【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

目 录

1 引言1

1.1 选题的依据及意义:1

1.2 国内外研究概况及发展趋势:1

1.3 PLC控制系统的发展概况:2

1.3.1国外PLC发展概况2

1.3.2 技术发展动向2

1.3.3 国内发展及应用概况3

1.4. 设计要求及工作内容:3

1.5. 目标、主要特色及工作进度4

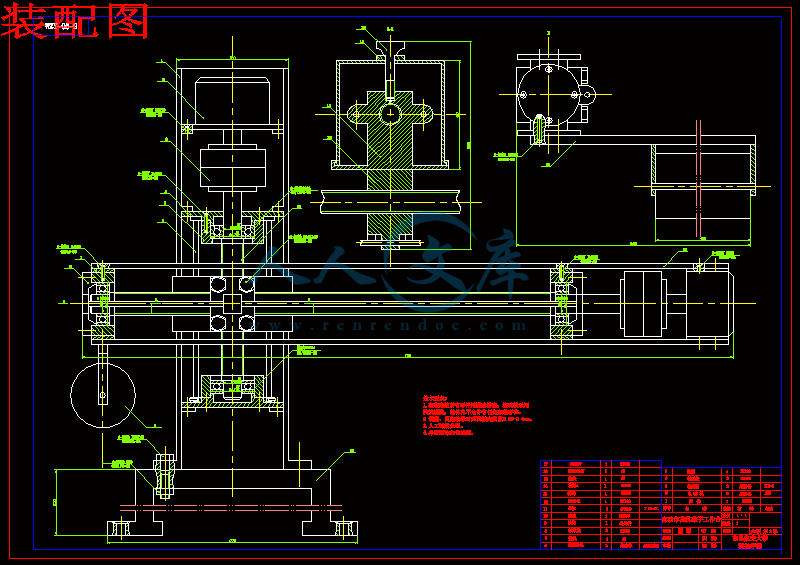

2 整体机械结构与旋转工作台的设计4

2.1整体系统结构分析5

2.2.旋转工作台的部件分析8

2.2.1 旋转工作台简介8

2.2.2 槽轮的结构分析8

2.2.3 滚动轴承类型的选择10

2.2.4 螺钉的强度校核12

2.2.5 轴的校核13

3 推网工作台与磙子工作台的结构设计14

3.1推网工作台和磙子升降台简介14

3.2推网工作台和磙子升降台结构14

3.3推网工作台和磙子升降台部件分析18

3.3.1滑动螺旋传动的校核计算18

3.3.2联轴器的选择21

3.3.3导轨的选择22

4 自动印花设备的控制系统24

4.1可编程控制系统的基本结构24

4.2自动印花设备的控制要求及印花工艺26

4.3控制系统设计及功能28

4.3.1 控制系统的构成28

4.3.2主电动机的控制29

4.3.3输入、输出地址分配,PLC外部接线图和限位开关的位置31

4.3.4 软件编程32

4.4总结与评价35

结论37

参考文献38

致 谢39

丝网印花机构设计

摘要:在自动印花设备结构设计时,采用了外槽轮机构带动工作台旋转,并在印花机构和推网机构中采用螺旋机构进行传动。最后成形时所包含的主要部件是底座、槽轮、销子、螺杆、螺母、导轨、轴、工作台等。需要对一些重要部件进行强度校验。

采用传统的继电器控制系统来实现电动机的控制与保护功能时,由于机械接触点很多,接线复杂,因此传统的控制方式已经越来越满足不了生产过程复杂多变的控制要求。

应用PLC实现电动机的启动与停止、正反转、顺序启动、降压启动以及互锁保护等功能,可以充分发挥PLC“软接控制”的优点、通过变成实现复杂的逻辑控制功能;另一方面,应用PLC“软触点”来取代继电器控制线路中的自锁触点、互锁触点以及时间继电器触点等,使得PLC控制系统的硬件接线得到了很大程度上的简化,提高了系统的可靠性。因此,在电动机控制中,应用PLC取代继电器控制系统成为发展的必然。

在设计PLC控制系统时分为电路原理的设计,PLC流程图和外部接线图,以及梯形图和程序的设计等。

本自动印花设备由可转位的工作台,可上下、左右移动的印花机构,和可左右移动的推网机构组成。通过各机构的协调动作和控制系统的电路实现工作台和印花机构的逻辑动作,实现自动印花过程。自动化程度高、结构简单、控制方便,具有很高的实用价值和市场空间。

关键词:自动印花 槽轮机构 推网机构 PLC控制系统

Screen printing mechanism design

Abstract: The structural design of the automatic printing equipment used when driving outside the geneva mechanism rotating table, and network printing agencies and institutions to promote the use of screw drive bodies. Finally forming the main component is included in the base, tank rounds, pin, screw, nut, rail, shaft, table, etc.. Need to check

the strength of some important parts.

Traditional relay control system to achieve motor control and protection features, because a lot of mechanical contacts, terminal complex, the traditional control methods have become increasingly complex production process can not meet the control requirements.

Application of PLC to achieve the motor start and stop, rotating, and the order of start, step-down start and interlock protection features, you can give full play to PLC "soft take control" of the merits, by the logic becomes complex control functions; another , the application of PLC "soft touch" to replace the relay control circuit in the self-locking contact, interlock relay contacts and other contacts, and time to make the hardware connection PLC control system has been largely simplified, improve the reliability of the system. Therefore, motor control, the application of PLC control system to replace relay as inevitable.

In the design of PLC control system is divided into circuit design, PLC and external wiring diagram flow chart, and the ladder and procedures of design.

The automatic printing equipment can be transferred from the position of the table, can be up and down, move around in the printing sector, and can move around the push net institutions. Coordinated action by all agencies of the circuit and control system, the logical table and printing action, automatic printing process. High degree of automation, simple structure, easy to control with high practical value and the market space.

Keywords: automatic printing Geneva Mechanism push net institutions PLC control system

Signature of Supervisor:

川公网安备: 51019002004831号

川公网安备: 51019002004831号