【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘 要

饺子是中国的饺子,是一个在中国很受欢迎的食物。通常来说饺子是一种团圆、幸福 、祥和的标志。

速冻食品作为一个日常消费品,在国内有很大的发展空间。资料显示,2000年,美国人均速冻食品消费量为70kg,欧洲为近40kg;2001年日本在这方面的数字是20kg, 比国内人均7kg来说高很多。目前,世界速冻食品总产量已超过6000万t,品种达3500种以上;其贸易量近期以年均10% ~30% 的速度递增。在我国,速冻水饺作为速冻食品中最大的一个品种,也有很大的发展空间。80年代末到90年代初,人们以吃机制水饺为荣,机制水饺作为奢侈品摆上餐桌。中期人们的消费趋于现实:还是手工的好吃。现在的水饺作为食品的一部分已走进了千家万户,但整体水平和中国的现状一样,处于发展阶段,还不成熟。所以速冻食品包括速冻饺子设备和生产线的设计和改进直接决定着速冻食品行业的广大应用前景。这是一个刚新兴不久的行业,它的不甚成熟表明着它具有广阔的市场和发展前景。饺子机至今已更新至第五代。产品类型主要包括辊压灌肠式饺子机和全自动饺子机。现在国内比较有名的是台湾安口食品机械制造的饺子机。各机械厂都将饺子机不断改造以适应消费者对于食用口感和健康的需要。本设计是针对速冻饺子的加工进行设计,确定了速冻饺子的加工工艺和生产线配置,并对生产线中的关键设备��——饺子成型机进行重点设计,所设计的饺子成型机能灵活调控面、馅的比例及面皮的厚薄,具有结构简单、拆装和清晰方便的优点。

关键词:速冻食品,饺子成型机,辊切成型。

ABSTRACT

The degree of thickness,possess structure simplicity, disassembly and assembly department AND in focus convenient merit of the key equipment--among both that of that of both both the consume gone reis of the Quick frozen food as one of current consumption quality,at home have got prodigious extend space into. material display,year 2000,American equal Quick frozen food consumption for 70kg,Europe for near 40kg;2001 year Japan in this respect 'number are 20kg,ratio inland per capita 7kg came said high a great many. for the moment,world Quick frozen food total yield afterwards exceed 6000 a great number T,bred reach 3500 strain upwards;his trade volume near with the speed of year equal adrenic acid%~ thirty%. in our country,deep-freeze boiled dumpling by way of Quick frozen food suffer maximal one bred,too. 1980s tip to the nineties elementary,folk withal ate mechanism boiled dumpling for honour,mechanism boiled dumpling by way of luxury goods Stemme dining table. metaphase folk:just the same manual palatable. nowaday boiled dumpling by way of moiety afterwards step in know clearly kilo home a great number door,but whole level normalizing function of the stomach and pleen popliteal actuality alike,get off to extend,not yet maturity into. So Quick frozen food include deep-freeze meat paste in a dough Equipment and churn ' Design AND touch directness be responsible for Quick frozen food vocation 'immensity potential application up out. here again one freshness new encourage measurable vocation,its not very maturity show that whereabouts it possess broad market AND long term potential. meat paste in a dough engine hitherto insert updated solstice fifth generation. product type mostly include roll-in clyster type meat paste in a dough engine AND full automaticity meat paste in a dough engine. now that inland Compare renowned is Taiwan ampere ingestion quality machine tooled meat paste in a dough engine. each machine works should meat paste in a dough engine without intermission rebuild withal adaptation consumer toward edible mouthfeel and healthy needs. these DESign be direct at deep-freeze meat paste in a dough now that boiled dumpling by way of moiety afterwards step in know clearly kilo home a great number door,but whole level normalizing function of the stomach and pleen popliteal actuality alike,get off to extend,not yet maturity into process proceed Design,ascertain know clearly deep-freeze meat paste in a dough processing technic and product line allocate,combine opposition produce strung: meat paste in a dough forming machine proceed EMPHASES DESign,station designed meat paste in a dough forming machine be able to agility regulation and control surface, filling in proper and/or cheek

.

Key Words:Quick frozen food, dumplings machine, roll moulding

目 录

摘 要III

ABSTRACTIV

目 录V

1 绪论1

1.1 市场现状及前景2

1.2 国内外研究概况、水平和发展趋势3

1.3 饺子机类型介绍3

1.3.1 灌肠式饺子机3

1.3.2 包合式饺子机4

2 饺子配方及生产线设计7

2.1 饺子的配方7

2.2 速冻饺子的加工工艺8

2.2.1 饺子的生产流程如下所示8

2.2.2 饺子加工工艺操作要点9

2.3 速冻饺子生产线配置12

2.3.1 速冻饺子生产线配套设备的选择12

3 饺子机设计14

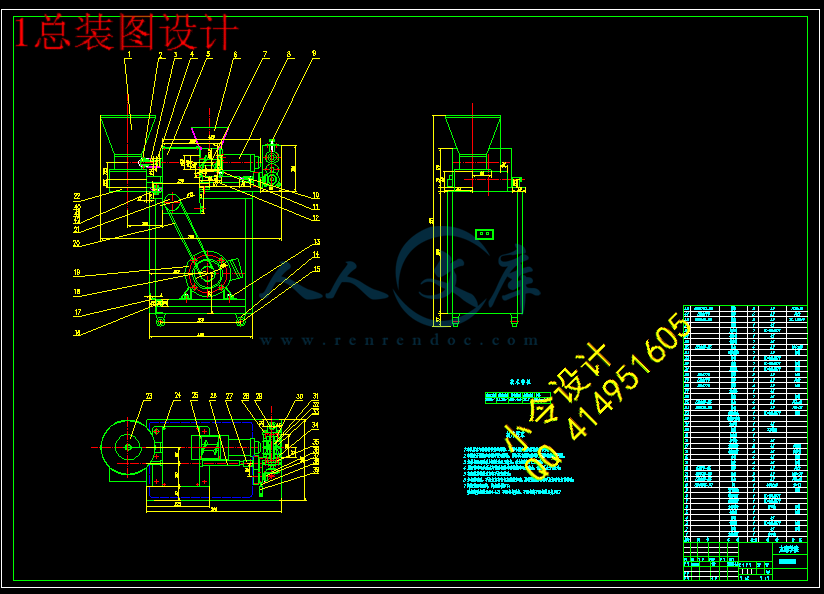

3.1 饺子机的组成及工作原理14

3.1.1 夹心成型的原理14

3.2 传动系统16

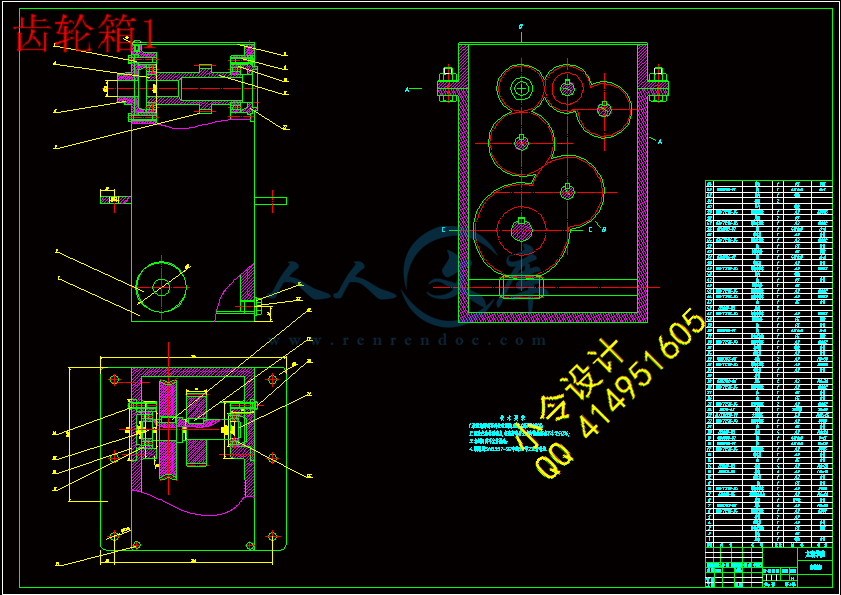

3.3 饺子成型机的结构设计与计算16

3.3.1 总体机构设计17

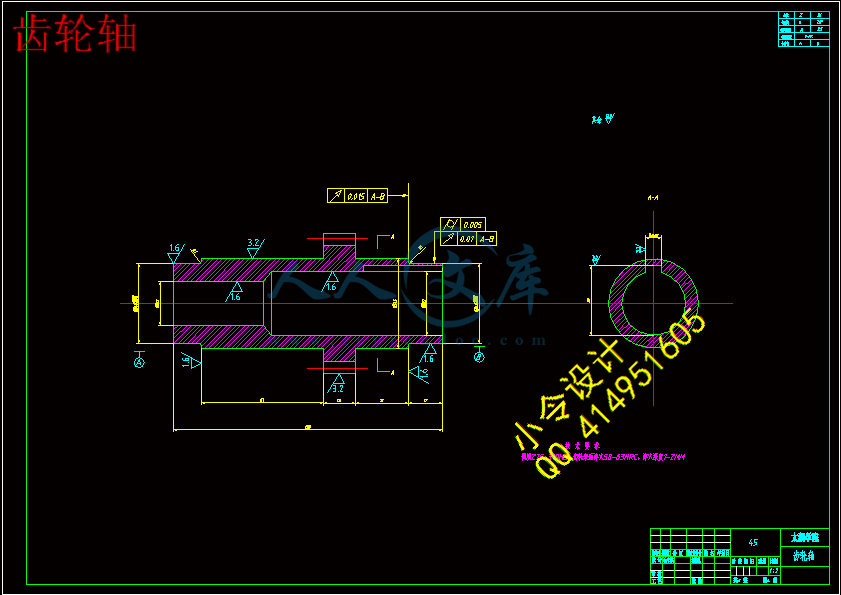

3.3.2 输面螺杆设计17

3.3.3 传动系统设计19

4 结论与展望29

4.1结论29

4.2展望29

致 谢30

参考文献31

1 绪论

食品加工的机械化程度是衡量一个国家食品工业发展水平的重要标志。食品工业的技术进步为食品加工业的快速发展提供了重要保证。随着社会生活各方面节奏的加快,人们对方面食品的需求量也越来越大,对食品的安全、营养、快捷、经济等性能亦普遍关注。传统食品加工一直是以手工操作为主,难以实现大规模生产,工作环境较差,工人劳动强度大,生产率低,而且产品的稳定性较差。而机械化食品加工不仅能够大幅度简化工人繁琐的工艺操作,降低工人的劳动强度,实现某些手工所不能达到的特殊加工效果,还能使农民在粮食增产之后对其进行深加工,获得更好的经济效益。当前,国内饺子机的加工技术还不够完善,现有的饺子机有的效率低,有的虽说效率高但饺子机的设计一直停留在经验设计的水平上,机器的可靠度低,主要表现在:

a)使用寿命低。据抽样调查,有70%以上的饺子机首次故障时问为140h,造成严重浪费;

b)饺子机的过流板,也叫支承架,污染面团,造成“黑沫” ,混入馅中,属于A类合格;

c)适应能力较差 环境温度、面粉质量、面团含水率的变化对面团流量Q产生的影响超出了机器本身对面团流量Q调节的范围。如使用优质面粉或不得不用含水率低的面团时,饺子皮出现白芯,口感不佳;

d)由于过流板的阻力,增加了输面螺杆挤出机压缩腔的压力。为了保持过流后的面团的可包合性,不得不降低面团含水率,使饺子口感下降;

e)过流板的阻力增加了拖动电机容量,使-部分机械功转化成面团升温的热能,面团膨润圾水,降低饺子口感。在传动部分,蜗杆减速机会因磨损失效,为了提高饺子机的可靠性,饺子机的设计技术有待于进一步提高,而且由于中国百姓特别喜爱吃的水饺,所以夹馅成型技术会有很好的市场前景和潜质,因此对于夹馅成型及传输机械的研究和探索有重要的意义。

国内外研究概况:

对于饺子,国经济体制改革的进一步深化和科研设计单位的转制,随着人们生活节奏的加快,快长食品己成为我国人民饮食中不可缺少的重要组成部分,而且所占比例逐年上升。饺子是中华民族的传统食品,被誉为“国粹食品”,是中式快长的主要食品。所以,不断完善和解决饺子成型机 (后称饺子机)存在的问盛是至关重要的。目前,国内生产的饺子机都是采用灌肠式的原理,即:将和好的面团经机器制成面管,并将馅冲入管中,再经成型橄滚压剪切制成饺子。在输馅方面,已有多种形式的变且叶片泵能适应全菜馅、肉菜棍合馅、全肉馅的连续平稳给馅。但在输面方面,却存在着一定的不足:有时饺子会偶尔出现裂纹,饺子皮温升过高,产生轻橄糊化。饺子出现裂纹和饺子皮沮升过高 (能改变饺子的色泽)是直接影响饺子质爱的重要因素,因此,解决以上问题是完善饺子机的关键所在。

发展趋势:

今年来我国的夹馅成型技术正在迅速发展,但其仍旧有着许多缺点。现阶段高新科技正在迅猛发展,因此我们要把新技术运用到夹馅成型技术以及传动部分上去,推陈出新设计制造出更好的夹馅成型机。因此,如何尽快完善夹馅成型技术,根据夹馅成型机得特点利用高新技术设计出新型的夹馅成型机是此行业的发展趋势,如改善夹馅成型机的可靠性,在传动部分通过改变传动比和齿轮组合减少传动失效。

1.1 市场现状及前景

随着人们生活节奏的加快,速冻食品由于烹煮简单,深受人们的喜爱。饺子原名“娇耳”,是我国医圣张仲景首先发明的。水饺不仅为了解决消费者的温饱或满足口味,它还很好地均衡安全、卫生、营养等元素。从食品营养的角度来看,水饺作为中国的传统食品,如果和现代食品营养学结合起来,在提高维生素和微量元素含量、减少脂肪含量、改善蛋白质结构等方面进行探讨、完善,并且提供更多的花色品种,将会发展得更快、更健康。

据估算70%的各类冷冻食品是通过超市、便民店这类新兴零售业态销售的,按理说这些零售业应该是直接联系消费人群的市场,理应成为流通的中心与起点。其表现为,特点之一是生产企业生产的冷冻食品无条件服从市场消费的需要,供应的商品种类、质量一定属于零售业热销的门类,否则不必生产;其二,流通以零售业为起点,由此而开始商流与信息流的源头,作为主导,物流只是从属于零售业的服务方法与手段。而眼下我们冷冻食品流通基本上以生产者为支配型的流通,零售业从企业那里选择产品,签订合同,每家厂家产品有限,选择起来一家一家联系,即费事又送货分散,商品发送、结算与信息几乎一律从生产企业为起点,零售业反过来要适应厂家的条件。当然生产者可以改善服务,但无论如何零售业的主导作用难以体现。问题在于生产厂家直送商店弊病很大:一厂家至多送几十家商店,双方生意做不大;店铺分散各地,运输费用高出十倍;零售商怕得不到即时供货,只好准备大量库存;零售店接货单位多,"门庭若市",影响交通等。

改变冷冻食品流通现状,需要集商品、信息与结算等功能于一体的中间批发机构,或称"配送中心",它作为零售业与生产企业的中介桥梁,具有交易市场的类似功能,在流通中与零售业一起发挥中心主导地位作用,实现消费主导型的流通。这类冷冻、冷藏食品零售业的伙伴机构配送中心,应是社会性的,独立经营,不从属于任何产品企业,否则对同类产品有排他性。这个机构除了先进的冷藏、运输与结算手段外,府具有以下的有效功能:1.同种商品的广泛选择性;2.热销商品供货的充足性;3.价格水平的合理性;4.流通费用的低成本[2]。

速冻食品作为一个日常消费品,在国内还有很大的发展空间。资料显示,2000年,美国人均速冻食品消费量为70kg,欧洲为近40kg;2001年日本在这方面的数字是20kg, 比国内人均7kg来说高很多。目前,世界速冻食品总产量已超过6000万t,品种达3500种以上;其贸易量近期以年均10% ~30% 的速度递增。在我国,速冻水饺作为速冻食品中最大的一个品种,也有很大的发展空间。80年代末到90年代初,人们以吃机制水饺为荣,机制水饺作为奢侈品摆上餐桌。中期人们的消费趋于现实:还是手工的好吃。现在的水饺作为食品的一部分已走进了千家万户,但整体水平和中国的现状一样,处于发展阶段,还不成熟。所以速冻食品包括速冻饺子设备和生产线的设计和改进直接决定着速冻食品行业的广大应用前景。这是一个刚新兴不久的行业,它的不甚成熟表明着它具有广阔的市场和发展前景。

1.2 国内外研究概况、水平和发展趋势

哈尔滨商业大学50年代研制出中国第一台饺子机,为饺子成为中式快餐和产业化做出了贡献。另一说,1956年,毛泽东发出了向科学进军的号召。一场以摆脱笨重体力劳动为主的技术革新运动随之展开1958年哈尔滨三八饭店研制了饺子机生产线的雏形,哈尔滨饮食机械厂后来将自动切菜机、自动切肉机、自动包饺子机等整合在一起,这就是现在的速冻饺子生成线,并支撑着这个企业四十多年。金美乐商业机械公司:本公司是中国第一台饺子机发明企业。美乐饺子机于1965年曾获由国家科委颁发的“发明证书”,并先后荣获国家质量金奖,莱比锡国际博览会金奖等殊荣。饺子机至今已更新至第五代。产品类型主要包括辊压灌肠式饺子机和全自动饺子机。现在国内比较有名的是台湾安口食品机械制造的饺子机。各机械厂都将饺子机不断改造以适应消费者对于食用口感和健康的需要。

川公网安备: 51019002004831号

川公网安备: 51019002004831号