【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘 要

随着我国社会经济的飞速发展,整个制造业的加工生产水平也在不断的提高。为了适应汽车行业的快速发展,需要越来越多的特殊加工设备来完成单一的、精度要求较高的工序,而多轴钻床就是一种专为进行汽车轮辐扩钻孔加工而设计的一种高精度机床。

DZZ-10多轴钻床专为汽车轮辐十个螺纹孔的扩钻孔加工工序而设计,它包括机床本体支承件、动力部分、传动部分、液压传动部分等几大部分,在设计之前,首先应对机床的整体布局设计提出一个方案,再根据所加工工件的要求确定机床所需的功率,然后进行电动机的选取,依据传动比依次选择减速器、联轴器并进行各参数的计算,由计算所得参数设计各轴和齿轮的结构并进行强度的校核,同时还应对机床的工作台、底座、床身和立柱进行设计,最后选择传动进给系统的液压缸,绘制整台机床的装配、零件等图纸。

本文主要对机床的一般设计方法和各部件的选用计算进行介绍。

关键词:多轴钻床;汽车轮辐;扩钻孔加工

Design of DZZ-10 multi-axis drilling machine

Abstract

With the rapid development of China's social economy, the manufacturing level of production has been improved. In order to adapt to the rapid development of automobile industry, special processing equipment more and more necessary to complete a higher single, accuracy requirements of the process, while the machine is a kind of special for automobile wheel expanding drilling and design of a high precision machine tool.

The design of DZZ-10 machine for automobile spoke ten threaded hole expanding drilling process, which comprises a machine tool body support, power part, transmission part, a hydraulic transmission part of several major, in the design, first proposed a scheme of overall layout design of the machine tools, and then determine the machine power required according to the workpiece requirements, then the selection of motor, based on the calculation of transmission ratio in order to choose the reducer, coupling and parameters, the calculated parameters checked by design of the shaft and gear structure and strength, but also to the machine table, a base, the bed and column design, the final choice of hydraulic cylinder drive feed system, drawing the assembly, parts and the whole machine drawings.

The main design method of machine and the calculation of the components are introduced.

Key Words: multiple spindle drill; automobile spoke; expanding drilling

目 录

1 绪论1

1.1 研究背景及意义1

1.2工艺方案的分析1

1.3 论文的组织架构1

2 总体设计3

2.1原始条件的分析3

2.2选择工艺基准3

2.3制定工艺路线4

2.3.1 工艺过程4

2.3.2 绘制工序图4

2.4 刀具的选择5

2.4.1刀具选择应遵循的原则5

2.5切削用量的计算5

2.5.1切削速度的计算5

2.5.2吃刀深度的计算5

2.6 对机床性能的要求6

2.6.1机床的加工范围6

2.6.2对加工精度和粗糙度的要求6

2.6.3经济效益7

2.6.4人机关系7

3 多轴钻床整体布局设计8

3.1整体布局设计要求8

3.2机床整体布局方案的选择8

3.2.1方案的提出8

3.2.2方案的比较10

3.3机床支承件的设计10

3.3.1机床支承件的功能10

3.3.2支承件的分类10

3.3.3支承件的变形11

3.4立柱的设计11

3.4.1导轨的设计12

3.5机床底座的设计14

3.5.1材料的选取14

3.5.2底座结构设计14

3.5.3底座的尺寸15

4 传动部分的设计计算16

4.1主轴箱与传动系统设计计算16

4.2齿轮齿数的确定19

4.3齿轮的校核及几何尺寸计算21

4.3.1按弯曲疲劳强度进行校核21

4.3.2按接触疲劳强度校核23

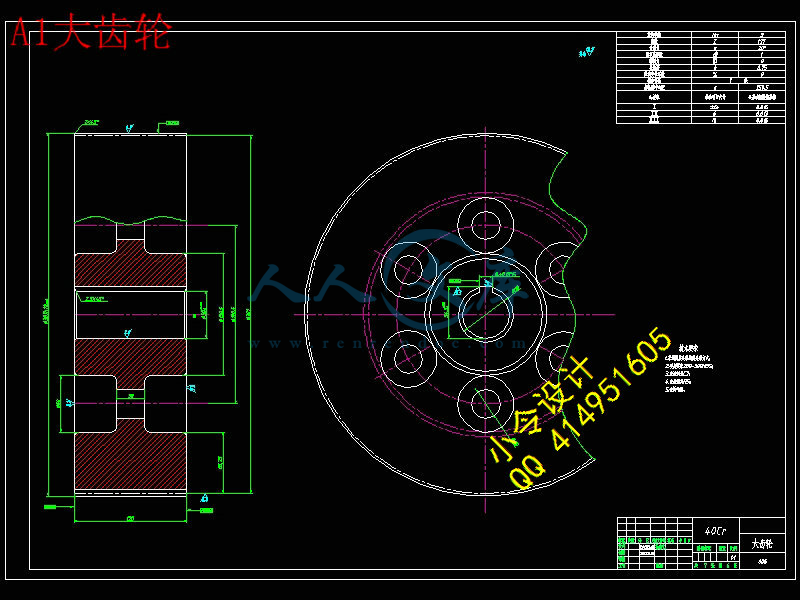

4.3.3大小齿轮几何尺寸24

4.3.4齿轮的结构设计25

4.4轴的设计25

4.4.1大齿轮轴的设计计算25

4.4.2小齿轮轴的设计计算30

4.5轴承的选择与计算33

4.5.1大齿轮轴轴承的校核33

4.5.2小齿轮轴轴承的校核34

4.6键连接的选择和校核36

4.6.1联轴器与大齿轮轴的键连接36

4.6.2大齿轮与大齿轮轴的连接36

4.6.3小齿轮与小齿轮轴的连接37

5 液压传动部分设计38

5.1液压传动系统的设计要求38

5.2工况分析与液压系统主参数的确定38

5.2.1负载分析38

5.2.2各参数的计算38

5.2.3工况负载分布表40

5.2.4负载在各工况阶段分布图40

5.3液压缸的设计计算41

5.3.1液压缸参数计算41

5.3.2快进、工进、快退时液压缸各参数计算41

5.4液压系统的设计42

5.4.1液压回路的选择42

5.4.2液压系统原理图43

6 结论45

参考文献45

致 谢47

1 绪论

1.1 研究背景及意义

对于机床的总体设计,应该从被加工零件,即汽车轮辐入手,依据零件的尺寸,来确定具体的加工方案并进行前期的设计计算,尺寸确定以后,就可以进行图纸的绘制,包括零件图,装配图等图纸。

专用钻床与普通的钻床最大的区别在于加工零件的单一性,因为它不具备普通钻床的通用性能,故所能加工的零件较单一,它最大的优点在于可以加工出高精度的零件,由于专用钻床是为加工某一特定的零件而服务的,所以专用钻床的样式、规格和先进程度都取决于工艺的需要,只有制定出了合理的加工工艺,才能设计出满足加工要求的专用钻床。

本次设计的题目为DZZ-10多轴钻床的设计,随着我国制造业的飞速发展,板类零件的加工越来越多,要求也越来越高。为了适应飞速发展的汽车工业,需要设计这样一种专用于汽车轮辐扩钻孔工序的新型多轴钻床,这样一台钻床应由机床本体支承件、传动部分、液压传动部分等几大部分组成。

1.2工艺方案的分析

在通常的情况下利用机械加工的方式直接改变零件毛坯的形状、性能以及尺寸的过程称之为机械加工工艺过程。在设计时,机械加工工艺的选定是否合理,直接影响着零件的生产效率与产品的质量。所以,在制定工艺方案时,应首先分析生产的类型,生产类型决定着生产的规模。

由于生产的类型不同,生产的组织和管理,车间人员的配备以及厂房的布置等方面的要求均不同。在大批量的生产规模之下,每个工序的任务都比较单一,因此,可以采用高效率的专用机床,生产和工作的效率可以大大提高,随之产品的成本也可以得到控制。但如果是小批量的生产,就没有必要采用高效率的专用设备来完成加工工作,因为那样不但不能降低成本,还会造成资源的浪费,所以在制定加工工艺时,必须与生产类型相适应。

1.3 论文的组织架构

本论文的组织结构如下:

第一章:介绍了研究多轴钻床的背景以及意义,对前期的工艺性能进行了简要的分析。

第二章:对机床的总体布局进行了设计规划,制定了工艺路线,明确了对机床的性能要求。

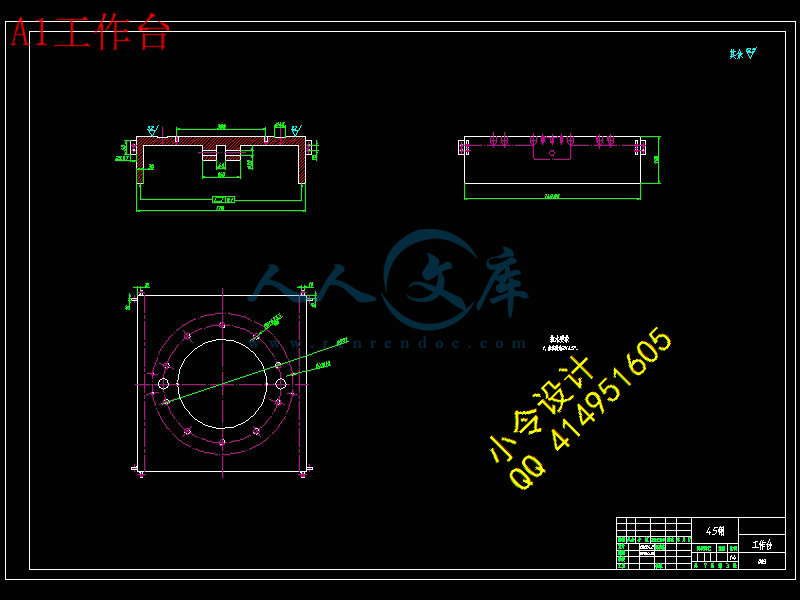

第三章:对机床的整体布局以及床身、立柱和底座等支承结构件进行了初步的设计,拟定各主要尺寸。

第四章:进行了机床传动部分的计算,包括电动机、减速器和联轴器的选定,大小齿轮以及各轴几何尺寸的计算和结构的设计,强度的校核等。

第五章:液压传动部分的设计计算,包括液压缸的选择,液压原理图的绘制等。

第六章:本章为论文的总结。

川公网安备: 51019002004831号

川公网安备: 51019002004831号