【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

伺服液压千斤顶

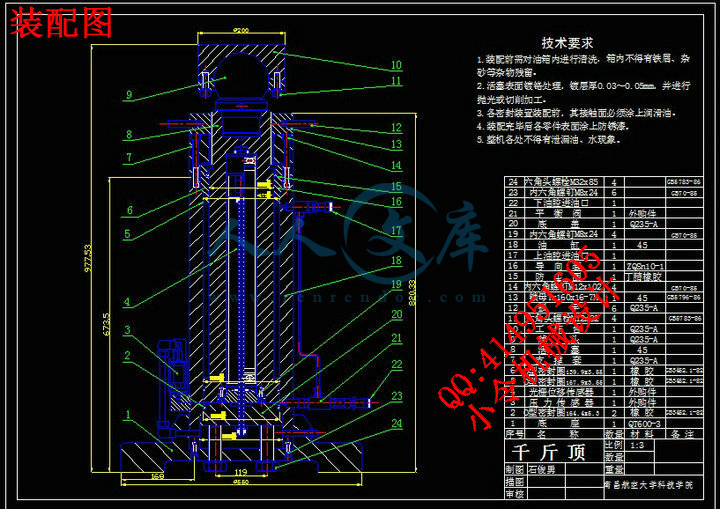

摘要:所设计的四顶顶升系统的主要参数是每只千斤顶高约1000mm,最大行程为400mm,最大载荷为20t。因千斤顶载荷较大,位置精度要求较高,故顶升速度不宜过大,最大顶升速度应控制在60mm/min以内。

工作原理是,二位四通电磁换向阀的电磁铁的工作状态是由单片机控制的,当换向阀电磁铁通电时,换向阀左位接入系统,油液经电磁换向阀和平衡阀进入油缸下腔,使得千斤顶上升,再从油缸上腔流出,经电磁换向阀和滤油器流回到油箱内,这时平衡阀的作用相当于一个单向阀;反之,当换向阀电磁铁断电时,换向阀右位接入系统,油液经换向阀流入油缸上腔,当上腔压力达到一定值时,平衡阀上位接入系统,这时平衡阀的作用相当于一个节流阀,油液从油缸下腔流出,经平衡阀、电磁换向阀和滤油器流回到油箱。从而实现了千斤顶升降换向功能,并具有过载保护和断电保护的功能。

为了适应复杂工作表面的工件,千斤顶的工作台与活塞杆应采用转动连接副相连当顶升系统工作时,液压千斤顶工作台可随工件表面形状进行自由转动调节,所以设计时将活塞杆顶部插入球头,与工作台形成转动副。

由于光栅尺的尺寸较长,将活塞和活塞杆做成中空状来放置光栅。工作时发光元件与光敏元件随活塞作同步运动,光栅尺下端固定在底盖上不动,光源与光栅尺的相对位移量通过读数头转化为数字信号传递给单片机。

关键词: 四顶同步顶升 单片机 光栅

Servo hydraulic jacks

Abstract: Digg this liter four-designed system, the main parameter is the high per jack about 1000mm, the maximum stroke is 400mm, the maximum load of 20t. Jack load due to a larger location with high precision, thus lifting speed should not be too large, the maximum lifting speed should be controlled within the 60mm/min.

Works, the two four-way solenoid valve of the solenoid working state is controlled by the microcontroller, when the solenoid valve energized, the valve Left access system, oil by the solenoid valve and balancing valve into the cylinder under the cavity, so jack up, and from fuel tanks on the cavity flow, flow through solenoid valve and filter tank back in, then the role of balancing valve is equivalent to a one-way valve; the other hand, When the solenoid valve power, the valve access system the right position, oil flows through valve cylinder on the cavity, when the chamber pressure reaches a certain value, the upper balance valve access system, when a balance acts as a throttle valve, the oil flow from the fuel tank under the cavity, by balancing valve, solenoid valve and filter flow back to tank. In order to achieve a lifting jack for the function, and have overload protection and power protection.

In order to adapt to the complex work piece surface, jack the table should be used with the piston rod connected to rotate connections made at work when lifting systems, hydraulic jack table with the surface shape can be adjusted freely rotate, so when the piston rod at the top of the design Insert the ball, and form a rotating table vice

As the size of a long grating, the piston and piston rod to place the grating made of hollow shape. Work light emitting devices with photosensitive elements for synchronous movement with the piston, the bottom grating fixed to the bottom cover fixed, light source and grating by reading the relative displacement of the first into a digital signal is passed to the microcontroller.

Keywords: 4 Synchronous Lift SCM Grating

目录

1. 引言2

1.1 选题的依据及课题的意义2

1.2 国内外的研究概况3

1.3 单片机控制系统的发展概况4

1.4 PID控制算法的发展概况5

1.5 设计要求及工作内容6

1.6 目标、主要特色及工作进度7

2. 机械结构与液压传动系统设计7

2.1系统结构分析7

2.2 千斤顶零部件分析9

2.3 油缸与螺纹的校验12

2.3.1油缸的壁厚校验12

2.3.2 锁母螺纹牙剪切强度校验13

2.3.3锁母螺纹牙的弯曲强度校验14

2.4 液压系统分析14

2.5 液压泵与电动机的选择15

2.6 超高压泵站简介16

3 . 单片机控制系统设计17

3.1 单片机的选用及功能介绍17

3.2 片外存储器功能简介18

3.3 显示部分设计21

3.4 键盘部分设计25

3.5 交流异步电动机变频调速系统27

3.5.1 交流异步电动机变频调速原理28

3.5.2主电路和逆变电路工作原理28

3.5.3 变频与变压32

3.6 位移检测部分的设计38

3.6.1 位移检测传感器的选用38

3.6.2 光栅位移传感器与单片机的接口设计40

3.7 位移传感器部分的设计43

3.7.1 A/D转换器的选择43

3.7.2 压力传感器与单片机的接口设计47

4.系统的PID控制算法48

4.1 PID控制原理48

4.2 数字PID控制算法50

4.2.1 位置式PID控制算法50

4.2.2 增量式PID控制算法51

4.3 智能自适应PID控制器52

5. 系统模拟仿真57

5.1 SIMULINK概述58

5.2 SIMULINK的窗口和菜单58

5.3 用SIMUINK创建模型60

5.4 用SIMULINK进行系统仿真与分析61

5.4.1 建立控制系统模型61

5.4.2 系统模块参数设置与仿真参数设置62

5.4.3 系统仿真与分析64

6.结论67

7.致谢68

8. 参考文献68

1. 引言

1.1 选题的依据及课题的意义

随着现代社会的不断发展,工业化程度的不断深入,大尺寸、大重量、不规则表面的工件越来越多的成为工厂加工的对象。而在加工过程中如何将这些工件准确的提升至预定位置则成为最难解决的问题,这时传统的千斤顶和起重机等设备就显示出先天不足的缺陷来。也正是在这种环境下,同步顶升系统应运而生,并在建筑、机械加工、造船等行业扮演着越来越重要的角色。同步顶升系统是由控制系统协调控制多个千斤顶,使其具备顶升大重量、大体积、复杂工作表面的工件的能力,并具有同步升降、点动升降、连续升降、侧翻仰俯等功能的机电一体化设备。其控制系统可以是微机、单片机、可编程控制器等;其动力系统有液压式、气电式、汽液两用式等;吨位从几百公斤到几千吨不等,主要由动力方式和千斤顶的个数来决定 。由于其体积小、承载重、精度高、结构简单、控制方便、使用灵活等优点被广泛的用于电力、建筑、机械制造、矿山、铁路桥梁、造船等多种行业中,在设备安装、起顶拆卸、静力压桩、设备校调、基础沉降等工作岗位发挥了重要的作用。基于单片机控制、液压传动的四顶顶升系统是较常见的,控制算法较简单的一种。由于其控制简便、吨位适中、价格也很低廉的优点使得其在中小企业、民营单位甚至轻工业领域都有很高的使用度。其重要性不言而喻,对其进行研究和开发具有很大的市场空间和实用价值。

1.2 国内外的研究概况

国外对同步系统的研究起步较早,基于单片机控制、液压传动的四顶顶升系统是较常见的,控制算法较简单的一种。由于其控制简便、吨位适中、价格也很低廉的优点使得其在中小企业、民营单位甚至轻工业领域都有很高的使用度。美国实用动力ENERPAC是这一行业的佼佼者,在澳大利亚的昆士兰州,G&S 工程技术 服务公司就采用了 ENERPAC(恩派克)提供的同步顶升液压系统 成功地完成了重达 3500 多吨的矿山巨型索斗铲的顶升,误差小于 0.5mm。在上海因广场改造而需要整体平移的上海音乐厅使用了ENERPAC公司开发的一套具有四组共60个高精度顶升点的计算机控制同步顶升和顶推系统,以小于0.2mm的误差将建筑物同步顶升至预定高度并顺利完成平移任务。

我国在这领域起步虽晚,但发展迅速,经过多年的发展也获得了许多曙目的成就,今年(2006年)1月4日,目前世界上最大的闸门——葛洲坝1号船闸重达200吨、面积相当于篮球场大的上游人字闸门安装就位。此举标志着我国自主研制的第一套大型船闸门同步顶升系统获得成功。在上海兴建的磁悬浮列车的关键基础部件轨道梁是确保磁悬浮列车快速、平稳、安全的重要保证,其加工精度要求非常高,但每段轨道梁长25米,重16吨,对其进行精确升举困难重重,上海千斤顶厂自主开发的高精度同步顶升装置不负众望,顺利完成任务,其同步顶升精度≤0.03mm,达到国际先进水平。我国浙江省海盐县有“千斤顶之乡”的美誉。在千斤顶和同步系统方面形成规模化生产,年生产能力达800万台以上,销量位居世界前列。

1.3 单片机控制系统的发展概况

单片机,就是单片微型计算机的简称,又称微控制器。自上世纪70年代面世以来不过短短30余年的历史,但因嵌入式应用而得到迅猛的发展,各种新颖的单片机层出不穷,令人目不暇接。它具有因体积小、成本低、控制能力强等优点,又由于现在开发环境的不断改善,正在以空前的速度迅速取代经典电子系统,广泛的应用于家用电器、机器人、工业控制单元、仪器仪表、汽车电子系统、金融电子系统、通讯系统等嵌入式产品中。

目前单片机的种类繁多,世界各国厂商已研制出大约50个系列、30多个品种的单片机产品。与早期经典的8位单片机MCS-51相比,无论是频率、字宽、寻址范围、集成度等方面都有了巨大的突破。现代科技的发展使得单片机的功能正日渐完善:

1、单片机集成越来越多资源,内部存储资源日益丰富,用户不需要扩充资源就可以完成项目开发,不仅是开发简单,产品小巧美观,同时系统也更加稳定,目前该方向即是发展为SOC(片上系统)。

2、单片机抗干扰能力加强,使的它更加适合工业控制领域,具有更加广阔的市场前景。

3、单片机提供在线编程能力,加速了产品的开发进程,为企业产品上市赢得宝贵时间。

4、在线仿真变的容易。用户一旦开发一个比较大的系统,开发调试变的非常复杂,同时由于单片机资源有限,不能象PC一样直接调试自己的软件,于是出现了品种繁多的专业仿真器,为用户的开发提供了强大功能,加速了开发进程,降低了开发难度。目前还已经有公司推出了可以在线调试的单片机,使得单片机系统的调试与开发变得更加方便、快速。

随着单片机的发展,人们对事物的要求越来越高,单片机的应用软件技术也发生了巨大的变化,从最初的汇编语言,开始演变到C语言开发,不但增加了语言的可读性,结构性,而且对于跨平台的移植也提供了方便,另外一些复杂的系统开始在单片机上采用操作系统,一些小的嵌入式实时操作系统(RTOS)等,一方面加速了开发人员的开发速度,节约开发成本,另外也为更复杂的实现提供了可能。当前比较流行的RTOS有:WINCE,uClinux,Linux,uC/OS等等。

本次设计的四顶同步顶升系统再选择控制系统时在综合考虑了微机、单片机和可编程控制器的成本、控制的难易程度和结构化布线等因素后,也拟定采用单片机进行控制。

川公网安备: 51019002004831号

川公网安备: 51019002004831号