【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘 要

机械专业的毕业设计针对广大完成机械专业相关学科学习的应届毕业生,一次重要的事件性教学环节。同时也是高等工科院校大多数专业学生第一次较全面的设计能力训练,在此过程中,毕业生们将会对所学专业知识进行全面复习与实践。其目的是培养理论联系实际的设计思想,训练综合运用机械设计和相关选修课程的理论,结合实际分析和结局工程实际问题的能力,巩固、加深和扩展有关机械设计方面的知识。

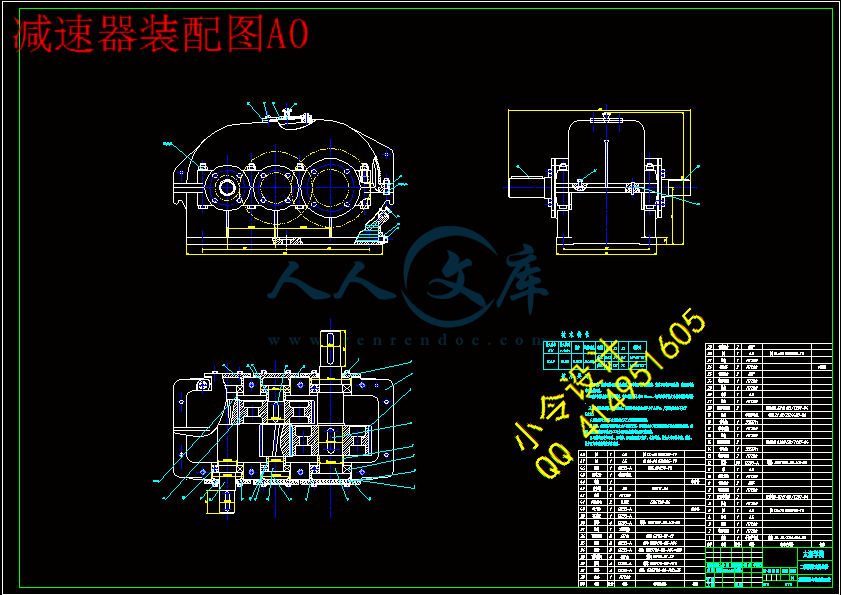

此次设计的论文题目是《工业窑炉的设计(输送装置)》。选择输送装置方向的毕业设计题目完全符合本专业的要求,从应用性方面来说,输送装置又是很多机器所必不可少的一个部分。有效保证输送装置的功率及稳定性能够达到设计的要求,具有很好的发展前途和应用前景。带式输送机是胶带兼作牵引机构和承载机构的一种机械设备,因此本课题研究带式输送机的工作原理,以及整体机械中的零件尺寸计算、选用标准和强度校核,必须要求学生要有良好的心理素质和仔细认真的作风,对学生也是一次很好的练习机会。根据题目要求和机械设计的特点做了以下几方面的工作:①选择适宜的带式输送机的总体设计方案;②选择电动机并计算传动装置的运动和动力参数;③传动零件以及轴的设计计算,轴承、滚动轴承、键、联轴器的选择及校验计算;④绘制减速器装配图及典型零件图;⑤编写一份分析明晰,计算正确,阐述清晰的设计说明。

关键词:带式输送机;减速器 ;机械设计计算;校验计算

Abstract

Mechanical design course design is in complete mechanical design course, an important practical teaching link. Is higher engineering college students is the first time most comprehensive design ability training, but also of the mechanical course thoroughly review and practice. Its purpose is to develop the theory with the practice of design thought, training comprehensive use of mechanical design and relevant elective curriculum theory, combining with the production design analysis and the ability of solving engineering problems, consolidate, deepen and expand the mechanical design knowledge.

This design topic is the design of industrial furnace(the conveying appliance).Choose the graduation design topic conveyor direction completely meet the professional requirements. From the application aspect, Conveying device is a part of the essential for many machine. Effectively guarantee the power and stability of conveying device can meet the design requirements, Having the good development prospect and application prospect. Belt conveyor is a kind of mechanical equipment tape used as traction mechanism and carrying mechanism, Therefore, the research of belt conveyor working principle,And the whole machinery parts size calculation, selection criteria and strength check, Must require students to have a good psychological quality and carefully, The student is also a very good opportunity to practice. According to the topic request and mechanical design features the following aspects of work to do:①Select the general design scheme of belt conveyor is suitable for the design ;②Kinematic and dynamic parameters selection and calculation of the motor drive device ;③Calculation of transmission parts and shaft design, selection and check of bearing, rolling bearing, bond, coupling calculation; ④Rendering speed reducer assembly drawings and parts of typical figure ;⑤To prepare an analytical calculation is correct, clarity, clarity on the design description .

Key words: belt conveyer; speed reducer; Mechanical design ; check computation

目 录

摘 要III

AbstractIV

目 录V

1 绪论1

1.1 课题研究的背景和依据1

1.2 本课题的研究意义1

1.3 课题国内外研究现状及发展趋势1

1.3.1 国外带式输送机技术的现状及趋势1

1.3.2 国产带式输送机的发展现状及趋势1

2 带式输送机简介3

2.1 带式输送机概述3

2.2 带式输送机的特点3

2.3 带式输送机安全运行保护装置3

3 输送装置的总体设计5

3.1 原始数据及设计要求5

3.2 传动方案分析5

3.2.1 所选方案的优缺点5

3.3 电动机的选择5

3.3.1 选择电动机的功率5

3.3.2 选择电动机的转速6

3.3.3 选择电动机的类型6

3.4 传动比的分配6

3.5 传动装置的运动和动力参数分析7

4 传动件的设计计算9

4.1 齿轮传动的设计计算9

4.1.1 高速级齿轮的传动设计9

4.1.2 低速级齿轮的传动设计12

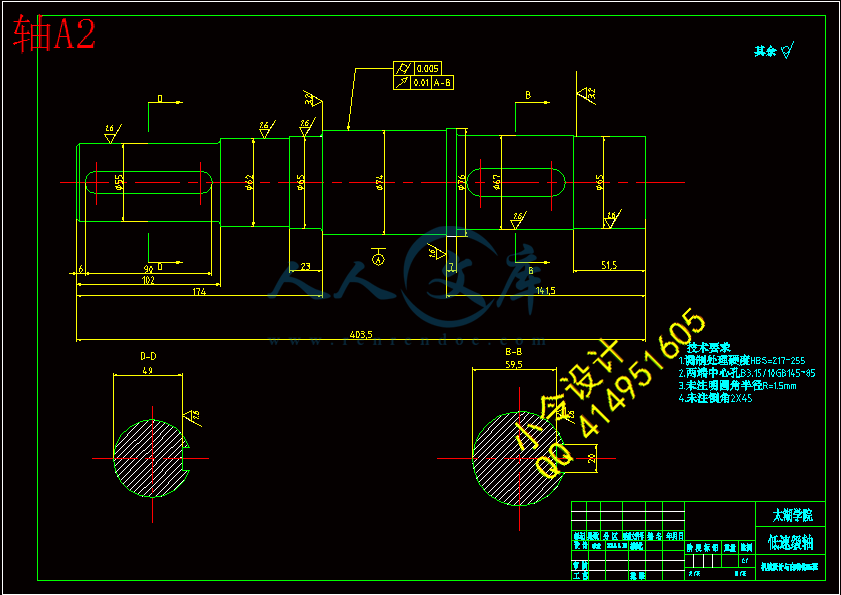

5 轴系零部件设计16

5.1 轴的设计和计算16

5.2 滚动轴承的选择和计算20

5.2.1 1轴上的轴承的选择和寿命计算20

5.2.2 2轴上轴承的选择计算20

5.2.3 3轴上轴承的选择计算21

5.3 键连接的选择与计算22

5.4 联轴器的选择与计算23

6 润滑与密封的说明24

6.1 润滑说明24

6.2 密封说明24

6.2.1 减速器的密封24

6.2.2 轴伸出端的密封24

6.2.3 箱体结合面密封24

6.2.4 轴承靠近箱体内外侧的密封24

7 拆装和调整的说明26

8 减速器箱体附件的说明28

9 结论和展望29

9.1 结论29

9.2 不足之处及未来展望29

致谢31

参考文献32

1 绪论

1.1 课题研究的背景和依据

带式输送机发展已逾百余年,随着科技和社会生产力的不断发展,带式输送机的设计由初期的主要用于农业作物等较小密度物料的输送,发展至用于制造、设计和安装的各种新技术、新方法的出现以及输送带接头技术的不断完善,带式输送机技术进入了一个高速发展阶段。它既可以进行散物料的输送,也可以进行成件物品的输送。除进行纯粹的物料输送外,还可以与各工业企业生产流程中的 工艺过程的要求相配合,形成有节奏的流水作业运输线。 带式输送机可以用于水平运 输或倾斜运输,使用非常方便,广泛应用于现代化的各种工业企业中,如:矿山的井下巷道、矿井地面运输系统、露天采矿场及选矿厂中。

1.2 本课题的研究意义

随着带式输送机在各行业的广泛应用,其结构简单、运行平稳、能耗低、对环境污染小、便于集中控制和实现自动化、管理维护方便、并可在连续装载条件下实现连续运输等许多优点,人们越发深刻理解和认识,因而带式输送机得到更多重视和高速发展。本设计在全面考虑多齿啮合、运转平稳等运动学和动力学的要求,实现高承载能力、高传递效率、高可靠性、优良动力学性能和送料定位准确等指标,而且要便于制造、装配和检修,设计了该具有合理结构的带式输送机。

此次毕业设计为设计一台工业窑炉的上下料输送机构。适用于产品340*340*30。要设计出结构,并且各个部件结构可以对应安装起来。生产率为80件/每分钟。要求运动平稳,送料定位准确。

1.3 课题国内外研究现状及发展趋势

1.3.1 国外带式输送机技术的现状及趋势

国外带式输送机技术的发展很快,其主要表现在2个方面:一方面是带式输送机多元化功能、扩大应用范围化(高倾角带输送机、管状带式输送机、空间转弯带式输送等各种机型)方向发展;另一方面是带式输送机本身的硬件设备和技术有了很大提高,长距离、大运量、高带速等大型带式输送机成为重点发展,而将动态分析与监控技术用于带式输送机,从而使得运行性能和可靠性得到提升.

1.3.2 国产带式输送机的发展现状及趋势

我国带式输送机行业起步相对国外较晚,但是在冶金、矿山、煤炭、交通、能源、建材等基础工业的带动下,我国带式输送机行业发展速度较快。近年来国产带式输送机产量逐年增长,根据中国重型机械工业协会数据显示,2009年我国带式输送机产量超过800万米。在产量逐年增长的同时,国产带式输送机产品的种类和技术水平也有了较大程度的提高。当前我国已经建成以北方重工、安徽盛运、山东矿机为代表的大型的带式输送机生产企业,并且随着国家产业结构的调整以及节能减排等政策的实施,行业内企业开始逐渐加大技术的研发力度,液压自动张紧技术、转弯技术、柔性制动技术、胶带防跑偏技术、监控技术以及变频技术在带式输送机上的逐步应用,使得带式输送机的安全可靠性得到了大幅度提高,同时,多转弯、上运、下运以及胶带翻转等关键技术都得到了很好地解决。当前,我国自主开发的带式输送机产品已经具备装备国内重大工程的能力,并已开始向海外市场进军。据资料显示,2009年,我国带式输送机出口产值约占带式输送机工业总产值的

15%-20%。

从未来国内市场的发展前景来看,煤炭、矿山开采、港口码头、电力、钢铁、粮食等行业的投资规模将继续扩大,这也必将带动带式输送机的市场需求不断增大;国际市场上,发展中国家正大力发展其本国的基础工业,如印度、巴西、东南亚、非洲、拉美等国家和地区对带式输送机的需求量也在逐渐增加。国产带式输送机由于的性价比较高,在国际市场上具有很强的竞争力。因此国内外市场的发展角度来看,国产带式输送机都具有较大的需求空间。根据市场的需求趋势,带式输送机将朝着长距离、大功率、大运量的方向发展,同时随着节能减排等政策的实施以及政府和全社会对安全生产的重视程度的增加,小规模火电、煤矿及水泥等生产企业相继关闭,取而代之的是具有先进工艺的大型企业,因此,对带式输送机的性能、质量、安全可靠性等方面的要求更高。由于带式输送机的核心部件决定了其整机的综合性能,因此带式输送机核心部件的专业化分工与协作将成为该行业发展的必然趋势,在带式输送机市场需求的带动下,其核心部件的市场价值也逐渐凸显。

川公网安备: 51019002004831号

川公网安备: 51019002004831号