【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘要

冲击回转钻进技术的设想始于欧洲。从上世纪五十年代开始,在美国,加拿大和前苏联才研制出几种具有实用意义的液动冲击器。我国从1958年底开始在原地质矿产部勘探技术研究所对液动冲击回转钻进技术进行研究,几乎与世界同步。

液动冲击器是液动冲击回转钻探的关键设备。随着中国现代化建设的不断推进和发展,国民经济增长对液动冲击回转钻探不断提出更高的要求,所以,加速液动冲击器的研究势在必行。

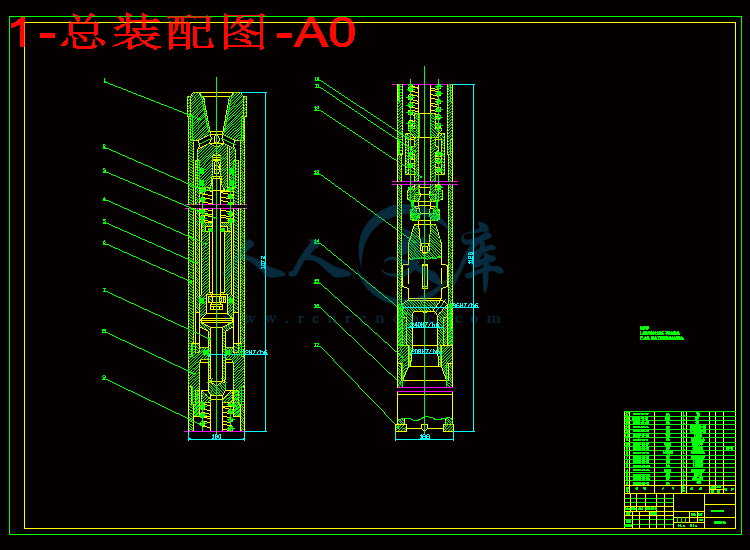

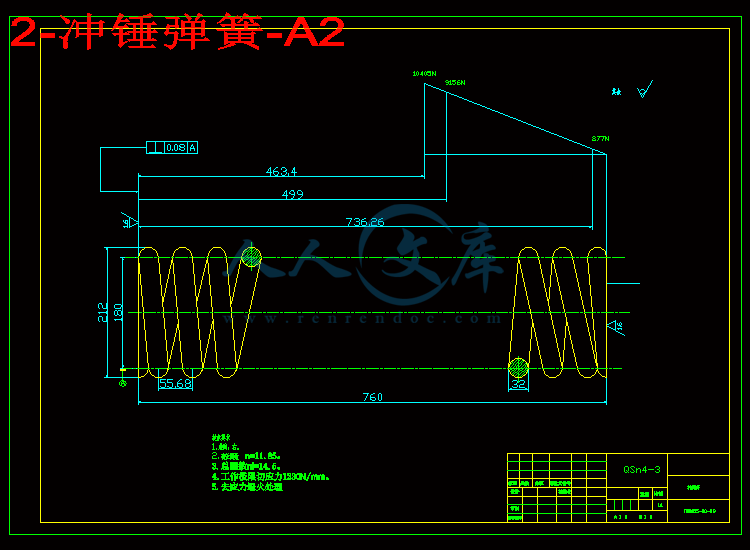

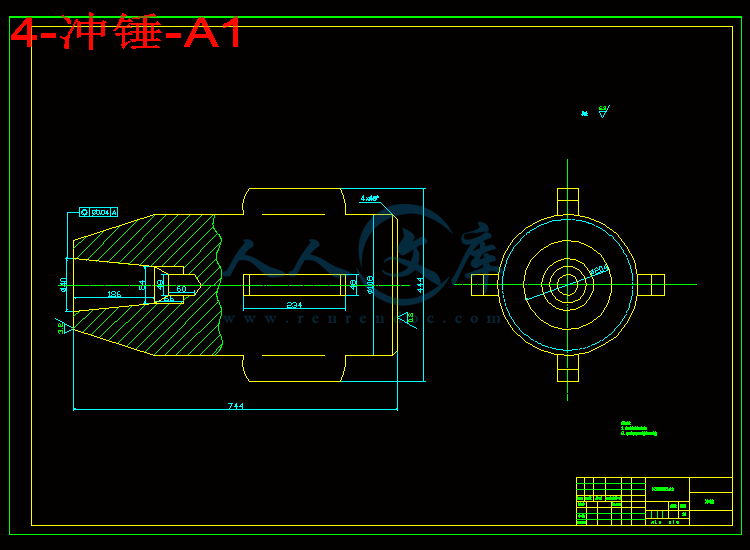

本文在综述了国内外液动冲击回转钻探和液动冲击回转钻探核心机械—液动冲击器的基础上,研究阀式反作用液动冲击器的工作原理和结构特点,并提出了计算液动冲击力和冲击频率的方法。通过分析,指出阀式反作用液动冲击器适用于中到中硬以上的岩层,并且应尽量增大泥浆排量,采用较大刚度的冲锤弹簧,以使冲击器的优点得到充分发挥。并针对液动冲击器的关键零件—冲锤弹簧进行了详细的分析计算和验算。并从技术和经济学角度分析了液动冲击回转钻探的技术经济效果。本文主要作了以下工作:

1)详细阐述了液动冲击回转钻探;

2)详细介绍了各种液动冲击器;

3)分析了反作用液动冲击器的结构原理和结构特点

4)阀式反作用液动冲击器的性能分析和参数计算。

关键词:液动 回转 钻探 反作用 冲击器

Abstract

The text ,basing on summing up the studying of nation inside and outside n circumgyrate drilling of fluid move concussion and fluid move impulsion implement of counteractive of valve style,study working principle and frame characteristic of fluid move impulsion implement of counteractive of valve style.And it advances the measure that account the wallop and concussion frequency.Overpass the analysis,it indicate that the fluid move impulsion implement of counteractive of valve style is the same with the terrane that whose rigidity is middle or upwards.Besides it should accretion the arrange quantity of slop to the best of its abilities and adhibits clash spring of the greater limit to exert the excellence of impulsion implement.It also makes detailed analyzed account and checking computations in allusion to the key part of the impulsion implement,and analyses the technic economy effet of the impulsion implement.The text do mianly these work:

1)expound circumgyrate drilling of fluid move concussion particular.

2)introduce diversified impulsion implement particular.

3)analyse orking principle and frame characteristic of fluid move impulsion implement of counteractive of valve style.

4)capability analysis and parameter account of fluid move impulsion implement of counteractive of valve style.

Key words: fluid move, circumgyrate, drilling, counteractive ,concussion implement

目录

摘要1

Abstract2

第一章 液动冲击回转钻探1

1.1概述1

1.2冲击回转钻进的实质和特点2

1.3冲击回转钻进的应用范围3

1.4冲击回转钻进的发展概况4

1.5液动冲击回转钻在地质岩心钻探中技术经济效益6

第二章 液动冲击器8

2.1冲击器的种类8

2.2 反作用式液动冲击器15

2.2.1 反作用式液动冲击器的结构原理15

2.2.2 反作用式液动冲击器的结构特点15

2.3 阀式反作用液动冲击器性能分析及参数计算16

2.3.1 功率特性及活塞冲锤运动特性分析16

2.3.2 参数计算16

2.4 本章小结22

第三章 ГВМС—5型液动锤23

3.1 ГВМС—5型液动锤工作原理及特点23

3.2 冲锤弹簧设计和计算24

3.2.1原始条件的确定24

3.2.2.参数计算:25

3.2.3验算27

第四章 液动冲击回转钻进的发展展望27

4.1 液动冲击回转钻进的发展方向27

4.2 基础理论方面的重大课题30

4.3 应用研究30

第五章 液动锤的仿真分析31

致谢35

参考文献36

1.1概述

采用冲击回转钻进技术的设想始于欧洲。1867—1887年期间,一些企图代替钻杆冲击钻的潜孔式液动冲击器相继出现,1887年在英国曾授予德国沃·布什曼以新钻井方法的专利,其技术核心就是利用泵供给的液能驱动液动冲击器对回转着的钻头进行连续冲击,从而实现冲击回转钻进。

从本世纪五十年代开始,在美国、加拿大和苏联才研制出几种具有实用意义的液动冲击器。海湾石油公司和壳牌石油公司对比进行过研究,其目的主要是应用于石油钻井及排除卡钻等,故直径较大,冲击锤有重达300kg者,且冲击频率较低。在地质矿产钻探方面国外研究最有成效的是苏联,从1900—1905年间即开展对液动冲击回转钻进技术的研究,但直到1970年才开始逐步在生产实践中得到应用,其间历经约七十年。匈牙利在六十年代研制了直径从48到160mm的五种双作用液动冲击器,其特点是组装在一专用拖车上并配有相应的泵、除砂器、取心工具、钻头和处理事故工具等,以便能够灵活运输,在施工矿区或工地为好几台钻机服务。当某台钻机遇到坚硬地层需要进行冲击回转钻时,可以及时运来“全套”的附属机具进行施工,而后又可以灵活地运往其他机台的孔段服务。匈牙利的这种液动钻探设备不但在地质矿山钻探中使用,其较大口径的液动冲击器也用于水井钻和工程施工钻探。日本对液动冲击钻的研究约有十余年的历史,比较成功的例子为利根公司研制的wH—120N型双作用式液动冲击器,其最大的特点是采用气液作为工作介质。

我国从1958年底开始在地质矿产部勘探技术研究所对液动冲击回转钻进技术进行研究。至1965年设计研究了七种不同结构形式的液动冲击器,并在周口店试验站专门建立的试验室中进行了性能对比和岩样钻进试验。其中最好的一种YZ—2型冲击器外径89mm,当供给的液量为0.2—0.3立方米每分时,冲击功为58—88J,冲击频率是16—25HZ。在试验台用硬质合金钻头钻进VII级花岗闪长岩时,最高钻进速度可达85mm/min。1966年在湖南柿竹园多金属矿进行了生产试验,最大孔深达430m。勘探技术研究所为推动此种技术的发展,曾于1963年编辑了(冲击回转钻专辑)第一辑,广泛介绍了国内外的文献资料,为液动冲击回转钻在我国的发展做了有益的工作。原北京地质学院和武汉地质学院也进行了大量的工作,培养了数批以冲击回转钻为主要内容的研究生,为系统的深入研究创立了良好的人才条尤其应当指出的是辽宁地质矿产局第九地质大队与长春地质学院等单位从1971年开始研究了一种具有独创性的sc—89和JSC—75型射流式冲击器,并于1982年获得科学技术奖,这是国内得到广泛应用的第一种液动冲击器。从1975年以后,我国除了地质系统广泛地研制了掖动冲击器外,其他几乎全部有钻探任务的兄弟部门都对此种钻进技术进行了研究,它们在生产实践中几乎部得到了肯定的好评。这种先进的钻进技术正在地质钻探、石油和天然气钻井以及各种工程钻中稳定地发展着。其技术核心——液动冲击器正逐步形成孔底动力钻的一个重要分支。

1.2冲击回转钻进的实质和特点

冲击回转钻就是在回转钻的基础上对岩石破碎工具——钻头,施加具有一定频率的冲击能量,因此对回转着的钻头不但对岩石有静的给进压力和扭矩,而且附加了一种连续的冲击动载荷。换言之,冲击回转钻就是一种带有冲击负荷的回转钻。

冲击回转钻进所以能够提高钻进效率的原因,归纳起来有下列几点:

1.冲击裁荷的特点是接触应力瞬时可达极高值,应力比较集中。所以尽管动硬度要比静硬度大,但仍易产生微裂纹。并且冲击速度愈大,岩石脆性增大,有利于裂隙发育。因此可以不大的冲击功(数个公斤米)就可破碎坚硬岩石,而静压人时则需很大的力;

2.切削刃具磨损减少。在冲击回转钻进中切削刃具的磨损减少的原因有:(a)钻进中所得的轴向压力较小,转速很低;(b)体积破碎的摩擦系数低于表面破碎时的摩擦系数,而在冲击回转钻进中容易达到体积破岩的程度;(c)钻速快,切削具的相对磨损就减小,(d)冲击破碎岩石时刃具与岩石的作用时间很短。

3.因为在冲击时还加有一定的轴向压力,改善了冲击功能的传递条件,增大了冲击效果。

4.因为高频并连续地给岩石施加冲击载荷,所以在碎岩过程中缝隙发育较完全,更有利于破碎较硬岩石。

5.因为在冲击中又有连续不断的回转切削作用,改变了冲击裁荷的传递方向,充分发挥了冲击碎岩和切削碎岩的效果。

1.3冲击回转钻进的应用范围

冲击回转钻进除了可以提高钻速外,又由于钻进中所需的轴向压力较小,转速较低,所以钻孔不易弯曲,孔内事故也较少,原材料的消耗低,

所以它是当前的一种现实可行的高效、优质、低消耗的钻进方法。特别是在中等硬度的岩石中,其效率更为显著,所以冲击回转钻进方法应用范围愈来愈广。据美国1973年和1974的统计贫科说明,使用冲击回转钻进方法完成的工作量占总工作量的23.2%一23.6%,仅次于一股的回转钻进(占62.7%一63.3%)而属第二位的钻进方法。

冲击回转钻进最适宜于钻进粗粒而不均匀的地层,在6—9级岩石中钻进效果尤为突出。近几年来冲击回转钻进不仅用于硬合金钻进,而且也应用于钢粒钻进和金刚石钻进以及牙轮钻进,适用的岩层范围扩大了。最近,苏联将冲击回转钻进应用于金刚石小口径钻进中,它不仅提高了钻进效率和钻头寿命,而且还克服了金刚石钻进裂隙发育地层、“打滑”地层和容易引起强烈弯曲的地层的困难。或因钻机开不了高速而影响孕镶钻头钻进时,用冲击回转法也可弥补其不足。

冲击回转钻进所钻的孔深和孔径日有发展。可以满足地质勘探钻进的要求。美国在石油钻井中,用巴辛格尔液动冲击器钻井深度达2750米。苏联利用ВВО—3型液动冲击器在石油钻井中可深达1280米。利用Г—3A型液动冲击器在地质钻探中孔深已达700多米。苏联近几年研制丁Г—7、Г—9型液动冲击器,并且为了增大效能,采用了ПП—70型气动孔底反射器,其孔深可达1500米或更深。

总之,冲击回转钻进方法现在已用于不同的地层和不同的钻进方法,其孔径和孔深也不断扩展,是—种很有发展前途的钻进方法。

1.4冲击回转钻进的发展概况

冲击回转钻进法的应用已有上百年的历史。早在十九世纪六十年代就有人进行丁潜孔式冲击器的试制工作。早期在法国研制过低频液动冲击器。后来在苏联和美国进行过“涡轮锤”和“涡轮振动钻”的研究工作。

二十世纪三十年代发展了风动潜孔锤。到五十到六十年代获得了较为广泛的应用。在此期间,美国在3500米的深井中,成功地进行了风动潜孔锤冲击回转钻进。随后又在水并钻和工程钻中广泛应用。到六十年代末,在我国矿山开采中推广使用了风动潜孔锤冲击回转钻进,代替了旧的钢丝绳冲击钻进。

二十世纪四十年代,苏联葛奠夫研制了滑阀式正作用液动冲击器,美国巴辛格尔也研制了活阀式正作用动冲击器。在液动冲击器的研制方面取得了很大的进展。到五十年代,美国艾莫雷研制了活阀式反作用的冲击器,到五十年代后期就出现了种类繁多的双作用的冲击器各种冲击器一直发展到现在,都得了较大的发展。

虽然苏联在1960年使用反作用式的ВВО—3型液功冲击器,在2400一2700米的深井中成功地进行了冲击回转钻进,但是总的看来,六十年代以来,在1500来以内的钻并中,使用效果较好的液动冲击器多属于正作用冲击器。

我国自1958年开始研制冲击回转钻具,许多单位在研制冲击器和冲击回转取心钻进方面进行了好多工作,但后来研究中断。从1971年起,辽宁铁岭地质队,长春地质学院等单位又先后开始研制液压射流式冲击器,取得了不少的成就。现在射流式冲击器和阀式冲击器已在地质勘探取心钻进生产中应用起来,并敢得了较好的成果。例如某队用射流冲击器钻进6—7(少最8)段岩石,取得进尺1132米的最高台月效率,江西某队用阀式冲击器钻进一万六千多米,在玄武岩、花岗岩地层中平均台月效率比钢离钻进提高30一60%。

冲击回转钻进方法虽然应用日广,但尚须进—步完善和提高。应当研究冲击回转钻进的碎岩原理,研究设计新型的冲击器,应尽先研制用于坚硬岩层的大冲击功的冲击器,泥浆钻进用的冲击器以及小口径金刚石钻进用的高频冲击器,研究冲击器的设计和计算方法;设计适应冲击回转钻进用的水泵及钻机,研究冲击回转钻进用的钻头结构、硬合金的材质和形状及其镶焊方法;制订合理的钻进工艺参数。

川公网安备: 51019002004831号

川公网安备: 51019002004831号