【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘 要

压缩机是用来提高气体压力和输送气体的机械。从能量转换的方式来看, 压缩机是属于将原动机的动力能转变为气体压力的工作机。本设计为中压活塞式空气压缩机设计。活塞式压缩机与其他类型的压缩机相比,其优点是:压力范围最广、效率高、适应性强,即排气量范围较广,且不受压力高低的影响。活塞式压缩机应用较广泛,例如在吹瓶机、核电站、仪表等方面,特别是在中小制冷范围内成为应用最广,生产批量最大的一种机型。

本次整个设计的内容包括压缩机的总体、气缸及基本部件的设计。主要通过热力计算和动力计算来确定压缩机的总体结构方案设计,和各种零部件的设计。同时,在本次的设计过程中,开发了一个计算机软件来完成热力计算和动力计算,借助AutoCAD绘图软件绘图。

关键词:活塞式压缩机;计算机编程;热力计算;动力计算;主要零部件设计

Abstract

The compressor is used to increase the gas pressure and gas transportation machinery. Judging from the energy conversion, the compressor is working machine, which can transform the prime mover into gas pressure. This design is for the medium-pressure piston air compressor. Compared with other types of compressors, advantages of piston compressor are: pressure range is the most extensive, high efficiency, adaptability. That means a wider range of displacement and pressure level will not affect it. The piston compressor is used widely, such as blowing machine, nuclear power plants, instrument, particularly in small and medium-sized refrigeration. It is also the largest production volume of a model.

The entire design includes the design of the compressor overall, the cylinder and the basic member. The compressor overall structure of the program and various parts of the design is mainly determined by thermodynamic calculation and dynamic calculation.In the design process, I develop a computer software to complete the thermodynamic calculation and dynamic calculation, drawing with AutoCAD drawing software.

Key words: piston compressor; computer programming; heating calculation; dynamic calculation; structural design

目 录

摘 要III

AbstractIV

目 录V

1 绪论1

1.1本课题的研究内容和意义1

1.2国内外的发展概况1

1.3本课题应达到的要求2

2总体设计方案3

2.1设计参数及依据3

2.1.1 设计参数3

2.1.2 设计活塞压缩机应符合以下基本原则3

2.2 主要结构参数的选择3

2.2.1 转速n3

2.2.2 行程S3

2.2.3 活塞平均速度4

2.3 结构方案的选择4

2.3.1 气缸排列的型式及其选择4

2.3.2 运动机构的结构及选择5

2.4 中间冷却器5

3 热力计算7

3.1 概述7

3.2 热力计算原始数据13

3.3 初步确定各级名义压力15

3.4 计算各级排气温度17

3.5 确定各级的排气系数19

3.5.1 容积系数19

3.5.2 压力系数21

3.5.3 温度系数21

3.5.4 气密系数21

3.5.5 排气系数22

3.6 确定各级干气系数22

3.7确定各级抽气系数22

3.8 确定各级气缸行程容积22

3.9 确定各级气缸直径24

3.10 圆整后各级名义压力及温度26

3.10.1 确定圆整后各级实际行程容积26

3.10.2 求各级压力修正系数、27

3.10.3 修正后各级名义压力及压力比29

3.10.4 修正后各级排气温度30

3.11 计算活塞力31

3.11.1 计算气缸内实际吸排气压力31

3.11.2 计算各列的活塞力32

3.12 计算轴功率,选取电机35

3.12.1 计算各级指示功率35

3.12.2 整个机器总指示功率36

3.12.3 轴功率36

3.12.4 选择电机36

4 动力计算37

4.1 概述37

4.2 初始数据37

4.3 作各级气缸设计示功图37

4.4 作往复惯性力图44

4.5 计算各级往复摩擦力47

4.6 作综合活塞力曲线图47

4.7 作切向力图52

4.8 确定飞轮距56

5 主要零部件设计58

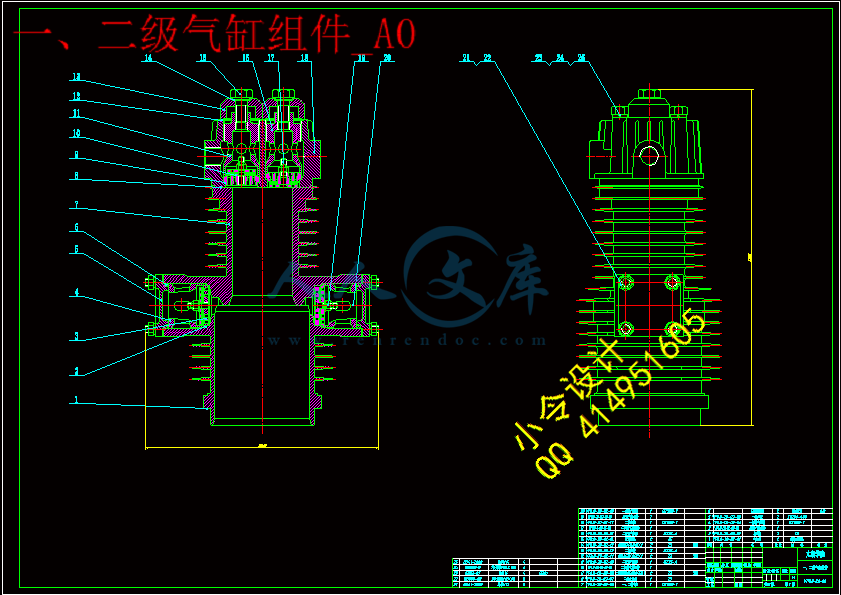

5.1 一、二级气缸设计58

5.1.1 气缸结构型式58

5.1.2 气缸结构设计58

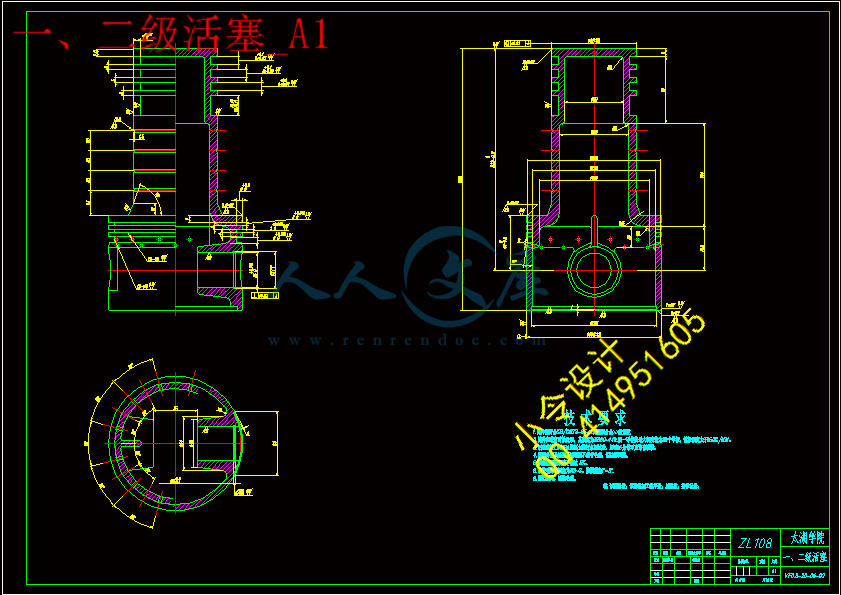

5.2 一、二级活塞组件61

5.2.1 活塞61

5.2.2 活塞环与活塞环的润滑62

5.3 一、二级气阀65

5.3.1 气阀的基本要求65

5.3.2 气阀主要参数的确定65

结论与展望71

6.1 结论71

6.2 不足之处及未来展望71

致谢72

参考文献73

附录74

1 绪论

1.1本课题的研究内容和意义

随着现代工业的发展,压缩机的使用已十分普遍,所占的地位相当重要。压缩机是输送气体介质并提高其压力能的机械装置,它在国民经济各部门中特别在化工、石油、矿山、冶金、机械、农田灌溉以及国防工业中已成为必不可少的关键设备。其重要的应用场合有:

(1)化工工艺过程上的应用

在化工生产中,为了保证某些合成工艺能在高压条件下进行,往往通过压缩机把气体

预先加压到所需的压力。例如高压聚乙烯的聚合反应要求把乙烯加压到2000kgf/cm�2以上;合成氨的反应要求把合成气加到320kgf/cm2;石油裂解如氢要求把氢气加压到150kgf/cm2以上等。

(2)动力工程上的应用

在动力、机械以及国防工业上常采用压缩空气作为驱动装置的动力气源,例如常见的

风动机械,要求空气的压力为8kgf/cm2;用于控制仪表及自动化装置上的气源压力6kgf/cm2;国防工业中某些武器的发射、潜水艇的沉浮、鱼雷的发射驱动等需要采用压缩机。

(3)气体输送

在石油、化工生产中,为了输送原料气,常用压缩机增压。例如从油田输出天然气,煤气厂输出煤气都要求事先加以增压。

压缩机种类有很多,有往复式压缩机、回转式压缩机、透平式压缩机、喷射式压缩机等。其中在往复式压缩机中最典型的是活塞式压缩机。活塞式压缩机是依靠气缸内活塞的往复运动来压缩气体。活塞压缩机由于具有耗能低、适应性强和灵活性大等优点,应用比较普遍。所以活塞压缩机的设计及研究对国民经济的发展具有十分重要的意义。

由于计算机的飞速发展与普遍应用,在活塞式压缩机设计中,可以使用计算机编程来实现热力计算和动力计算。通过利用计算机编程,可以使得热力计算和动力计算变得迅捷、方便、精确。同时借助AutoCad的二次开发,可以很方便的生成气缸的示功图、综合活塞力图、切向力图和总切向力图。

本次设计中编程语言采用C#。C#是一款面向对象的编程语言,是微软公司在2000年7月推出.NET Framework的第1版时提供的一种全新语言,它从C和C++语言演化而来,并吸取了以往的教训,考虑了其他语言的许多优点,并解决了它们的问题[12]。本次设计使用Visual Studio 2010开发工具进行所有的C#编程。

1.2国内外的发展概况

近年来,国民经济不断的发展,行业集中度提高了许多,大企业进一步集中供货。气体压缩机的产业布局,正在逐步合理的向新局面发展。由于战略性的经济重组的不断推进,很多不合格的企业退出,杰出的企业找准发展方向,加强主要业务的发展,不断做大做好,达到强强联合,承担起国家重大技术装备项目。在相关政策方面,为应对全球性金融危机对我国经济的影响,早在09年年初,国家已经制定了一系列的刺激经济方案,重点调整振兴包括石化、冶金等气体压缩机的下游产业在内的十大产业。由于这些措施,使得气体压缩机产业得到了积极的发展,同时也使得压缩机行业经济在2009年的下半年逐渐变好。在开拓国际市场方面,压缩机行业应积极而谨慎地探索自己的国际化道路。近年来,压缩机行业的国际化步伐放缓,特别是在2009年,压缩机的出口形势不容乐观,这主要表现于国内压缩机行业技术发展水平与国外压缩机技术发展水平存在一定的差距,真正意义上的具有国际竞争力的大型国际企业集团还没有形成。但是在将来,压缩机的需求在我国压缩机市场中将进一步提高。

2013年,是压缩机行业发展的新起点,预计行业未来呈现出新的发展态势。首先是结构调整将有重大突破。目前在我国的压缩机行业中,企业规模小而且分散,产业集中度低;生产力布局不合理现象依然存在;企业节能减排的任务重;科技创新能力不强;资源控制力不强,保障体系建设滞后等。正因为压缩机行业中存在这些矛盾,所以,特别的要在压缩机行业中特别的调整好压缩机产业结构,不断升级产业,并且解决压缩机行业的重大问题,不影响其发展。第二,行业内要大力推动共性技术研究开发,掌握核心技术、关键技术的自主知识产权。当前,压缩机行业共性技术的科研经费投入不足,研究开发力量薄弱。2013年,各企业应加大在我国重点培育自主知识产权的技术装备研发力量。可以循序渐进地加强建设国家工程技术研究中心、国家重点实验室、行业科研院所等共性技术研究开发平台,重点对原创性技术、战略性关键技术、及共性技术的研究开发,并且培养一支既精通基础技术又熟悉行业技术的高科技人才队伍,努力使其掌握关键技术、核心技术和重要产品的自主知识产权。第三,进入加快发展制造服务业阶段。当前,压缩机行业存在一些不利于产业发展的缺陷,如缺少高端技术,企业规模偏小等。面临这些问题和激烈的市场竞争,压缩机企业极需提高自身的核心竞争力,转变增长方式。在制造过程中,并且在市场调研,销售,产品报废回收过程中,力争为客户提供方便,高品质的优异服务,这点对一个压缩机企业的发展有着重要意义,因为通过这些可以实现可持续发展。现代服务业主要投入的大部分是人力资本和知识资本,这些解决了压缩机企业发展、升级问题,并且提升了市场竞争力。

我国往复压缩机设计与制造技术水平跟国外水平相比,主要差距是在研究基础理论上的差距,开发产品的技术能力相对较低,落后国外的工艺装备和实验手段,产品技术起点不高。另外,技术含量高和特殊要求的产品在国内压缩机市场上供不应求。

1.3本课题应达到的要求

1、根据设计参数,利用计算机编程进行压缩机的热、动力计算(主要包括缸径的确定,电动机功率计算及选型,压缩机中的作用力的分析,飞轮距的确定);

2、对压缩机主要零件进行强度校核;

3、根据计算结果,确定压缩机结构尺寸,绘制主要零部件图及一、二级气缸组装图;

4、查阅相关资料,完成毕业设计说明书一份,不少于30页。

2总体设计方案

2.1设计参数及依据

2.1.1 设计参数

排气量:0.85m3/min

压缩介质:空气

进气压力:大气压

公称排气压力:5 MPa(表压力)

排气温度:25℃

2.1.2 设计活塞压缩机应符合以下基本原则

a.满足用户提出的排气量、排气压力,及有关使用条件的要求。

b. 使用寿命要足够长,即压缩机需要大修时间间隔的长,使用可靠性要足够高,及压缩机被迫停车的次数短。

c.有较高的运转经济性。

d.有良好的动力平衡性。

e.维护检修方便。

f.尽可能采用新结构、新技术、新材料。

g.制造工艺性良好。

h.机器的尺寸小、重量轻。

川公网安备: 51019002004831号

川公网安备: 51019002004831号