 开展的基本条件35

4.2 初步可行性研究35

4.2.1 投资机会是否有希望35

4.2.2是否需要作详细可行性分析35

4.2.3 有待解决的关键性问题36

4.2.4 初步经济效益预测36

第5章 专题37

自动化立体车库管理系统37

结 论44

参考文献45

致谢46

附录1:翻译(英文)47

附录2:翻译(汉文)68

摘要

随着汽车工业和建筑业两大支柱产业的快速发展,在一些大、中城市相继出现了停车难和乱停车的现象。在解决城市城市停车难的问题中,机械式立体停车设备以其独特的优点,引起了各界的重视,得到了广泛的应用。

车辆无处停放的问题是城市的社会、经济、交通发展到一定程度产生的结果,立体停车设备的发展在国外,尤其在日本已有近30~40年的历史,无论在技术上还是在经验上均已获得了成功。我国也于90年代初开始研究开发机械立体停车设备,距今已有十年的历程。由于很多新建小区内住户与车位的配比为1:1,为了解决停车位占地面积与住户商用面积的矛盾,立体机械停车设备以其平均单车占地面积小的独特特性,已被广大用户接受。

机械车库与传统的自然地下车库相比,在许多方面都显示出优越性。首先,机械车库具有突出的节地优势。以往的地下车库由于要留出足够的行车通道,平均一辆车就要占据40平方米的面积,而如果采用双层机械车库,可使地面的使用率提高80%-90%,如果采用地上多层(21层)立体式车库的话,50平方米的土地面积上便可存放40辆车,这可以大大地节省有限的土地资源,并节省土建开发成本。

论文以研究工作的进展顺序为序,分章、节逐一论述了课题的来源,目的及意义,设计过程,在设计中遇到的问题与难点及其解决方法与措施。在设计过程部分,详细论述了设备总体结构设计、横移传动系统设计、提升传动系统设计、存取车结构设计、控制系统设计和安全防护设计 。

关键词:立体停车设备 ; 传动设计; 控制系统 ; 升降机构; 安全性

Abstract

Along with the fast development of two major of pillar industry of the automobile industry and building industry, the city one after another appears to park the car the phenomenon of the difficult and disorderly parking in somely bigly,.In resolve the city city park the car difficult problem, stereoscopic parking equipments of the machine type with its special advantage, caused the value of the public, get the extensive application.

The vehicle has no a the society, economy, transportation that the problem for park is a city to develop output result to certain extent, the development of the stereoscopic parking equipments is abroad, particularly at Japan already is close to 30~40 years of history, all have already acquired the success on the technique still on the experience regardless.The our country also starts study to develop the stereoscopic parking equipments of machine at the beginning of in 90's, being apart from to already have the process of the decade now.Because a lot of set up the little inhabitant inside the area to go together with the car to compare to 1 lately:1, for solving the parking lot to cover the area and inhabitant's company to use the antinomy of the area, stereoscopic machine parking equipments with it average the bicycle covers the small special characteristic of area, have already been accept by the large customer.

The machine garage and traditional get off the database to compare naturally, in many respect display the superiority.First, the machine garage has an advantage of outstanding stanza.Before underground garage because of toing stay to go the car passage enough, average car will occupy 40 areas of the square meters, but if a layer of adoption machine garage, can make the utilization rate of the ground raise 80%-90%, if an up many type garages with stereoscopic layer(21 layers) of adoption, can deposit 40 cars then on 50 areas of the land of the square meters, this resources that can save the limited land consumedly, and save the soil to set up to develop the cost.

Currently the society contain a lot of mature and technical parking equipmentses for example:Ascend and descend horizontal move the type;Perpendicular and circulating type;Level circulation type;The flat surface moves the type;A of tunnel;The perpendicular rise and fall type;Simple rise and fall.Pass the comparison and analysises to these garages type characteristicses, I was end to choose a garage type that is the design.

Thesis with research the progress of the work is in proper order for the preface, dividing the chapter, stanza to discuss the source of the topic one by one, purpose and meaning, the design process, problem meet in the design with a little bit difficult and it resolve method and measure.At design the process part, detailed discussed the total structure of equipments design, horizontal move to spread to move the system design and promote to spread to move the system design, access the car structure design, control the system design and safe protection design.

Keyword: stereoscopic parking equipments; The structure design; Control the system; PLC; Safety

川公网安备: 51019002004831号

川公网安备: 51019002004831号