【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘 要

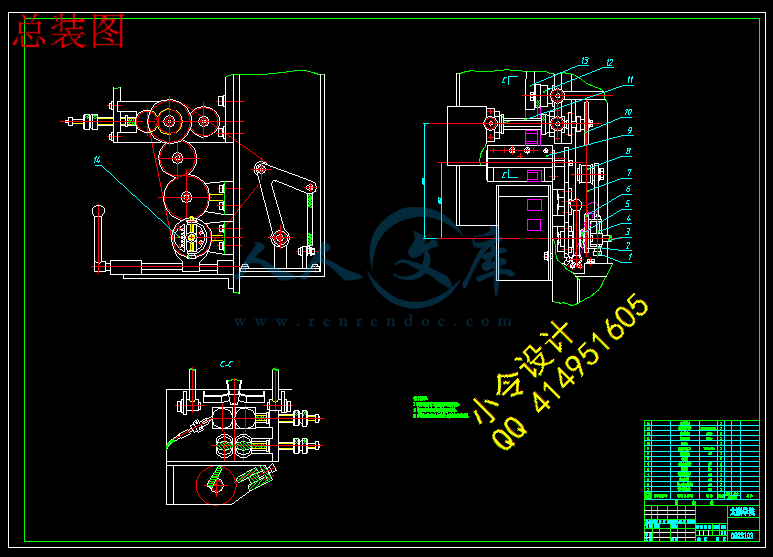

本研究主要包括偏心链轮的结构改进设计,并设计出试验装置,进行设计工艺参数的试验研究。在整机设计中,通过对偏心链轮总体方案的分析,编制了工作循环图,确定主要装置(偏心链轮,从动轮,张紧轮,调节机构)之间的相互配合关系;完成了偏心链轮的结构改进设计和理论分析及其主要参数的确定;对横封装置进行了改进设计,提出适应包装袋长度可连续变化的翻领成型器,扩大了偏心链轮的使用范围,并进行了理论研究,本文的研究对其它偏心链轮机械的设计和开发有着积极的指导意义。

利用设计的试验装置,确定了偏心链轮传动的特性,即匀速度传入主动轮偏心链轮中,由于偏心链轮各处的中心距不等,呈现增大减小的规律运动,所以滚子链的瞬时速度也不一样,其运动类似于正弦运动,传到从动轮上的速度也就是正弦运动,此运动方式适用于包装机,包装机在包装物品时,就需要快慢不一的速度。本研究结果对包装材料的生产厂家、偏心链轮械生产厂家、机械用户以及科研人员具有十分重要的意义。

关键词:偏心链轮;横封装置;包装

Abstract

This study included the modified structure design of the eccentric sprocket, the finite element analysis and solid modeler. Besides, designed tester and tested sealing quality.

In the entire machine design, established working cycle and conformed work in relations of main fixtures(feeding ,forming, retractor, sealing, driving)through analysis of eccentric sprocket overall plan; completed the modified structure design of the forming filling sealing eccentric sprocket and conformed the main parameters. In this paper, designed the horizontal sealing fixtures and advanced new forming fixture which can adjust the packaging length and extended the useable range of the eccentric sprocket and studied. At the same time, offered a method of parallel measure feeding and founded vibration feeding fixtures of oscillatory differential equation. This study can direct the design and exploitation of other bag eccentric sprocket actively.

Using the tester carries on the package sealing test, the tensile test and the endure stress test that the tests were based on the national standards, experimented data and the results indicate sealing intensity conforms to the national standard. Through data analysis obtained the permits packing sealing temperature range and the relations of the sealing intensity of the horizontal fixtures and the vertical sealing fixtures ,time and temperature and the best packing material sealing condition.

Key words: eccentric sprocket;horizontal sealing;packing machine

目录

摘 要III

AbstractIV

目录V

1 绪论1

1.1 本课题的研究内容和意义1

1.2 国内外的发展概况1

1.3 本课题应达到的要求1

2 总体方案设计3

2.1 偏心链轮机构的组成3

2.2 偏心链轮运动规律的分析5

2.2.1 偏心链轮机构工作原理5

2.3 偏心链轮各基本参数的确定9

2.3.1 主动链轮的偏心距的计算9

2.3.2 链轮的节圆半径11

2.3.3 主从动链轮传动轴的中心距12

2.4 轴承的选择12

2.4.1 轴的设计校核12

2.4.2 轴承的润滑及密封15

3 热封装置设计18

3.1 热封材料及封口方法18

3.2 纵封滚轮的设计及计算18

3.3 横封装置设计19

3.4 封合调整22

4 包装机的设计24

4.1 包装机工作原理及功能24

4.1.1 功能要求24

4.1.2 主要构成及工作原理24

4.1.3 执行机构的动作配合25

5 链轮的设计26

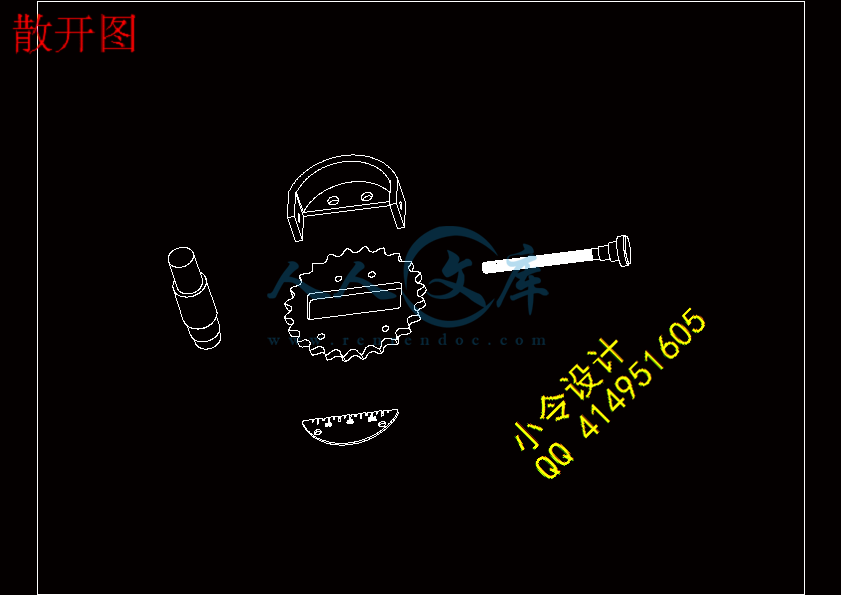

5.1 链轮设计与机械加工26

5.1.1 常见链轮的形状与结构26

5.1.2 链轮材料的选择26

5.1.3 链轮的基本参数26

5.1.4 链轮齿形的几何形状与设计原则26

5.1.5 链轮设计与加工27

5.1.6 刀具设计28

6 结论与展望30

致 谢31

参考文献32

1 绪论

1.1 本课题的研究内容和意义

随着社会的发展、生活水平的提高,尤其是加入WTO后,人民对热封装置提出了更高的要求。与人民生活和工农业生产密切相关的粉粒状物料,如生活日用品、营养食品、药品,种子、化肥、农药、化工原料等工农业生产用品,都需要稳定的热封装置。

偏心链轮是现代工业的基本设备,是商品生产中必不可少的关键性技术设备。随着人类社会的进步,国民经济的发展,人民生活水平的提高,人们越来越重视链轮的质量、品种类型,链轮机械在工业领域中起着重要的作用。链轮机械是使产品实现机械化、自动化的根本保证。它能够大幅度地提高生产效率;降低劳动强度,改善劳动条件;保护环境,节约原材料,降低产品成本;有利于热封机械的发展,提高产品效率,增强市场销售的竞争力。

偏心链轮保证包装机热封的质量高、生产效率高、品种多、生产环境好、生产成本低、环境污染小,因而获得较强的市场竞争能力,带来巨大的社会效益和经济效益。偏心链轮被堪称为拥有漫长发展历史和富有强大生命力的主导机型。现已被各国视为前景较好的热封机械。据调查,现有偏心链轮机构存在以下问题:

(1)速度不稳定;

(2)薄膜送进速度难以与热封辊圆周速度相等;

(3)链轮传送消耗大;

(4)包装机的横封机构运动形式的不合理,将导致封口质量问题。

包装容器的封口,是包装工艺中不可缺少的工序。封口的好坏将直接影响生产效率。因此,包装质量在很大程度上取决于封口质量,所以链轮机构的研究改进对提高封口质量有着重要的意义,本研究在整机研究的基础上,针对横封封口形式影响封口质量这个问题进行深入的研究。同时,通过一系列试验,研究总结出较为完整的工艺参数,对实际生产具有十分重要的现实意义。

1.2 国内外的发展概况

从广义而言,现代机械的含义和领域很广,包括各种自动化和半自动化传动机械、包装机械、横封机械等。这些相互密切联系的机械设备组成了现代化的传动机械体系。

随着科技和经济的快速发展,社会对自动化设备的需求越来越大,此机构用于塑料制袋包装机上,利用偏心链轮可以使塑料薄膜送进速度与热封辊圆周速度相等,保证热封辊快速张开,以免热封辊被包装物相碰。这一研究对工业有很大帮助。

1.3 本课题应达到的要求

设计偏心链轮不等速机构,运用于塑料制袋包装机上,其原理方案的功能实现,总体方案的设计,结构形式,结构参数,工作参数的设计。要求:

(1)热封时,塑料薄膜送进速度必须与热封辊圆周速度相等。由于产品规格不同,袋长不同,要求送料速度变化,这时热封辊速度必须随之产生相应的变化,因此,要求回转一周时获得快慢变化的周期变速运动,以使热封时热封辊与薄膜送进达到相等的速度。从而可以使包装物顺利传送。

(2)热封后,最好能保证热封辊快速张开,以免热封辊与被包装物相碰。

![二维图[共11张].gif](/ueditor/net/upload/2015-05-30/be985215-5ecc-4394-b4b1-298eb0da1330.gif)

川公网安备: 51019002004831号

川公网安备: 51019002004831号