【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘 要

机械加工工艺规程是规定产品或零部件机械加工工艺过程和操作方法等的工艺文件。为能具体确切地说明工艺过程,一般将机械加工工艺过程分为工序、安装、工位、工步和走刀。而生产规模的大小、工艺水平的高低以及解决各种工艺问题的方法和手段都要通过机械加工工艺规程来体现。因此,机械加工工艺规程设计是一项重要而又严格的工作。一般包括以下步骤和内容:阅读装配图和零件图;工艺审查;熟悉或确定毛坯;拟定机械加工工艺路线;确定工艺装备(包括机床、夹具、刀具和量具等);确定各主要工序的技术要求和检验方法;确定各工序的加工余量、计算工序尺寸;确定切削用量;确定时间定额;填写工艺文件[1]。

夹具是一种装夹工件的工艺装备。它广泛地应用于机械制造过程的切削加工、热处理、装备、焊接和检测等工艺过程。在生产中具有很大的作用,具体表现在:保证加工质量;提高生产率;减轻劳动强度;扩大机床的工艺范围。机床夹具对工件进行安装(又称装夹)包括两层含义:一是把工件安放在机床工作台上或夹具中,使它和刀具之间有相对正确的位置,称为定位;二是将工件固定,使其在加工过程中保持定位位置不变,称为夹紧。

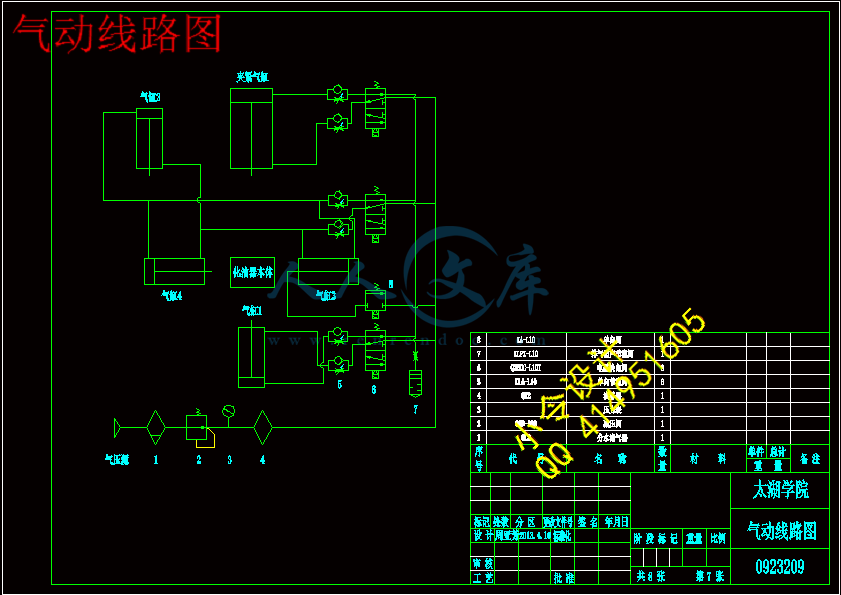

气动系统[2]的设计是设备控制与运行设计的重要内容。根据机电设备对液压、气压系统的具体要求,利用气动传动的基本原理,拟定合理的气动系统图。气压传动是利用空气压缩机将电动机或其他原动机输出的机械能转换为空气的压力能。在控制元件的控制和辅助元件的配合下,通过执行元件把空气能转换为机械能,从而完成直线或回转运动并对外做功。

本次毕业设计的课题是PD24J化油器怠速孔试密封设备设计,首先要对化油器本体进行分析,进行机械部分夹具的设计,包括夹具的定位误差分析和夹紧力的计算;其次是气动部分的设计,包括气动回路的设计和管道的计算;最终是电气部分PLC的设计,包括工作流程图和梯形图。

关键词:工艺规程;夹具;气动系统;夹紧力;PLC

Abstract

The machining process planning is the process of document products or parts machining process and method of operation. In order to exact description of process, the machining process is divided into process, installation, position, working step and walk the knife. While the production level, technology level and means to solve various technical problems are reflected by the machining process planning. Therefore, the machining process planning design is an important and strict working. Generally,it includes the following steps: reading assembly and parts drawings, process recviewing;being familiar with the blank or determining the blank, formulating the route of machining process, determination of process equipments (including machine tool, fixture tool,cutter and measuring tool), determination of the technical requirements of the main process and test methods, determination of machining allowance, the process calculation procedure dimensions, determination of the amount of cutting, determination of the time quota, filling the process documents.

Fixture is a device clamping workpiece. It is widely used in the manufacturing process of machining, heat treatment, welding equipment, and detection technology. It has a great role in the production, specifically manifested in: quality of assurance process, increasing of the rate of productivity, reducing the labor intensity, expanding the scope of technology of machine tool. Machine tool fixture installing on the workpiece (also called clamping) includes two meanings: one is that placing artifact in the workpiece worktable of a machine tool or fixture in order to make a relatively correct position between it and the tool called location. Another is that workpiece is fixed, so as to maintain position position unchanged in the process known as the clamp.

Design of the pneumatic system is an important content of equipment controlling and operation designing. According to the specific requirements of the electrical and mechanical equipment hydraulic, and the basic principle of transmission by gas,we can formulate reasonable pneumatic system diagram. Pneumatic drive can switch mechanical energy into air pressure by air compressor motor or other original motivation. With the help of the control elements and auxiliary components, it can switch air pressure into mechanical energy through the implementation of components,so as to complete the linear or rotary motion and external work.

The design topic is the design of PD24J carburetor idle hole test sealing equipment. Firstly,I must make the analysis to the carburetor body and design mechanical parts of fixture, including the calculation of positioning errors and the clamping force. Secondly,I should make the design of pneumatic parts, including the calculation of the pneumatic circuit and pipeline. The last one is that the design of electrical part of PLC, including the work flow diagram and ladder diagram.

Key words: Process specification; Fixture; Pneumatic; Clamping force; PLC

目 录

摘 要III

AbstractIV

目 录V

1 绪论1

1.1 本课题的研究内容和意义1

1.2 国内外的发展概况1

1.3 本课题应达到的要求1

2 总体方案设计2

2.1 本装置的主要组成部分2

2.2 机械部分的作用及其设计原则2

2.3 气动部分的功能2

2.4 PLC部分的功能3

3 机械部分的设计4

3.1 定位基准的选择4

3.1.1 粗基准的选择4

3.1.2 精基准的选择4

3.2 零件表面加工工序的选择4

3.2.1 工序顺序的安排原则4

3.2.2 加工阶段的划分5

3.3 机械加工工艺路线的拟定5

3.4 问题的提出7

3.5 夹具的设计7

3.5.1 夹紧力的计算8

3.5.2 加工误差分析8

3.6 机架的设计9

3.6.1 机架设计的一般要求9

3.6.2 机架的类型9

3.6.3 机架的常用材料及热处理方法10

3.6.4 焊接机架与铸造机架的特点比较10

4 气动部分的设计12

4.1 气动系统的设计12

4.1.1 回路压力的确定12

4.1.2 装置的工作要求12

4.2 气动回路的设计13

4.3 气动元件及配管尺寸的确定13

4.3.1 气缸的计算与选择13

4.3.2 辅助元件及配管尺寸的确定17

4.3.3 管道的计算20

5 电气部分的设计22

5.1 泄漏检测仪的选用22

5.2 PLC的设计23

5.2.1 PLC的优点23

5.2.2 被控对象的控制要求23

5.2.3 工作循环和状态流程图23

5.2.4 I/O接线图25

5.2.5 梯形图25

5.2.6 语句表26

5.2.7 使用注意事项27

5.3 零件的测绘27

6 结论与展望30

6.1 结论30

6.2 不足之处及未来展望30

致 谢31

主要参考文献32

1 绪论

毕业设计是大学本科教育培养目标实现的重要阶段,是毕业前的综合学习阶段,是深化、拓宽、综合教和学的重要过程,是对大学期间所学专业知识的全面总结,也是对每个即将毕业的大学生在校四年学习情况的综合测评和考量,具有非常重要的意义。这次毕业设计,不仅是对学校和家长做出一次总结性的汇报,也是对自我能力的一次展示,更是对自我不足的一种审查,同样也是非常有用的一次实践机会。

1.1 本课题的研究内容和意义

研究内容:1、方案设计,确定实用方案。

2、机械部分设计。此设备的机械部分主要是由焊接机架、工件

定位与夹紧部件组成,要进行夹紧力等的计算;并绘制机械部分cad

图纸。

3、气动部分设计。此设备的气动部分主要是由气源三联件、气

缸和气压控制阀组成,需进行气缸的相关计算。

4、部分电气部分设计。电气部分包括PLC控制,全电脑泄漏检测

仪的选用组成。

意义:通过本课题的研究,可以把有关化油器壳体的加工工艺与加工设备有机地结合起来;同时,通过采用优化的工艺方法、先进的加工设备,提高产品的质量稳定性,从而可以降低排放,减少对环境的污染。

1.2 国内外的发展概况[3]

汽油机在正常工作状态下,在小、中负荷时要求化油器随着负荷增加能供给由较浓逐渐变稀的混合气,在满负荷下又要求混合气由稀变浓,为了满足这些要求,在现代化油器上配备了一系列的混合气浓度补偿装置。在新型汽车中,开始普遍地采用燃油喷射系统,因为它可以使燃油效率更高而排放更低。但是,几乎所有的旧式汽车以及所有的像割草机和链锯之类的小设备均使用化油器,因为化油器既构造简单又价格便宜。

1.3 本课题应达到的要求

完成设备的机械部分、气动部分、电气部分的设计及相关计算,绘制好机械部分设计的若干份图纸。

2 总体方案设计

2.1 本装置的主要组成部分

摩托车化油器有严格的密封要求。针对密封性对化油器有着至关重要的地位,提高劳动生产效率,保证加工质量,降低劳动强度。本装置主要包括夹具、气缸、气体泄漏检测仪、试密封实验台等。其中,夹具主要包括以下几部分:定位元件、夹紧装置、导向元件和对刀装置、连接元件、夹具体、其他元件及装置;气缸主要是根据缸径和气缸的行程来确定气缸的型号;试密封试验台主要包括以下几个部分:台架和支撑板等的设计、气体泄漏检测仪的选用和气动元件的选取等。

2.2 机械部分的作用及其设计原则

机械部分的设计主要是为了设计一套夹具,在PD24J化油器进行试密封检测时可以结合气缸将化油器很好地定位与夹紧。从而,可以保证加工质量,如相对位置精度的保证,精度的一致性等;提高生产效率,用夹具来定位、夹紧工件,就避免了手工操作用划线等方法来定位工件,缩短了安装工件的时间;减轻劳动强度,如可用气动、电动夹紧;扩大机床的工艺范围,如在铣床上加一个转台或分度装置,可以加工有等分要求的零件,在车床上加上三爪卡盘,加工短轴类、套筒类零件等要方便的多,有些夹具对保证发挥机床基本性能的作用是很大的,如牛头刨床上没有虎钳是很难进行加工的。

其设计原则应遵循以下几点:

1.标准化原则——所设计的PD24J化油器试密封装备的规格、参数应符合国家标准。试密封装备应能最大限度地检测PD24J化油器产品的同类产品。

2.经济合理原则——所设计试密封装备应该结构先进、功能好、准确性高、成本低、操作简单及使用维修方便、在产品的寿命周内,用最低的成本实现产品的规定功能,做到物美价廉。

3.安全性原则——要确保证操作者和管理者,设备本身的安全,以及保证设备对周围环境无危害。

2.3 气动部分的功能

气动就是以压缩空气为动力源,带动机械完成伸缩或旋转动作。因为是利用空气具有压缩性的特点,吸入空气压缩储存,空气便像弹簧一样具有了弹力,然后用控制元件控制其方向,带动执行元件的伸缩与旋转。从大气中吸入多少空气就会排出多少到大气中,不会产生任何化学反应,也不会消耗污染空气的任何成分,另外气体的粘性较液体要小,因此流动速度快,且节能环保。由于本系统为一般的气动系统,故选系统压力[2]为0.5Mpa。执行元件用气缸,但由于化油器本体结构所限,且开闭行程较小以及安全性要求,拟采用单杆双作用气缸。气缸的动作速度一般为50~500mm/s。

2.4 PLC部分的功能[4]

PLC即可编程控制器(Programmable Logic Controller)是指以计算机技术为基础的新型工业控制装置。它采用可以编制程序的存储器,用来在其内部存储执行逻辑运算、顺序运算、计时、计数和算术运算等操作的指令,并能通过数字式或模拟式的输入和输出,控制各种类型的机械或生产过程。具有以下几个特点:可靠性高,抗干扰能力强;灵活性强,控制系统具有良好的柔性;编程简单,使用方便;控制系统易于实现,开发工作量小,周期短;维修方便;体积小,能耗低;功能强,性价比高;另外,PLC所提供的软元件的触点(如软继电器)可以无限次使用,方便地实现复杂的控制功能。同时,PLC的连网通信功能有利于实现分散控制、远程控制、集中管理等功能,与同等规模或成本的继电-接触器控制系统相比,无论其功能和性能,都具有无可比拟的优势。

川公网安备: 51019002004831号

川公网安备: 51019002004831号