【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘 要

旋转超声加工是集传统超声加工与磨粒磨削加工为一体的复合加工,是加工硬脆性材料的一种有效方法,具有良好的应用前景。然而,通过大量文献的阅读及实际的调查研究发现,国内目前还没有生产完善的旋转超声加工机床,超声加工的技术也远远滞后于发达国家的水平。

现今超声加工的工艺效果十分显着,国内外不断将超声加工与普通加工方式相结合应用,取得了较好的效果。超声加工具有较好的表面质量,不会产生表面烧伤和表面变质层。我们提出将超声加工与旋风铣削相结合来加工螺纹,在普通旋风铣削的装置的基础上进行结构的改进并加以超声装置,形成一套新的复合式的工艺装备,并仍与普通机床配套使用,不失其安装使用的灵活性。可以看出,改进后的超声旋风铣削装置可以弥补普通冷切削加工的不足,尤其适宜硬脆等难加工材料的加工,显著提高螺纹的加工质量。

关键字:旋风铣 超声 螺纹 变幅杆

Abstract

Rotary ultrasonic machining is a hybrid machining process which combines thematerial removal mechanisms of conventional ultrasonic machining (CUSM) and diamondgrinding. It is not limited by the electrical or chemical characteristics of the workpiecematerials. Thus it has been proved to be a promising and cost-effective machining methodfor hard and brittle materials, such as engineering ceramic, glass, stone, which has beenwidely used in many fields such as electronics, metallurgy, chemistry industry, machine,energy power, aviation and space flight.

Effect of ultrasonic machining process is very significant, domestic and abroad constantly ultrasonic machining processing methods combined with general application and achieved good results. Ultrasonic machining has good surface quality, does not produce surface burns and surface modification layer. We propose to ultrasound processing and integration to process Whirling threads, in general whirlwind milling devices based on the structure of improvement, and ultrasonic devices to form a new compound technology and equipment, and is still supporting the use of ordinary tools ,flexibility of installation and use is also very good. So that, the improved ultrasound equipment can make up ordinary Whirling cold cutting low, particularly suitable for processing hard and brittle materials such as hard processing, significantly improving the quality of thread processing.

Keyword:Whirlwind milling Ultrasound Screw thread

ultrasonic horn

前 言1

1 绪论3

1.1本课题来源及研究意义3

1.2 课题目前研究现状4

2 超声加工及旋风铣的基本介绍7

2.1超声波及其特性7

2.2超声加工基本原理9

2.3 旋风铣加工的基本介绍12

2.3.2旋风铣削加工螺纹的特点14

2.3.3 旋风铣削装置介绍15

2.4 典型螺纹类工件的加工情况17

3 超声旋风铣加工工艺22

3.1 普通蜗杆方法加工的工艺22

3.1.1 零件工艺性分析22

3.1.2 毛坯选择23

3.1.3 设计毛坯图25

3.1.4机械工艺路线确定26

3.1.5 定位基准的选择28

3.1.6 设备及其工艺装备确定28

3.1.7 车切削用量、工时定额确定29

3.2按旋风铣削加工方法进行的蜗杆加工32

4 超声加工装置设计34

4.1 超声加工装置的主要组成34

4.1.1 超声波发生器34

4.1.2 超声换能器36

4.2 超声振动系统设计38

4.3 超声变幅杆的设计39

4.3.1 超声变幅杆39

4.3.2变幅杆材料的选择42

4.3.3 变幅杆参数的设计43

4 4 1 变幅杆与换能器的连接与固定52

4.4 2 变幅杆的固定53

5 装置的设计与选用55

5.1 电动机的选择55

5.2 V带传动设计56

5.3 花键轴的设计58

5.5 各装置设计60

5.5.1刀体和刀头设计60

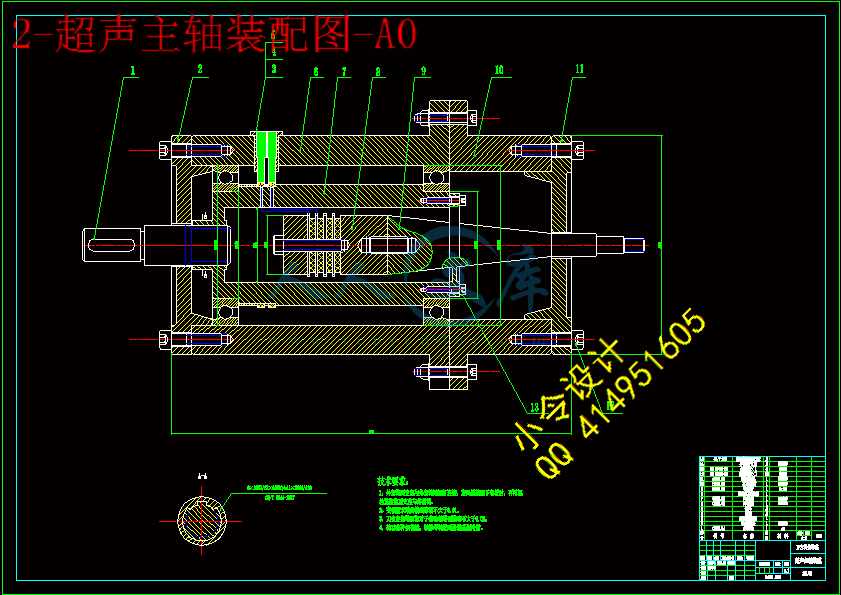

5.5.2 超声加工主轴设计61

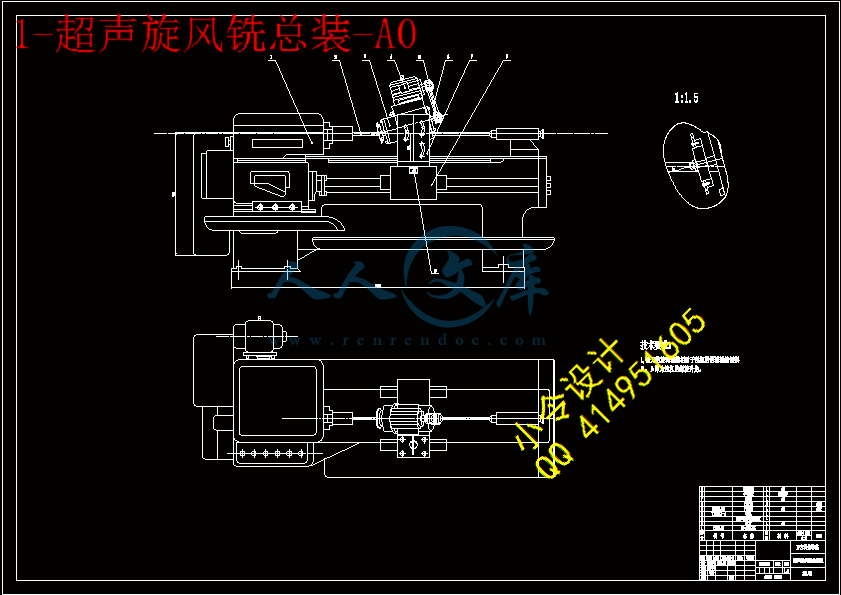

5.5.3 旋风铣装置整体设计62

5.5.4安装于机床后示意图63

致谢64

参考文献65

前 言

毕业设计是学生学完大学教学计划所规定的全部基础课和专业课后,综合运用所学的知识,与实践相结合的重要实践性教学环节。它是大学生活最后一个里程碑,是四年大学学习的一个总结,是我们结束学生时代,踏入社会,走上工作岗位的必由之路,是对我们工作能力的一次综合性检验。

1)毕业设计的目的

通过本次毕业设计,使达到以下几个效果:

(1)巩固、扩大、深化学生以前所学的基础和专业知识;

(2)培养学生综合分析、理论联系实际的能力;

(3)培养学生调查研究、正确熟练运用国家标准、规范、手册等工具书的能力;

(4)锻炼进行设计计算、数据处理、编写技术文件、绘图等独立工作能力。

总之,通过毕业设计使学生建立正确的设计思想,初步掌握解决本专业工程技术问题的方法和手段,从而使学生受到一次工程师的基本训练。

2)毕业设计的主要内容和要求

本次毕业设计的主要内容是超声旋风铣削的设计。具体设计内容和要求如下:

(1)调查螺纹蜗杆类零件对旋风铣削机床的具体要求,现在使用的加工方法;收集并分析国内外同类型加工方法的先进技术、发展趋势以及有关的科技动向;调查制造厂的设备、技术能力和生产经验等。

(2)设计装置的总体结构选择、传动参数设计、超声加工部件的选定与典型工件工艺的初步制定,确定各部分的相互关系;拟订总体设计方案,根据总体设计方案,选择通用部件,并绘制各零件的零件图和装配图;

(3)进行电机及各传动系统的运动计算和动力计算;

(4)超声加工部分零部件的设计和选择;

(5)编制设计技术说明书一份。

3)程序和时间安排

毕业设计是实践性的教学环节,由于时间的限制,本次毕业设计不可能按工厂的设计程序来进行,具体的说,可以分以下几个阶段:

(1)实习阶段,通过毕业实习实地调查、研究、收集有关资料,掌握超声加工加工技术,了解机床的结构、工作原理和设计的基本要求,花两周时间;

(2)制定方案、总体设计阶段,花两周时间;

(3)计算和技术设计阶段,绘制图纸,整理设计说明书,花四周时间;

(4)答辩阶段,自述设计内容,回答问题,花半周时间。

1 绪论

1.1本课题来源及研究意义

目前旋风铣螺纹存在的加工质量不高,以及其在硬脆材料加工上的不足,我们提出将超声加工与其复合,以在加工方式的根本问题上解决以上问题。目前国内外在此方面的研究尚属空白,具有一定的独创性和设计的合理性。在已有的旋风铣技术和超声加工技术的基础上,我们进行了超声旋风铣削的装置及工艺方面的设计。

现今超声加工的工艺效果十分显着,国内外不断将超声加工与普通加工方式相结合应用,超声加工具有较好的表面质量,不会产生表面烧伤和表面变质层。在旋风铣的基础上,我们提出将超声加工与旋风铣削相结合来加工螺纹,在普通旋风铣削的装置的基础上进行结构的改进并加以超声装置,形成一套新的复合式的工艺装备,并仍与普通机床配套使用,不失其安装使用的灵活性。可以看出,改进后的超声旋风铣削装置可以弥补普通冷切削加工的不足,尤其适宜硬脆等难加工材料的加工,显著提高螺纹的加工质量。

从已发表的文献资料来看,目前国内外学者对于旋转超声设备及其加工的研究存在很多的不足。

1)在旋转超声加工的设备方面,仅有个别实力雄厚的科研单位购买、使用价格昂贵的进口机床。国内没有专业从事旋转超声加工设备制造的商家,因此市场上没有出现完善机型。文献中所提到的设备,基本上都是在自身认识的基础上搭建简单的实验平台,将普通超声装置和钻铣床通过简单装配而成,或是探索性设计小功率超声加工机,因而出现设备个体差异大、超声功率低、超声能耗大、系统发热严重、加工性能差、超声波电源功率元件寿命低、旋转转速低等一系列问题。

2)在旋转超声加工实验研究方面,受限于超声加工设备的上述局限,目前基本上都集中在陶瓷等硬脆性材料的小孔加工方面,很少有关大平面磨抛加工的报到。为了拓宽硬脆性材料的应用,亟待解决此类材料的高效平面加工的技术“瓶颈”。

3)这些关于旋转超声孔加工实验研究多是集中在加工参数对材料去除率的影响、旋转超声加工机理及材料去除机理上。而在金刚石工具基体材料的选择、优化设计、金刚石工具的制作工艺对加工性能的影响、工具的寿命、加工过程中力的监控和控制等方面涉及较少,还没有形成统一的认识。这些问题的解决,将会更好解释旋转超声加工在硬脆性材料加工方面所具有的优越性,从而在推动旋转超声加工的研究及应用,解决目前非金属高性能材料在加工与使用的矛盾,促进其在工业应用上的发展。

1.2 课题目前研究现状

超声波加工技术的研究可追溯到1927年R.w.Wood和AIfred L LoomiS的奠基性工作,并于1954年由L.Balamuth研制出第一台超声波加工机床。半个多世纪以来,经过各国学者的不懈努力,这一技术已有了长足的进步。主要体现在如下几个方面:

1)实验出加工参数(振幅、频率、静压力、磨料材料及颗度、悬浮工作液的浓度和工作液循环方式等)对加工效率的影响规律;

2)总结出静压力、工件材料硬度加工具材料硬度是影响工具损耗的主要因素;

3)总结出磨料粒度及悬浮工作液的均匀性对工件表面质量具有影响规律;

4)利用有限元的方法,使变幅杆的设计更合理;

5)机械增益Q值高的材料用于制作变幅杆,性能优良的PCD用于制做工具头,使加工效率大大提高;

6)工具头回转的超声波加工使加工效率提高3至4倍;

7)采用性能优良的压电陶瓷换能器使加工机床的体积大大减小,能量利用率大大提高。

90年代Suzuki,K.研制的工程陶瓷无旋转超声波磨削新技术明显提高家工效率,也可以用来成型加工较复杂的型面。

1996年,德国亚琛工大研制了一种新的超声研磨技术,用它不仅可以进行超声仿形,而且可以根据工具的轨迹运动产生各种不同的曲面。

Z.J.Pei研制出旋转超声波面铣削加工新技术,并进行了实验研究。利用工具共振频率和工具长度的关系,通过检测超声波加工过程中工具的共振频率来监测工具的损耗。

随着超声波加工技术的研究进展和新技术的不断出现,超声波加工的应用范围在不断扩大。产生于60年代,在近40年中逐步发展起来的超声波旋转加工方法把金刚石工具的优良切削性能与工具的超声频振动结合在一起,可很好地提高加工效率,减小工具磨损,同样条件下,旋转超声加工RUM加工速度是传统USM的10倍,是传统磨削的6~10倍。

由于超声旋转加工只能加工圆形孔和型腔,z.j.Pei将其拓展到超声波面铣削方法加工陶瓷,并通过实验研究了陶瓷材料塑性去除及脆性去除机理。配以适当的数控系统,借鉴数控铣削的方法,国外许多学者正在开展数控超声旋转加工技术的研究。最近,德国已有成型的DMS系列超声加工机床上市,有3轴联动控制和5轴联动控制两种类型,主轴转速20~6000r/min,还可选配刀库和自动换刀装置,从而成为既具有超声波加工功能,又能进行钴、铣、磨等多工序复合加工的机床。近几年,国内清华大学、太原理工大学和大连理工大学对旋转超声波加工技术进行了初步研究。

川公网安备: 51019002004831号

川公网安备: 51019002004831号