【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘 要

随着市政道路和高等级公路建设突飞猛进,大规模的机械化养护时代已经到来。作为路面养护和再生设备的主要机种之一的路面铣刨机正越来越引起道路养护专家和施工单位的关注。

路面冷铣刨机是一种高效的路面维修养护设备, 具有使用成本低、铣深范围广及不污染环境等优点。主要用于大面积路面铣刨破碎、常见病害的铣平修整以及路面拉毛作业。 路面铣刨机的主要工作装置是铣刨转子,铣刨转子上均匀布置着按左右对称螺旋线排列的铣刀。铣刨转子是以垂直进给和水平进给两种方式进行工作。路面铣刨机以工作速度向前移动,铣刨转子旋转均匀分布于滚筒上并按螺旋线排列的铣刨刀,铣刨刀顺序接触路面,路面材料在铣刨转子刀具的冲击和挤压下破碎为颗粒状;同时呈螺旋状对称排列的刀具将铣下的废料向转子中央聚集,通过抛料板将废料抛到输送机上,并转移到指定位置和运输车辆上。

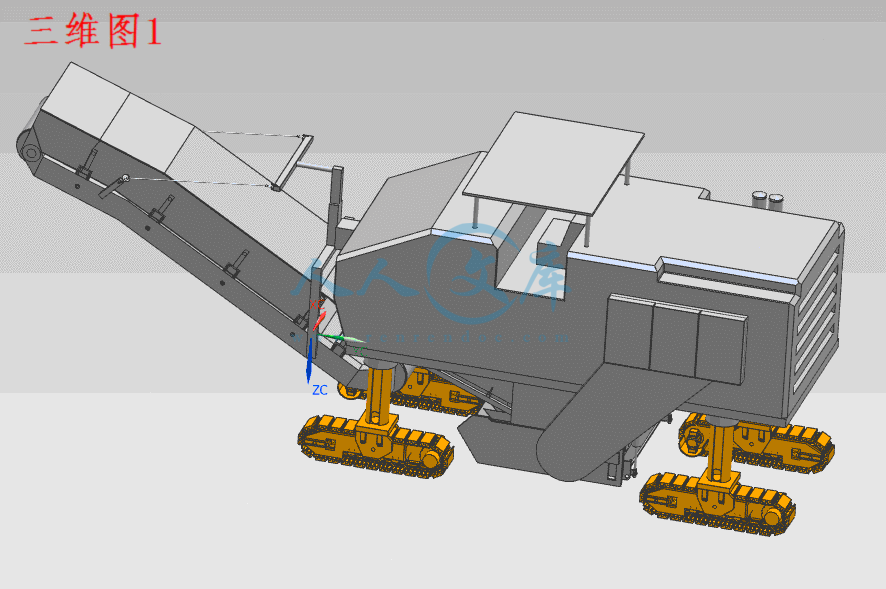

本设计说明书包括了整机的总体设计和计算,动力机构及行星减速器的设计,行走机构的设计,铣刨部分的设计,输料装置的设计,并对路面铣刨机械的技术发展趋势和市场前景做了简单介绍。

本说明书与图纸配套使用。

关键词:铣刨机;行星减速器;履带;输料装置;刀具

Abstract

With rapid advances in municipal roads and the construction of high-grade highways, mass maintenance time has come. As road maintenance and recycling equipment of main machine kind of pavement milling machine is one of a growing source of concern for experts of road maintenance and construction units.

Cold milling machine is a high performance pavement maintenance equipment, with low cost, wide range of milling depth and does not pollute the environment and so on. Mainly used for common disease of large area of broken pavement milling, milling picking jobs in flat trim as well as pavement. Road milling machine milling rotor are the main working device, evenly milled rotor layout arranged in a symmetrical helical milling cutters. Rotor is based on vertical and horizontal milling feed work in two ways. Pavement milling planing machine to work speed forward mobile, milling planing rotor rotating uniform distribution Yu drum Shang and by spiral arranged of milling Shaver, milling Shaver order contact pavement, pavement material in milling planing rotor tool of impact and extrusion Xia broken for particles shaped; while is spiral shaped symmetric arranged of tool will milling Xia of waste to rotor Central gathered, through throwing material Board will waste throwing to conveying machine Shang, and transfer to specified location and transport vehicles Shang.

The design specifications, including the the overall programme, power and design of the planetary gear reducer, mechanism design, milling parts design, design of the feeding device, and pavement milling machine technology trends and market prospects of doing a simple introduction.

Supporting the use of these instructions with drawings.

Keywords: milling planer ;planetary reducer ;track ;transporting machine ;tool

目 录

摘 要III

AbstractIV

1 绪论1

1.1路面铣刨机及其发展概况1

1.1.1路面铣刨机的分类1

1.1.2路面铣刨机的应用特点2

1.1.3 路面铣刨机的主要结构及工作原理2

1.1.4 国内外路面铣刨机发展概况3

1.2 路面铣刨机设计的指导思想5

1.3 路面铣刨机设计的设计原则5

1.4本文设计的主要内容5

2 路面铣刨机的总体设计6

2.1 路面铣刨机的选型6

2.2路面铣刨机的总体参数的选型6

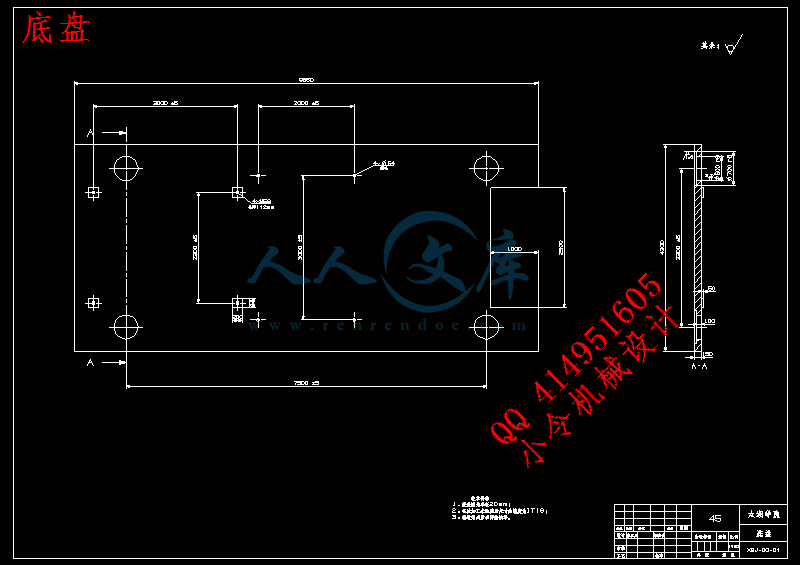

2.3 路面铣刨机的总体布置8

2.4 铣刨机总体方案的设计8

3 铣刨机动力机构及行星减速器的设计10

3.1 发动机的选择10

3.2 传动形式的选择11

3.3 行星减速器的设计13

3.3.1 型行星减速器的运动设计13

3.3.2 减速器的结构设计17

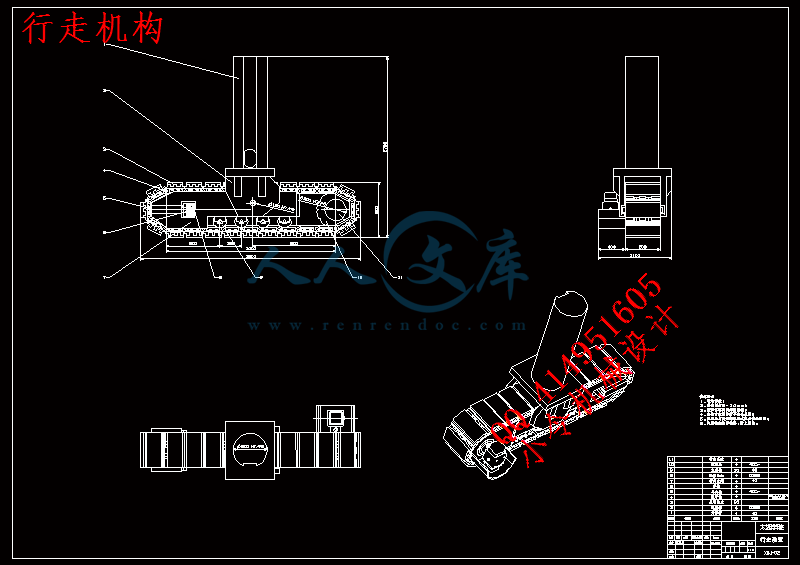

4 铣刨机行走系统的设计20

4.1 铣刨机行走系统的基本要求20

4.2 铣刨机行走驱动形式20

4.3 导向与张紧缓冲装置的设计参数分析21

4.4 履带式铣刨机的运动学与动力学分析25

4.4.1 铣刨机行驶系统的运动学分析25

4.4.2 履带式铣刨机动力学分析26

4.5 附着条件决定的最大切线牵引力27

4.6 行走系统功率分析27

5 铣刨机铣刨系统的设计29

5.1 路面铣刨机铣刨转子排列方式分析29

5.2 路面铣刨机铣刨轮刀具排列参数分析30

5.3 路面铣刨机铣刨轮主要参数的研究34

5.3.1 铣刨轮的切削量34

5.3.2 铣刨轮直径35

5.3.3 铣刨轮最佳螺旋升角的选取36

6 输料系统的设计38

6.1 输料系统的主要功能部件38

6.2 输送带的跑偏及防偏措施40

6.2.1 跑偏的危害及原因40

6.2.2 输送带跑偏的常见处理方式40

7 总结与展望43

7.1 总结43

7.2不足之处及未来展望43

致谢45

参考文献46

附录48

1 绪论

1.1 路面铣刨机及其发展概况

路面铣刨机是一种高效的沥青路面维修养护设备,其原理是利用滚动铣削方式把沥青路面局部或全部破碎。铣削下来的沥青碎料经处理后,可直接用于路面表层的重新铺筑。主要用于公路、城市道路、机场、货场、停车场等沥青砼面层开挖翻新;沥青路面拥包、油浪、网纹、车辙等的清除;水泥路面的拉毛及面层错台铣平等。随着市政道路和高等级公路建设突飞猛进,大规模的机械化养护时代已经到来。作为路面养护和再生设备的主要机种之一的路面铣刨机正越来越引起道路养护专家和施工单位的关注。公路建设部门对路面铣刨机等成套设备的需求会越来越迫切,需求量也会越来越多。

1.1.1路面铣刨机的分类

按照铣刨宽度,路面铣刨机可分为大中小三种,0.3~1.0米为小型;1.2~2.0米为中型,2.0米以上为大型。对于铣刨宽度小于或等于1.0米的小型铣刨机主要是机械传动,机械式传动工作可靠、维修方便、传动效率高、制造成本低,但其结构复杂、操作不轻便、作业效率较低、牵引力较小,一般适用于小面积的路面维修、刮除喷涂标线、铣刨小型沟槽等,一般不带废料回收装置。铣刨宽度在1.2米以上的中型铣刨机主要是液压传动,液压式结构紧凑、操作轻便、牵引力较大,但制造成本高、维修较难,适用于切削较深的中、大规模路面养护作业。我国目前以生产小型路面铣刨机为主,且以 0.5米和1.0米两种规格居多,大中型产品基本上还是空白。

另外,按铣刨型式不同,可分为热铣和冷铣。热铣式因为增加了加热装置而使结构比较复杂,一般用于路面再生作业。冷铣由于适用范围广,目前占据主导地位。冷铣式配置功率比较大,刀具磨损比较快,切削料粒度较为均匀,可设置洒水装置喷水,使用广泛,且产品成系列;按铣刨机按行走方式不同,可分为轮式和履带式。轮式的机动性好、换场方便,特别适合于中小型的路面作业。履带式多为铣削宽度2000mm以上的大型铣刨机,有旧材料回收装置,适用于大面积路面再生工程;按铣刨鼓旋转方向与行走方向不同,可分为逆铣和顺铣;按有无废料回收输送机,可分为输送式和无输送式;按铣刨鼓安装方式不同,可分为固定式和移动式。

图1.1 轮式铣刨机

图1.2 2m履带式铣刨机

1.1.2 路面铣刨机的应用特点

1. 使用铣刨机铣削路面,可以快速有效地处理路面病害,使路面保持平整;

2. 道路的翻修工程采用铣削工艺可保持原路面的水平高程。铣削工艺可将损坏路面切除掉,由新材料填补原有空间,经压实后与原路面等高,保持路面的原有水平高程,这使穿行于高架桥或立交桥涵的路面载荷对桥体不致产生冲击载荷,并且桥涵通过高程不变;

3. 保证新旧路面材料的良好结合,提高其使用寿命。采用铣削工艺可使填料坑边侧及底部整齐、深度均匀,形成新旧料易于结合的齿状几何表面,从而使翻修后新路面的使用寿命大大提高;

4. 有利于旧路面材料的再生利用。由于可以掌握切削深度,铣削下来的材料不仅干净且呈规则的小颗粒,可以不用再破碎加工即可遮现场或固定料场再生利用,大大降低了施工成本,同时也是一种环境保护措施。

川公网安备: 51019002004831号

川公网安备: 51019002004831号