【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘要

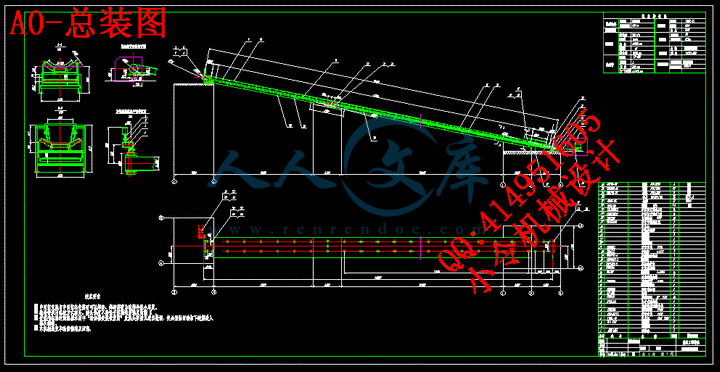

上运机是一种利用连续运动的无端输送带向上输送工程物料的带式输送机。输送带根据摩擦传动原理而运动,既是承载货物的构件,又是传递牵引力的构件。带式输送机输送能力大,输送距离长,结构简单,工作可靠,操作管理简单,能量消耗少。因而被广泛地运用于矿山、冶金、铸造、化工等行业的输送和生产流水线以及水电站建设工地。本文以煤矿作业为背景,对此工况下所要求的上运机进行了设计与计算。针对实际生产中对上运机结构的要求,从整体结构出发,对整个装置中的驱动装置和拉紧装置进行设计与计算。其中驱动装置的设计,选择电动机—减速器作为驱动设备,由电动机通过联轴器、减速器带动传动滚筒通过摩擦将牵引力传给输送带使其运动并输送货物。而拉紧装置则选择液压系统来对整个装置进行拉紧,设计了液压系统,并对主要元件进行了计算与选择。同时也对装置中的制动部分和辅助部件如清扫装置做了必要的选择。

关键词 上运机;输送带;减速器;液压拉紧

Abstract

The up-transmisstion machine is one kind of the machines which transport the goods upside,it is also one of the machines that are used most widely. It is widely used in the place of mine and so on. But it requests differently in every part, and this article is to the requests in the industry of the mine. This article briefly introduce the structure and its characteristic of the up-transmission machine, facing the problem of the request of equipment and the request of the driving、tensing 、stopping in the working. The article gives the design and calculation of the drive equipment and the tense equipment, in the design of tense equipment, here we choose the hydraulic system, in order to better the designation. Besides, This article also takes a simple elucidation of the stop equipment and the assistant equipment. This design mainly design the structure of the decelerater ,and get all the main parameter that needed , also it design the tense equipment that controlled by the liquid pressure system , and give a detailed analysis of it’s working principle. This design’s main characteristic is: Save the investment and convenient control.

Keywords Up-transmisstion Machine Transmisstion Belt Decelerater Hydraulic System

目 录

1绪论…………………………………………………………………………………………...1

1.1序言………………………………………………………………………………………..1

1.2概述………………………………………………………………………………………..1

1.3 设计思路………………………………………………………………………………….2

2输送机构整体设计…………………………………………………………………………...3

2.1输送带材料选择…………………………………………………………………………..3

2.2传动装置倾角选择………………………………………………………………………..3

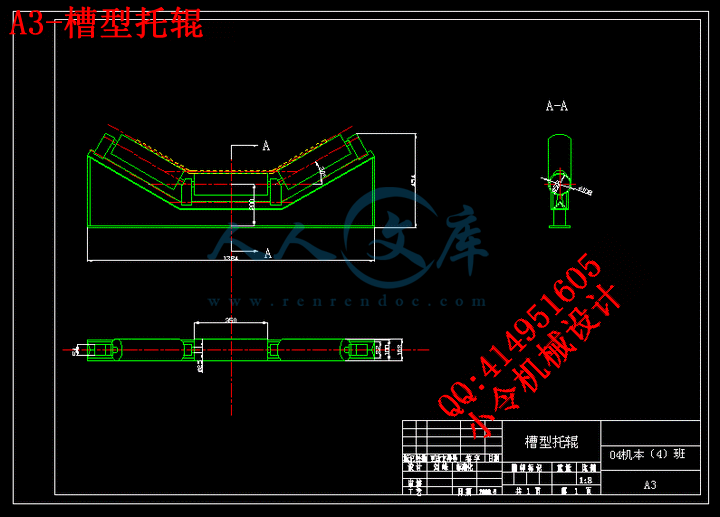

2.3上托辊选择………………………………………………………………………………..4

2.4 传动滚筒的选择………………………………………………………………………….4

3主参数及初步设计计算……………………………………………………………………...5

3.1带速选择…………………………………………………………………………………..5

3.2输送能力计算……………………………………………………………………………..5

3.3 胶带运动阻力的计算…………………………………………………………………….5

3.4胶带张力计算及强度垂度校核…………………………………………………………..7

3.5圆周牵引力及功率的计算………………………………………………………………..8

4驱动装置的设计和计算……………………………………………………………………...9

4.1电动机的计算与选择……………………………………………………………………..9

4.1.1电动机的选择和计算……………………………………………………………….....9

4.1.2确定电动机转速…………………………………………………………………….....9

4.1.3 电机的选择……………………………………………………………………………10

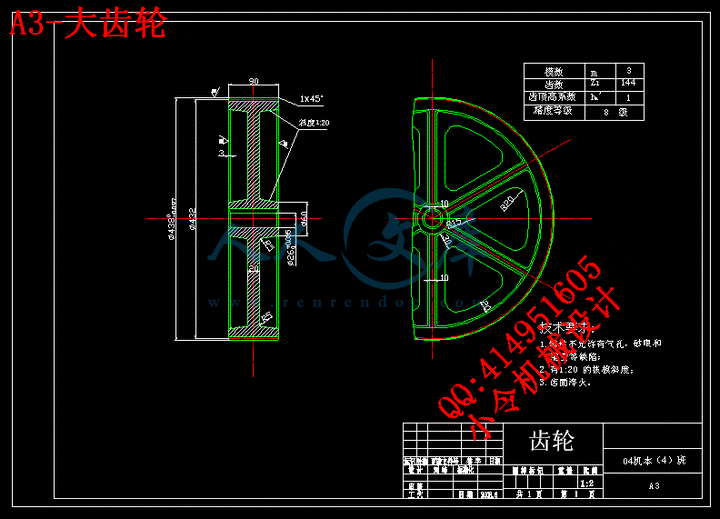

4.2 减速器的设计与计算…………………………………………………………………….10

4.2.1 计算传动装置的传动比、动力参数…………………………………………………11

4.2.2 减速器结构的设计……………………………………………………………………12

4.2.3 传动零件的设计与计算………………………………………………………………13

4.2.4轴的设计计算与校核………………………………………………………………….22

4.2.5 滚动轴承的选择………………………………………………………………………26

4.2.6键的选择及强度校核………………………………………………………………….28

4.2.7联轴器的选择与计算………………………………………………………………….29

4.2.8减速器附件设计……………………………………………………………………….29

4.3减速器的密封和润滑…………………………………………………………………....30

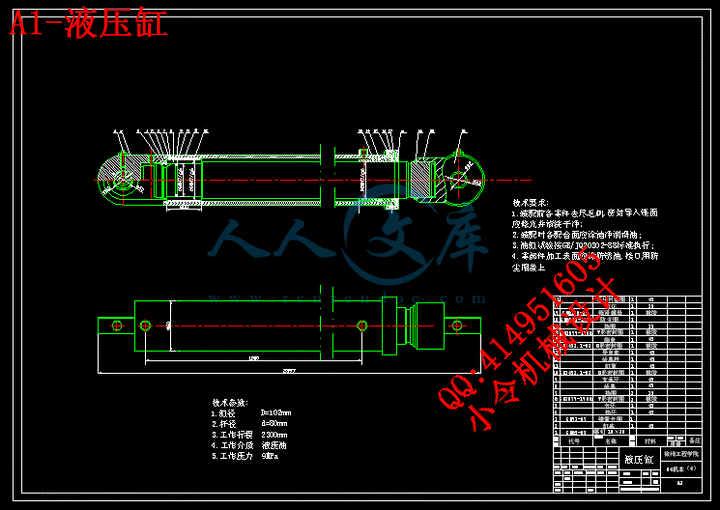

5拉紧装置的设计与计算……………………………………………………………………...32

5.1总体结构………………………………………………………………………………......32

5.2 液压系统………………………………………………………………………………….32

5.3液压元件的计算与选择…………………………………………………………………34

5.3.1液压缸的设计计算…………………………………………………………………...34

5.3.2液压泵计算与选择…………………………………………………………………...37

5.3.3阀类及辅助元件的选择……………………………………………………………...38

5.3.4电动机的选择………………………………………………………………………...39

5.4液压系统性能验算………………………………………………………………………39

5.4.1液压系统压力损失的验算…………………………………………………………...39

5.5几个问题的讨论…………………………………………………………………………40

5.6小结………………………………………………………………………………………41

6制动、辅助装置的设计与选择…………………………………………………………….42

6.1制动装置………………………………………………………………………………....42

6.1.1逆止器工作原理……………………………………………………………………...42

6.1.2逆止器的安装………………………………………………………………………...42

6.1.3逆止器的润滑与保养………………………………………………………………...42

6.2辅助设备…………………………………………………………………………………42

6.2.1输送带清扫装置……………………………………………………………………...42

结论……………………………………………………………………………………………44

致谢……………………………………………………………………………………………45

参考文献………………………………………………………………………………………46

附录……………………………………………………………………………………………47

附录1…………………………………………………………………………………….......47

附录2………………………………………………………………………………………...51

川公网安备: 51019002004831号

川公网安备: 51019002004831号